A continuous sludge dewatering method based on hydrothermal treatment

A technology of hydrothermal treatment and sludge dewatering, applied in dewatering/drying/concentrating sludge treatment, sludge treatment through temperature control, etc., can solve the problems of high energy consumption, difficult to reduce the moisture content of sludge, etc. The effect of calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

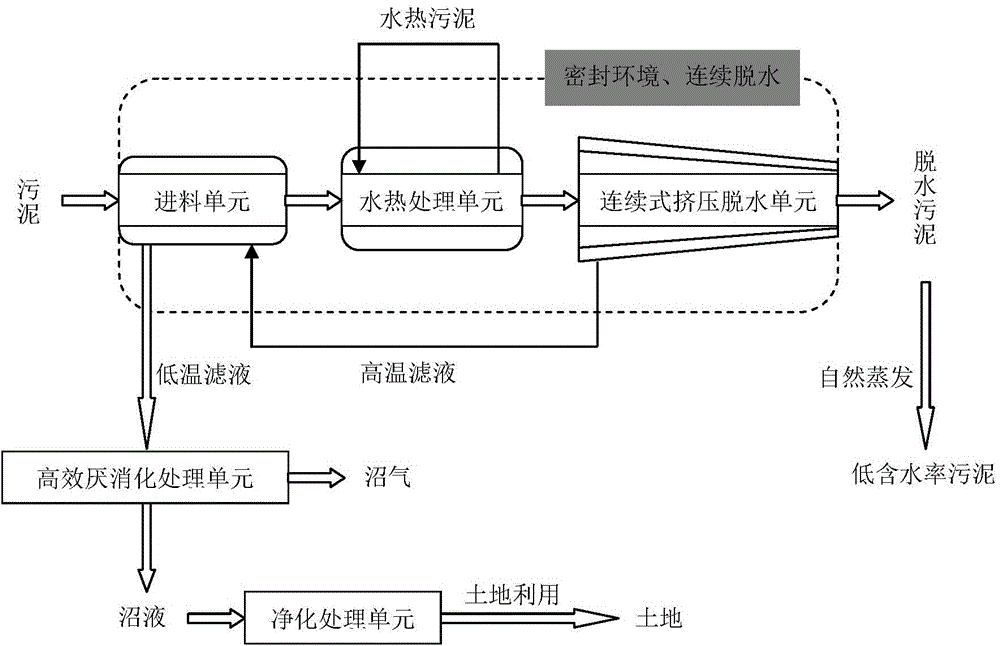

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings and technical solutions.

[0021] As shown in the figure, the continuous sludge dewatering method based on hydrothermal treatment proposed by the present invention comprises the following steps:

[0022] 1) The sludge is continuously introduced into the feed unit by means of a screw or a pump.

[0023] 2) The high-temperature filtrate from the continuous extrusion dehydration unit is introduced into the external heat exchanger of the feeding unit, so that the sludge is preheated during the feeding process, and the preheating time is controlled by adjusting the feeding speed.

[0024] 3) The preheated sludge enters the hydrothermal treatment unit under the impetus of the power of the feeder, which is a sealed environment. The sludge is heated to 150-250°C by the heating device installed outside the hydrothermal treatment unit, and the hydrothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com