Membrane distillation dehydration method for polyatomic alcohol water solution produced from corn

A polyol and membrane distillation technology, which is applied in the application field of vacuum membrane distillation technology, can solve the problems of high cooling equipment and operating costs, take away, and high energy consumption, so as to save dehydration energy consumption, reduce losses, and high energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

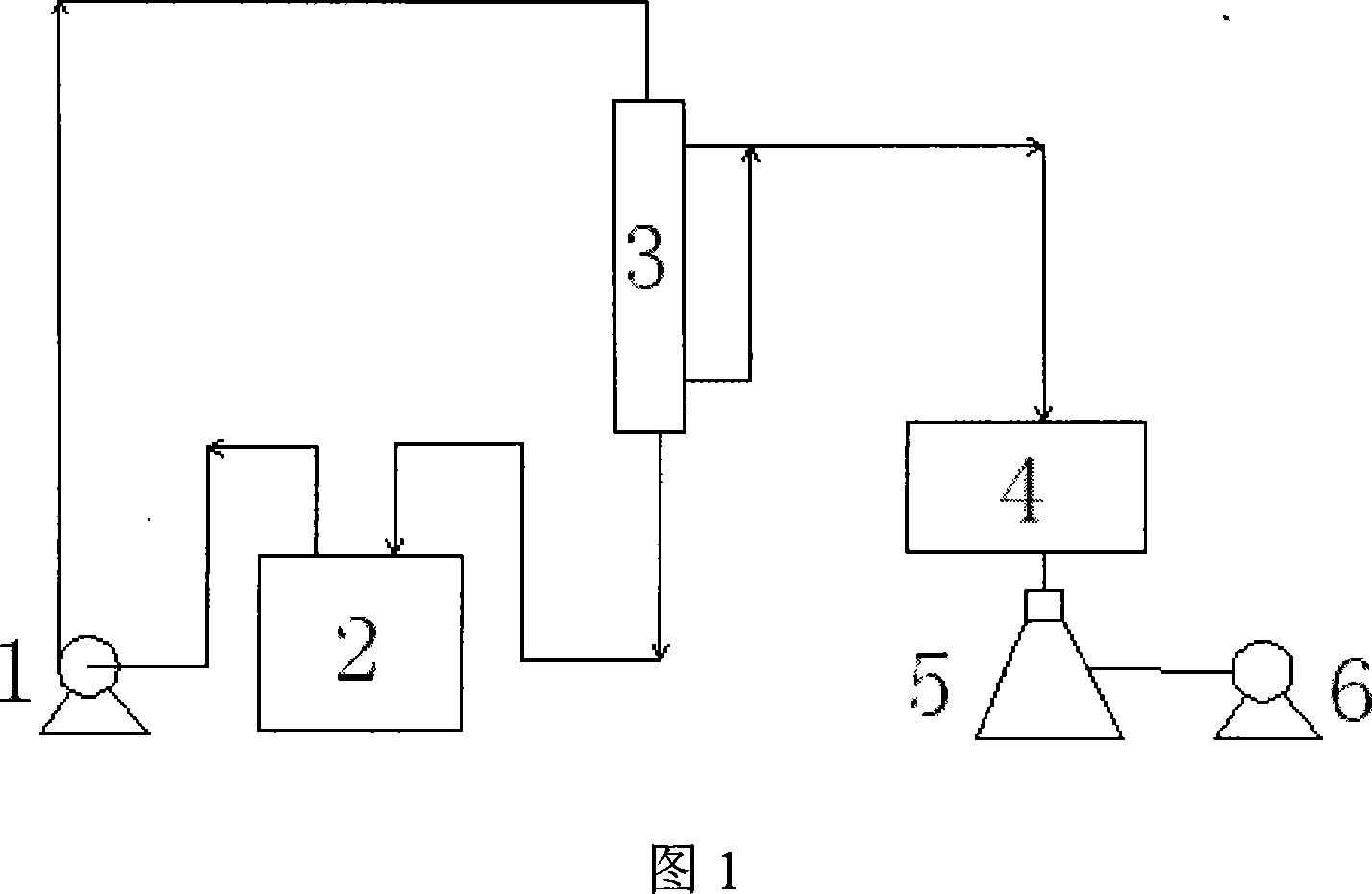

Embodiment 1

[0010] 85 polypropylene hollow fiber membranes are filled in the casing with a specification of Φ16mm×300mm, the inner diameter of each membrane is 800μm, the outer diameter of the membrane is 1000μm, the average radius of the membrane pores is 0.095μm, the porosity is 45.4%, the effective length of the membrane is 250mm, and the membrane area 0.05338m 2 (calculated based on fiber inner diameter). Preparation mass content is 1,2 propanediol 6.08%, ethylene glycol 4.21%, glycerol 3.27%, butanediol 1.16%, sorbitol 2.8%, the remainder is the polyhydric alcohol aqueous solution 2000g of water, the polyhydric alcohol aqueous solution is heated to 61 After ℃, the temperature is kept constant, and then pumped into the tubular membrane module 3 through the raw material pump 1, the feed liquid flows through the polypropylene hollow fiber membrane at a flow rate of 32L / h, and the shell side of the membrane module, that is, the outer side of the hollow fiber membrane, forms a 0.085 The ...

Embodiment 2

[0012] 85 polypropylene hollow fiber membranes are filled in the casing with a specification of Φ16mm×300mm, the inner diameter of each membrane is 800μm, the outer diameter of the membrane is 1000μm, the average radius of the membrane pores is 0.095μm, the porosity is 45.4%, the effective length of the membrane is 250mm, and the membrane area 0.05338m 2 (calculated based on fiber inner diameter). Preparation mass content is 1,2 propanediol 6.08%, ethylene glycol 4.21%, glycerol 3.27%, butanediol 1.16%, sorbitol 2.8%, the remainder is the polyhydric alcohol aqueous solution 2000g of water, the polyhydric alcohol aqueous solution is heated to 61 After constant temperature after ℃, feed into the tubular membrane module 3 through the raw material pump 1, the feed liquid flows through the polypropylene hollow fiber membrane at a flow rate of 32L / h, and the outer side of the hollow fiber membrane in the membrane module forms a pressure of 0.089MPa through the vacuum pump 6. Vacuum...

Embodiment 3

[0014] 85 polypropylene hollow fiber membranes are filled in the casing with a specification of Φ16mm×300mm, the inner diameter of each membrane is 800μm, the outer diameter of the membrane is 1000μm, the average radius of the membrane pores is 0.095μm, the porosity is 45.4%, the effective length of the membrane is 250mm, and the membrane area 0.05338m 2 (calculated based on fiber inner diameter). Preparation quality content is 1,2 propylene glycol 6.08%, ethylene glycol 4.21%, glycerol 3.27%, butanediol 1.16%, sorbitol 2.8%, the rest is the polyol aqueous solution 1230g of water, the polyhydric alcohol aqueous solution is heated to 65 After ℃, the temperature is kept constant, and then pumped into the tubular membrane module 3 through the raw material pump 1. The feed liquid flows through the polypropylene hollow fiber membrane at a flow rate of 32L / h, and the outer side of the hollow fiber membrane in the membrane module is formed to 0.085MPa by the membrane vacuum pump 6. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com