Multi-layer compound-bottom aluminum pot

A multi-layer composite and aluminum pot technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve problems such as shedding, pollution, and affecting the overall appearance of the pot body, and achieve the effect of avoiding high temperature and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

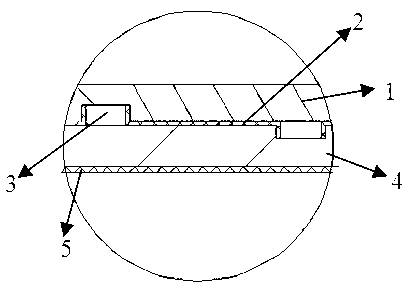

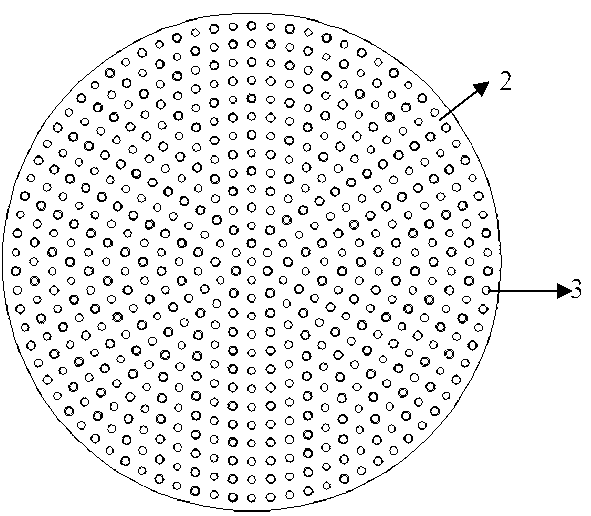

[0016] Such as Figure 1 to Figure 4 As shown, a multi-layer composite bottom aluminum pot of the present invention includes a pot body 1, the bottom of the pot body and four kinds of metals are respectively a high thermal conductivity layer (gold or silver, copper, etc.) 2, a two-way connecting piece 3, a composite metal Plate (aluminum alloy 4, magnetic steel 5). Among them, the high thermal conductivity layer (gold or silver, copper, etc.) 2 is clad on the surface of the two-way connecting sheet 3, and the thermal conductivity of the high thermal conductivity layer (gold or silver, copper, etc.) 2 is good and uniform, and then the composite metal plate (aluminum alloy 4 The surface of the magnetic steel 5) is smooth, and the double bottom of the magnetic steel 5 can be widely used on various stoves. Because the surface of the composite metal plate is flat, it can effectively avoid scratching the surface of the induction cooker when used on the induction cooker. Through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com