Sludge substance deep dehydrating method based on thermal conditioning coupling filter pressing

A technology of deep dehydration and filter press dehydration, which is applied in pyrolysis treatment of sludge, dehydration/drying/thickened sludge treatment, etc., can solve the problem of high energy consumption in thermal drying and dehydration, and achieve avoiding a large amount of decomposition, reducing difficulty and saving energy The effect of consuming input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

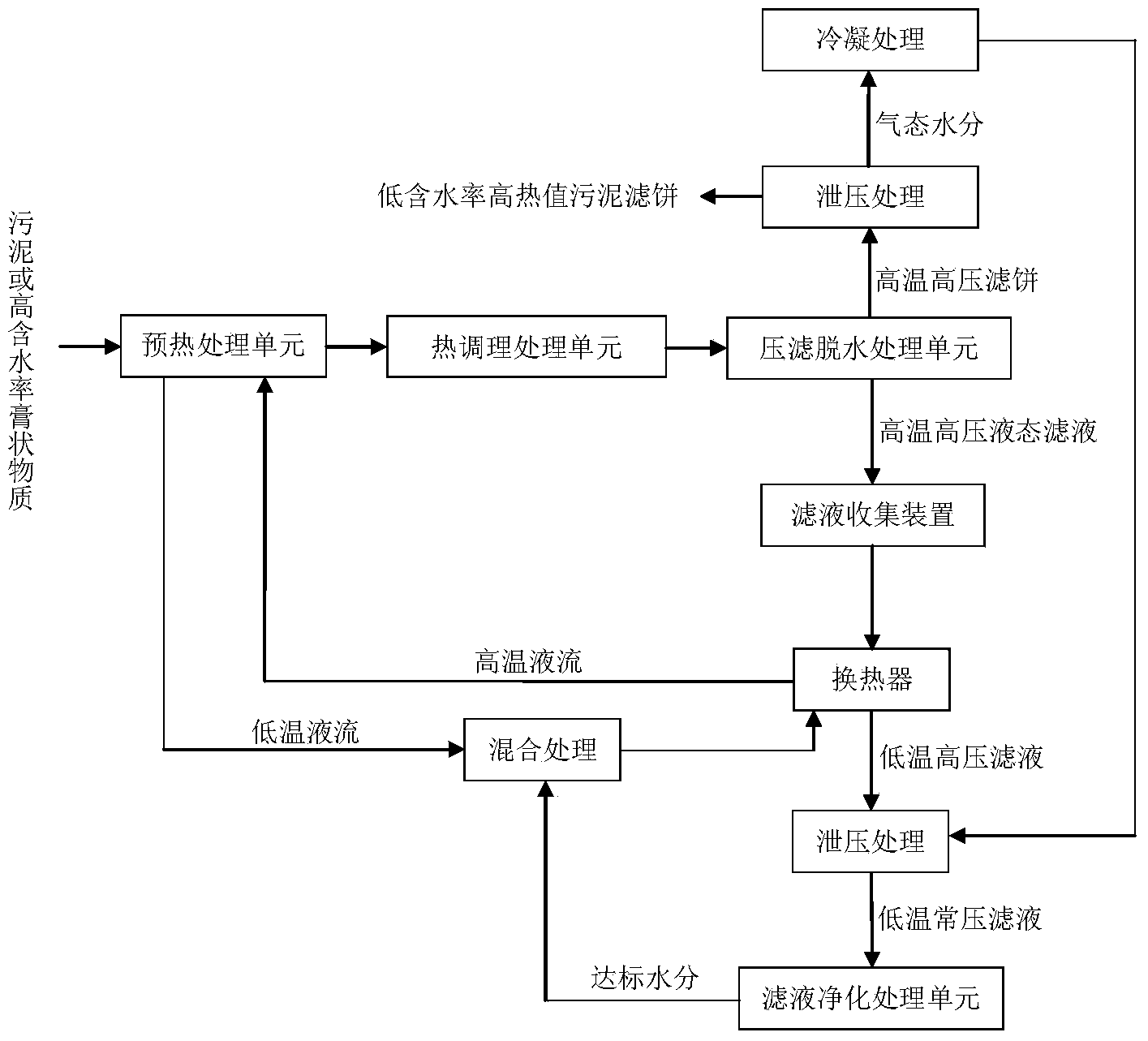

[0028] As shown in the figure, the method for deep dehydration of sludge based on thermal conditioning coupled with filter press proposed in the present invention includes the following steps:

[0029] (1) Add the sludge to the sludge pre-heat treatment unit through the sludge pump.

[0030] (2) The sludge stays in the preheat treatment unit for 30-60 minutes, and the preheated sludge is pumped into the heat conditioning treatment unit through a pump.

[0031] (3) The sludge is heated to 120-250°C in the thermal conditioning treatment unit, and stays at this temperature for 10 to 90 minutes.

[0032] (4) Before the heat conditioning treatment is completed, the filter press dehydration treatment unit is filled with air and other gases to make the air pressure higher than the saturated vapor pressure of the moisture at the corresponding temperature.

[0033] (5) Immediately transfer the sludge after the thermal conditioning reaction to the press filter dehydration treatment unit, press an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com