Patents

Literature

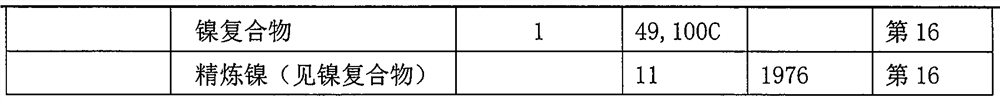

82results about How to "Reduce oil fume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

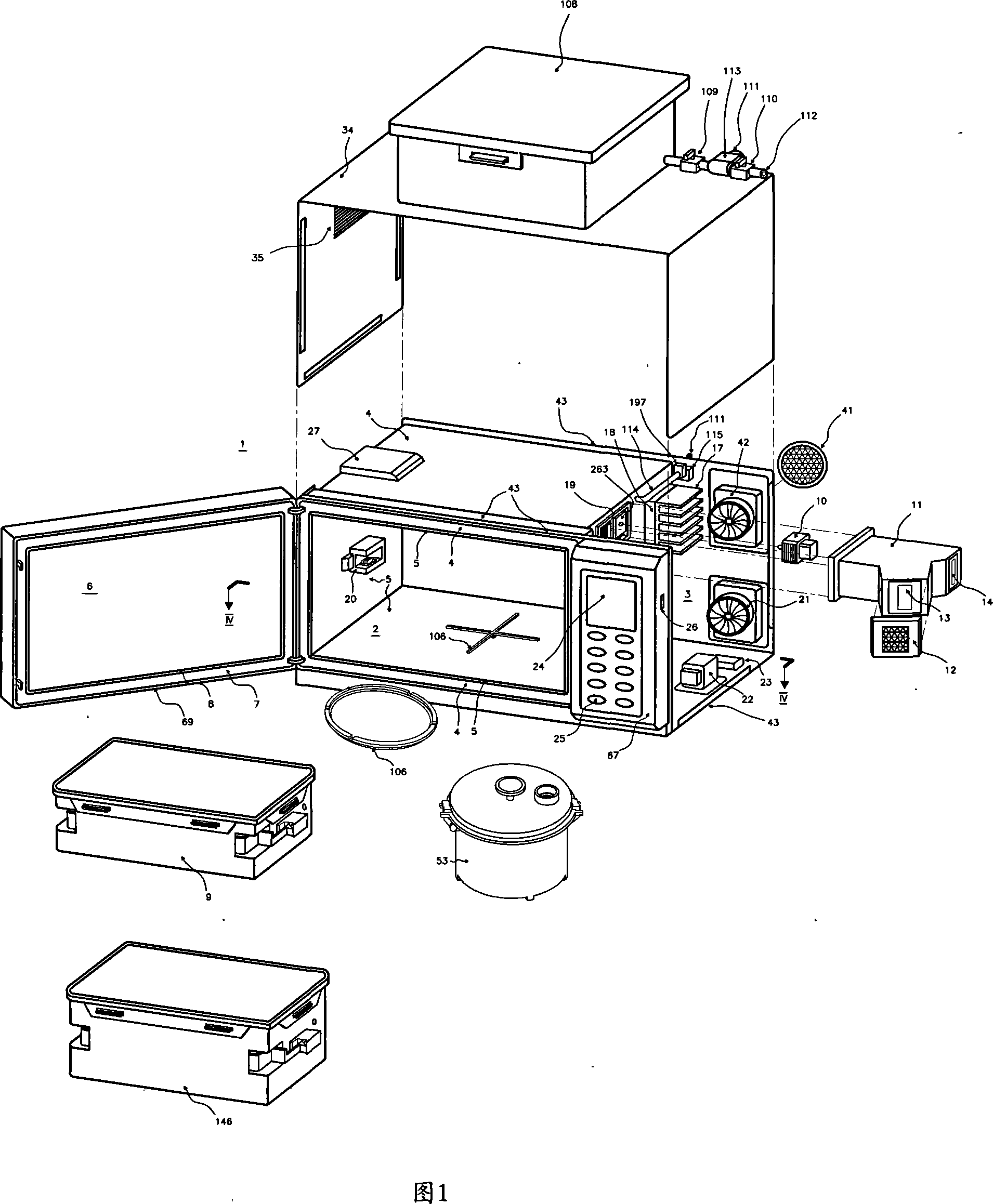

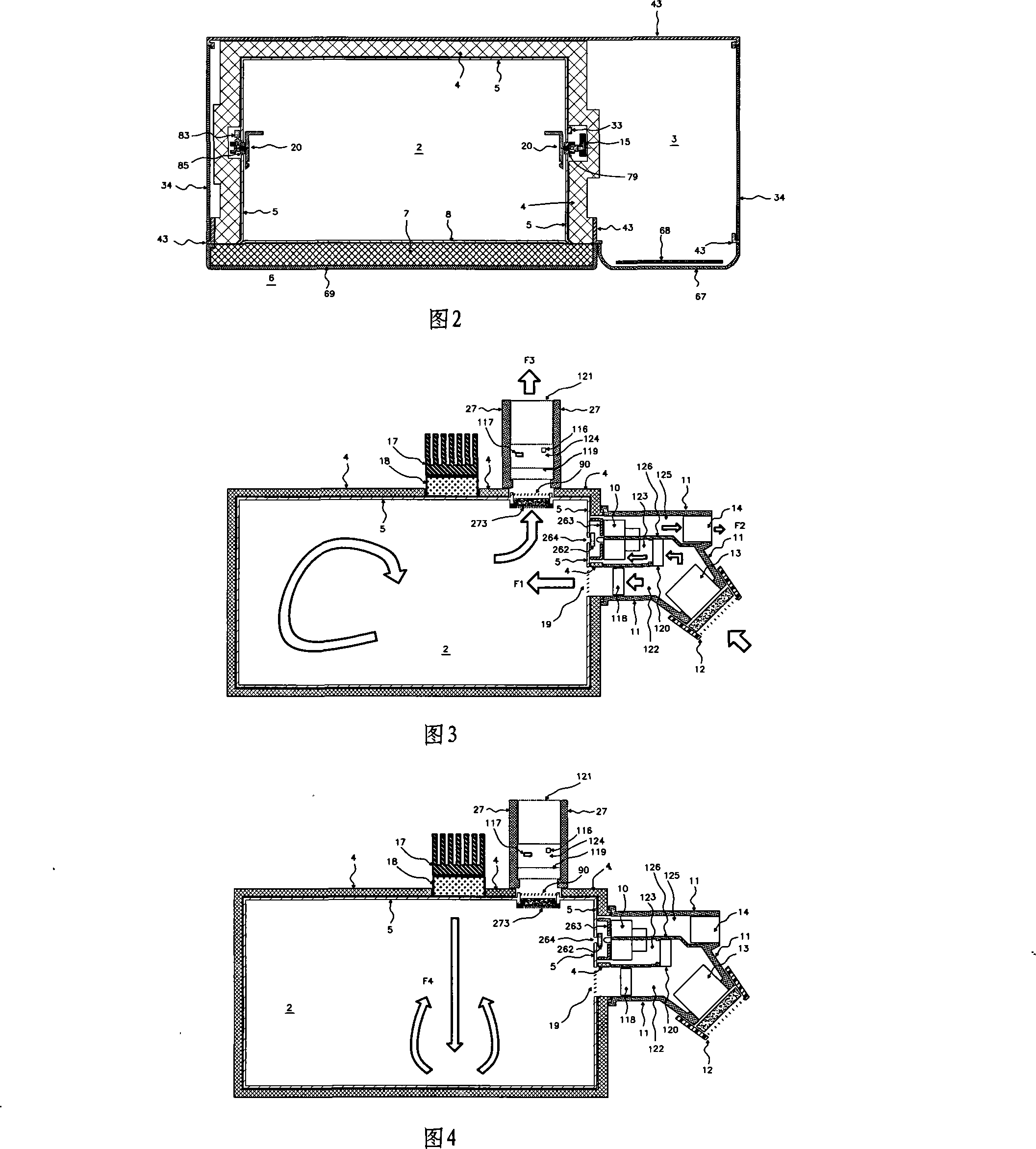

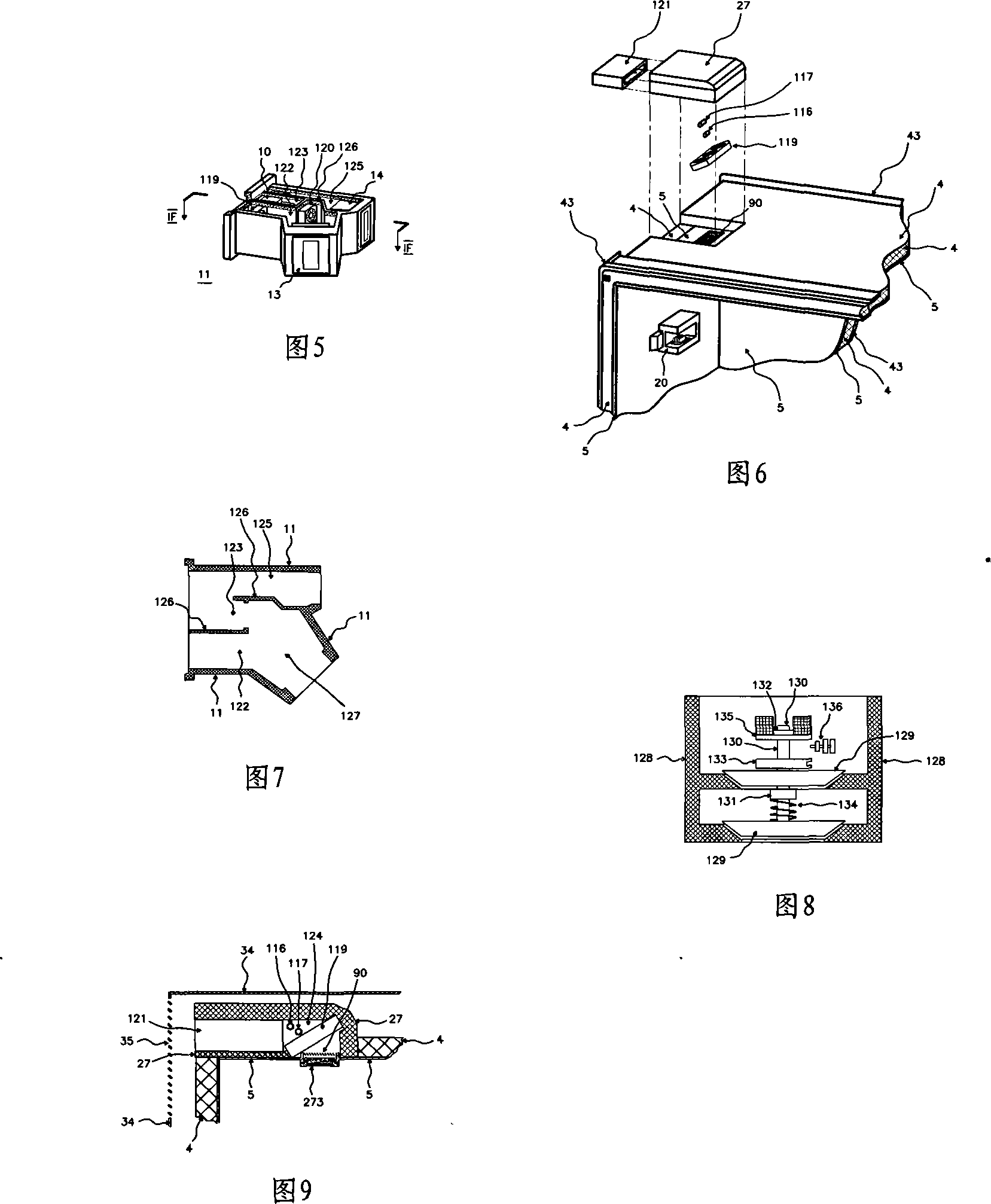

Single electric appliance intelligent kitchen

InactiveCN101169261AMix well and evenlyEasy to cleanStoves/ranges foundationsDomestic stoves or rangesPhysical spaceEngineering

The invention provides a single electrified intelligent kitchen, belonging to the filed of home appliance. The main component and structure consist of a casing, a machine cover, a chamber liner, a working chamber, a mechanical room, a liner heat-insulating layer, a chamber door, a refrigerating unit, a heating component, a food box, a food box support, an air intake pipeline, an air outtake pipeline, a cooling fan, an exhaust fan, an electromagnetic air valve, a water supply unit, a temperature sensor, a humidity sensor, a control unit and a control panel. The invention is classified into a fundamental type and a comprehensive type; wherein, a comprehensive type can be formed by a plurality of fundamental types. The structures of the food box and the food box support cooperate with each other, and the food box is internally provided with a seasoning storing structure; the seasoning and / or water can be automatically added. The invention organically combines the refrigerator and the microwave oven, and realizes remote control; the food refrigeration storage and automatic cooking can be switched at the same physical space according to the preset parameters or the will of the user; furthermore, the invention can be configured as a general microwave oven or a general refrigerator. Besides, the comprehensive type can store and cook one meal or multiple meals at the same time.

Owner:梁福鹏

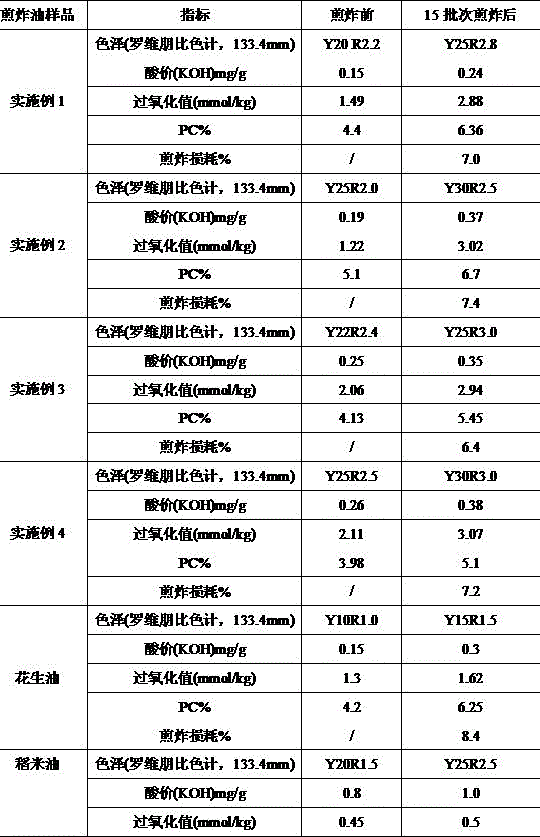

Special blend oil for frying and preparation method thereof

The invention discloses special blend oil for frying. The special blend oil for frying contains 10-50% by weight of high oleic acid peanut oil and 10-50% by weight of rice oil. The blend oil for frying is prepared by compounding any two or more than two of sunflower seed oil, olive oil, soybean oil, corn oil, cottonseed oil, palm oil, rapeseed oil, safflower oil, linseed oil and sesame oil in different proportions. The blend oil for frying is rich in fragrance, bright in color, high in content of oleic acid, rich in oryzanol and vitamin E, reasonable in composition of fatty acids and free of stickiness. Through a high-temperature frying test, the blend oil is high in smoke point, low in content of trans-fatty acids and high in frying stability. The fried food is small in oil content, good in crispy property, excellent in taste and nutritional and healthy. The blend oil disclosed by the invention can be used for frying different food materials, is suitable for being used as special fat for frying food in family and catering industry, is long in expiration date, and is novel nutritional and healthy special blend oil for frying.

Owner:山东金胜粮油食品有限公司

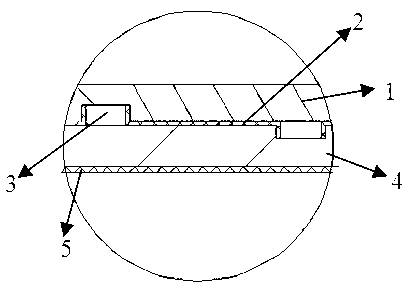

Apparatus for fire prevention of oil smoke pipeline and purifying oil smoke

InactiveCN101130149AEliminate fire hazardsReduce oil fumeDomestic stoves or rangesDispersed particle filtrationWater flowEngineering

The invention discloses a fire-proof and oil smoke clarifier for removing fire hazard in the oil smoke duct of the kitchen and cleaning the oil smoke duct. The water pump presses the water of the tank in the water burner cap of water spray smoke duct, and the water burner cap sprays water to the oil smoke screen, the oil soot in the oil smoke is separated from the gas by intercepting with oil smoke screen when the oil smoke which is sucked to the oil smoke duct by the air extractor enters the water spray duct, and the oil soot on the oil smoke screen and water flow from the discharging port of the water spray duct to the discharging pipe to the water tank under the terrestrial gravity when the oil smoke screen is sprayed by the water spray cap. The fire star on the cooking stove is sucked to the oil smoke duck by the air extractor and is extinguished by the water sprayed by water spray cap, and the big fire star is intercepted by the oil smoke screen of the spray water smoke duck and is extinguished by the water.

Owner:骆恩震

Oil immersion rust prevention method for cast iron pan

InactiveCN106000840AKeep natural effectDoes not destroy nutrientsPretreated surfacesCoatingsCooking & bakingIron supplement

The invention discloses an antirust method for immersing a cast iron pan in oil. Its oil-soaked anti-rust formula is: 10 parts of lard, 60-70 parts of peanut oil, 20-30 parts of palm oil; the treatment method is: first polish and clean the cast iron pan, then mix the above raw material oils, pour them into In the electric heating container, heat the oil to 200°C and put it into the pot. The hot oil should submerge the whole pot. After the oil is heated to 245°C, heat it for 60 minutes until the oil is heated to 280°C. Soak for 72 hours, then put the treated pot into the oven to bake, and finally fix the pot handle with stainless steel rivets, and then put a label on it and pack it into the warehouse. Because the invention adopts a scientific heating oil immersion treatment process, it not only maintains the natural effect of the original cast iron pot, but also increases the health function of the original ecological oil immersion treatment, and also has the effect of rust prevention and iron supplementation. And the surface is smooth, non-stick pan, less oily smoke, good cleaning work, which reduces the operating intensity of cooking.

Owner:鹤壁市甲午三义炊具有限公司

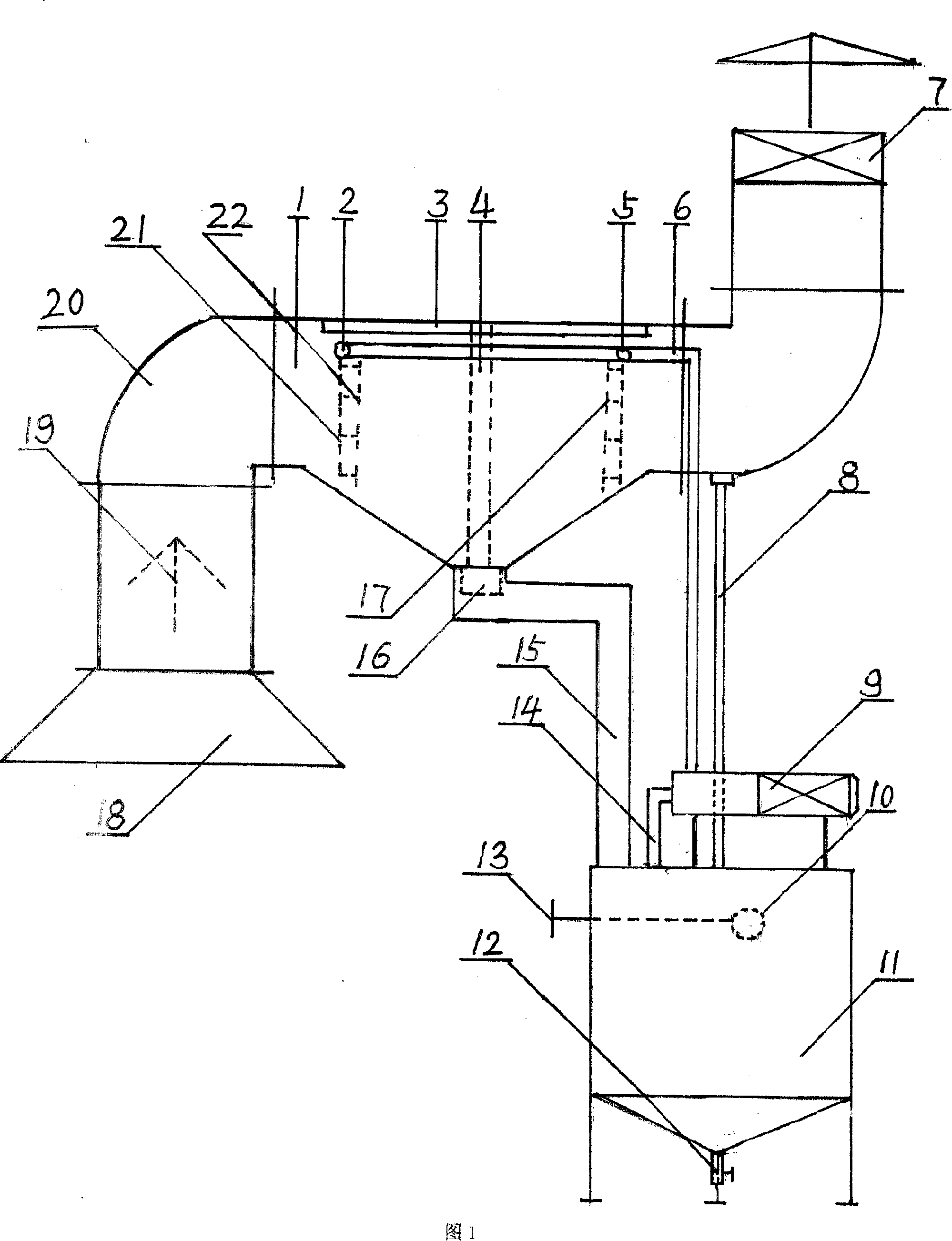

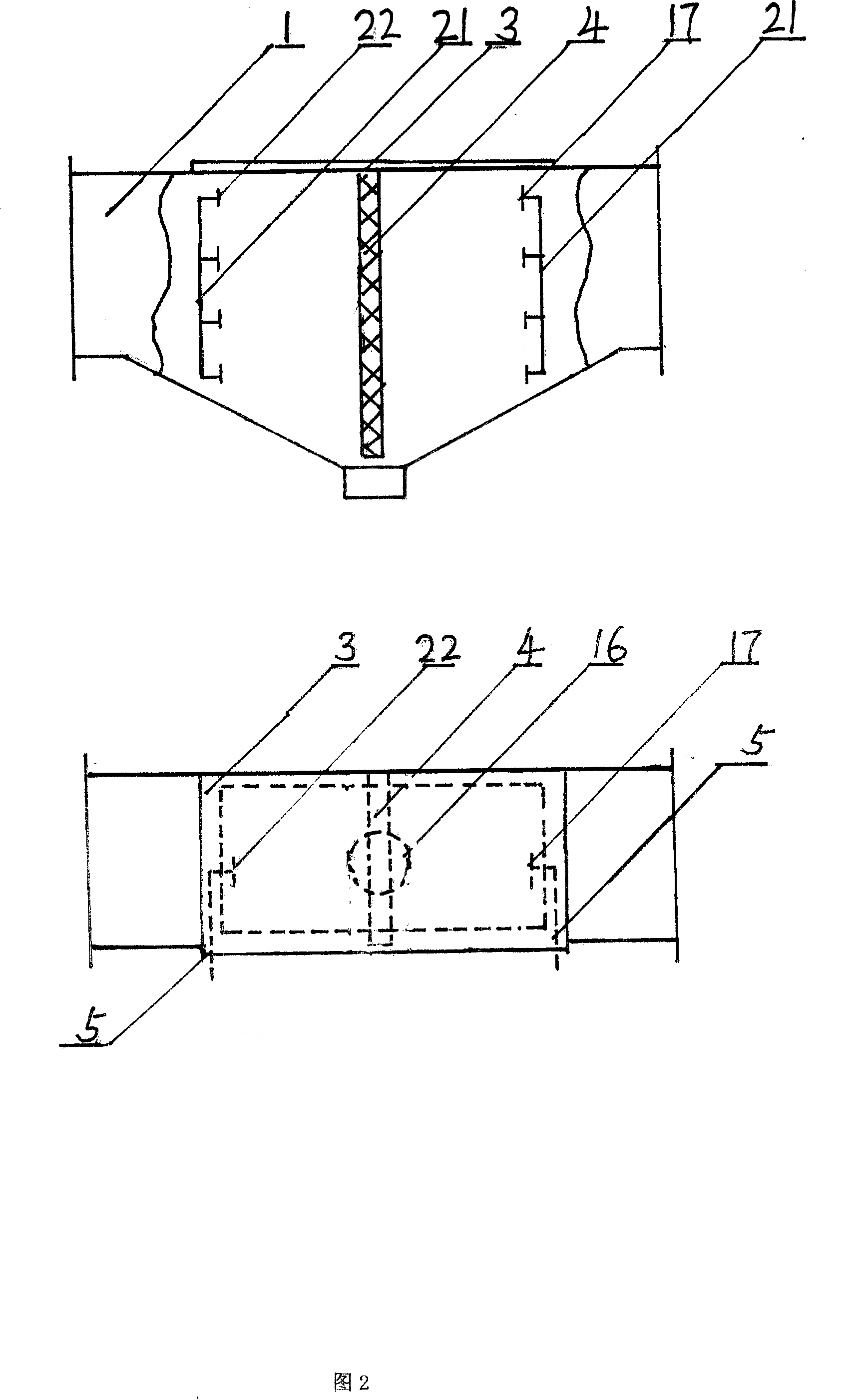

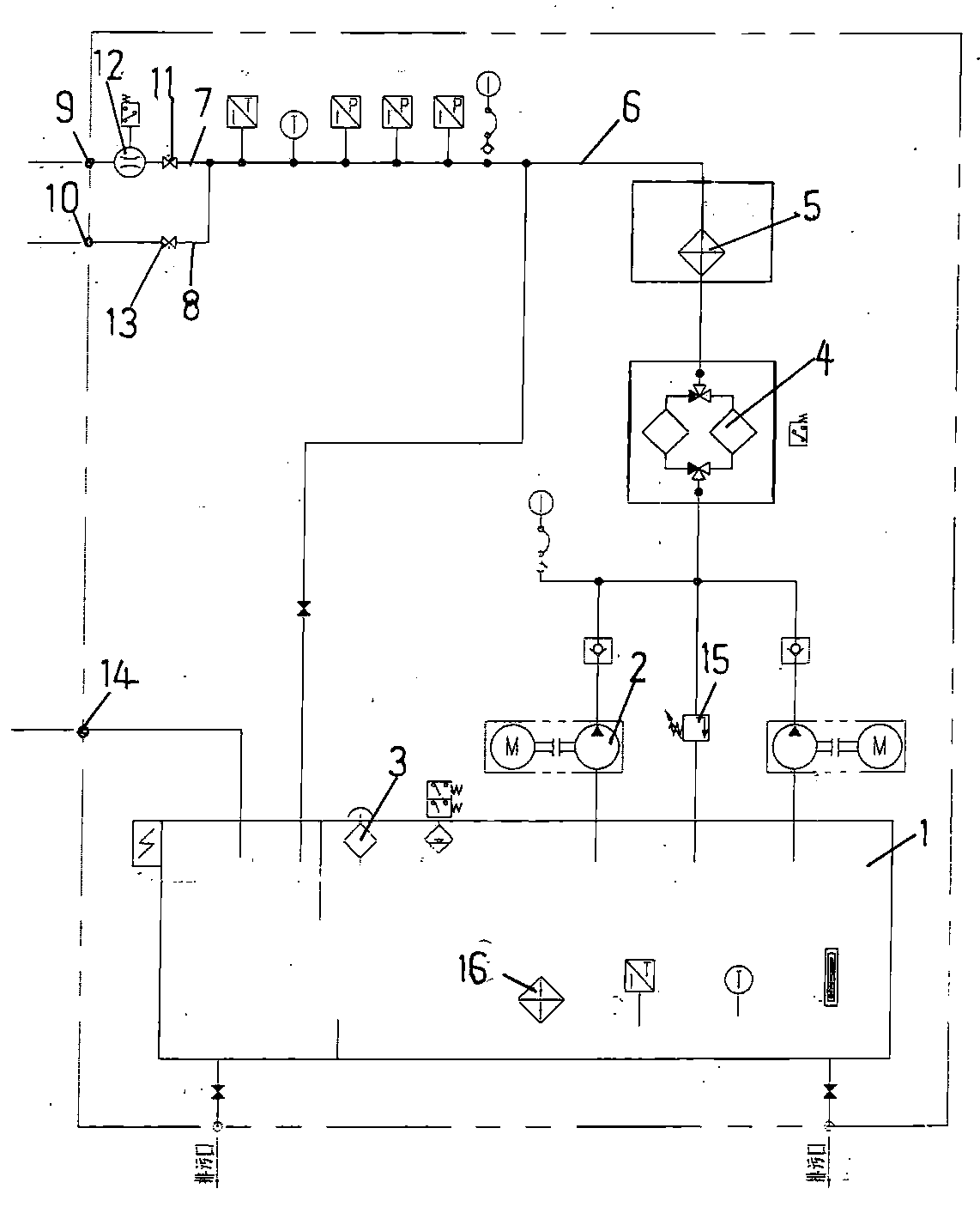

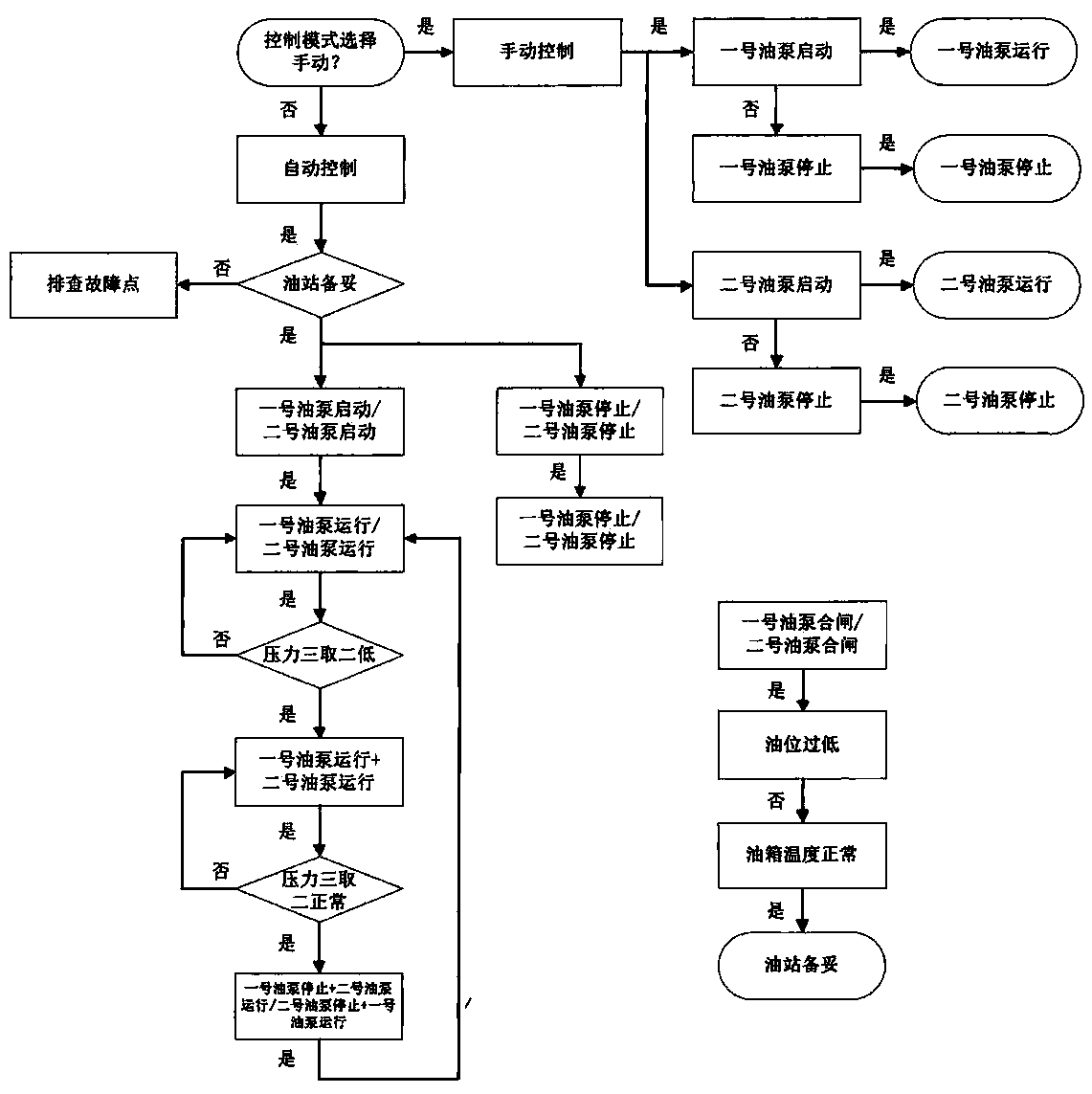

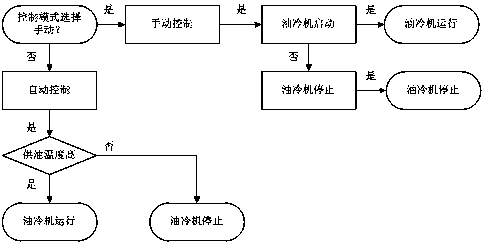

High-performance intelligent lubricating device for permanent magnet motor and with cooling function

InactiveCN110985866AReduce pollutionReduce oil fumeLubrication elementsSafety/regulatory devicesElectric machineryBall valve

The invention discloses a high-performance intelligent lubricating device for a permanent magnet motor and with a cooling function. A hermetic oil tank is adopted as the oil tank, an oil mist filter is installed on the oil tank, and two oil pumps are arranged, wherein one oil pump is for current use, and the other oil pump is for standby use. The oil pumps are connected with a filtering device, wherein the filtering device comprises two filters, one filter is for current use, and the other filter is for standby use. The filters are connected with compressor refrigeration equipment to cool oil,an oil transport port of a compressor is connected with an oil output pipeline, and after the oil output pipeline is divided into two paths, the two paths are connected with two oil supply ports which supply oil to a magnet disk of the permanent magnet motor respectively, wherein one path is provided with a butterfly valve and a throttling valve which are connected in series, the other path is provided with a ball valve, and an oil return port for collecting return oil communicates with the oil tank. According to the high-performance intelligent lubricating device, the oil supplied to the magnet disk of the permanent magnet motor is low in temperature and does not cause heavy pollution. Meanwhile, the oil is filtered by the oil mist filter, and 95% or more of oil fume can be reduced.

Owner:江苏指南润滑液压科技有限公司

Non-stick frying pan and production process thereof

InactiveCN105559519AIncrease contact areaFacilitate conductionCooking-vessel materialsWater basedAdhesion force

The invention discloses a non-stick frying pan and a production process thereof. The non-stick frying pan comprises a pan body and a handle, wherein a layer of rough surface, which is formed by steel ball collision, is arranged on the inner surface of the pan body; and a water-base polytetrafluoroethylene paint is coated on the rough surface. The non-stick frying pan disclosed by the invention has the following beneficial effects: 1. through the roughness of the substrate of the pan body, adhesion force is enhanced and service life is prolonged; 2. a liquid contact area is increased and thermal energy conductivity is improved; 3. the direct contact area with solid food materials is reduced and cooking fume is relieved; 4. the non-stick frying pan is commonly used in various fire source such as an induction cooker, a gas cooker and briquette; and 5. since the pan body is thinner than a pot bottom or a pot opening, the non-stick frying pan is uniform in heat conduction and is material-saving.

Owner:ZHEJIANG COOKER KING COOKER

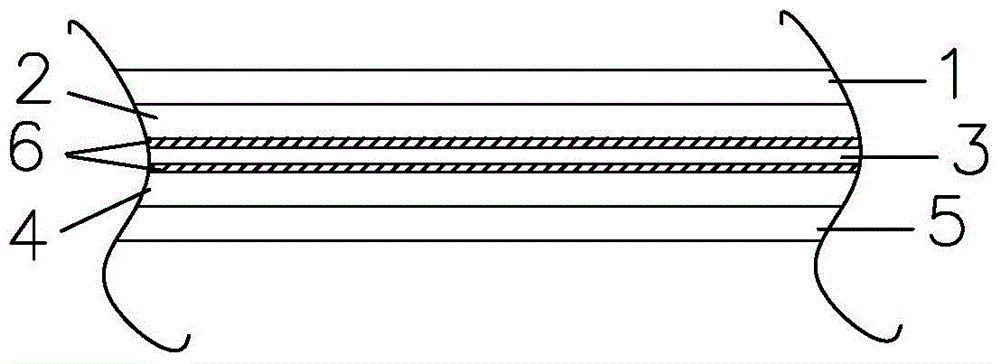

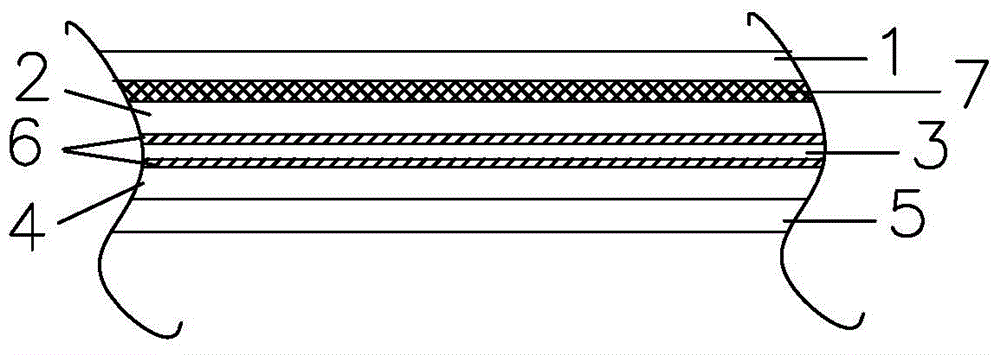

Multi-element composite titanium pot and manufacturing process

The invention discloses a multi-element composite titanium pot. Integral thickness of the multi-element composite titanium pot is 2.0-4.0mm, and the multi-element composite titanium pot sequentially comprises a pure titanium or titanium alloy layer of 0.4-0.8mm, a pure aluminum layer of 0.4-1.5mm, a red copper layer of 0.2-0.6mm, an aluminum alloy layer of 0.4-1.5mm and a stainless steel layer of 0.2-0.8mm from inside to outside. The invention further discloses a manufacturing process of the multi-element composite titanium pot. The manufacturing process includes the steps of pretreatment, preliminary treatment, plating of a nanoscale metal adhesion layer, plating of a nanoscale metal heat-conducting layer and high-temperature high-pressure press fitting. The multi-element composite titanium pot has the advantages of being high in heat-conducting speed, uniform in heating, high in cooking speed, free of pot sticking, little in cooking fume, supportive of various heating modes like coal gas, natural gas and electromagnetic oven, good in combining effect, less prone to layering and deforming, convenient to manufacture, light in weight and cost saving.

Owner:SUZHOU XINJINGYI TITANIUM PROD

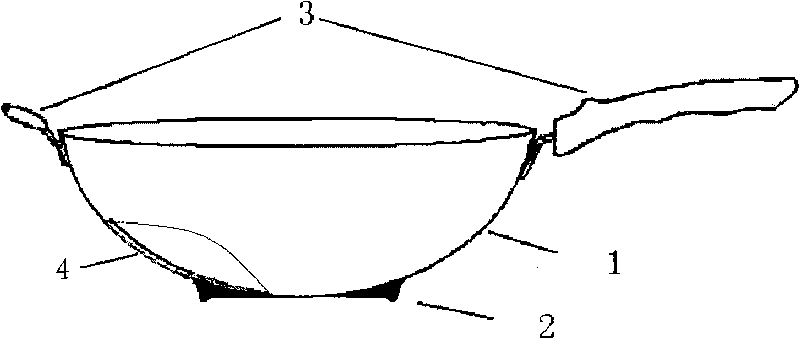

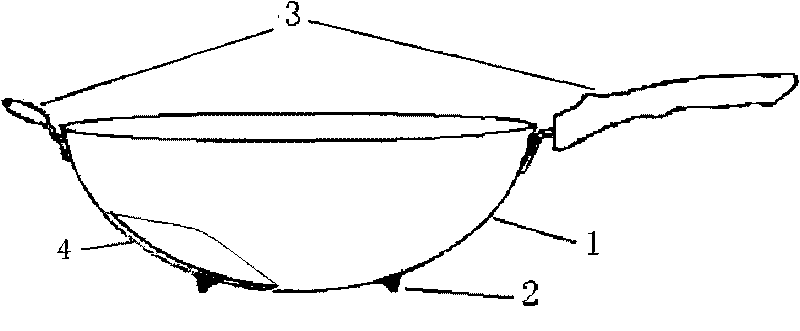

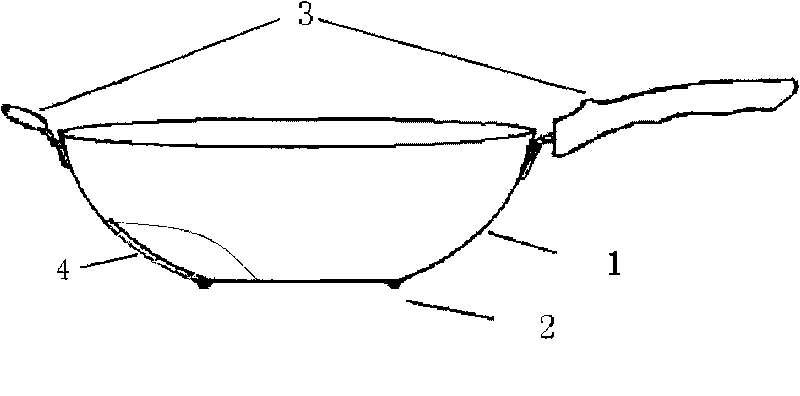

Health protection rust preventing energy-saving quick-fried pan

InactiveCN101721114AReduce heating rateIncrease the rate of heatingCooking-vessel materialsFrying pansTrace elementEngineering

The invention provides a health protection rust preventing energy-saving quick-frying pan which belongs to the field of articles for daily life and relates to a cooker. The pan comprises a pan body, a handle and a special pan bottom structure. The traditional iron pan has defects in use on an electromagnetic oven. The invention just solves the problem in the aspect. In the pan, the outer surface of the bottom of a concave bottom pan is thickened to form a flat bottom or the thickened part is changed into a circle shape or a circular structure is added to the periphery of the bottom of the pan; the pan can be stably placed on the electromagnetic oven; the center of the pan bottom is not in contact with the panel of the electromagnetic oven to reduce the heat from transferring to the panel of the electromagnetic oven, and the pan has the energy-saving function; and the pan temperature is high, and the heat storage is large so that the pan has the quick-frying function. The pan body contains various trace elements, such as ferrum, zinc, selenium, and the like which are necessary for a human body. The rust prevention processing is carried out on the inner surface of the pan body, and the outer surface is coated with a rust corrosion preventing layer, thereby obviously improving the corrosion resistance of the iron pan and prolonging the service life. The pan is suitable for various ovens.

Owner:石正友

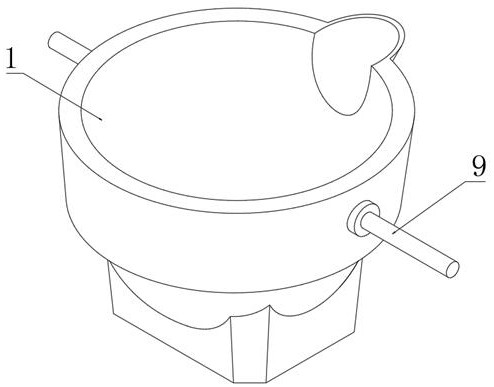

Barrier-free soup-adding hot pot

InactiveCN108903588AConvenient diningLarge dining areaCooking insertsCooking vessel constructionsFuel tankFood material

The invention provides a barrier-free soup-adding hot pot, and relates to an intelligent hot pot. The intelligent hot pot comprises a table body, a heating device, a pot body, a rotating mechanism, anautomatic oil tank system, an automatic soup system, a lifting mechanism, an upper cover body and the like, wherein the table body comprises a table panel and a bottom plate; the center of the tablepanel is hollowed-out; the heating device is mounted at the hollowed-out position; the pot body is placed on the heating device; the heating device and the pot body are annular; the automatic oil tanksystem and the automatic soup system are mounted on the bottom plate; and the output end of the automatic oil tank system successively penetrates through the hollowed-out position of the table panel,the central hole of the heating device and the pot wall of the inner side of the pot body and extends to the position above a cavity of the pot body. Soup and edible oil can be added automatically, the space of the table body does not need to be occupied, the hot pot does not hinders diners, splashing can further be prevented when soup and water are added, the barrier-free soup-adding hot pot hasthe characteristics of convenience in cleaning, simplicity and attractiveness, convenience in isolation of a seasoning from food materials, stirring and clamping are facilitated, food is convenient to find, lampblack is small, degree of automation is high, the hot pot is convenient to use, and the like, and the barrier-free soup-adding hot pot is easy to popularize and use.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Energy-saving environmentally-friendly barbecue grill

InactiveCN102100493ALow power consumptionReduce oil fumeRoasters/grillsExhaust gasEnvironmentally friendly

The invention relates to an energy-saving environmentally-friendly barbecue grill. The energy-saving environmentally-friendly barbecue grill comprises a grill body, wherein the grill body is a hollow shell; the hollow shell comprises a first end and a second end which are opposite to each other; an inward combustor is arranged on the top or on the side part of the hollow shell; flame generated by the combustion of the combustor is jetted towards the grill body; and a basin for accommodating oil and fat dripped from meat during combustion is arranged on the lower part of the hollow shell. Due to the structure, the fat of the meat during combustion can directly fall down the basin; benzopyrene, which is generated by combination of heat polymerization caused by high temperature and coking and protein in the meat, is reduced; barbecue food has good quality and comprises a small amount of benzopyrene; power consumption is low; and oil smoke is reduced greatly. In addition, the meat is preheated by a great deal of residual heat in the grill body through a second space and exchanges heat with water, so that energy is absorbed completely and the temperature of exhaust gas discharged finally is lower than 70 DEG C.

Owner:GREAT THUNDER TECH

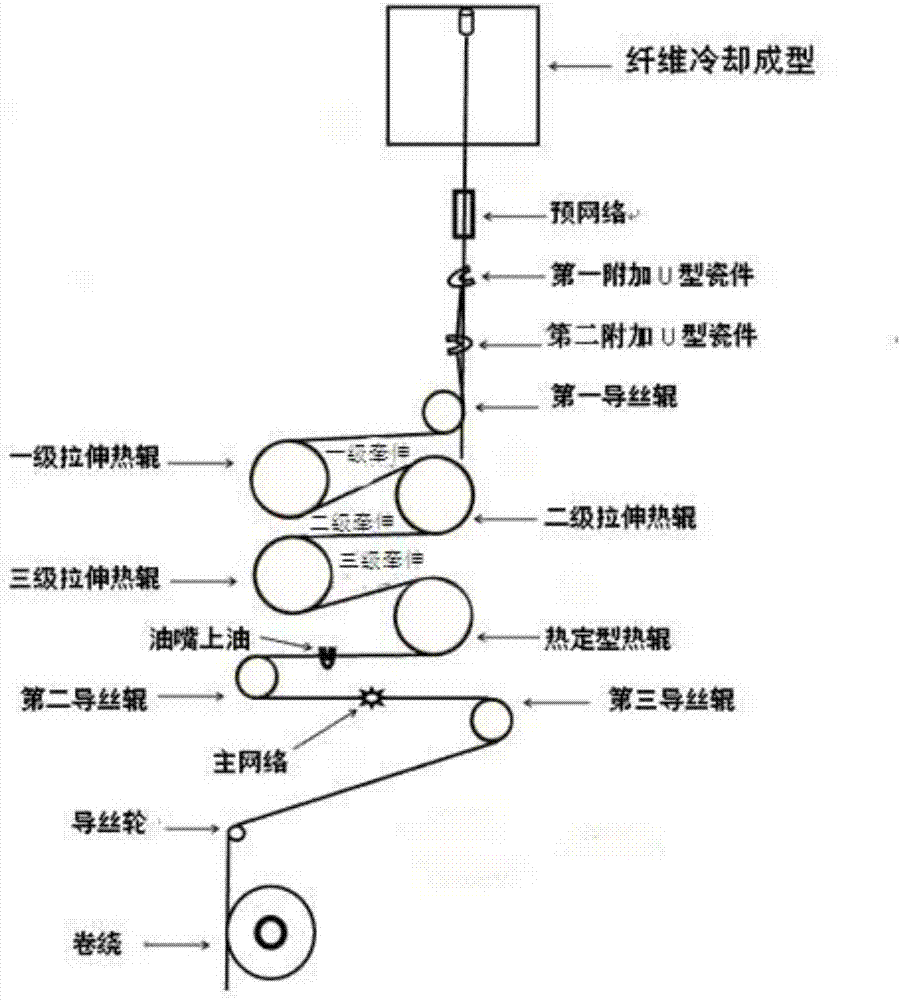

Production process of polyester FDY multi-roll oil-free full-draft fibers

InactiveCN107034533AAvoid slipping and shakingGuaranteed spinnabilityArtificial thread manufacturing machinesFilament manufacturePolyesterDistributor

The invention discloses a production process of polyester FDY multi-roll oil-free full-draft fibers. The production process includes the following steps that polymerization is conducted in a final polymerization autoclave, raw materials are then processed by means of a melt conveying pump, a melt distributor and a melt booster pump in sequence, the obtained melt is conveyed and then processed by means of a melt cooler, a static mixer, a melt distribution valve and a spinning box in sequence, then the melt is extruded in a metering pump and processed by means of a spinning assembly, fiber cooling and molding is conducted, then semi-finished fibers are processed by means of a U-shaped ceramic piece, a secondary network, a spinning channel, a first additional U-shaped ceramic piece1, a second U-shaped ceramic piece 2, a first silk guide roller, a first-level hot pulling roller, a second-level hot pulling roller, a third-level hot pulling roller and a heat-setting hot roller in sequence, a lubricating nipple is used for oiling, and the obtained fibers are processed by means of a second silk guide roller, a primary network, a third silk guide roller and a guide wheel and subjected to coiling, doffing, quality testing and packaging. According to the production process of the polyester FDY multi-roll oil-free full-draft fibers, the product quality is improved, the running environment of equipment and the working environment of workers in a FDY production place are optimized, yarn path operation is simplified, and energy conservation and high efficiency are achieved.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

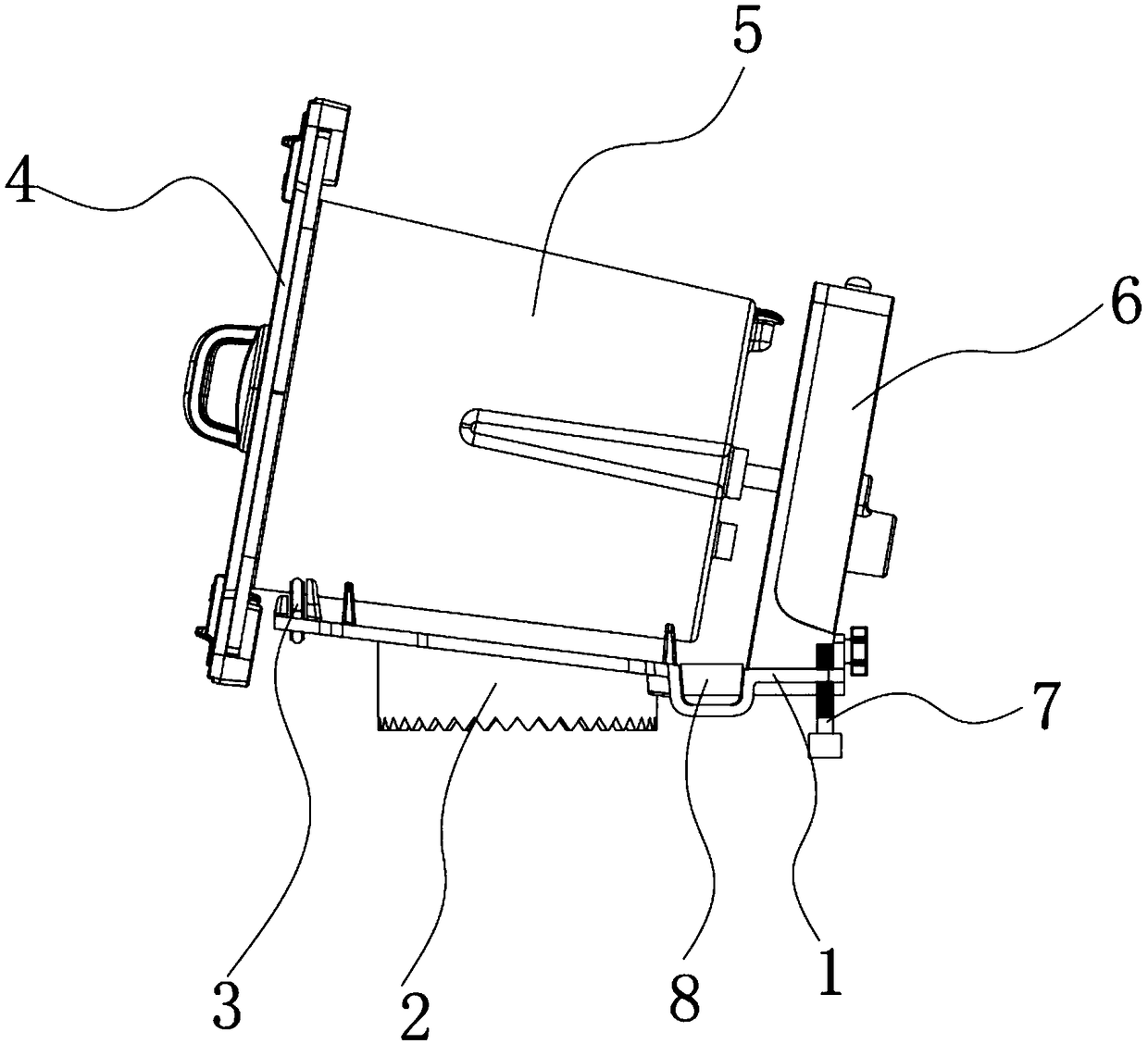

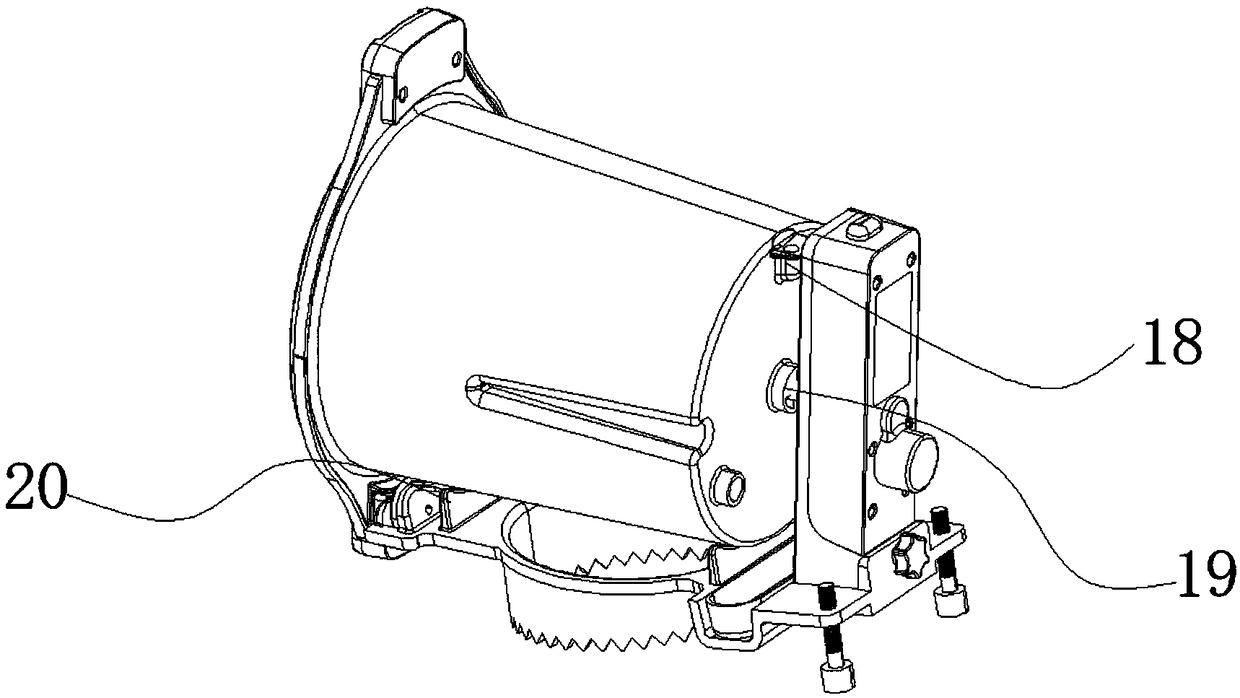

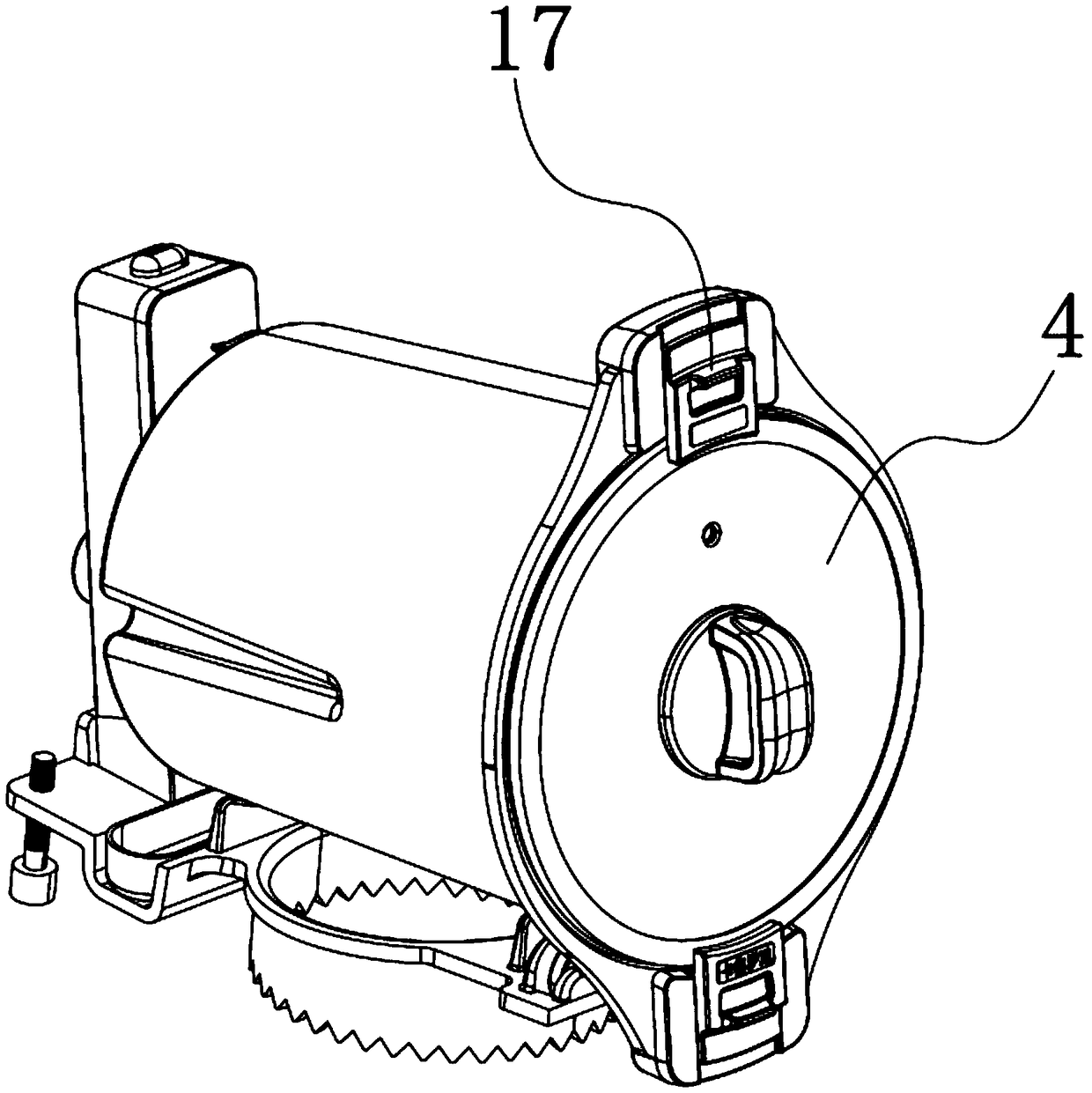

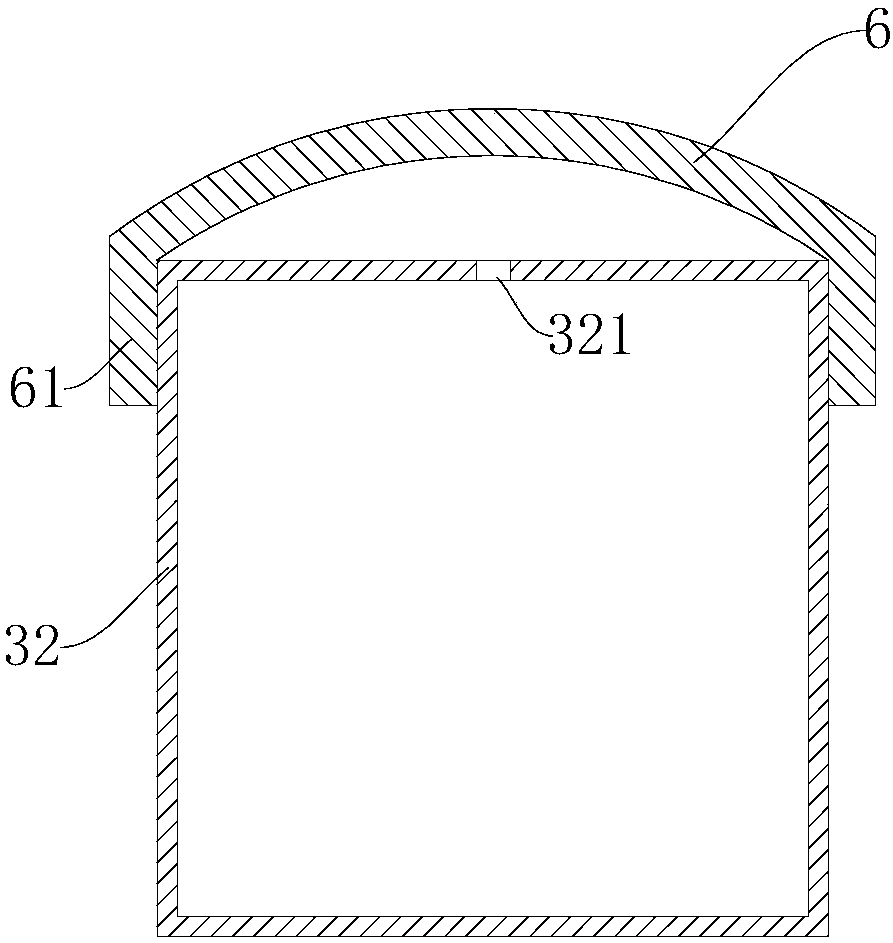

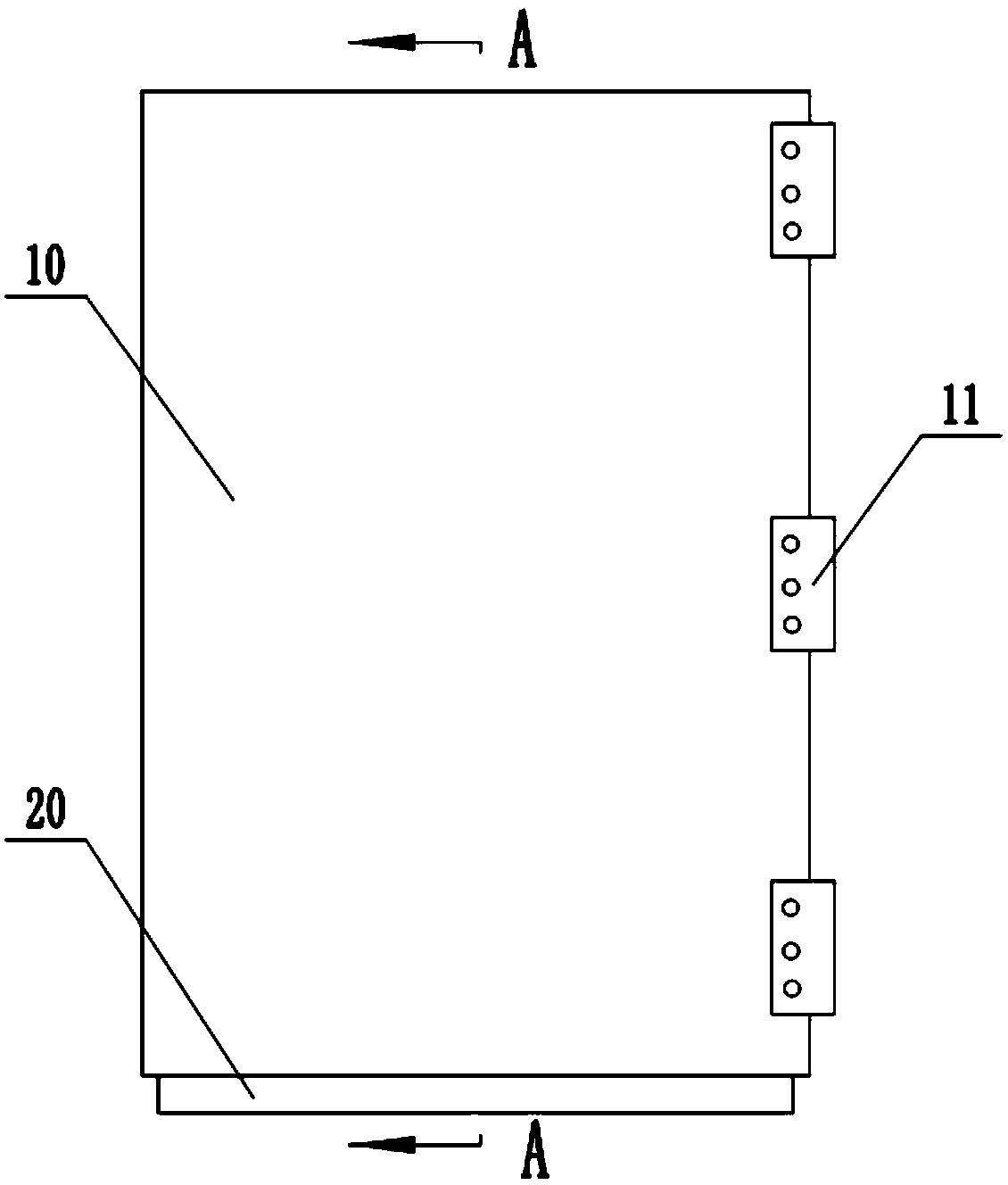

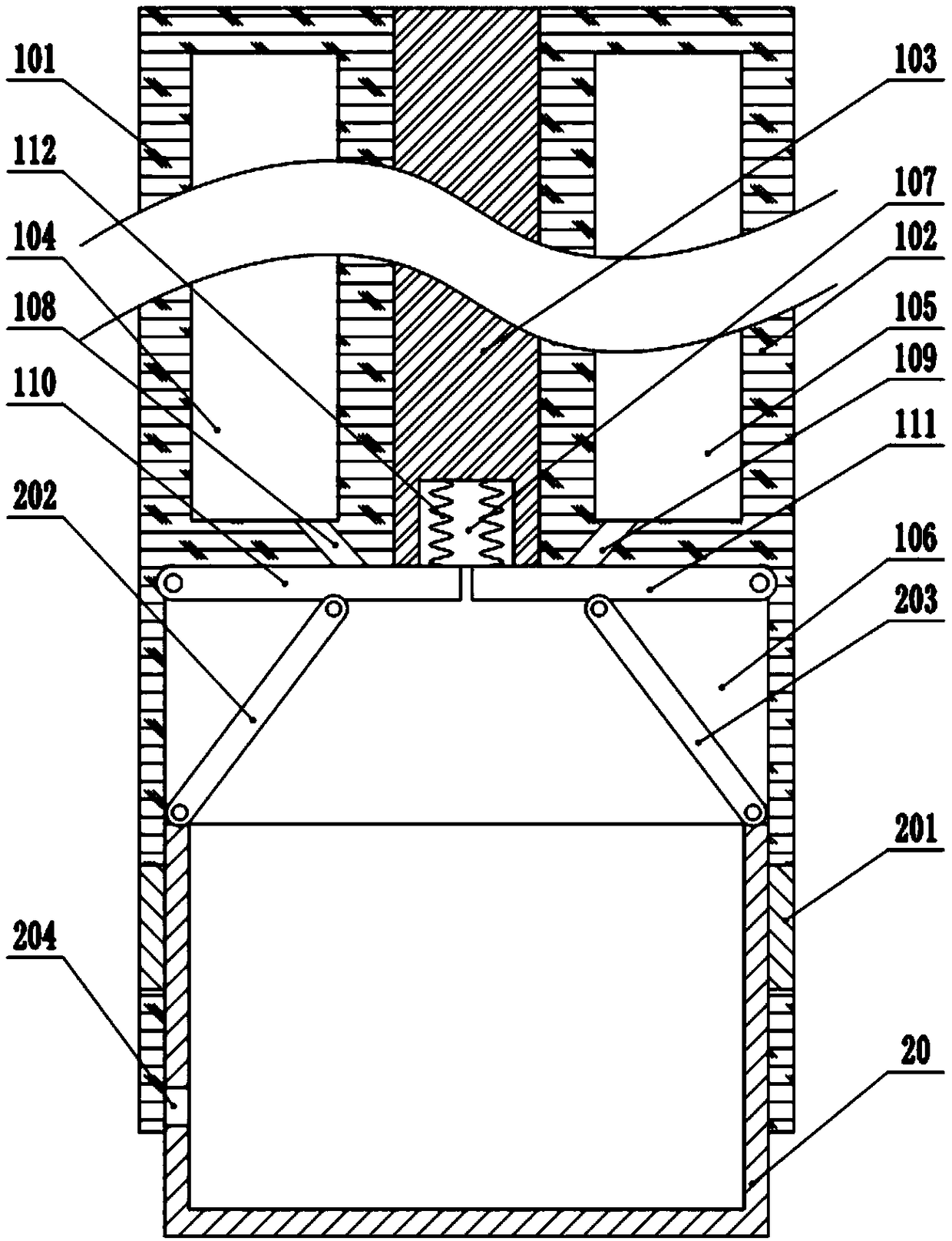

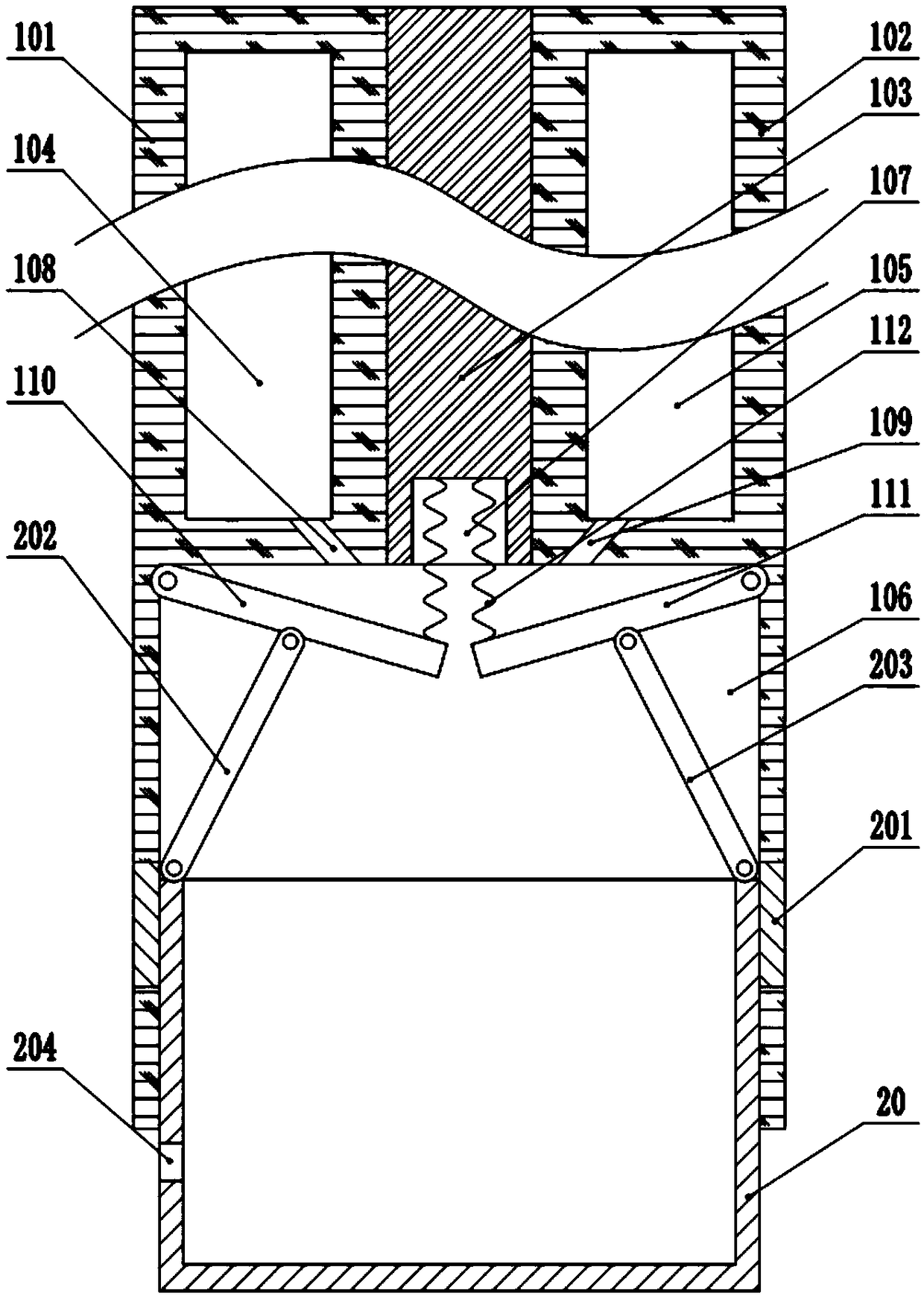

Rotary stir-frying type cooker

ActiveCN111358274AImprove cooking efficiencyLower barriers to useVessels with intergral heatingCooking vessel constructionsRotational axisEngineering

The invention discloses a rotary stir-frying type cooker, belongs to the field of kitchen household appliances, can realize direct stir-frying of a cooking container, and can solve the problem of steam exhaust in the cooking process. The rotary stir-frying type cooker comprises a shell and a rotatable accommodating body, the accommodating body is arranged in the shell; a cooking container and a container cover which integrally rotate along with the accommodating body are also arranged in the accommodating body; the accommodating body is provided with a taking and placing opening for taking andplacing the cooking container; the taking and placing opening is located in the direction of the rotating axis of the accommodating body. The container cover is arranged on one side of the taking andplacing opening of the cooking container, so that a cooking cavity is formed in the inner side of the taking and placing opening of the cooking container in the rotating axis direction, a steam exhaust opening is formed in the container cover, and the cooking cavity exhausts steam to the outer side of the taking and placing opening in the rotating axis direction through the steam exhaust opening.

Owner:JOYOUNG CO LTD

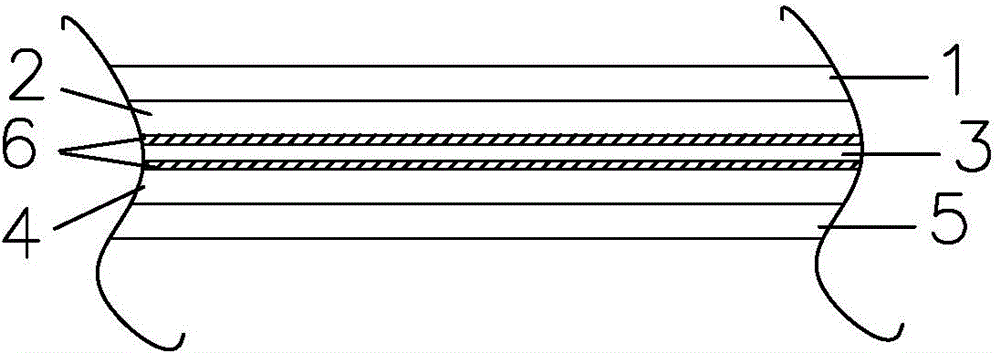

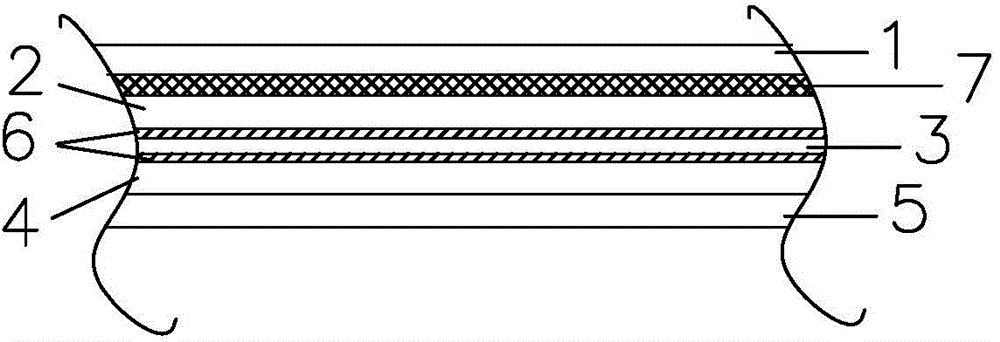

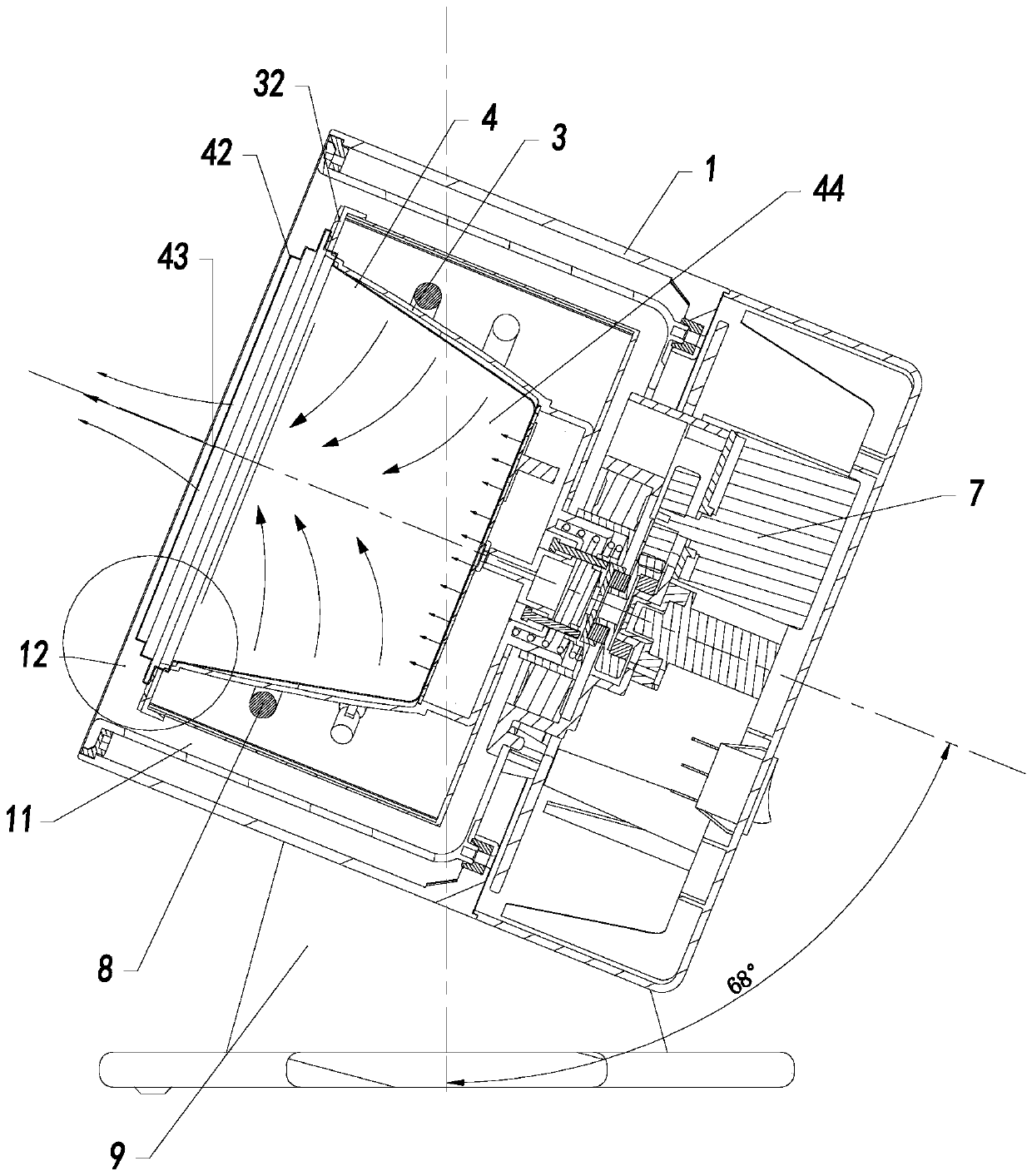

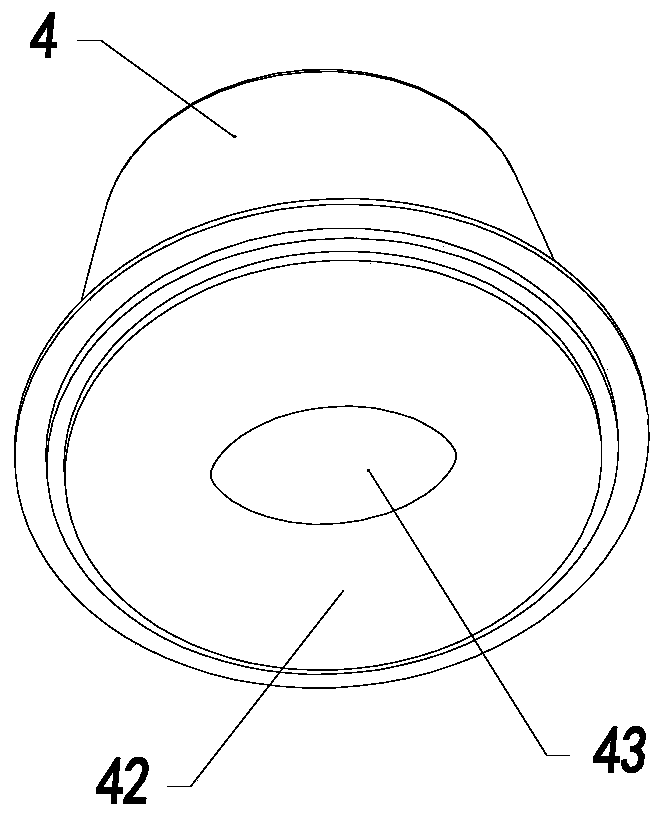

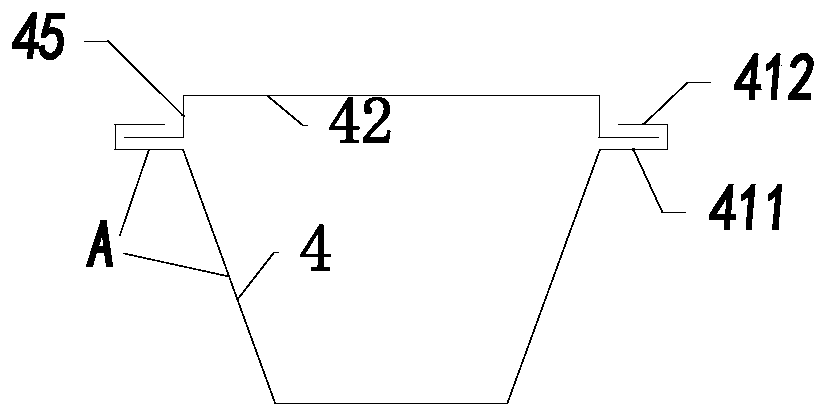

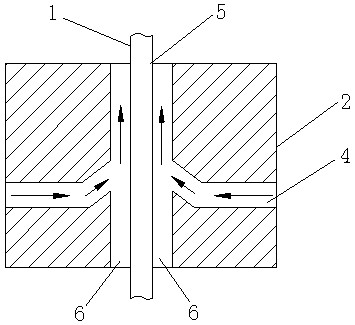

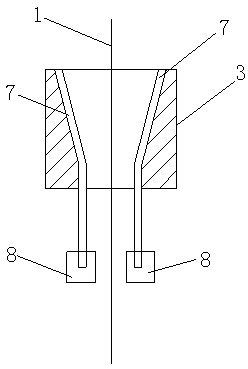

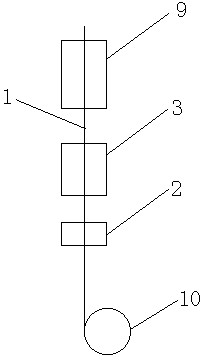

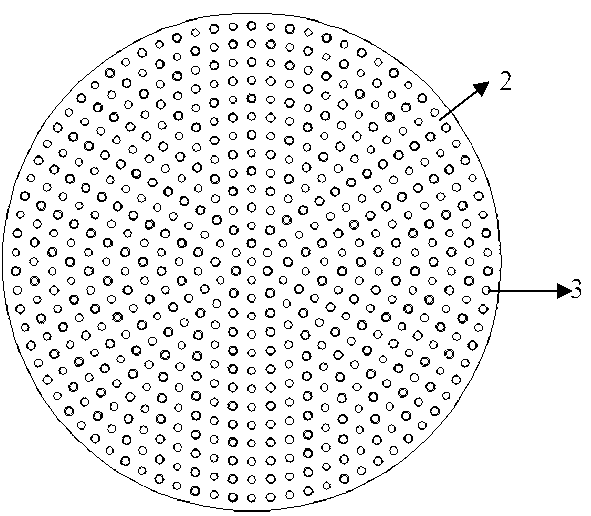

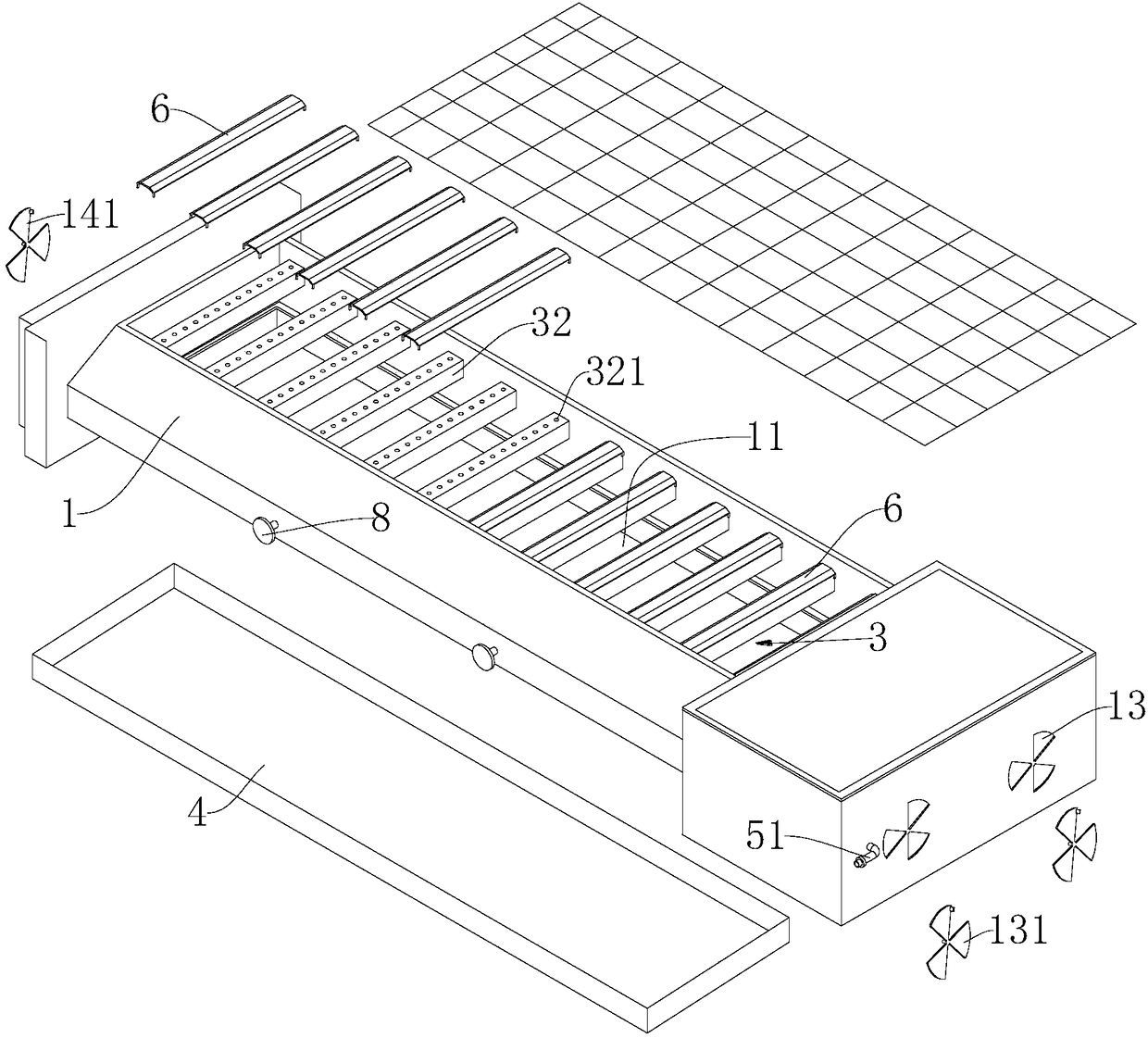

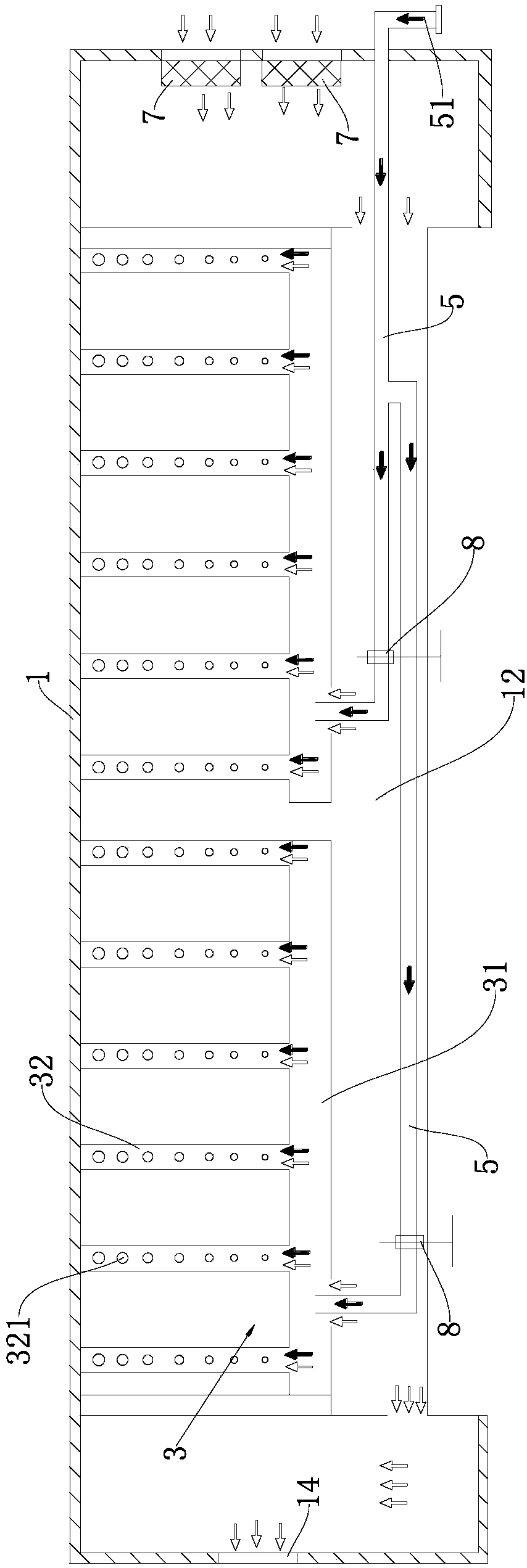

Oil fume blowing and collecting device for fiber drawing tower

The invention belongs to the fiber manufacturing industry, and discloses an oil fume blowing and collecting device for a fiber drawing tower. The device comprises a blowing device and an oil collecting device arranged on the upper part of the blowing device, a fiber passage is formed in the blowing device, a clearance serving as a gas passage is reserved between the fiber passage and the blowing device, the outer surface of the blowing device is provided with an air inlet hole, and the air inlet hole is communicated with the gas passage. The device can effectively reduce oil fume attached to the surface during fiber production, meanwhile collects the oil fume for centralized treatment, and produces good influence on the environment.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

Special high-frequency water-based quenching liquid for induction gear and preparation method of special high-frequency water-based quenching liquid for induction gear

InactiveCN107641686AImprove cooling effectImprove hardness is not enoughFurnace typesQuenching agentsWater basedPolyvinyl alcohol

The invention discloses a special high-frequency water-based quenching liquid for an induction gear. The special high-frequency water-based quenching liquid for the induction gear is prepared from thefollowing substances in parts by weight: 25-30 parts of polymer polyvinyl alcohol resin particles, 50-60 parts of deionized water, 1-2.5 parts of an efficient brightener, 2.5-3 parts of an anticorrosion inhibitor and 1.5-2 parts of a surfactant. A preparation method of the special high-frequency water-based quenching liquid for the induction gear comprises the following steps of (1) in a normal temperature state, dissolving a proper amount of the polymer polyvinyl alcohol resin particles into a certain amount of the deionized water, performing stirring for 20-25min, then heating a mixture to80-85 DEG C, and performing continuous stirring for 2-2.5h at a constant temperature; and (2) filtering impurities from a mixture, then sequentially adding the efficient brightener, the anticorrosioninhibitor and the surfactant according to a ratio, performing continuous stirring for 40-60min, and performing uniform stirring to obtain the special high-frequency water-based quenching liquid for the induction gear. The special high-frequency water-based quenching liquid for the induction gear can greatly improve the cooling performance during quenching of the induction gear, is small in oil fume after quenching, pointedly solves the problem of insufficient hardness of quenching structures of various induction gears, is good in mechanism performance with a metallographic structure, is permanently sheeny and is liable to clean.

Owner:郑州市欧普士科技有限公司

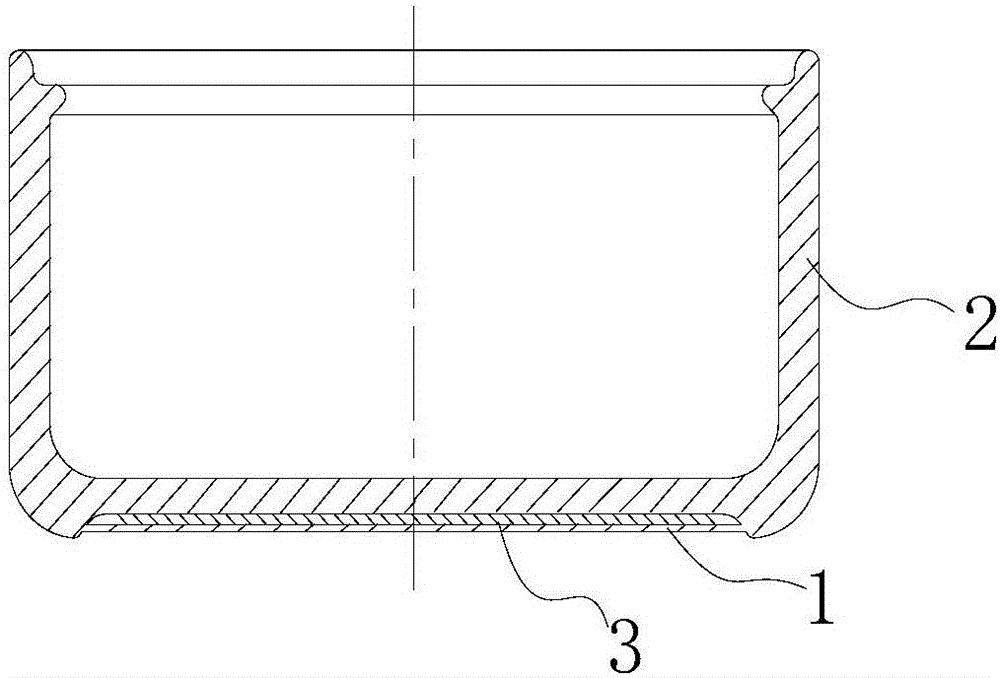

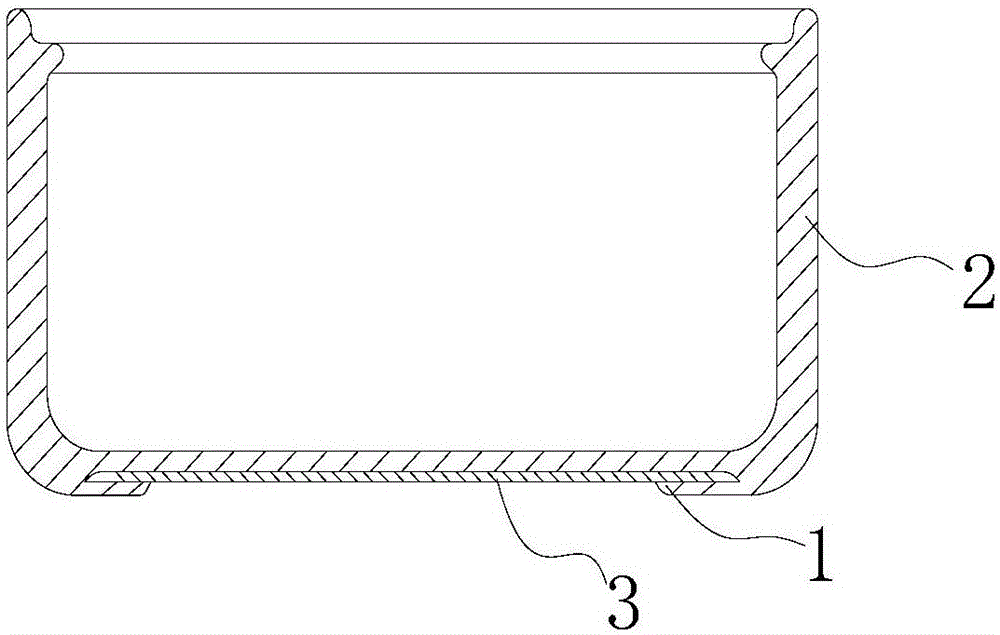

Automatic temperature-control ceramic pot suitable for electromagnetic stove

InactiveCN106308469AAvoid breakingReduce oil fumeCooking-vessel materialsEmbrittlementCurie temperature

The invention provides an automatic temperature-control ceramic pot suitable for an electromagnetic stove. The ceramic pot suitable for the electromagnetic stove is provided with a side wall and a pot bottom which are each provided with a ceramic layer; the ceramic pot is characterized in that the pot bottom is provided with a temperature-control layer which is made from an alloy material of which the Curie temperature ranges from 200 DEG C to 230 DEG C. According to the automatic temperature-control ceramic pot suitable for the electromagnetic stove, under regulation of precision alloy of the temperature-control layer, the temperature of the ceramic pot can be controlled to be within 230 DEG C in the cooking process, and rupture caused by high-temperature embrittlement is avoided; meanwhile, the temperature of cooked food can be controlled to be within 220 DEG C, the oil fume, burnt and paste pot problems and other problems can be reduced, and the cooking effect is improved while the safety of ceramic pots is guaranteed.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

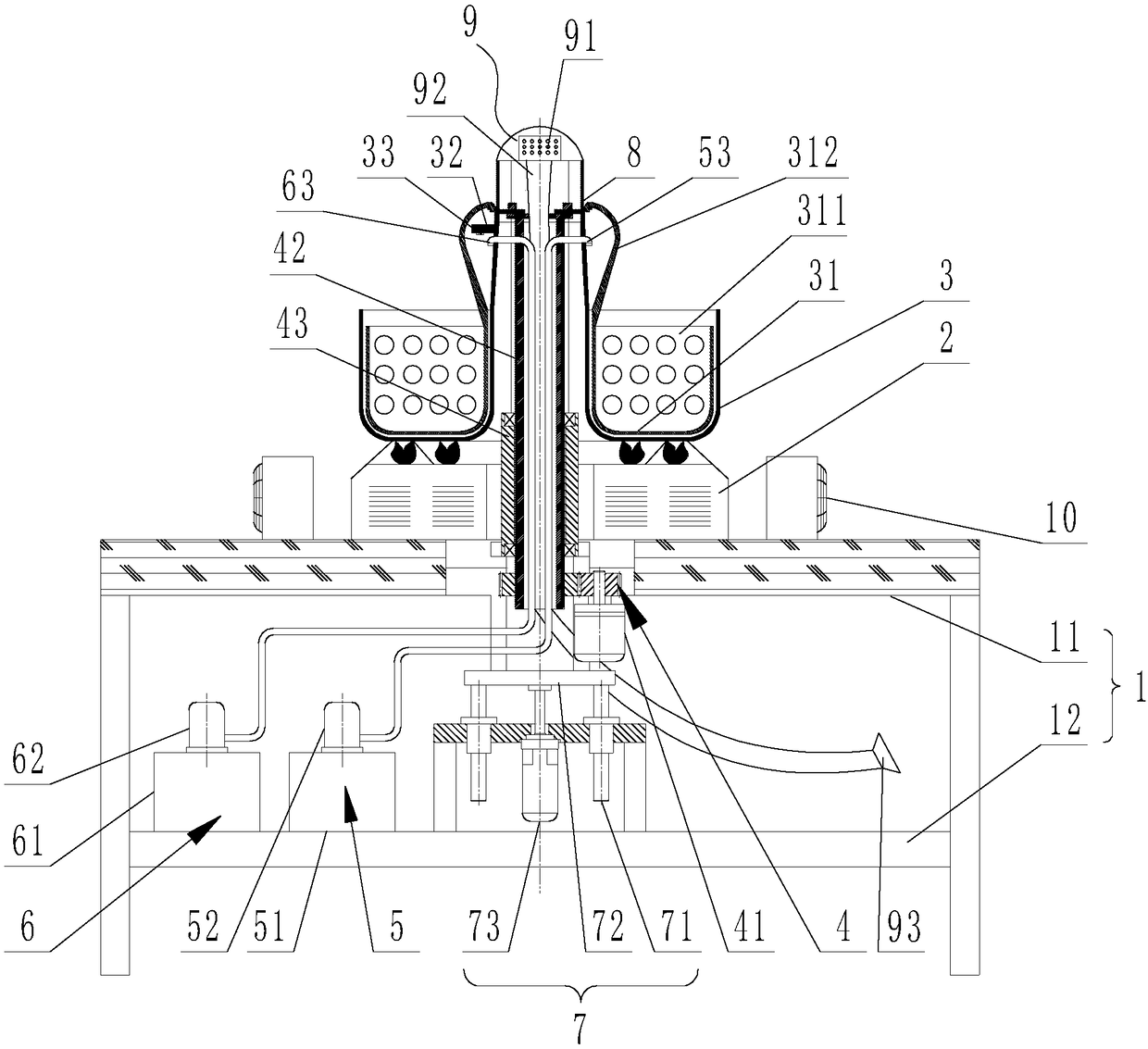

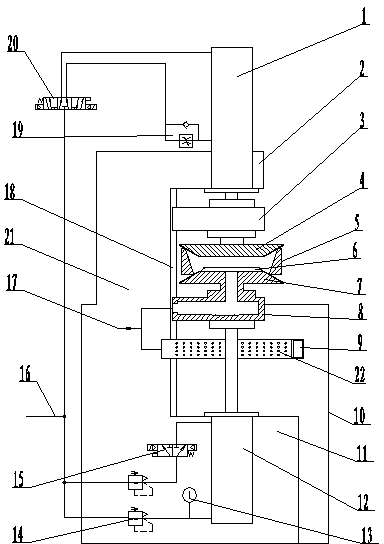

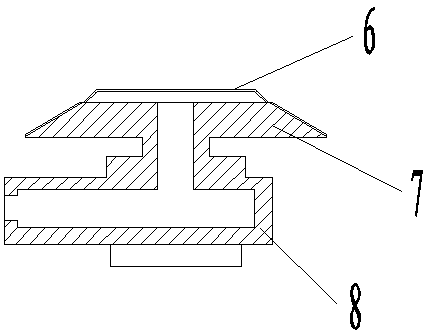

Die press quenching device for fully quenching steel ferrules

ActiveCN103451406AIncrease manufacturing costReduce manufacturing costsFurnace typesHeat treatment process controlHigh pressureQuenching

The invention relates to a heat treatment quenching device, in particular to a die press quenching device for fully quenching steel ferrules. The die press quenching device comprises a base, a stand column at one side of the base and a cross beam at the upper end of the stand column, wherein an upper sliding block and a lower sliding block are respectively arranged on a guiding rail of the stand column, and piston rods of an upper die cylinder and a lower die cylinder are respectively connected with the upper sliding block and the lower sliding block. The die press quenching device is characterized in that a high-pressure pipeline is connected with the upper die cylinder and the lower die cylinder respectively, a one-way speed regulating valve and a reversing valve I, which are used for controlling the speed and the direction of the upper die cylinder, are respectively arranged on a high pressure pipeline connected with the upper die cylinder, a pressure regulating valve and a reversing valve II, which are used for controlling the pressure and the direction of the lower die cylinder, are respectively arranged on a high pressure pipeline connected with the lower die cylinder, and cooling oil for quenching is connected with an oil outlet and an oil spraying ring on the lower die. According to the device, the press quenching force and the press quenching speed can be precisely regulated, the quenching time is short, the deformation of quenched workpieces is small, the quenching quality is effectively ensured, and existing quenching and controlling technologies are greatly improved.

Owner:NINGXIA MACHINERY RES INST

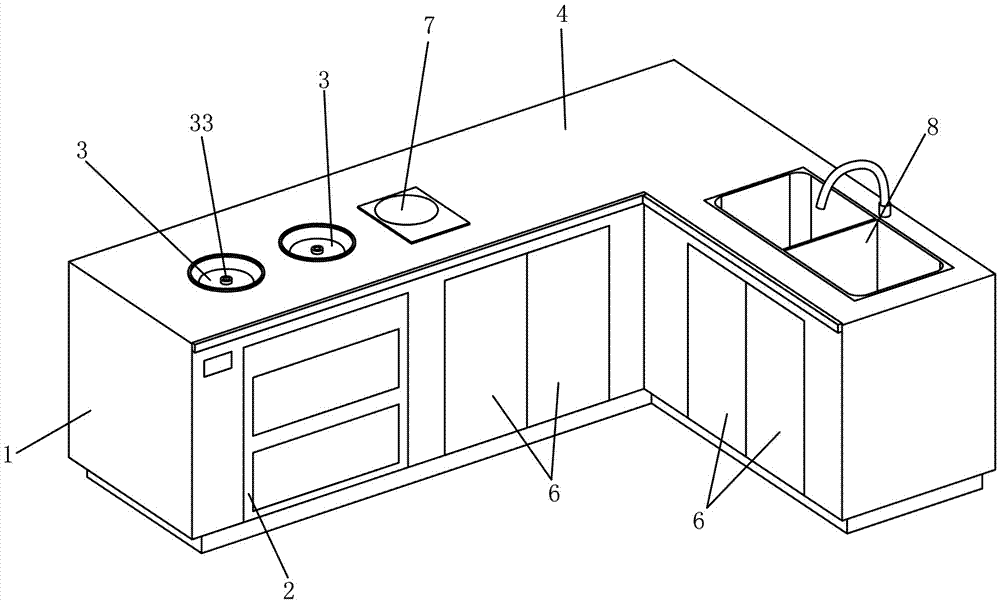

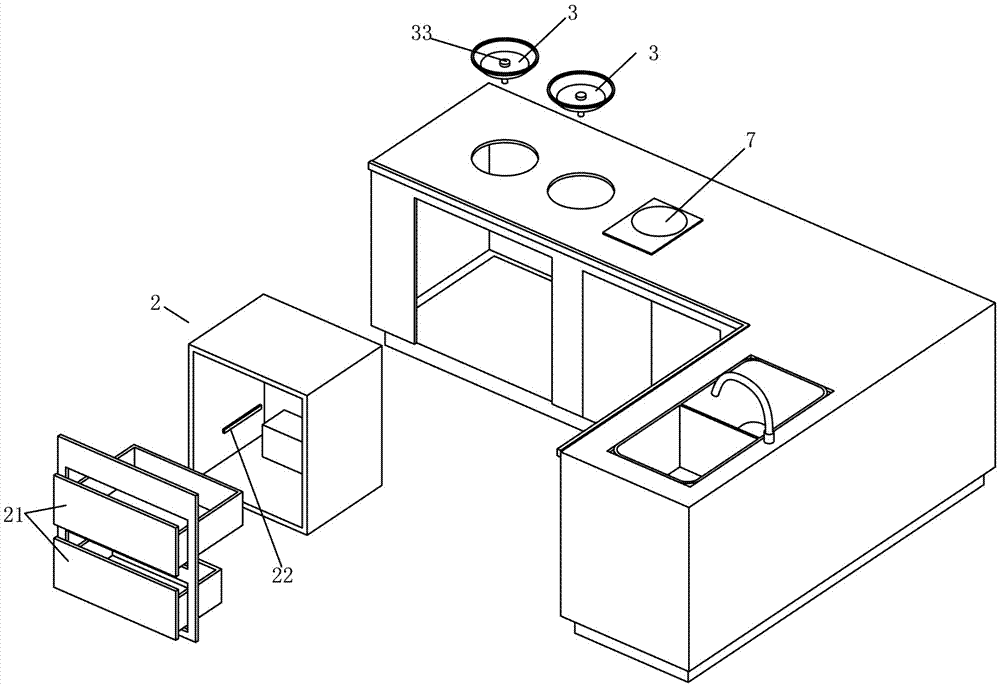

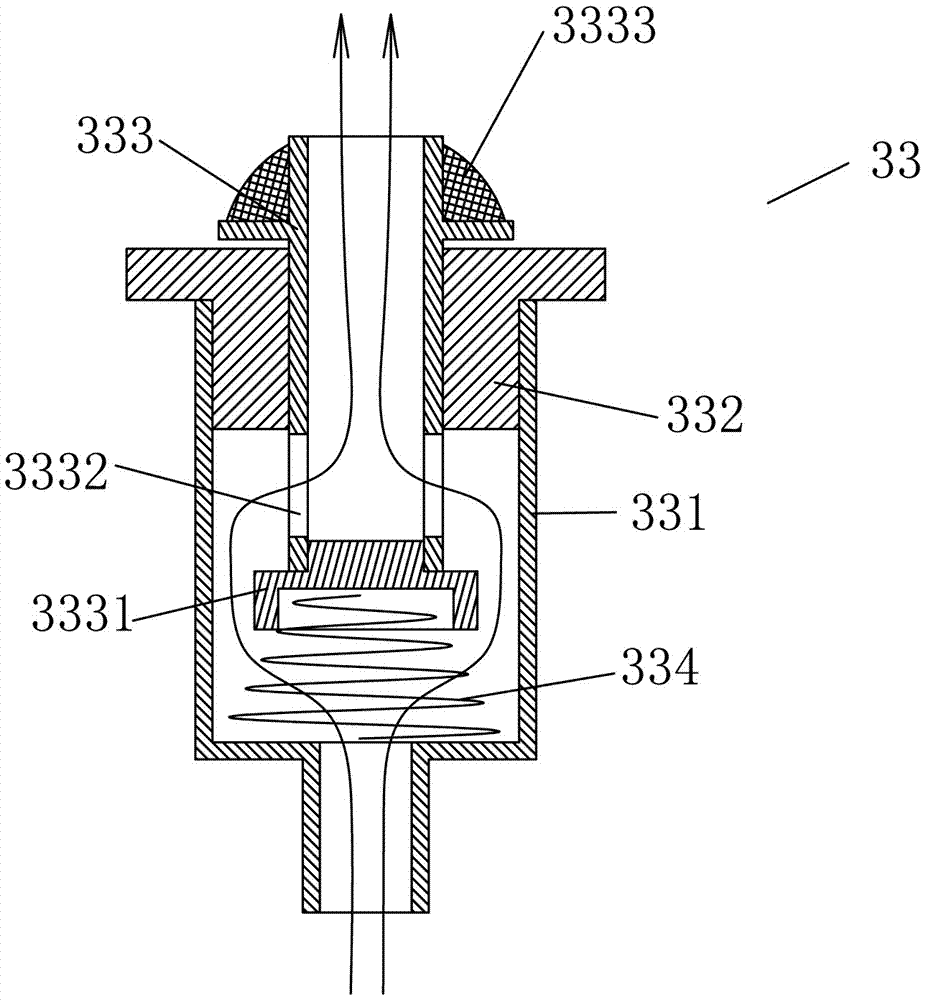

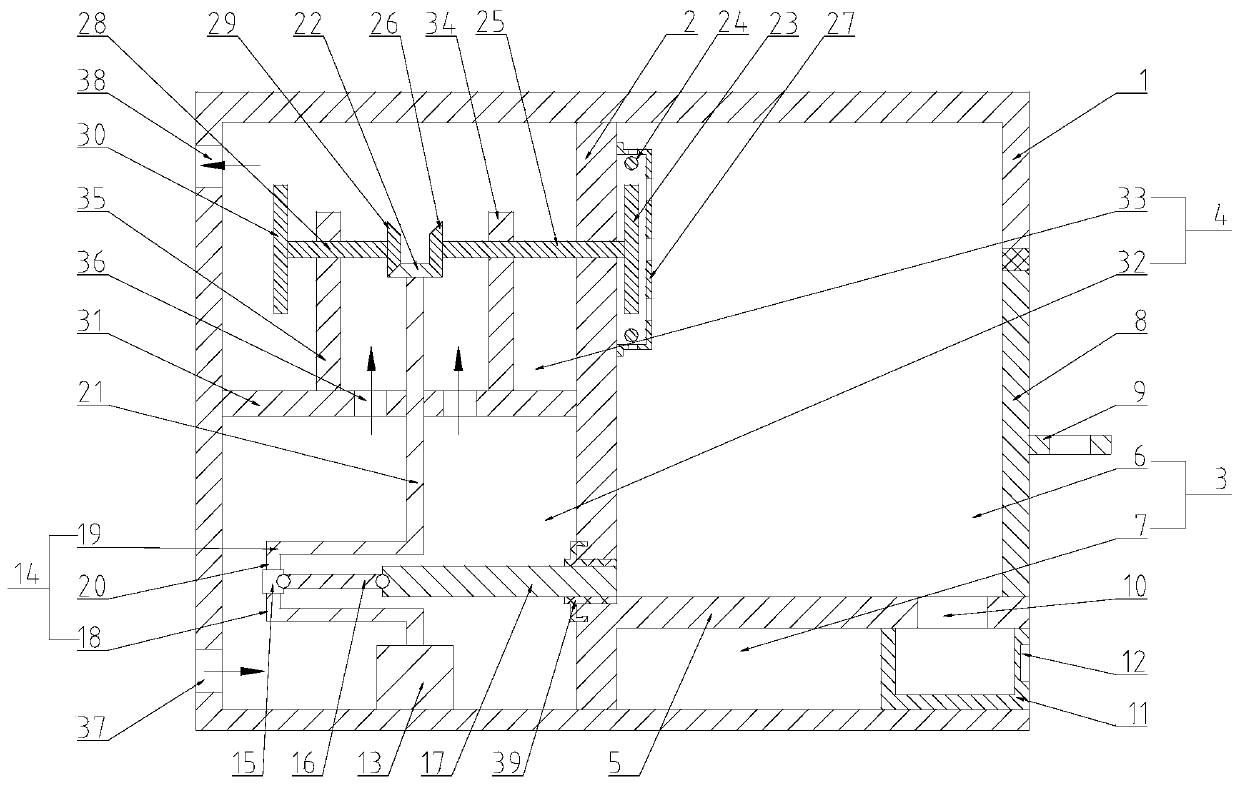

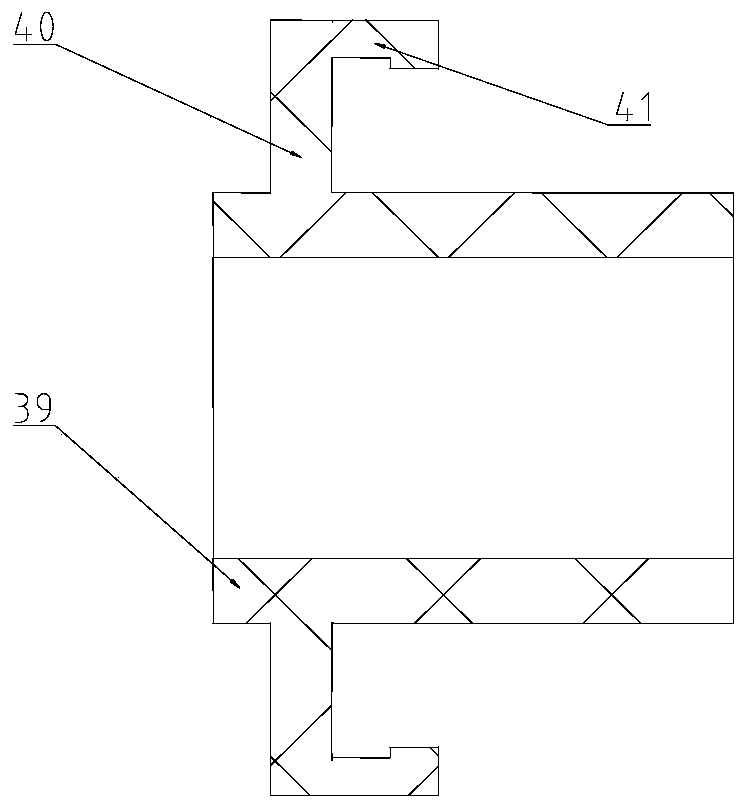

Intelligent kitchen system utilizing steam

ActiveCN106923527ASo as not to damageImprove energy efficiencyKitchen cabinetsWater vaporEngineering

Provided is an intelligent kitchen system utilizing steam, relating to the technical field of kitchen equipment. The invention particularly relates to equipment used for tableware disinfection and food heating in a kitchen. The intelligent kitchen system utilizing steam comprises a main cabinet body. The top of the main cabinet body is provided with a table surface and is embedded with a tableware disinfecting cabinet. The intelligent kitchen system utilizing steam is characterized in that a steam generator is arranged in the main cabinet body or the tableware disinfecting cabinet and connected with a disinfecting chamber of the tableware disinfecting cabinet through a steam pipeline; more than one steam kettle base is arranged on the table surface; and the center of the steam kettle base is provided with a steam joint connected with the steam generator. The intelligent kitchen system utilizing steam has the following beneficial effects: high-temperature water steam is utilized directly for tableware disinfection and food heating; food can be directly steamed by high-temperature water vapor of 100 DEG C produced by the steam generator, boiled and fried; utilization rate of energy is high; nutrition loss is few; oil smoke is avoided; food tastes good; and the system is convenient to use.

Owner:王佰忠

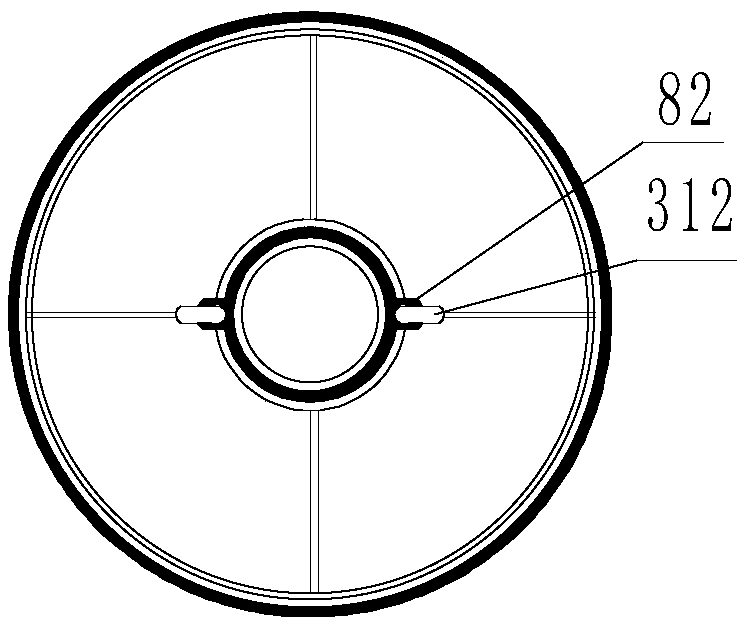

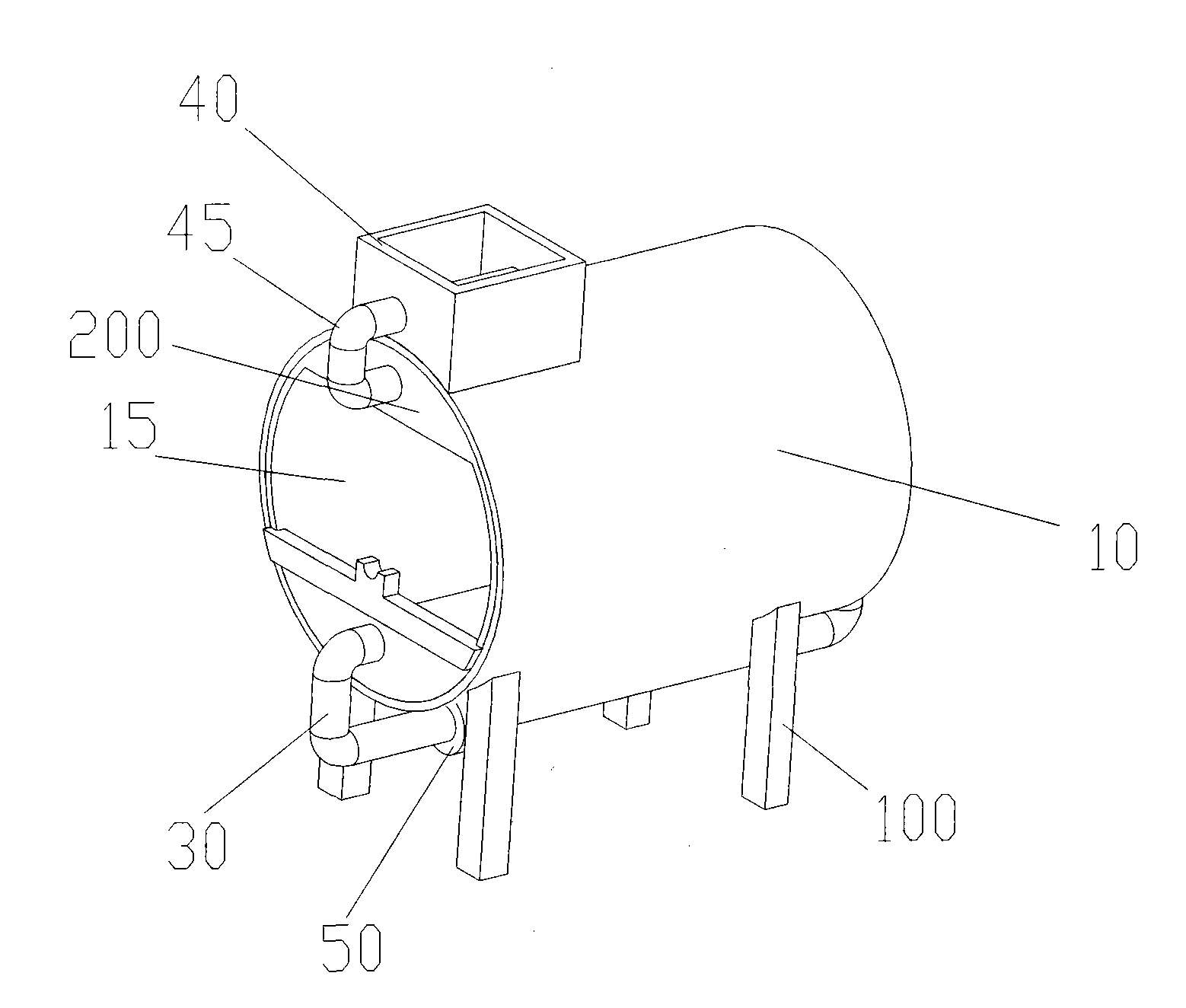

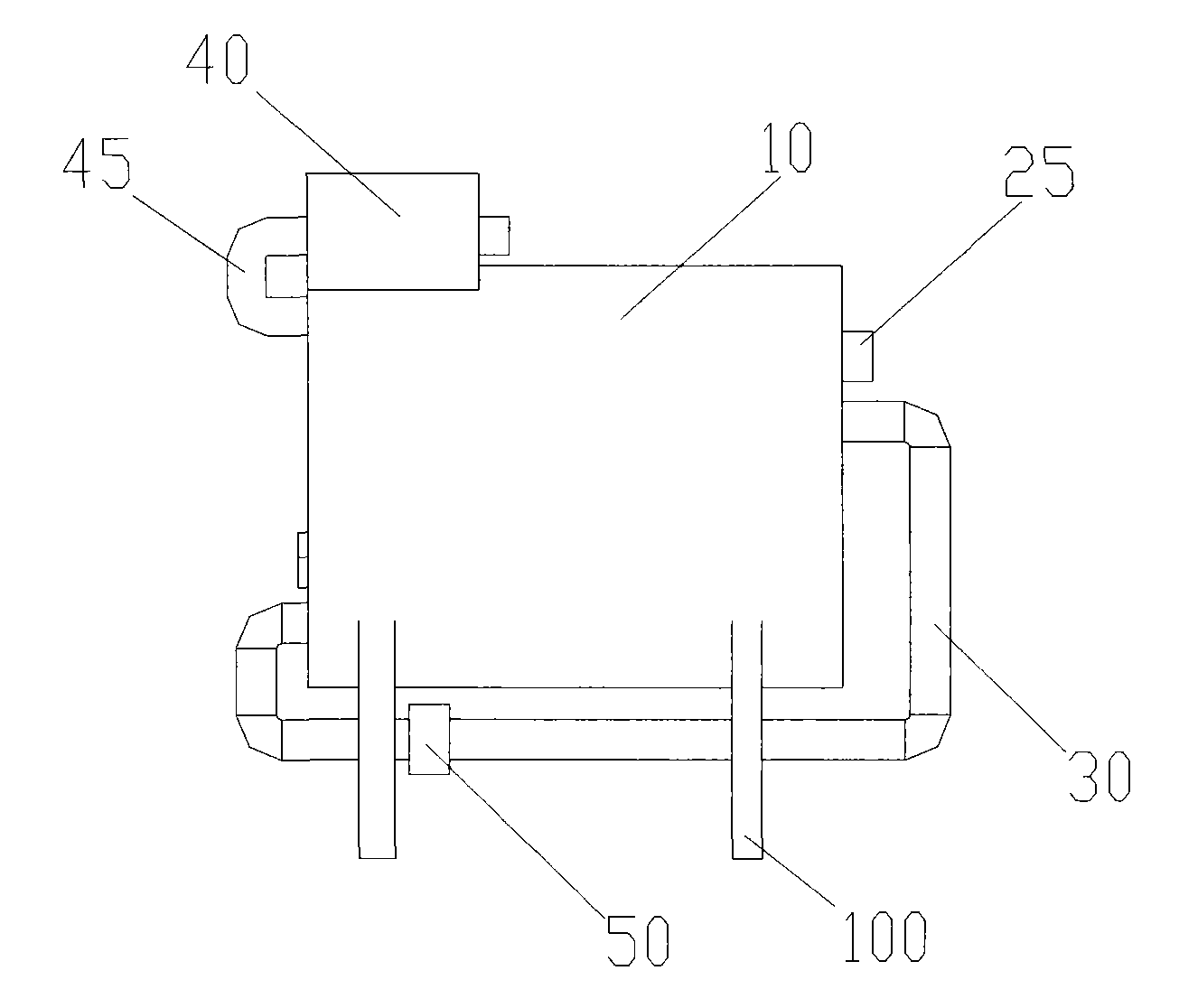

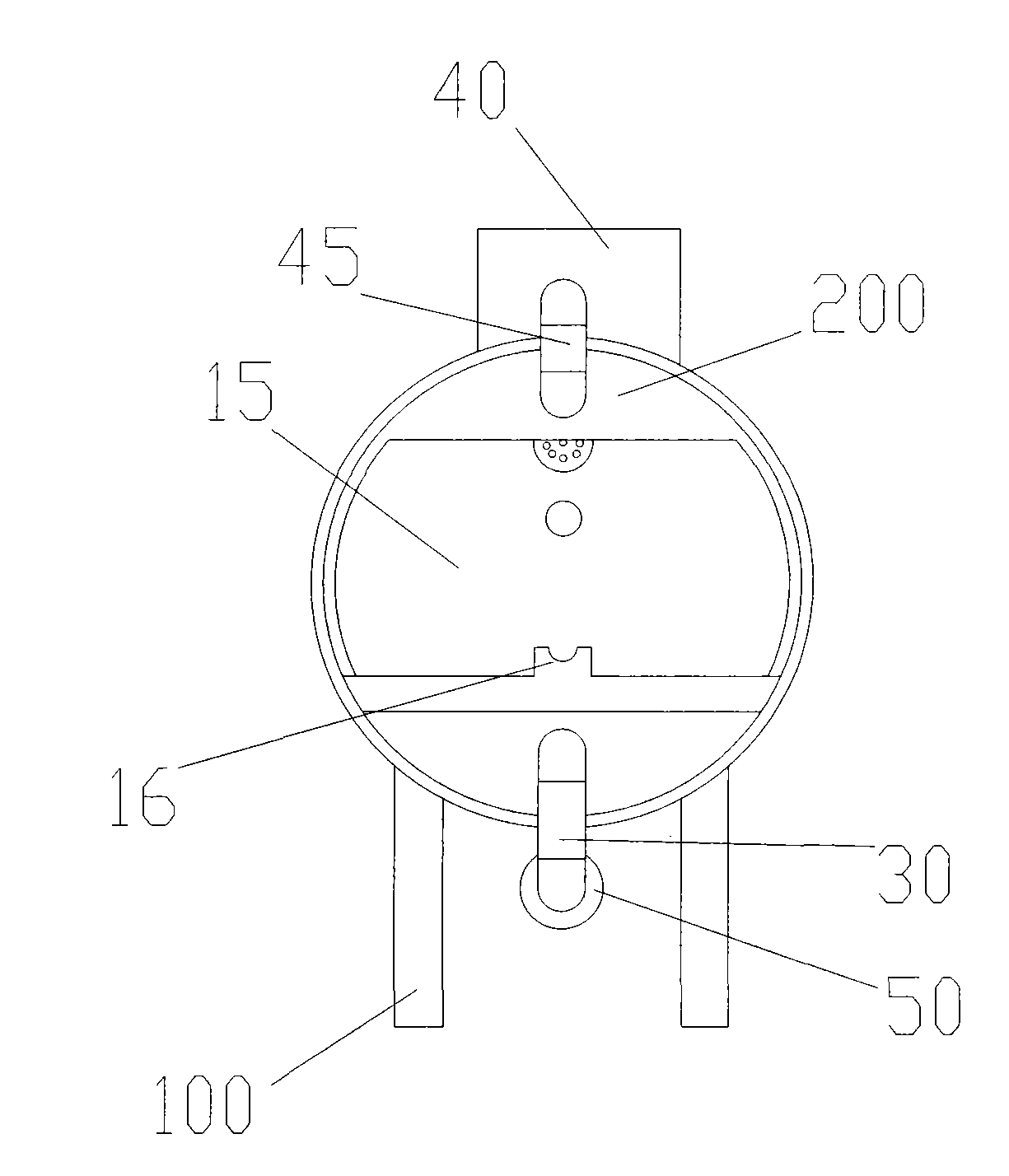

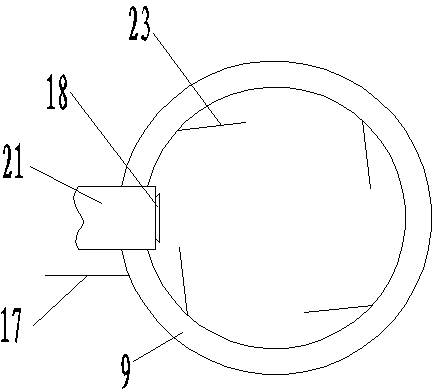

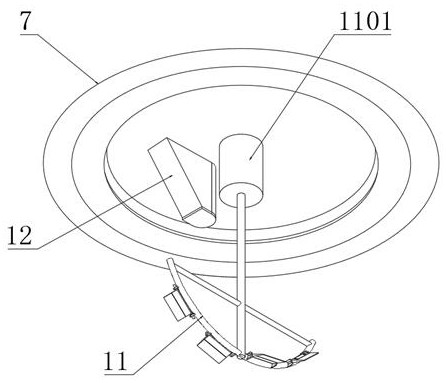

Rotary barrel type barbeque cooking device

PendingCN108852022ASimple structureDoes not produce carcinogensRoasting apparatusRoasters/grillsEngineeringIdler-wheel

The invention relates to a rotary barrel type barbeque cooking device which comprises a support and a rotary barrel, wherein the support is provided with an oven erecting seat, the rotary barrel is arranged on the support, a pot cover is arranged at one end of the rotary barrel, a rotary connection device is arranged at the other end of the rotary barrel, the rotary connection device is connectedwith a rotary driving module arranged at one end of the support, an idler wheel is arranged at the other end of the support, and one end of the rotary barrel is arranged on the idler wheel. The rotarybarrel type barbeque cooking device disclosed by the invention has a simple structure; by means of the structure design, a barbequing mode is completely changed, and food can be barbequed in a relatively sealed container in a mode of separating from fire; in a barbequing process, cooking fume is less, cleanness and hygiene are achieved, local superhigh temperature is avoided, and cancerogenic substances are prevented from being generated.

Owner:何廷贵

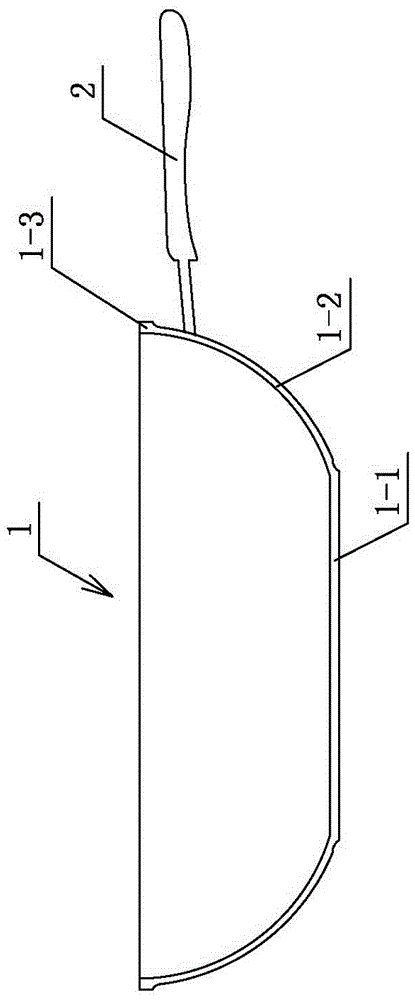

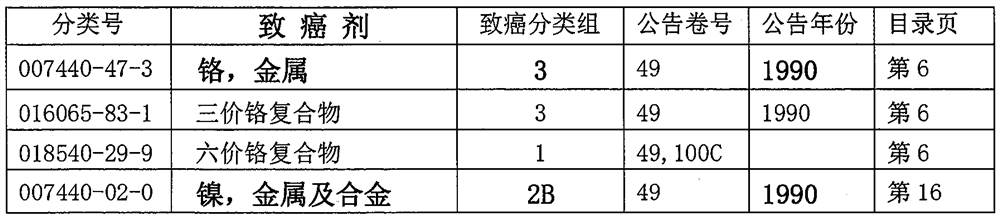

Carcinogenicity-free stainless frying pan

PendingCN112244615ANon-carcinogenicNon-allergenicCooking-vessel materialsCooking vessel constructionsNichromeNickel alloy

The invention belongs to a carcinogenicity-free stainless frying pan of a Chinese cooking segment-shaped frying pan, and relates to a principle and a manufacturing method of the carcinogenicity-free stainless frying pan. According to the principle and the manufacturing method of the carcinogenicity-free stainless frying pan, a 26-38cm small-caliber frying pan main body piece is manufactured by mould pressing of a cold-rolled low-carbon steel plate without carcinogen chromium, nickel, chromium metal, nickel metal and nickel alloy; a large-diameter wok main body part of 56-108 cm is cast by graycast iron and nodular cast iron; and then a nitriding or nitrocarburizing process is adopted for the frying pan main body part which is formed through mould pressing or casting, so that a nitriding layer with the thickness ranging from 0.20 mm to 0.42 mm is generated on the surface of the frying pan, and the nitriding layer has very high abrasion resistance and corrosion resistance. Even if the wok is frequently collided and ground by a metal frying shovel in the frying process, particles enter dishes and are eaten into a digestive system of a human body, and the particles are iron and tracenitrogen and carbon which are harmless to the human body. Due to the fact that the heat conductivity is lower than that of a nitriding layer made of steel, cooking fumes of initial-stage frying oil can be reduced; the anti-sticking tendency is realized, and the cleaning is easy.

Owner:马兆瑞 +1

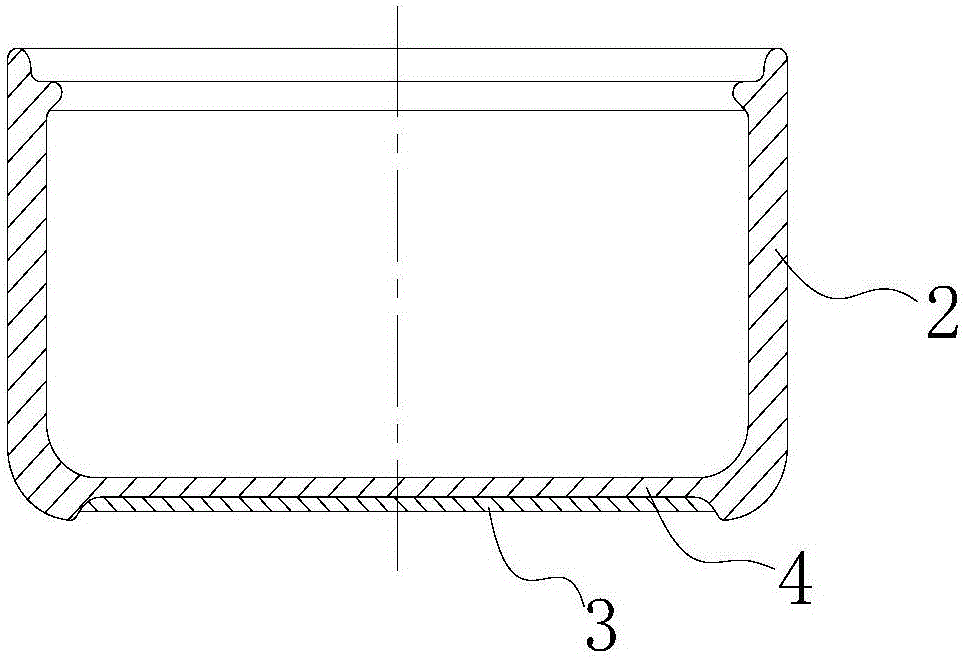

Multi-layer compound-bottom aluminum pot

The invention provides a multi-layer compound-bottom aluminum pot, comprising a pot body, wherein the bottom part of the pot body is connected with a plurality of metal materials to form the compound pot bottom by extrusion; the plurality of metal materials are as follows: a high heat-conductive layer, a double-direction connection sheet, aluminum alloy and magnetic steel; the high heat-conductive layer is melted to cover the double-direction connection sheet; the highly heat-conductive layer has good and uniform heat conduction performance; the aluminum alloy is compounded with the magnetic steel to form a metal plate with a flat surface; the magnetic steel compound bottom can be used for all kinds of stoves; as the surface of the compound metal plate is flat, the compound metal plate can be used for avoiding scratching the surface of an induction stove when the compound metal plate is used on the induction stove; convex holes at the front side of the double-direction connection sheet face the pot bottom and concave holes at the back side of the double-direction connection sheet face the compound metal plate, so that the pot bottom and the metal plate are extruded to form the compound-bottom aluminum pot by the double-direction connection sheet via the high-strength extrusion process at normal temperature; the compound pot bottom is formed by direct extrusion at normal temperature. When the multi-layer compound-bottom aluminum pot provided by the invention is used, the phenomena of deformation and falling of the compound bottom of the aluminum pot caused by the heat expansion can be effectively avoided. The high-strength extrusion process is simple and convenient, does not cause environmental pollution and noise pollution in the production.

Owner:ZHEJIANG YUNMA TECH

Full-automatic barbecue machine

PendingCN110693340ANo action requiredEvenly bakedRoasting apparatusProcess engineeringMechanical engineering

The invention discloses a full-automatic barbecue machine. The full-automatic barbecue machine has a series of automatic functions of automatic overturning barbecue, automatic constant temperature electric heating, automatic kebab delivery, automatic seasoning scattering, random barbecue time adjustment and the like. According to the automatic overturning barbecue, an upper belt and a lower belt clamp a roasted object in a one-moving and one-static mode to rotate forwards at a constant speed, the rotating speed can be adjusted in advance, and the time for roasting materials can be adjusted. The automatic delivery means that a to-be-baked object is put into the delivery mechanism of the machine and is stably delivered into the rotating equipment at a constant speed along with the preset speed. According to the automatic seasoning scattering function, when kebabs are conveyed to the range sensed by the sensor through the rotating mechanism, seasoning is automatically put into the seasoning scattering box. According to the barbecue machine, a lot of work of barbecue personnel before and during barbecue can be completed only by putting kebabs into the barbecue equipment, and a lot of procedures in operation are omitted.

Owner:胥文君

Straw-wood chip honeycomb fuel and preparation method thereof

Provided are a novel straw-wood chip honeycomb fuel and a preparation method thereof. The preparation method comprises the steps: crushing straw, grass wood chips and the like into a crushed materialwith the particle size of less than or equal to 5 mm, mixing calcium oxide with the crushed material according to a weight ratio of 3:(4-5), adding an appropriate amount of water, and stirring into acohesive state, preparing straw-wood chip honeycomb balls by a coal ball machine, air-drying, baking and charring in a sealed room at the temperature of 300 DEG C or less, spraying a potassium permanganate solution before leaving a factory, and air-drying. The straw-wood chip honeycomb fuel can be fully burned and has no pollution. A principle comprises that quick lime undergoes a reaction with water to produce slaked lime, the slaked lime calcium hydroxide removes grease from the straw and wood chips and undergoes a reaction with carbon dioxide in air to produce calcium carbonate, and the straw-wood chip honeycomb balls are hard and easy to store.

Owner:贾谊峰

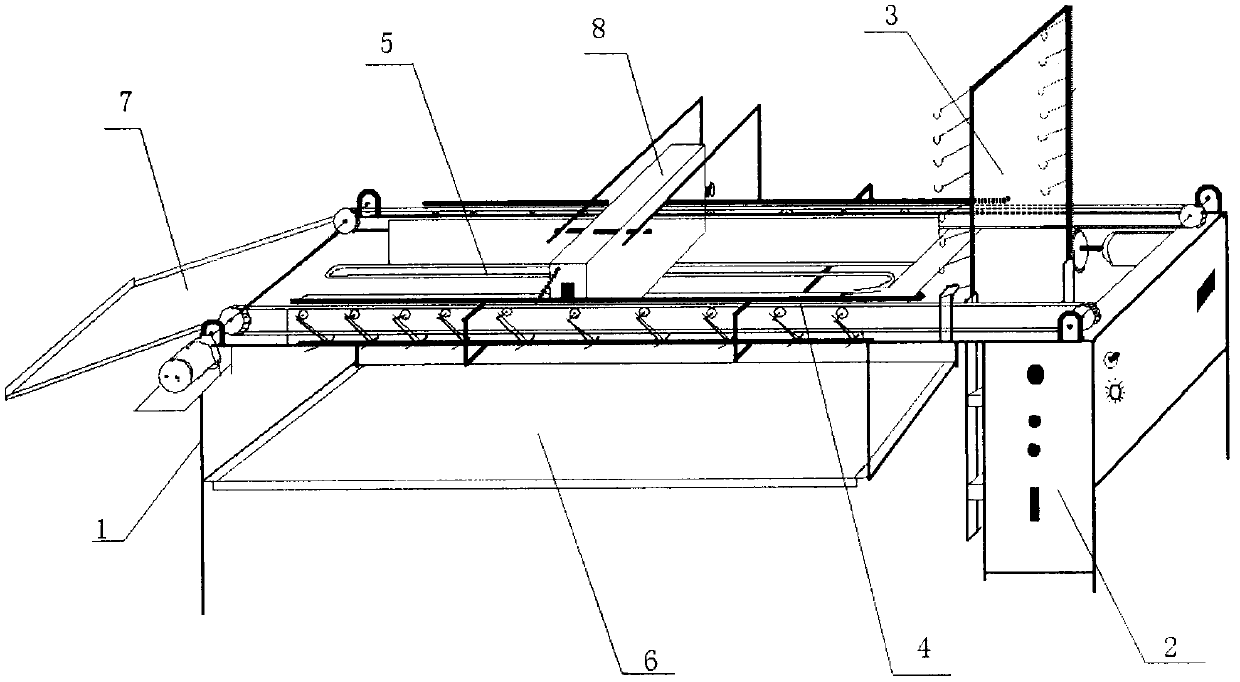

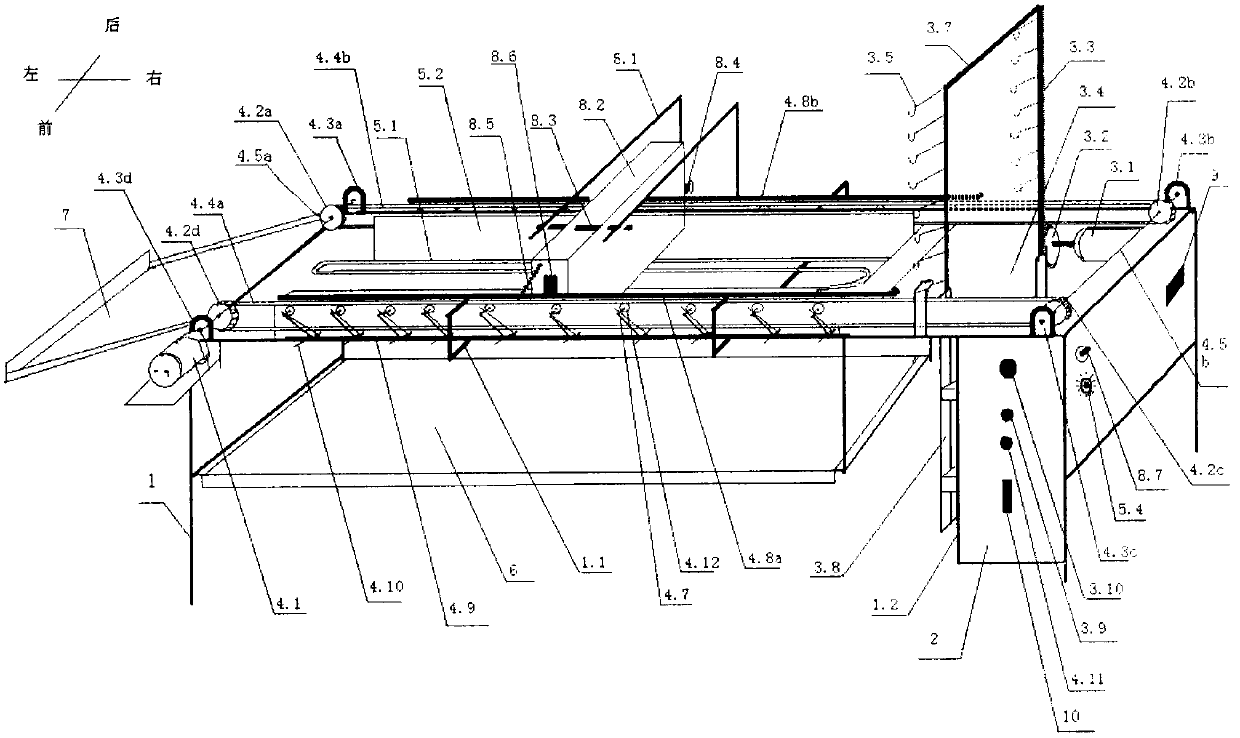

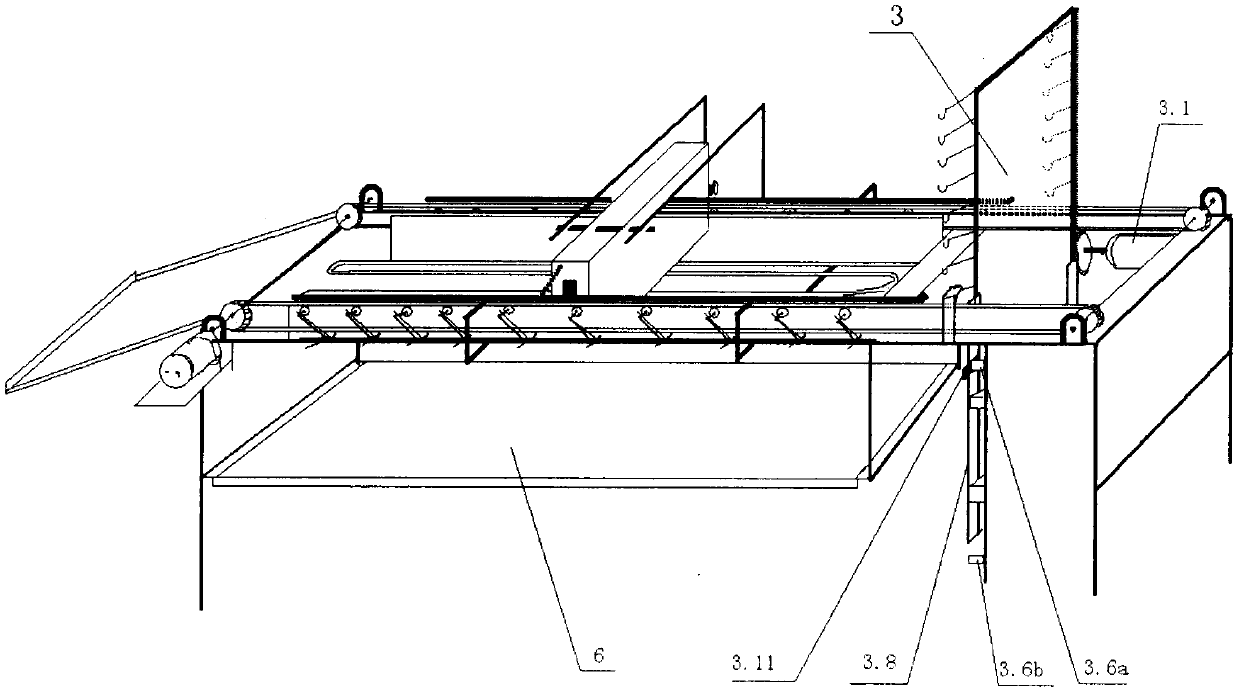

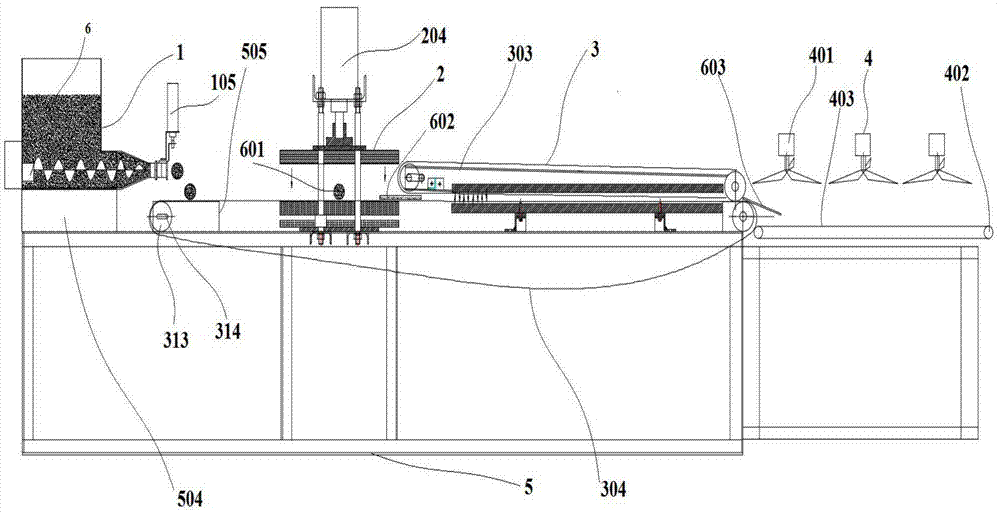

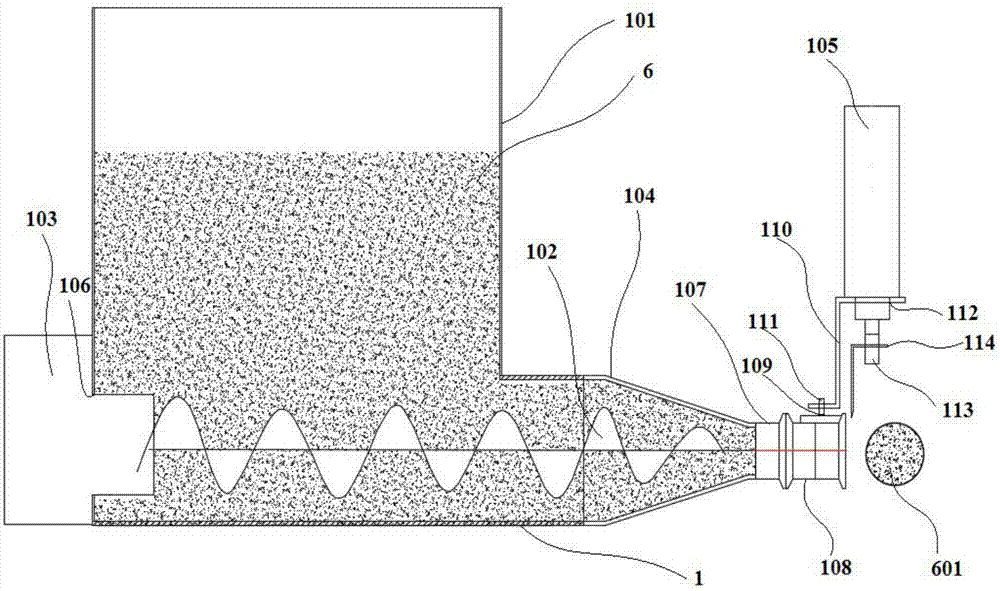

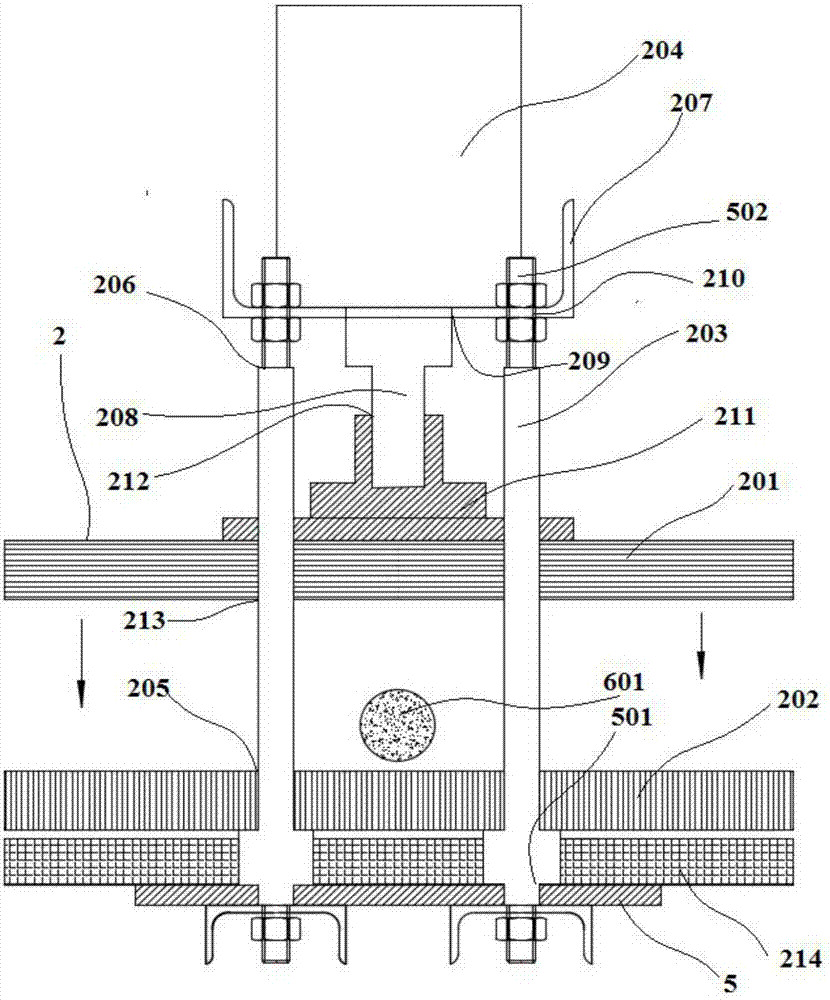

Multifunctional full-automatic numerical-control pancake making machine

PendingCN107372691ASolve operational problemsSolve efficiency problemsOil/fat bakingDough shaping and cutting apparatusNumerical controlManual handling

The invention discloses a multifunctional full-automatic numerical-control pancake making machine and relates to the technical field of pancake making machines. The multifunctional full-automatic numerical-control pancake making machine comprises a dough cutting device, a dough sheet forming device, a baking device, an air cooling device and a pancake making machine support and is characterized in that a container support is arranged on one surface of the pancake making machine support; the container support is matched with dough cutting device; one surface of the pancake making machine support is provided with fourth through holes; the fourth through holes are matched with the dough sheet forming device; one surface of the pancake making machine support is provided with a plurality of third rotary wheel supports; the third rotary wheel supports are matched with the third rotary wheels of the air cooling device; one surface of the pancake making machine support is provided with a fan support; the fan support is fixed with a fan. The multifunctional full-automatic numerical-control pancake making machine has the advantages that by the aid of the dough cutting device, the dough sheet forming device and the baking device, the multifunctional full-automatic numerical-control pancake making machine is simple to operate, clean and sanitary and high in heat efficiency, and the problem that the quality of pancakes is affected by the manual operation level and the problems of smoke pollution and low efficiency are solved.

Owner:安徽汇诚精工机械制造有限公司

Oven

The invention discloses an oven. The oven comprises a box that is divided into a baking cavity and a control cavity by a longitudinal partition, wherein a transverse partition is arranged in the baking cavity, and the baking cavity is divided into a baking chamber and an oil collection chamber; the transverse partition is provided with an oil collection hole; a motor, an eccentric frame, a rotation sleeve, a connection rod and an oil pushing block are arranged in the control cavity; the bottom of the eccentric frame is in drive connection with the motor; a drive rod is connected to the top ofthe eccentric frame; a drive bevel gear is connected to the top of the drive rod; a first fan and an annular heating pipe are arranged in the baking chamber; a first driven rod is connected to a firstdriven bevel gear after penetrating through the longitudinal partition; the first driven bevel gear is meshed with the drive bevel gear; the motor drives the first fan to do circular reciprocating motion, and drives the oil pushing block to do linear reciprocating motion via the eccentric frame; uniform heat in the baking chamber is achieved via the circular reciprocating motion of the first fan;and grease and chips dropped on the transverse partition are pushed to the oil collection box via the oil collection hole via the linear reciprocating motion of the oil pushing block, so that the grease and the chips remained on the transverse partition is effectively reduced, and thus the generation of fume is reduced.

Owner:滨州高新材料产业园有限公司

Standard cooking kitchen system and rapid and efficient food cooking method thereof

InactiveCN108428198ASmall footprintEasy to control temperatureData processing applicationsMicrowaveFresh food

The invention provides a standard cooking kitchen system and a rapid and efficient food cooking method thereof, and belongs to the technical field of kitchen cooking. The standard cooking kitchen system comprises a basic seasoning option area, a basic food material option area, a fresh food material option area, a cooking and heating area and a standard recipe catering and guiding system, whereinthe cooking and heating area internally comprises at least one of an optical wave heating device, a microwave heating device and an electromagnetic induction heating device; and the standard recipe catering and guiding system is used for guiding standard catering manners of basic seasoning bags, basic food material bags and green food materials, and guiding operators to carry out standard cookingoperations in the cooking and heating area. By utilizing the standard cooking kitchen system to cook food, the cooking efficiency can be greatly improved, the cooking complexity can be reduced, the taste and health of the food can be ensured, and the generation of kitchen lampblack and cleaning sewage can be decreased.

Owner:成都清水荷花生物科技有限公司

Smoke-free gas barbecue grill

PendingCN108451386AEvenly heatedUniform temperatureDomestic stoves or rangesLighting and heating apparatusHeat conductingEngineering

The invention discloses a smoke-free gas barbecue grill. The smoke-free gas barbecue grill comprises a grill body, a gas division device and a grill grid, wherein an opening of which the upper part and the lower part penetrate through each other is formed in the furnace body; the gas division device is fixed in the opening; the grill grid is movably erected on the opening; the gas division devicecomprises a main pipeline and a plurality of branch pipelines communicated with the main pipeline; one end, away from the main pipeline, of the corresponding branch pipe is sealed and a column of exhaust holes are formed in the upper ends of the branch pipelines; an inner cavity communicated with the main pipeline is formed in the grill body; a gas pipe communicated with the main pipeline is arranged in the inner cavity; a gas inlet which enables the inner cavity to be communicated with the outside is formed in a side wall of the grill body. The smoke-free gas barbecue grill also comprises metal heat conducting pieces corresponding to the branch pipelines; the metal heat conducting pieces are detachably buckled and covered on the upper end surfaces of the branched pipelines; the cross sections of the metal heat conducting pieces are arched; an oil receiving tray is arranged under the opening. When the grill is used, heat is uniform, oil smoke is avoided, and the grill is clean and sanitary, and is convenient to clean.

Owner:GUANGZHOU HAKE KITCHEN EQUIP

Flow limiting type wooden door

PendingCN108868467AReduce the use of metalReduce weight and costFireproof doorsFire rescueAluminium saltsEngineering

The invention relates to the technical field of wooden door structures, and particularly discloses a flow limiting type wooden door. The wooden door comprises a first wooden layer, a second wooden layer and an iron layer; a first containing cavity is formed inside the first wooden layer, a sodium bicarbonate solution is contained inside the first containing cavity, a second containing cavity is formed inside the second wooden layer, an aluminum sulfate solution is contained inside the second containing cavity, a reaction cavity is formed inside the wooden door body, a first liquid outlet is formed in the bottom of the first containing cavity, a second liquid outlet is formed in the bottom of the second containing cavity, a first baffle and a second baffle are hinged to the side wall of thereaction cavity, the first baffle and the second baffle have soft magnetism, the wooden door further comprises a metal flow limiting box, a first connecting rod and a second connecting rod, and a fire extinguishing hole is formed in the side wall of the flow limiting box. The problems that in the prior art, a gap between the ground and a door installed at a kitchen is large, a large amount of cooking fume in the kitchen enters a living room and a bedroom, and the problem that air in the living room and the bedroom is polluted is solved.

Owner:重庆力迅家居有限公司

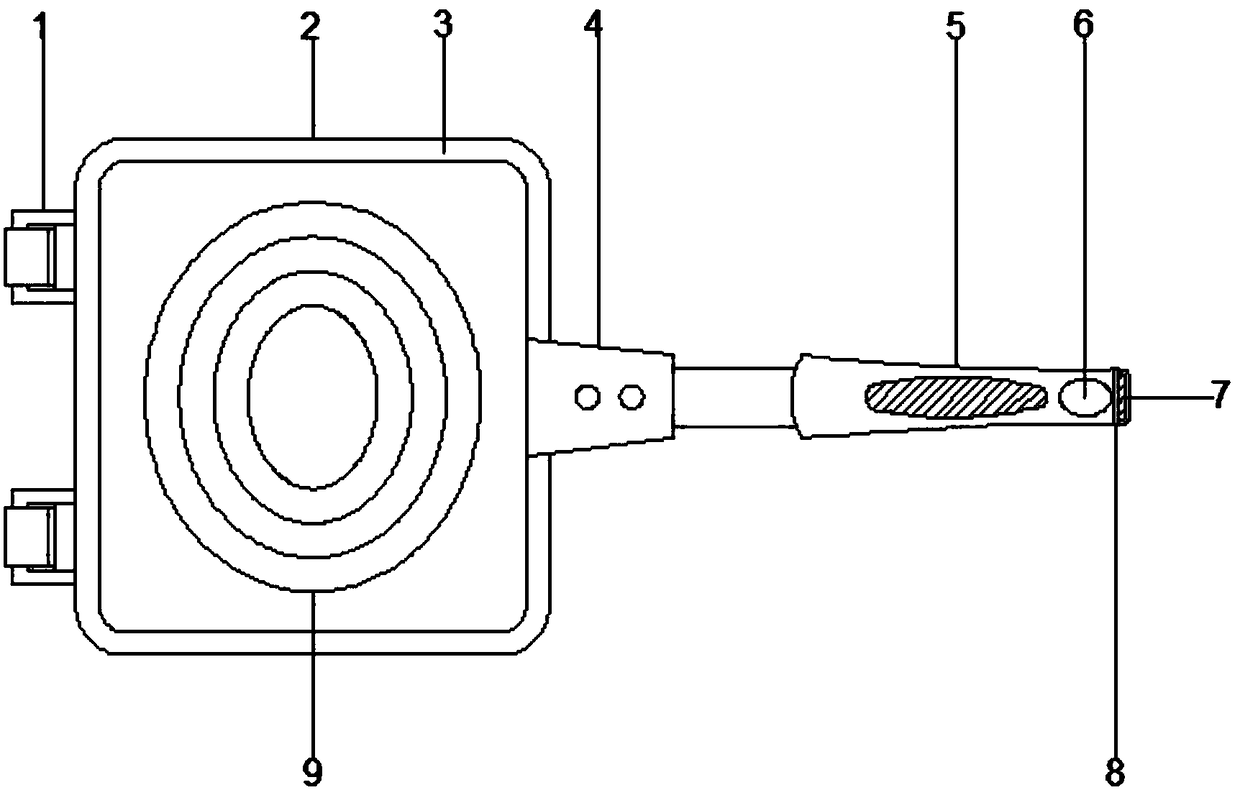

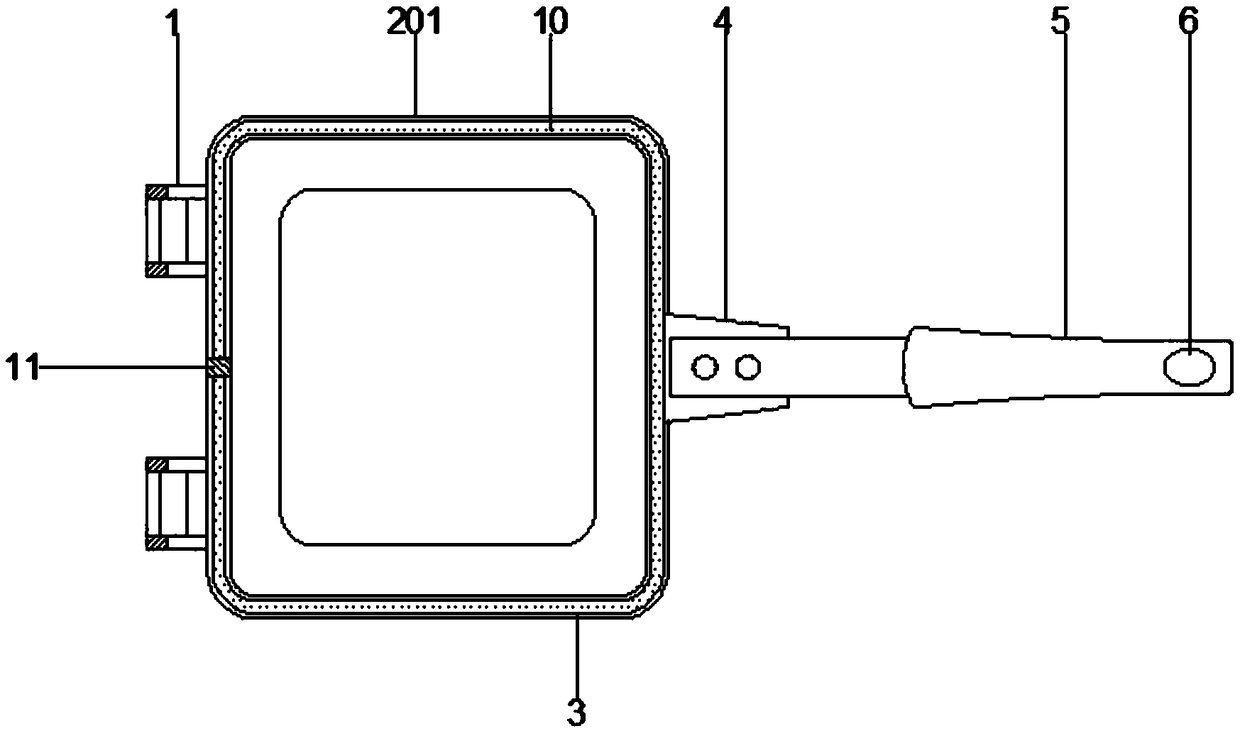

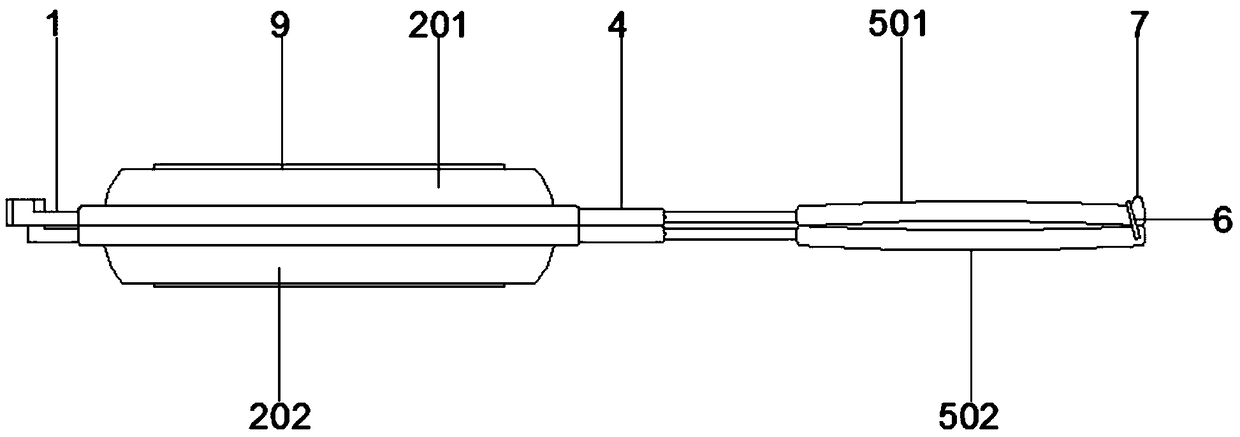

Uncoated physical non-stick multipurpose pot

InactiveCN108420302AExtended service lifeWeight increaseCooking-vessel materialsEnlarged heating surface vesselsFront coverCoating

The invention relates an uncoated physical non-stick multipurpose pot. The uncoated physical non-stick multipurpose pot comprises connecting lugs, a pot body, a pot edge, a connecting end, a handle, abuckle, an energy gathering ring, a sealing groove, an upper pot body, a lower pot body, an upper handle and a lower handle, wherein the pot body is rectangular from the downward angle; the pot bodycomprises the upper port body and the lower pot body which are matched with each other; the connecting lugs are arranged at one end of the pot body; the upper pot body is connected with the lower potbody through connecting lugs; trapezoidal connecting ends of which the positions are symmetric with each other are arranged at the other ends of the upper port body and the lower port body; the connecting ends, the upper pot body and the lower port body form an integrated structure. The uncoated physical non-stick multipurpose pot has the advantages that abrasion of the interior of the pot body can be effectively reduced, the service life of the pot body is prolonged, coating does not exist, oil fume can be reduced, safety wholesomeness is high, and the application range of a pot cover is expanded through modification, thereby effectively solving problems and deficiencies in one item of the background art.

Owner:SUZHOU XINJINGYI TITANIUM PROD

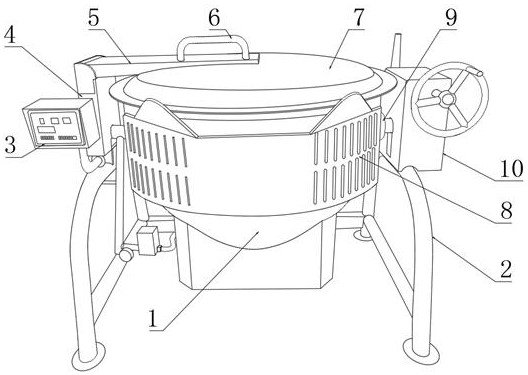

Intelligent control automatic cooker

ActiveCN112716266ANo stirring dead angleStir wellCooking insertsTime-controlled ignitorsTemperature controlElectric machinery

The invention discloses an intelligent control automatic cooker.The automatic cooker comprises a pot body, a pot frame is installed outside the pot body, a temperature control box is installed on one side of the top end of the pot frame, a supporting plate is installed at the position, corresponding to the temperature control box, of one side of the top end of the pot frame, a connecting plate is rotatably connected to the top end of the supporting plate, a pull rod is installed at the top end of one end of the connecting plate, a pot cover is installed at the bottom end of one end of the connecting plate, the pot body is sleeved with an external heat preservation cylinder, and rotating shafts are symmetrically installed on the outer end face of the pot body. By arranging a stirring motor, a stirring rod, a connecting cross rod, an arc-shaped rod, a connecting block, a rotating hole, a limit shaft, a clamping plate and a scraping plate, the stirring motor drives the arc-shaped rod and the scraping plate in the pot to rotate in the pot to stir and mix internal food materials, so that the internal food materials are stirred more uniformly, the scraping plate makes full contact with the pot body, the attachment degree is high, no stirring dead angle exists in the pot, bottom scraping is more thorough, and the pot pasting phenomenon is not likely to happen.

Owner:江门市永成厨具设备有限公司

A multi-component composite titanium pot and its manufacturing process

ActiveCN104473558BKeep it originalImprove thermal conductivityCooking-vessel materialsHeat conductingTitanium

The invention discloses a multi-element composite titanium pot. Integral thickness of the multi-element composite titanium pot is 2.0-4.0mm, and the multi-element composite titanium pot sequentially comprises a pure titanium or titanium alloy layer of 0.4-0.8mm, a pure aluminum layer of 0.4-1.5mm, a red copper layer of 0.2-0.6mm, an aluminum alloy layer of 0.4-1.5mm and a stainless steel layer of 0.2-0.8mm from inside to outside. The invention further discloses a manufacturing process of the multi-element composite titanium pot. The manufacturing process includes the steps of pretreatment, preliminary treatment, plating of a nanoscale metal adhesion layer, plating of a nanoscale metal heat-conducting layer and high-temperature high-pressure press fitting. The multi-element composite titanium pot has the advantages of being high in heat-conducting speed, uniform in heating, high in cooking speed, free of pot sticking, little in cooking fume, supportive of various heating modes like coal gas, natural gas and electromagnetic oven, good in combining effect, less prone to layering and deforming, convenient to manufacture, light in weight and cost saving.

Owner:SUZHOU XINJINGYI TITANIUM PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com