Graphene oxide master batch as well as preparation and application thereof

A technology of graphene and masterbatch, which is applied in the field of graphene, can solve the problems of high interface strength, simple production process, and low cost, and achieve the effects of enhancing interface bonding strength, facilitating industrial production, and promoting good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Firstly, the preparation method of the graphene oxide masterbatch according to the first aspect of the present invention will be described. A preparation method for graphene oxide master batch, comprising the following steps:

[0023] Mixing the graphene oxide aqueous solution and the aqueous polyurethane emulsion uniformly to obtain product A;

[0024] Mix the polypeptide condensing agent aqueous solution and the product A evenly, let stand, break the emulsification, and precipitate the product B;

[0025] The product B is crushed, washed, suction filtered, and dried to obtain the graphene oxide masterbatch, and the aqueous polyurethane emulsion includes anionic aliphatic aqueous polyurethane emulsion and / or anionic aromatic aqueous polyurethane emulsion.

[0026] The anionic aliphatic water-based polyurethane emulsion and / or the anionic aromatic water-based polyurethane emulsion provide anions to react with the nitrogen cations contained in the polypeptide condensing...

Embodiment 1

[0045] Embodiment 1 A kind of preparation of graphene oxide masterbatch and it is used for preparing shoe outsole and test sample

[0046] (1) 1g of graphene oxide is mixed with 0.1% graphene oxide aqueous solution and 100g of 30% anionic aromatic water-based polyurethane emulsion, and stirred at 200r / min for 30min to obtain product A, which is ready for use;

[0047] (2) Mix 0.5g of TBTU polypeptide condensing agent into 5% aqueous solution and product A, stir at 200r / min for 10min, place at 45°C for 12h, and demulsify and separate out product B;

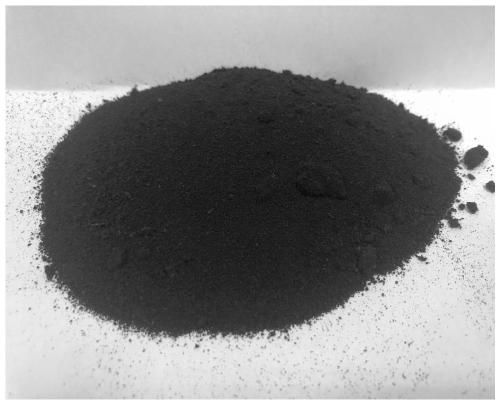

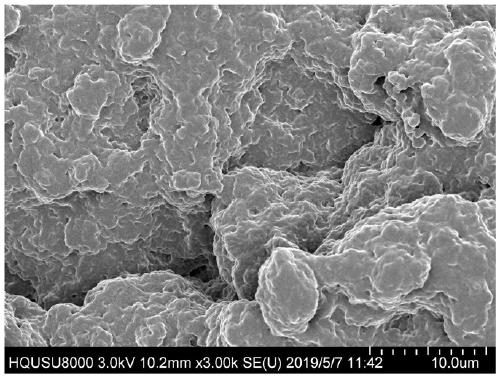

[0048] (3) The above-mentioned product B is crushed with a powder machine, washed with distilled water and suction-filtered twice, and then the product is placed in a 60° C. oven for 24 hours to obtain a graphene oxide masterbatch with a content of 3.3%.

[0049] (4) Add graphene oxide masterbatch to TPU and injection mold at 170 DEG C to form graphene oxide addition amount is 0.06% shoe outsole and test sample.

[0050] see ima...

Embodiment 2

[0053] Embodiment 2 A kind of preparation of graphene oxide masterbatch and it is used for preparing test sample

[0054] (1) 2g graphene oxide is mixed with 5% graphene oxide aqueous solution and 40% anionic aliphatic water-based polyurethane emulsion of 100g, and stir 10min with 500r / min rotating speed, obtain product A, stand-by;

[0055] (2) Mix 1 g of TBTU polypeptide condensing agent into a 10% aqueous solution and mix it with the above-mentioned product A, stir at 500 r / min for 5 min, place it at 20° C. for 24 hours, and separate out the product B through demulsification;

[0056] (3) The above product is crushed with a powder machine, washed with distilled water and suction filtered twice, and then the product is placed in an oven at 80°C for 18 hours to obtain a graphene oxide masterbatch with a content of 5.0%;

[0057] (4) Add the graphene oxide masterbatch to TPU and injection mold it at 180°C to form a test sample bar with a graphene oxide addition of 0.3%.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com