Fuel-cut cylinder of engine

An oil cylinder and engine technology, applied in engine components, engine control, machines/engines, etc., can solve the problems of reducing the service life of oil-stopped cylinders, failure of cylinder seals, and the inability of grease to withstand high temperatures, achieving long service life and high performance. Stable, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

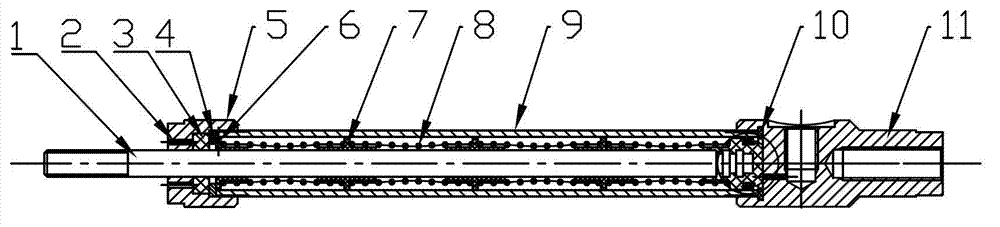

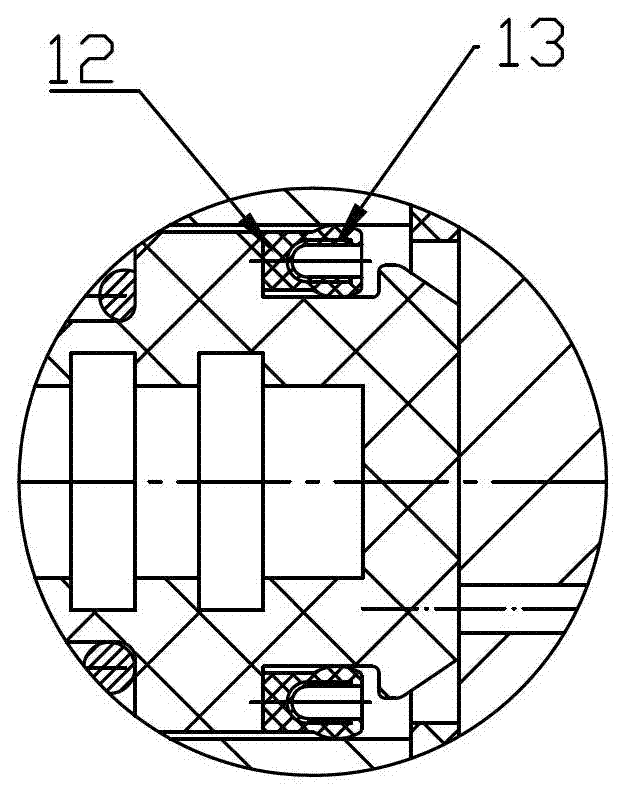

[0010] Attached below in conjunction with the manual figure 1 and attached figure 2 And the specific embodiment will further describe the present invention:

[0011] An engine oil stop cylinder includes a front end cover 5, a rear end cover 11 and a cylinder barrel 9 connecting the front end cover 5 and the rear end cover 11. The cylinder barrel 9 is provided with a piston rod assembly 1, a front spring seat 6, and a middle spring seat 7 and return spring 8; the front end cover 5 is provided with a felt air filter pad 3 and a retaining ring 4, and the top end of the front end cover 5 is provided with a through hole 2; the rear end cover 11 is provided with a rectangular gasket 10; The piston rod assembly 1 is equipped with a U-shaped ring 12, and the U-shaped ring 12 is equipped with a stainless steel V-shaped spring 13; the return spring 8 adopts a waist drum-shaped structure, and the section of the return spring 8 is formed inward. Concave arc.

[0012] The U-shaped ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com