Rapid feeding mechanism of shaft workpiece

A shaft workpiece and feeding mechanism technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of basic workpiece interference, axially extending body stuck to the vibrating plate, poor effect, etc., to solve the difficulty of feeding , the effect of fast and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

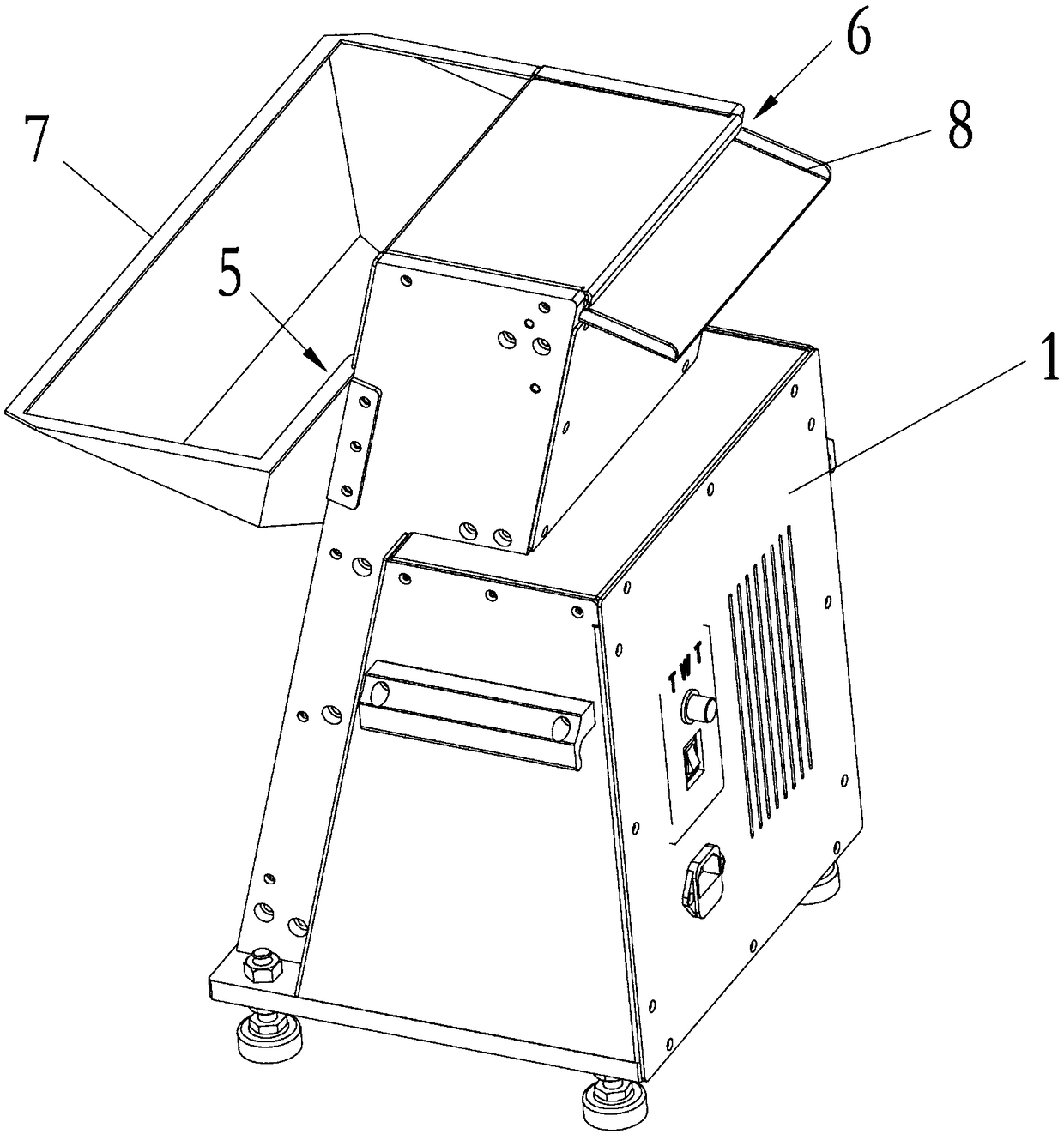

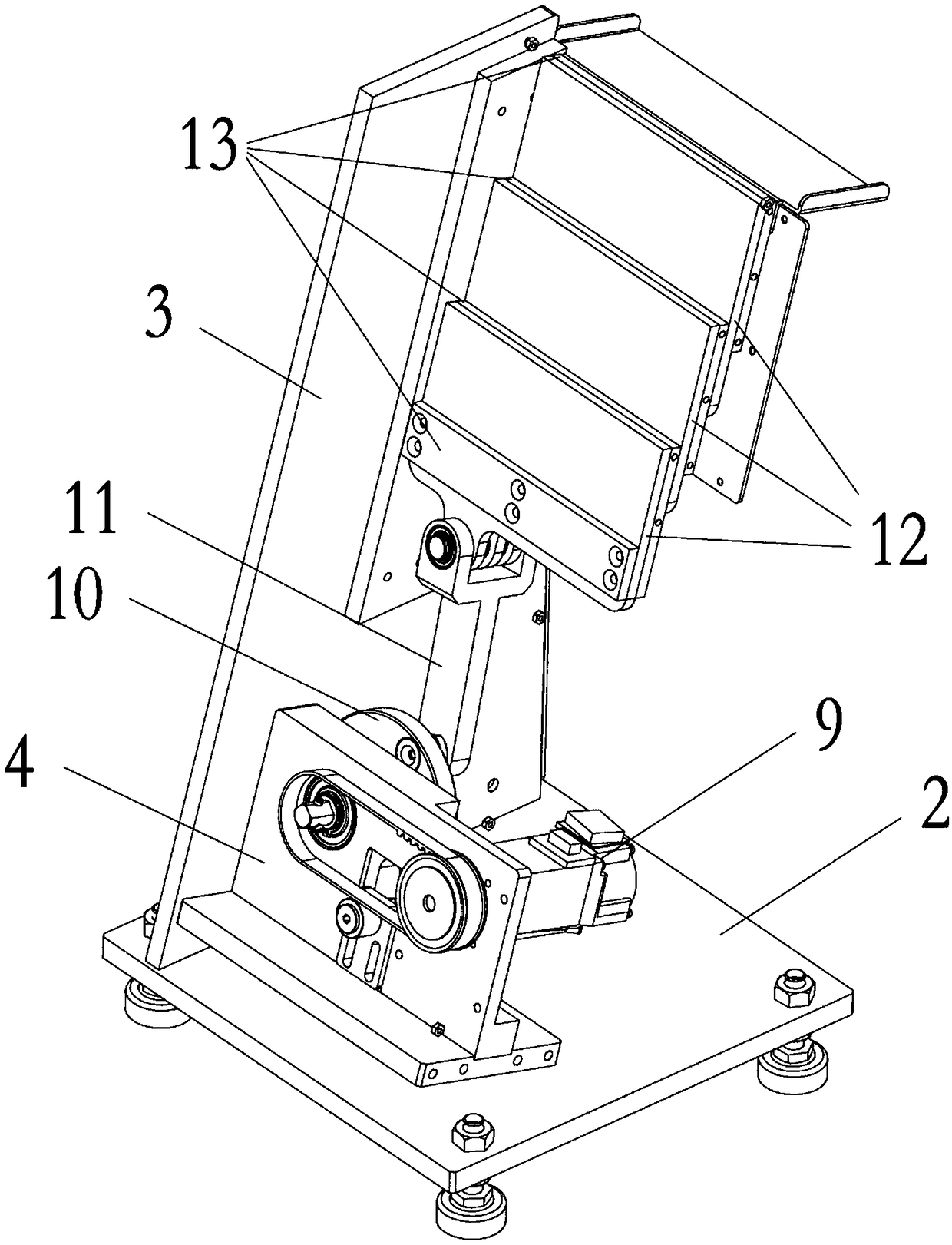

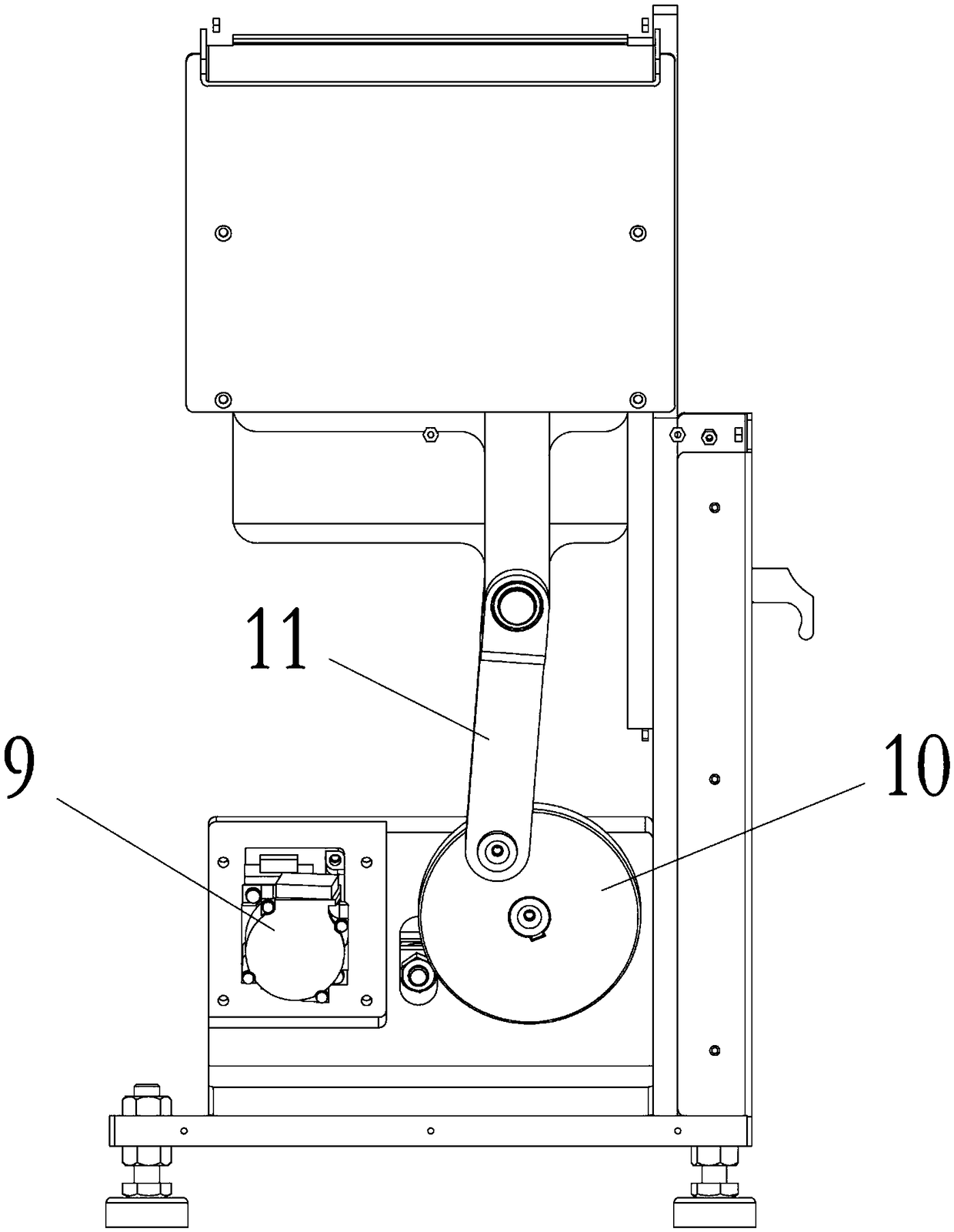

[0023] The invention discloses a fast feeding mechanism for shaft workpieces, such as Figure 1~Figure 5 As shown, it includes: a frame, and an outer cover 1 arranged on the frame. The frame includes a horizontal base 2, which is directly and horizontally placed on the ground or other horizontal surfaces, where the placement can be mobile or fixed. Two vertical boards 3 are fixed on the base 2 , and a base 4 is fixed between the vertical boards 3 . In this preferred embodiment, the base 4 is fixed obliquely, that is, it is set at an angle to the horizontal plane.

[0024] The frame is provided with a feed port 5 and a discharge port 6, the feed port 5 is vertically lower than the discharge port 6, in this preferred embodiment, the feed port 5 is A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com