A method for recovering oilfield associated gas

A technology of oilfield associated gas and recovery method, which is applied in the field of oilfield associated gas recovery, can solve the problems of insignificant advantages of DHX process and low LPG recovery rate, so as to avoid the export of lean gas to compressors and reduce the power consumption of the device. and equipment investment, the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

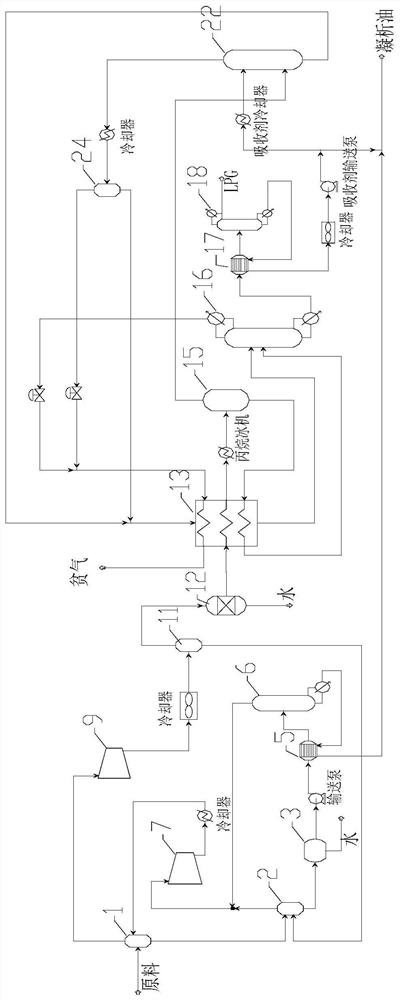

[0038] Below in conjunction with embodiment and attached figure 1 The present invention will be described in detail.

[0039] A method for recovering oilfield associated gas comprises the steps of pressurized separation, dehydration, liquefaction, refining and cold oil absorption:

[0040] Step 1: Pressure separation

[0041] The raw material gas enters the primary gas-liquid separator 1 for gas-liquid separation, the liquid phase in the primary gas-liquid separator 1 passes through the flash tank 2 to recover the LPG component in the liquid phase, and the liquid phase at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com