Non-stick frying pan and production process thereof

A frying pan and non-stick layer technology, which is applied to special materials for cooking utensils, cooking utensils, household appliances, etc., can solve the problems of not being able to meet the high requirements of non-stick, reduce oily smoke, improve heat conduction, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

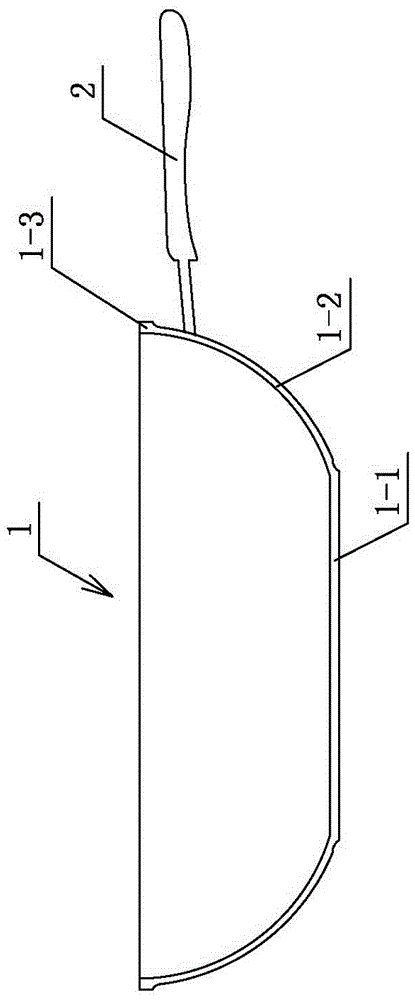

[0023] Such as figure 1 As shown, a non-stick frying pan, which includes a pot body 1 and a handle 2, the inner surface of the pot body 1 is provided with a layer of rough surface formed by the impact of steel balls, and the rough surface is sprayed with water-based polymer Tetrafluoroethylene coating, with a thickness greater than 27um, forms a non-stick layer; utilizes the roughness of the base material of the pot body to increase adhesion and prolong service life. The outside of the pot body is sprayed with silicone coating, the thickness is greater than 13um, which can be used in a variety of fire sources, such as induction cooker, gas stove and briquettes.

[0024] The pot body 1 is composed of a pot bottom 1-1, a pot body 1-2 and a pot mouth 1-3, and the pot mouth 1-3, the pot body 1-2 and the pot bottom 1-1 are integrally formed. The bottom of the pot 1-1 is pressed by multi-layer all-steel magnetic conductive sheets, which are durable and increase magnetic conductivit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com