Reciprocating rotating bidirectional replacement device

A reciprocating and bidirectional technology, applied in directional drilling, wellbore/well components, drilling equipment and methods, etc., can solve problems such as deformation and fracture of soft drilling pipes, bit shedding, difficulty in taking out, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

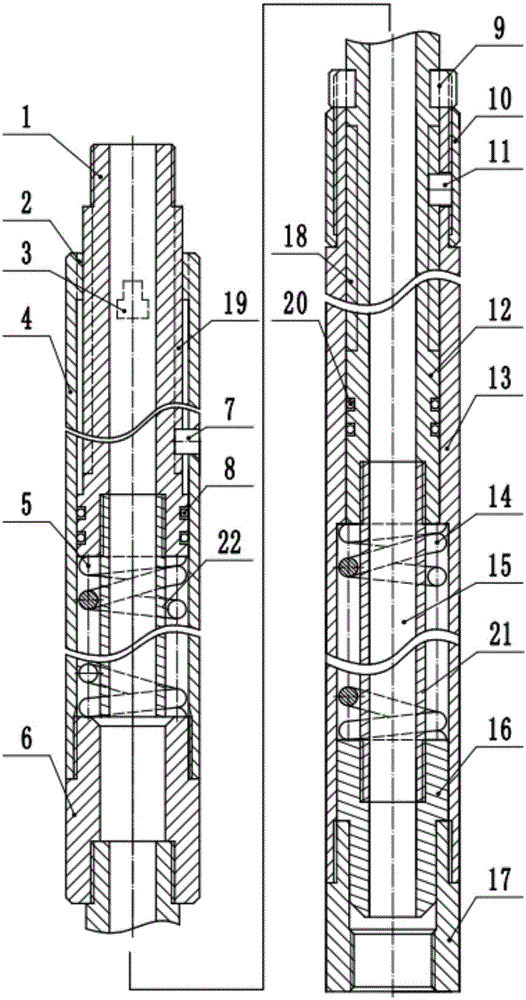

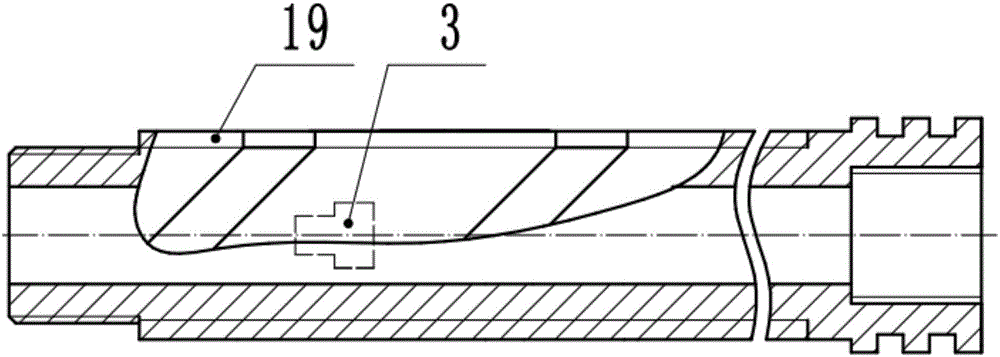

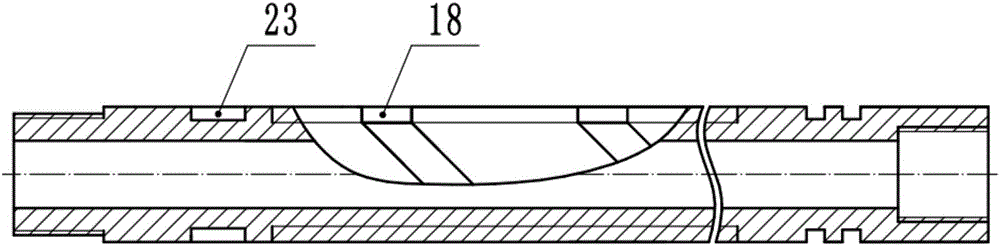

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a reciprocating and rotating two-way replacement device includes a motor joint 1, an outer cylinder I4, a conversion joint I6 and an outer cylinder II13; the upper end of the motor joint 1 is connected to a downhole power motor, and the outer wall of the motor joint 1 is welded and fixed with a limited locking block 3, The outer wall of the motor joint 1 is provided with a spiral guide groove Ⅰ19, the outer side of the motor joint 1 is covered with an outer cylinder Ⅰ4 and is sealed by a sealing ring Ⅰ8, and a plurality of limit locking grooves 2 are evenly distributed on the inner wall of the upper end of the outer cylinder Ⅰ4, and the limit locking block 3 and The limit lock groove 2 matches and can be moved down along the limit lock groove 2 to unlock. The inner diameter of the inner wall of the outer cylinder I4 where the limit lock groove 2 is located is smaller t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com