Composite oriented drilling equipment for coal mine underground complex stratum and application thereof

A technology of directional drilling and complex formation, applied in the direction of directional drilling, drilling equipment, drilling equipment and methods, etc., it can solve the problem that the influence of pressing force on drilling is not very large, there is no signal or signal due to poor contact, and copper cable drilling The rod structure is complex and other problems, to achieve the effect of facilitating hole cleaning, saving manpower, and reducing the risk of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

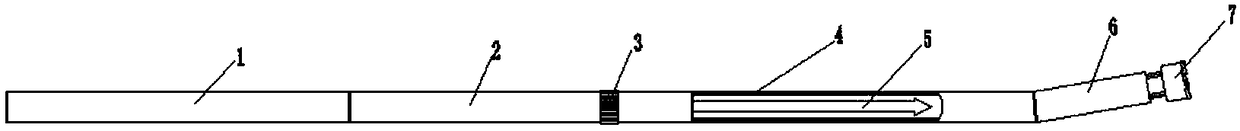

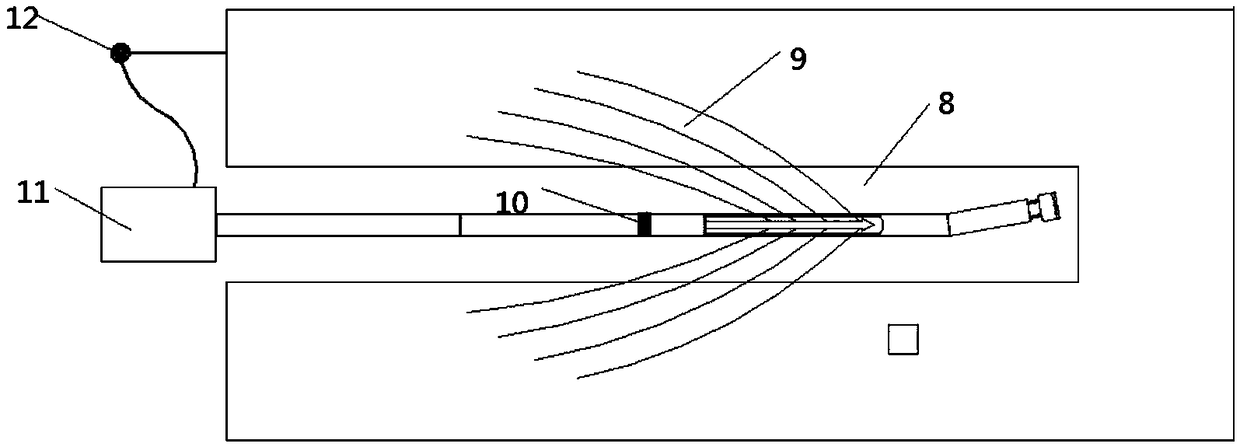

[0042] This embodiment relates to a kind of compound directional drilling equipment of the present invention which relates to complex formations in coal mines, as shown in the attached figure 1 , 2 , 3, 4, and 5: including: drill pipe, directional screw motor, wireless electromagnetic wave measurement while drilling system 5, and drill bit 7; the connection relationship is as follows: drill bit 7 + directional screw motor 6 + wireless electromagnetic wave measurement while drilling system 5 + ordinary Drill pipe + water braid, all connection methods are screw connection; the directional screw motor 6 is connected to the drill pipe through the non-magnetic outer pipe 4, and the wireless electromagnetic wave measurement while drilling system 5 is set on the non-magnetic outer pipe 4 internal.

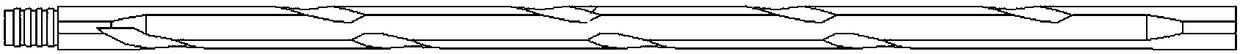

[0043] The drill bit 7 is a PDC drill bit, and the advantages of the PDC drill bit are mainly focused on two points: simple structure and high wear resistance of the drill bit. The arti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com