Dual-screw non-closed water removal device used for gunpowder continuous processing

A dehydration device and twin-screw technology, applied in heating devices, lighting and heating equipment, and drying solid materials without heating, can solve problems such as low production efficiency, achieve the effects of preventing outflow loss, ensuring safety, and promoting drying and dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

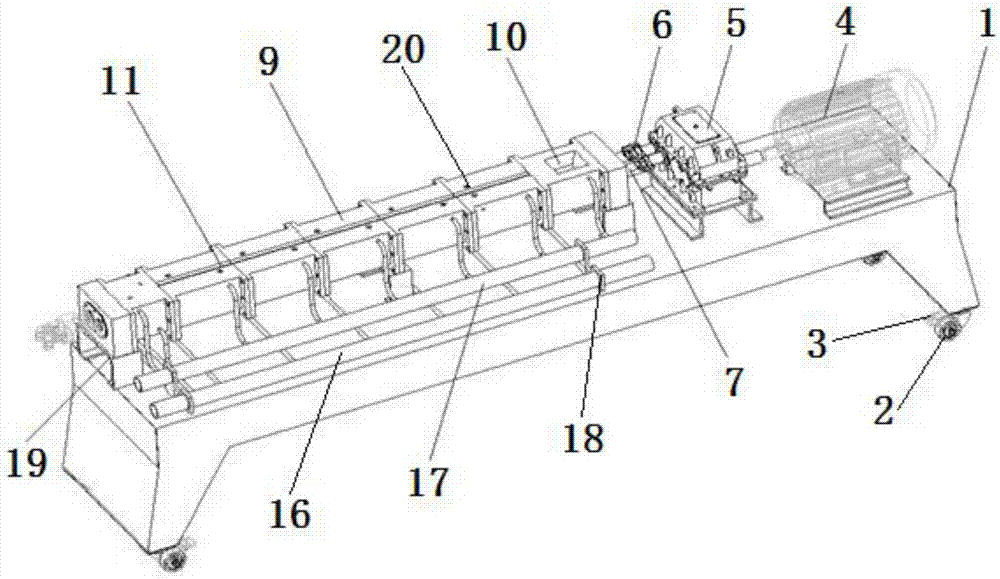

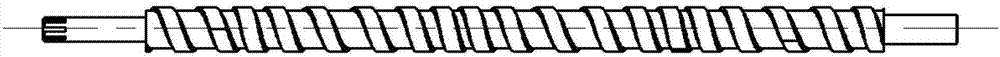

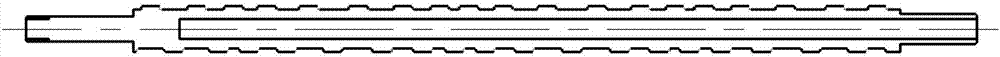

[0016]The main structure of the twin-screw non-closed dehydration device for the continuous processing of gunpowder involved in this embodiment includes a base 1, a universal wheel 2, a foot brake 3, a motor 4, a reduction box 5, a coupling 6, and a twin-screw assembly 7. Mandrel 8, machine barrel 9, drug inlet 10, rotating deflated roller 11, scraper 12, drainage hole 13, filter screen 14, hot water hole 15, No. 1 hot water supply pipe 16, No. 2 hot water supply pipe 17. Bracket 18, drug outlet 19 and exhaust hole 20; the four corners of the base 1 with an inverted U-shaped structure are respectively provided with a circular structure of the universal wheel 2, between the base 1 and the universal wheel 2 is provided with The foot brake pad 3 for braking the universal wheel 2, the top right end of the base 1 is provided with a motor 4, the motor 4 is connected to the reduction box 5 in a mechanical transmission type, the reduction box 5 is connected to the shaft coupling 6 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com