Oil fume blowing and collecting device for fiber drawing tower

A collection device and drawing tower technology, which is applied in the field of optical fiber manufacturing, can solve the problems of adverse effects in subsequent processes and adhesion on the surface of optical fibers, etc., and achieve the effect of reducing oil fume and improving the quality of optical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

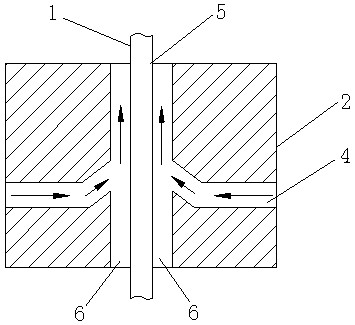

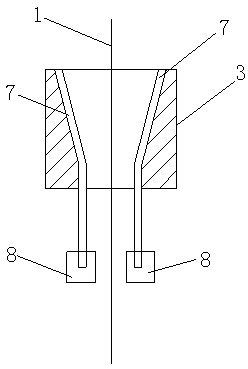

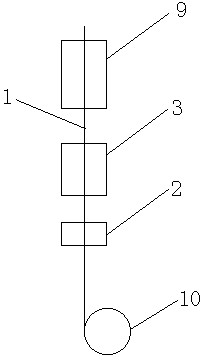

[0012] As shown in the accompanying drawings, an optical fiber drawing tower oil fume purging and collecting device includes a purging device 2 and an oil collecting device 3 installed on the upper part of the purging device 2, and the purging device 2 and the oil collecting device 3 are installed on the wire drawing Between the curing furnace 9 of the tower and the traction device 10, an optical fiber channel 5 is provided in the purging device 2, and a gap is left between the optical fiber channel 5 and the purging device 2 as a gas channel 6, and the purging device 2 The outer surface is provided with an air intake hole 4, the air intake hole 4 communicates with the gas passage 6, and an upward corner is provided at the connection between the air intake hole 4 and the gas passage 6, and the oil collecting device 3 includes The oil collecting tank 7 and the oil collecting bottle 8 located below the oil collecting tank 7, the gas setting of the purging device 2 is controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com