Double-layer barrel type drilling tool

A barrel-type, double-layer technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problems of affecting the quality or efficiency of hole formation, low drilling efficiency, and affecting the quality of hole formation, so as to improve drilling efficiency and Hole forming speed, improvement of drilling ability, and improvement of drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

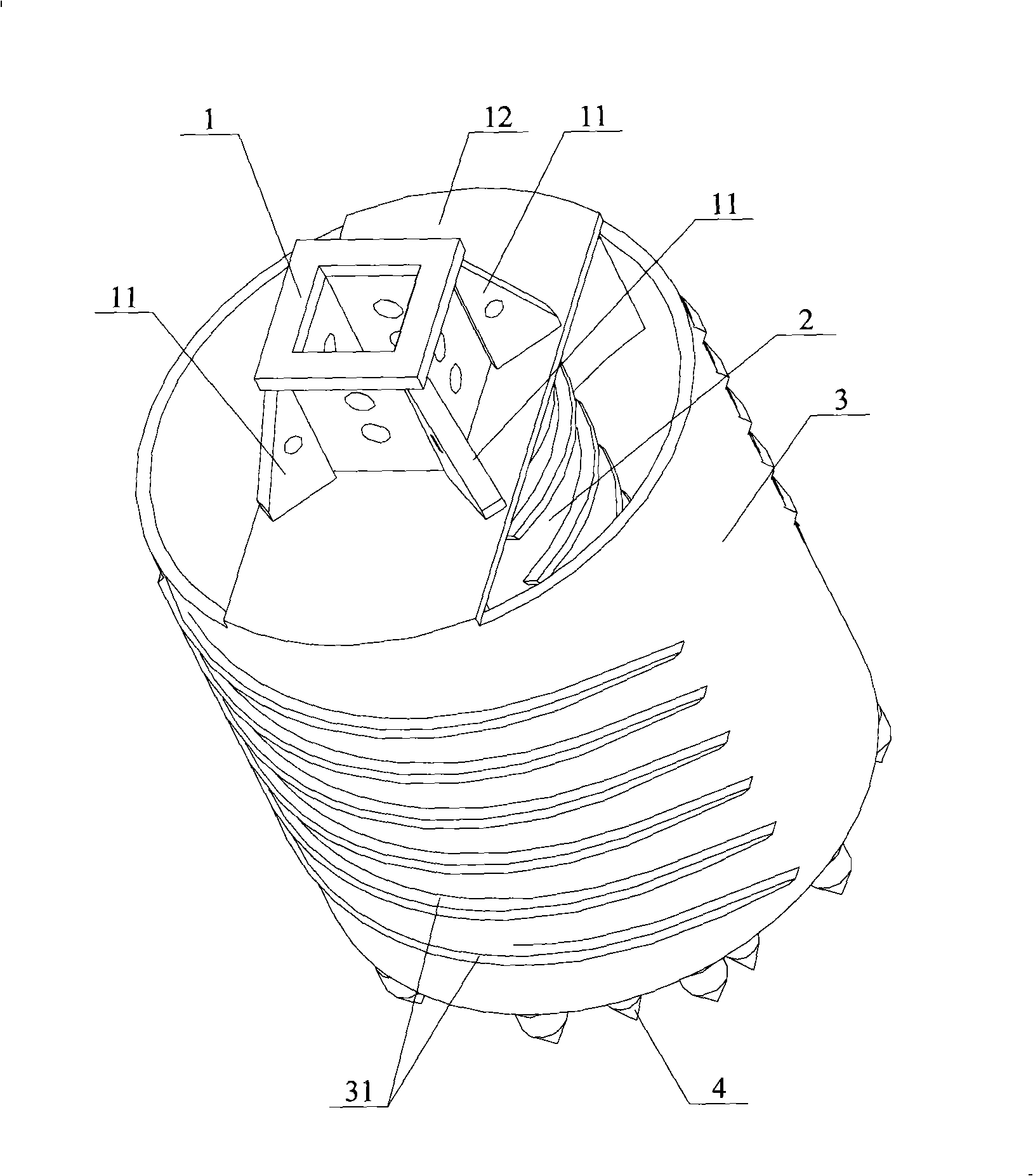

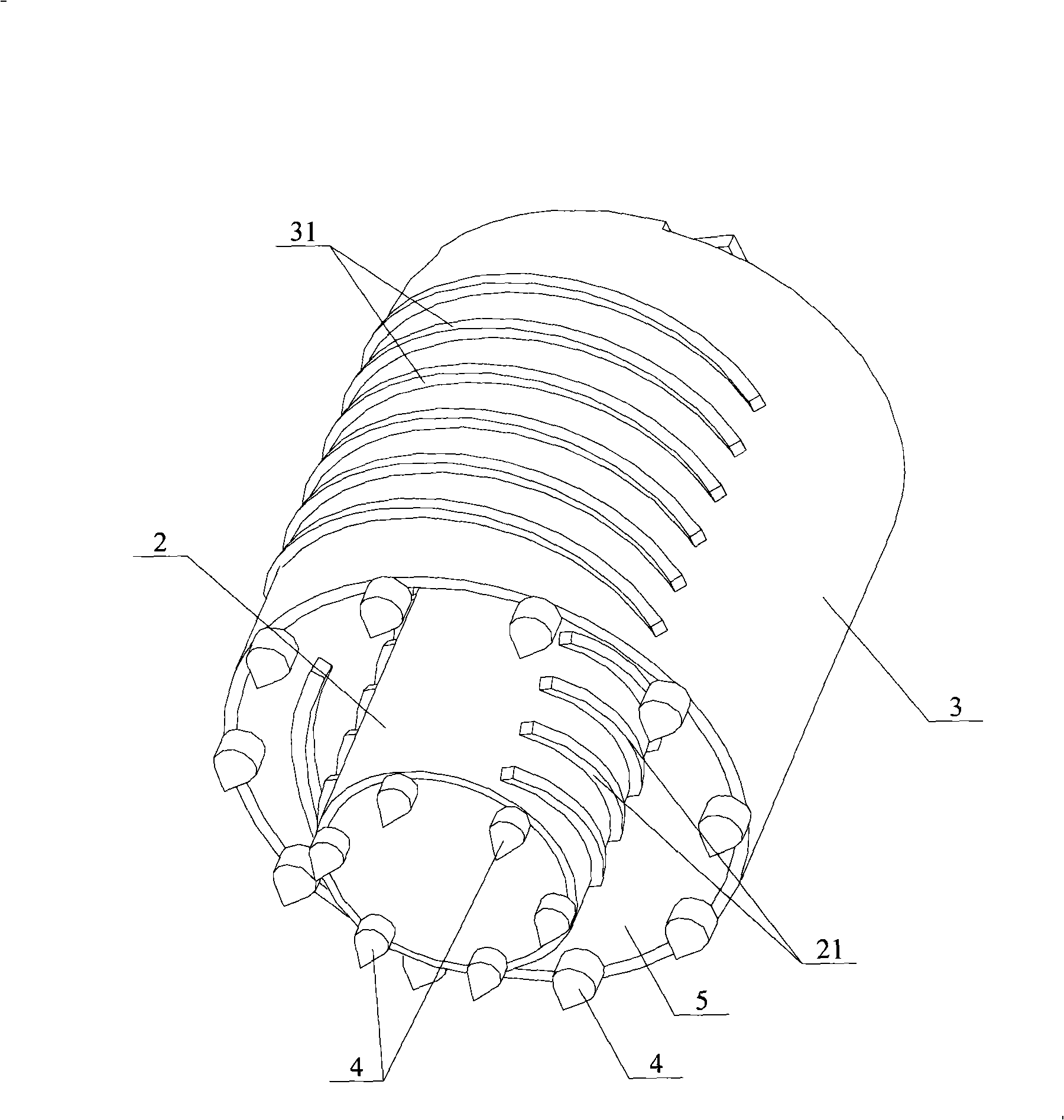

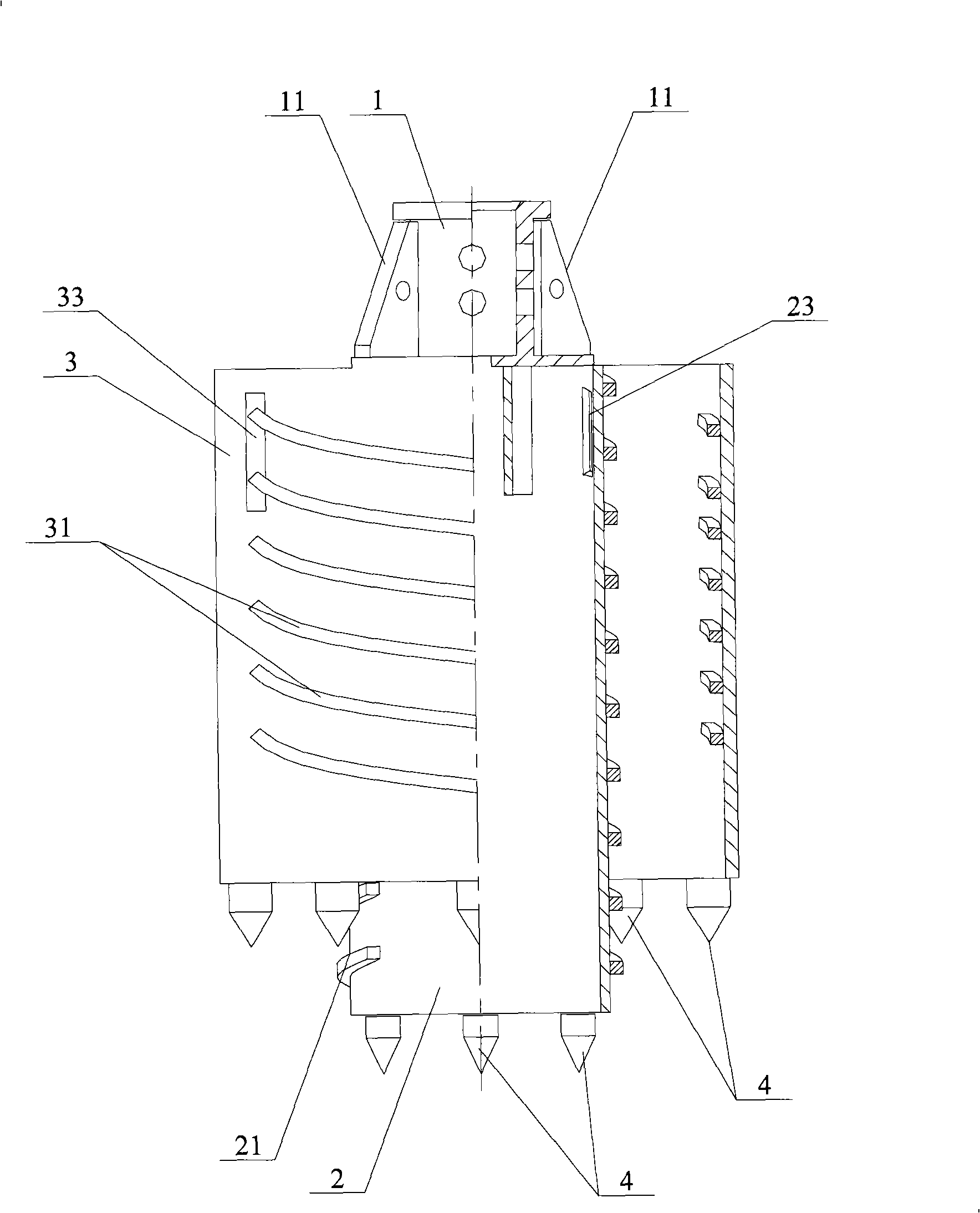

[0027] The key points of the design of the present invention are: on the basis of the existing barrel drill, an inner barrel drill is added, and the slag-carrying space of the barrel drill is divided into two parts: the inner cavity of the inner barrel and the space between the inner and outer barrels. The formed annular space; the double-cavity cylindrical drilling tool of the present invention is conducive to carrying hard granular drilling slag, thereby improving the slag-carrying ability of the drilling tool, and can effectively avoid the occurrence of drilling slag staying at the bottom of the hole. Drill sticking and other phenomena, thereby improving drilling efficiency.

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings.

[0029] Please refer to Fig. 1, which is a perspective view of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com