Preparation method of slow-release imazapyr particles

A slow-release technology of imazapyr, applied in the field of pesticides, can solve the problems of easy penetration into deep soil and groundwater pollution, and achieve the effects of reducing drug damage, low storage and transportation costs, and easy fine processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

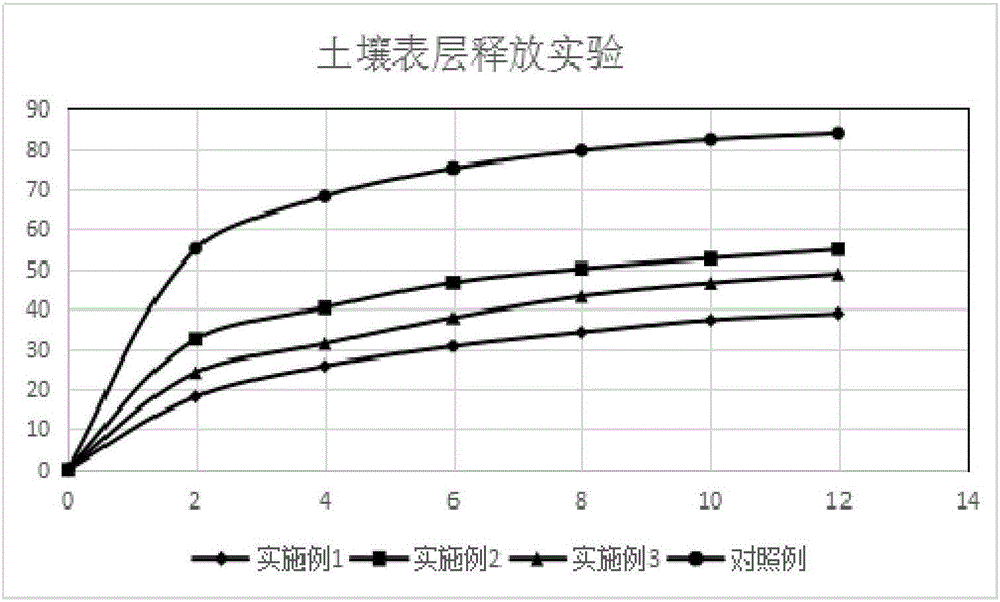

Examples

Embodiment 1

[0027] Get imazapyr former medicine 230g, be dissolved in 1L methanol under normal temperature, be mixed with imazapyr concentration and be the imazapyr methanol solution of 230g / L; Get expanded vermiculite 400g, zeolite 100g, bentonite 200g, it is pulverized into 20 ~100 meshes of mixed carrier powder; add the mixed carrier powder into the methanol solution of imazapyr, and stir in a closed reaction vessel at room temperature for 24 hours to obtain the mixed solution of imazapyr mixed carrier powder; add the mixed solution of imazapyr-carrier powder Add 35g of sodium silicate, and continue to stir for 1h until the mixture is uniform; the imazapyr-carrier powder mixture mixed with sodium silicate is distilled under reduced pressure until there is no obvious liquid residue, and passed through a 18-24 mesh sieve to obtain imazapyr Caopyr-carrier powder granules; Imazapyr-carrier powder granules are dried under reduced pressure to remove organic solvents until the organic solvent ...

Embodiment 2

[0029] Take 60g of imazapyr original drug, dissolve it in 1L of ethanol, and prepare an imazapyr ethanol solution with an imazapyr concentration of 60g / L; take 400g of expanded vermiculite, 20g of zeolite, and 20g of bentonite, and grind them into 100-200 The purpose is to mix the carrier powder; add the mixed carrier powder to the ethanol solution of imazapyr, stir in a closed reaction vessel at normal temperature for 10 hours, and obtain the mixed liquid of imazapyr-mixed carrier powder; add the mixed liquid of imazapyr-carrier powder 10g of hydroxypropyl cellulose, continue to stir for 6h to mix evenly; carry out the first vacuum distillation of the imazapyr-carrier powder mixture after being evenly mixed with hydroxypropyl cellulose until there is no obvious liquid residue, and after 18- 24-mesh sieve to obtain imazapyr-carrier powder particles; the imazapyr-carrier powder particles were dried under reduced pressure for the second time to remove the organic solvent until th...

Embodiment 3

[0031] Take 105g of imazapyr original drug, add it to 1L of dichloromethane, and dissolve it completely when heated to 38°C, and prepare an imazapyr dichloromethane solution with an imazapyr concentration of 105g / L; take 400g of expanded vermiculite, zeolite 50g, 100g of bentonite, crushed into 200-325 mesh mixed carrier powder; add mixed carrier powder into imazapyr methanol solution, stir in a closed reaction vessel at room temperature for 12h, and obtain imazapyr-mixed carrier powder mixed liquid ; Add 12 g of microcrystalline cellulose to the imazapyr-carrier powder mixed solution, and continue to stir for 5 hours to mix uniformly; carry out vacuum distillation to the imazazapyr-carrier powder mixed solution after being uniformly mixed with the microcrystalline cellulose until no obvious The liquid residue is passed through a 18-24 mesh sieve to obtain imazapyr-carrier powder particles; the imazapyr-carrier powder particles are dried under reduced pressure to remove the org...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com