High-temperature and high-pressure resistant quick drillable composite material bridge plug with combined sealing structure

A technology combining sealing and composite materials, which is applied in the directions of sealing/isolation, earth-moving drilling, wellbore/well components, etc. Guarantee reliability and overcome the effect of easy card

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

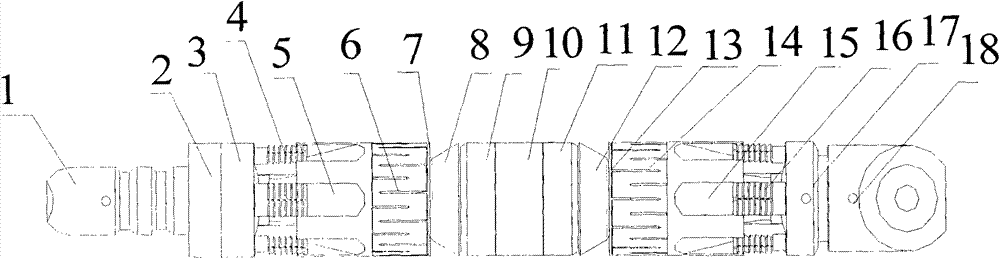

[0030] Such as figure 1 As shown, a high temperature and high pressure resistant rapid drillable composite bridge plug with a combined sealing structure according to an embodiment of the present invention, the bridge plug includes a mandrel 1, an upper push ring 3 and an upper slip 4 that are sequentially fitted on the mandrel 1 , the upper slip guide cone 5, the combined sealing structure, the lower slip guide cone 15, the lower slip 16 and the lower limiter 17, wherein the lower limiter 17 is fixedly connected with the mandrel 1, and the upper push ring 3, the upper clamp The shoe 4, the upper slip guide cone 5, the combined sealing structure, the lower slip guide cone 15, the lower slip 16 and the lower limiter 17 are all made of high temperature resistant composite materials.

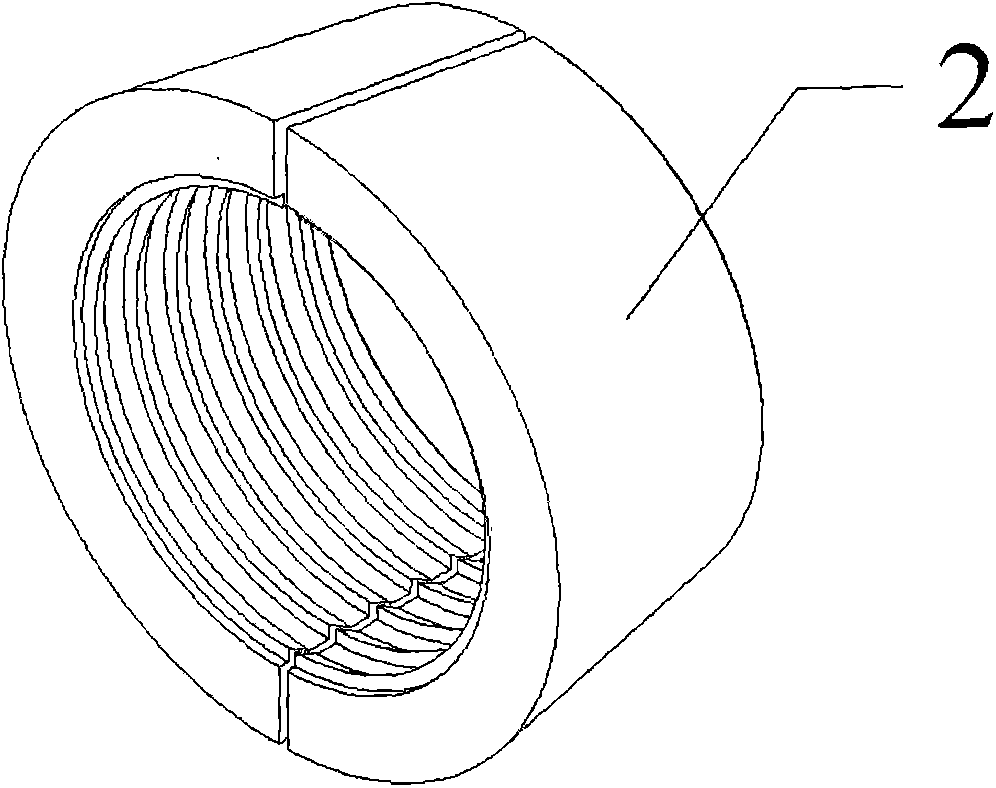

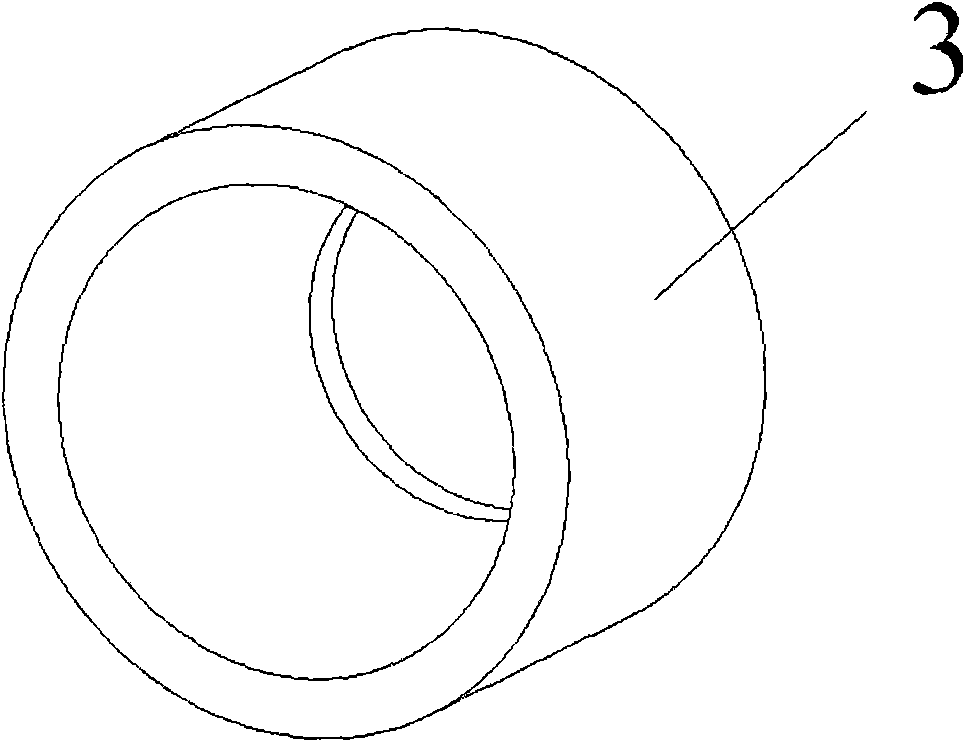

[0031] together with reference figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 , wherein the combined sealing structure includes an upper auxiliary rubber s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com