Special metal organic salt monomer for liquid stabilizer and preparation method thereof

A liquid stabilizer and organic salt technology, which is applied in the field of metal organic salt monomer and its preparation, can solve the problems of difficult operation control, complicated process, difficult technology popularization and product popularization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

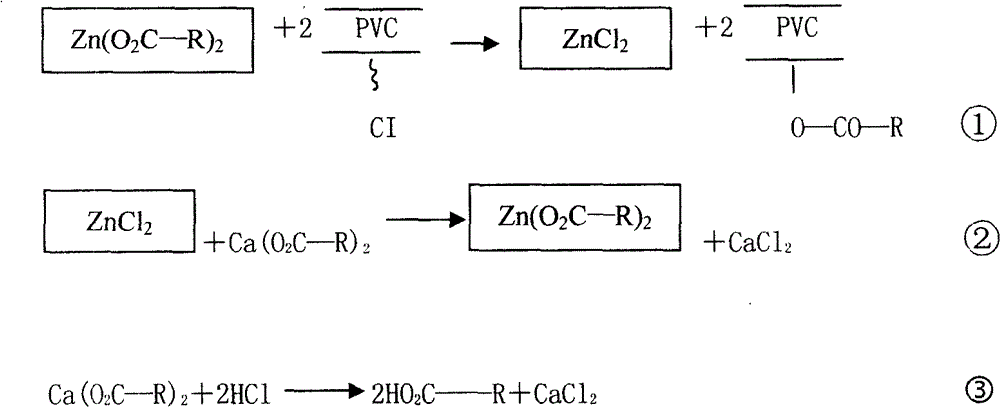

Method used

Image

Examples

Embodiment 1

[0088] Calcium monomer synthesis, wherein the calcium content is between 10% and 14%. The specific process is: first add 123kg of oleic acid, 200kg of 25# transformer oil, 160kg of isodecyl alcohol, 50kg of diethylene glycol monobutyl ether, three 7kg of ethylene glycol, 1kg of propionic acid and 30kg of water; under the protection of nitrogen, start the stirring device and raise the temperature to 80°C, and evenly add: 250kg of 25# transformer oil, 80kg of neodecanoic acid, 100kg of isodecanol, A mixture composed of 50kg of ethylene glycol monobutyl ether and 350kg of calcium hydroxide; then pass carbon dioxide, the rate is controlled at 45 liters / hour, after 4 hours of reaction, the temperature is raised to 95°C; the carbon dioxide is turned off, the temperature is raised to 150°C, vacuum dehydration, adding An appropriate amount of filter aid is used to filter the reactant by suction filtration to obtain a transparent and clear amber overbased oleic acid / calcium carbonate li...

Embodiment 2

[0090] Synthesis of zinc monomer, in which the zinc content is between 10% and 14%. The specific process is: sequentially add 400kg of isooctanoic acid, 600kg of oleic acid, 150kg of lauric acid, 350kg of p-tert-butylbenzoic acid, 75kg of benzoic acid, and dipropylene glycol 20kg of methyl ether, start stirring, put in 300kg of zinc oxide after 5 minutes; then raise the temperature to 95°C, react for 2 hours, raise the temperature to 125°C, and react for 0.5 hours; after vacuum dehydration, add 400kg of phosphite, and stir at 105°C Cool down to normal temperature after 1 hour, take a sample and analyze the zinc metal content, put it into a storage tank for standby, adjust the amount of solvent as needed to obtain the monomer with the required zinc metal content.

Embodiment 3

[0092] Magnesium monomer synthesis, wherein the magnesium content is between 4% and 10%. The specific process is: sequentially add 80kg of dipropylene glycol methyl ether, 50kg of tripropylene glycol, 280kg of nonylphenol, and 260kg of isooctanoic acid; under nitrogen protection, Start stirring, put in 100kg of magnesium hydroxide 5 minutes later, and put in evenly within 15 minutes; continue to stir for 15 minutes, raise the temperature to 135°C, and remove water at the same time; Short time; the end point temperature is controlled at about 180°C, the water content is less than 0.3%, cooled to 120°C, and filtered to obtain the finished product. After sampling and analyzing the content of magnesium metal, put it into a storage tank for standby use, adjust the amount of solvent as needed to obtain a monomer with the required content of magnesium metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com