Weakly-consolidated rock test piece machining technology

A processing technology and rock test piece technology, applied in the field of weakly cemented rock research experiments, can solve the problems of weakly cemented rocks that cannot meet the actual production requirements, low bonding degree of weakly cemented rock particles, and rock particles that are easy to soften and disintegrate when encountering water. To achieve the effect of protecting the body's health, ensuring the integrity, and avoiding unsmooth drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

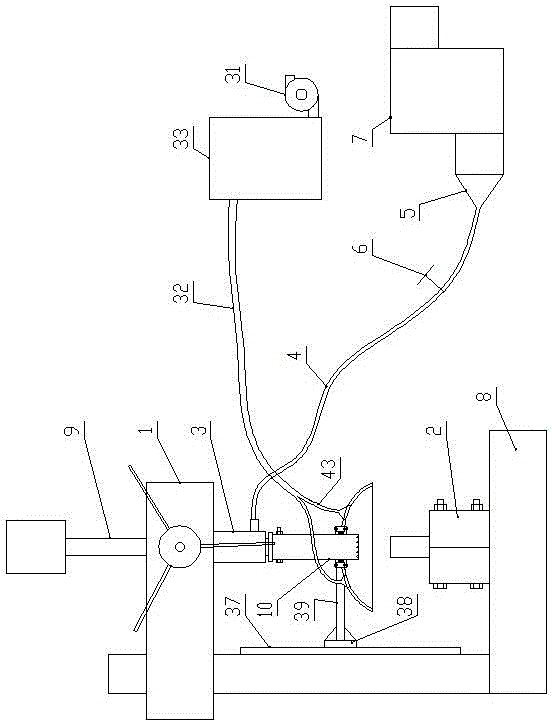

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the rock weakly cemented rock specimen drilling system of the present invention includes a rocker drill 1, a clamp 2, a sealing connection device 3, an air guide pipe 4, an air collecting cover 5, an air volume regulating valve 6 and a blower 7; the clamp 2 It is arranged on the platform 8 of the rocker drill 1, and the blower 7 is arranged on one side of the rocker drill 1. The drill rod 9 of the rocker drill 1 is a hollow structure, and the lower end of the drill rod 9 is connected with a drill tube 10 coaxially. 9. A sealing connection device 3 located above the drill tube 10 is provided on the outside, and a baffle plate 11 located above the drill tube 10 is provided inside the drill rod 9. The air outlet of the blower 7 is connected to one end of the air guide pipe 4 through the wind collecting cover 5. The other end of the air guiding pipe 4 is connected with the sealing connecting device 3 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com