Method for preparing anionic polyacrylamide microspheres

A polyacrylamide, anionic technology, applied in the field of preparation of anionic polyacrylamide microspheres, to achieve the effect of stable properties, high active ingredients and high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

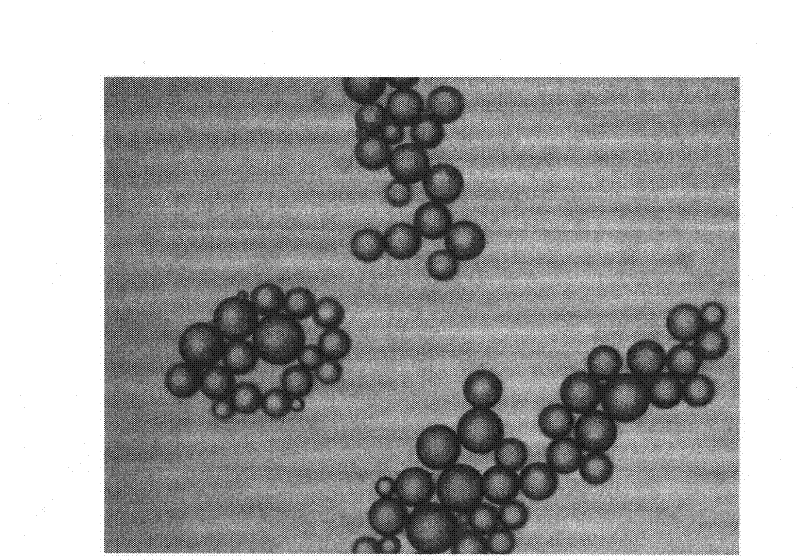

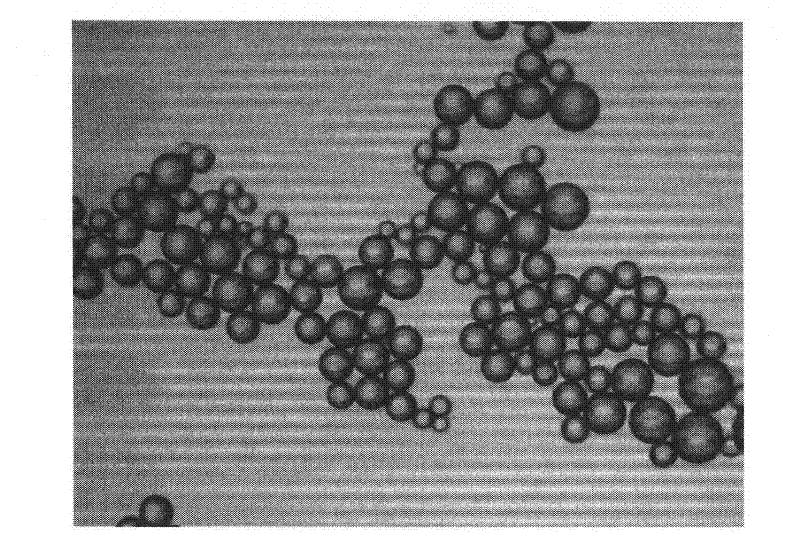

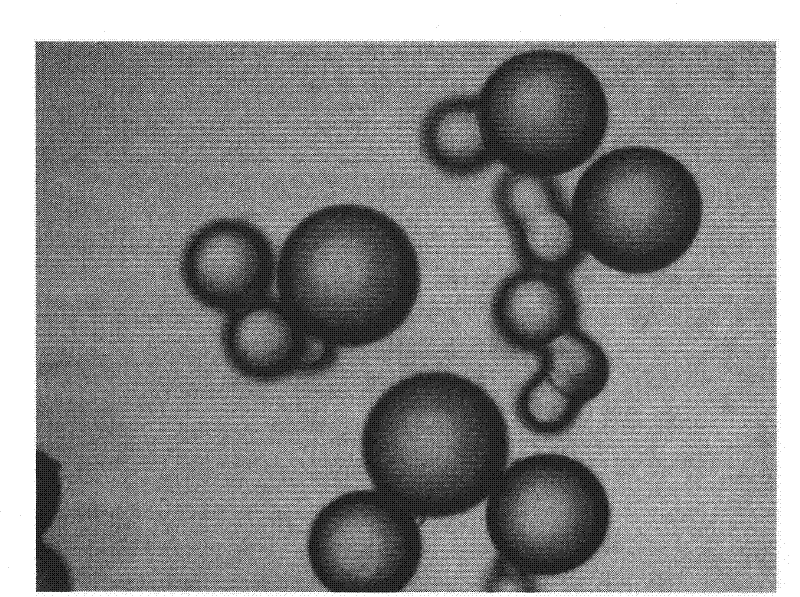

Image

Examples

Embodiment 1-4

[0024] According to the data of table 1, in the 250mL four-neck flask, add 150mL of dispersed phase cyclohexane and dispersant (dispersant can be selected sorbitan monostearate, sorbitan monooleate, sorbitan Trioleate, sorbitan tristearate, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan trioleate Ester, polyoxyethylene hydrogenated castor oil ester, soybean lecithin, stearyl phosphate, polyoxyethylene nonylphenol ether, sodium dodecylsulfonate, sodium dodecylbenzenesulfonate, octadecyl Trimethylammonium bromide or dihexadecyltrimethylammonium bromide), heated to 50°C and stirred to dissolve the dispersant, then cooled for later use.

[0025] Add NaOH into the beaker to neutralize the protons in the monomer solution of acrylamide, dissolve it with a small amount of distilled water, and cool it at room temperature for use. And dissolve completely with a small amount of distilled water. Put the monomer solution in an ice-wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com