Cotreatment device for ship tail gas pollutants

A technology for co-processing and ship exhaust, applied in gas treatment, air quality improvement, membrane technology, etc., can solve the problems of easy decomposition of ozone and high-temperature exhaust gas, uneven mixing of ozone and exhaust gas, etc., to avoid a large amount of decomposition and maintain water balance. , The effect of simplifying the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

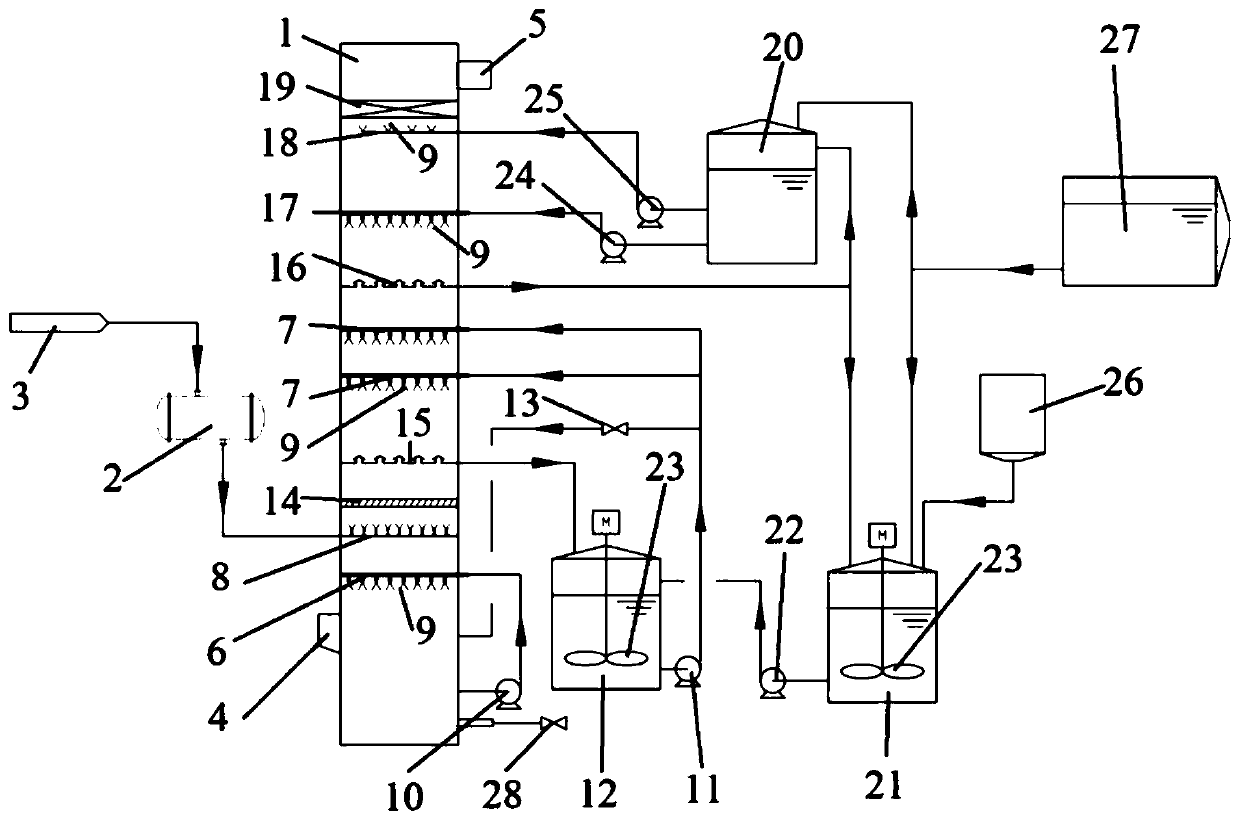

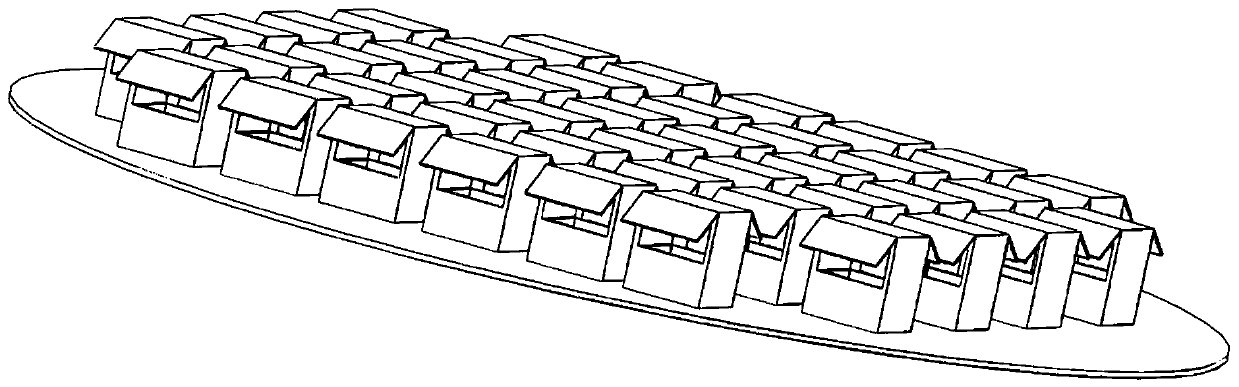

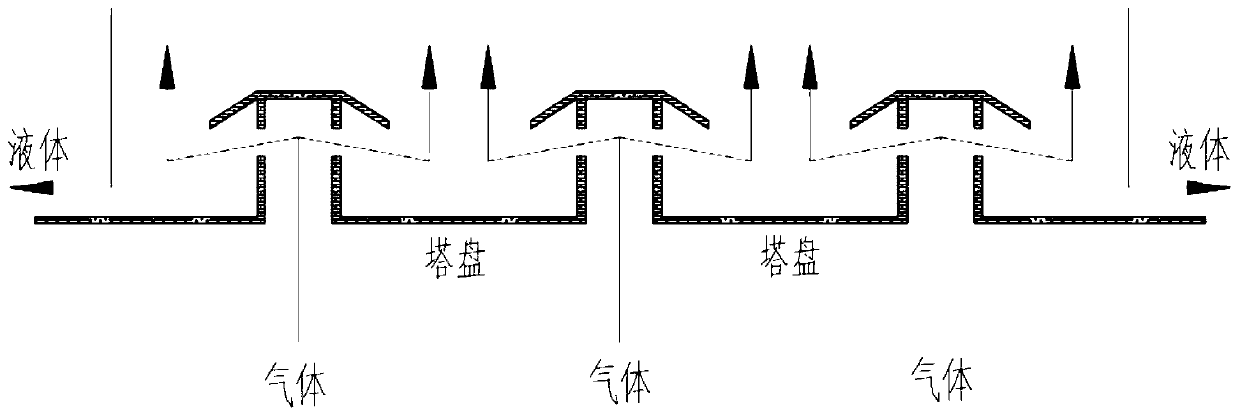

[0033] Comply with the above technical solutions, such as Figure 1 ~ Figure 3 As shown, the present embodiment provides a co-processing device for ship exhaust pollutants, comprising an absorption tower 1 and an ozone generator 2 connected to the absorption tower 1, an air source 3 is connected to the ozone generator 2, and one end of the absorption tower 1 is connected to There is an exhaust gas inlet 4, and the other end is connected with an exhaust gas outlet 5. The absorption tower 1 is provided with a cooling layer 6 and an absorbing layer 7 along the direction of exhaust gas movement, and an ozone injector 8 is arranged between the cooling layer 6 and the absorbing layer 7. The ozone injector 8 Connect with ozone generator 2. The exhaust gas from the ship enters the lower part of the absorption tower from the exhaust gas inlet 4, and flows upwards. It first passes through the cooling layer 6 to cool down the temperature of the cooling water, so that the temperature drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com