Combined technology for heavy oil processing

A combined process and heavy oil technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, can solve the problem of separation of high softening point asphalt from solvent, high softening point asphalt transportation, difficulty in reducing coke and gas production Rate, affecting the stability of modified products and other issues, to achieve the effect of reducing C7 asphaltene and metal content, increasing API degree, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

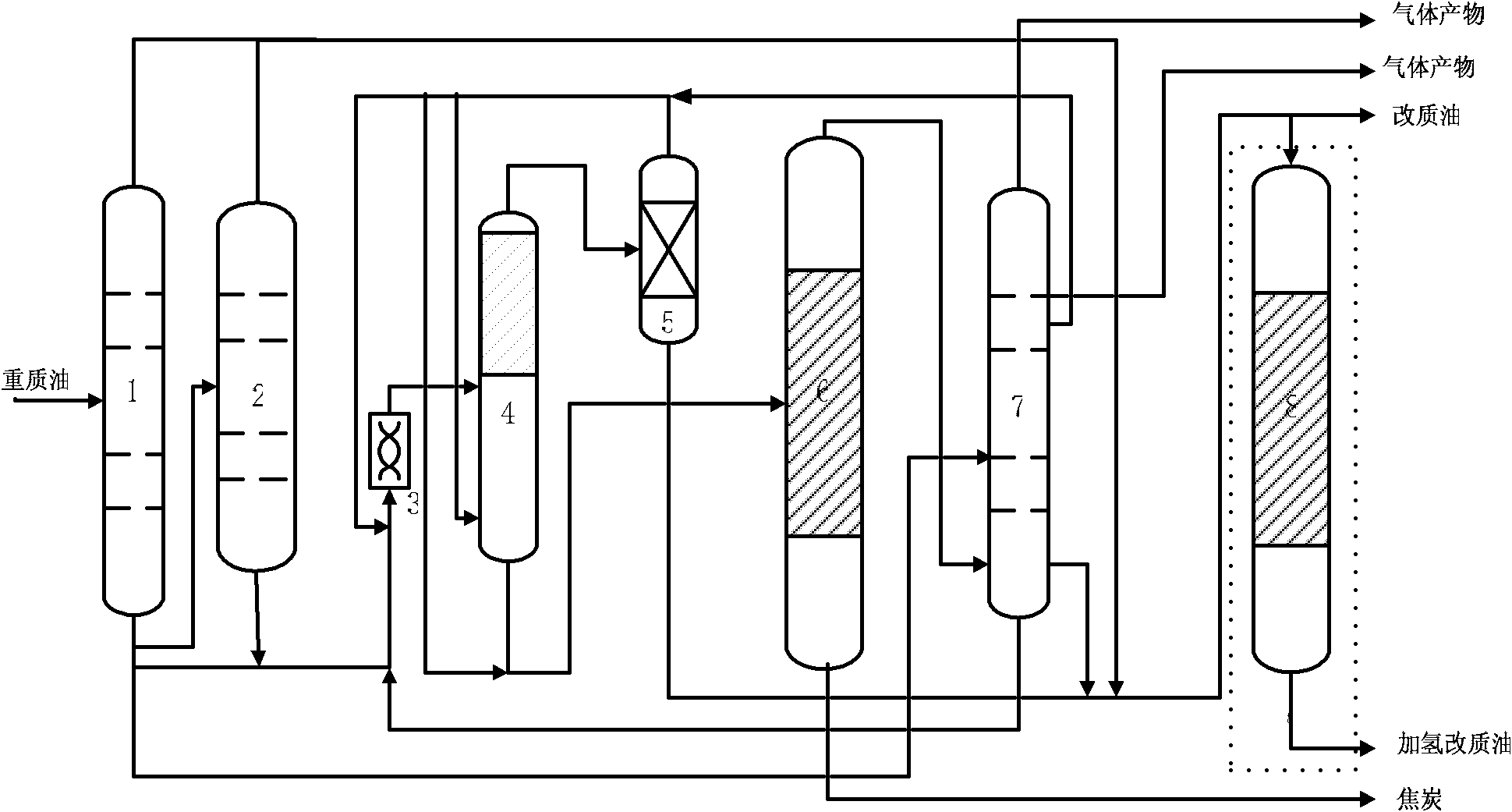

Method used

Image

Examples

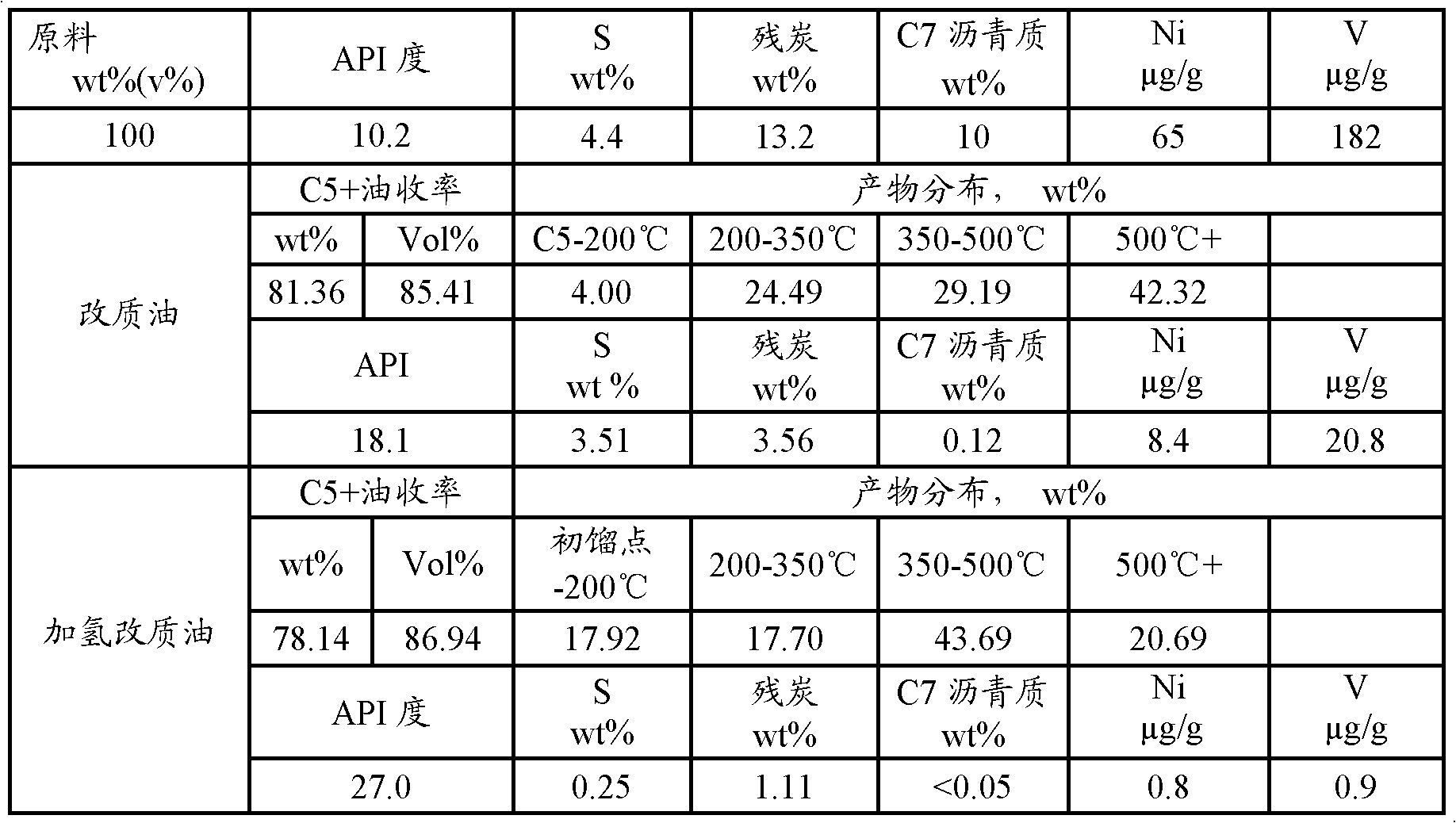

Embodiment 1

[0046] Canadian Cold Lake Bitumen (Cold Lake Bitumen), API is 10.2, sulfur content is 4.4wt%, Kang's carbon residue is 13.2wt%, C7 asphaltene is 10.0wt%, Ni and V content are 69μg / g and 182μg / g.

[0047] The oil sand pitch is firstly subjected to atmospheric distillation, and fractionated to obtain a 200-350°C diesel fraction (15.0wt%) and an atmospheric column bottom (residual oil) with a boiling point higher than 350°C.

[0048] The bottom of the atmospheric column uses isobutane (iC4) as the extraction solvent for solvent deasphalting. First, the bottom of the feed is mixed with the main solvent and sent to the extraction tower 4 from the middle or upper part, and the auxiliary solvent is from the lower part of the extraction tower. Enter into countercurrent contact with deoiled asphalt, and again perform enhanced extraction on the asphalt phase extracted by the main solvent. The temperature at the bottom of the extraction tower is 120°C, the temperature at the top of the tower...

Embodiment 2

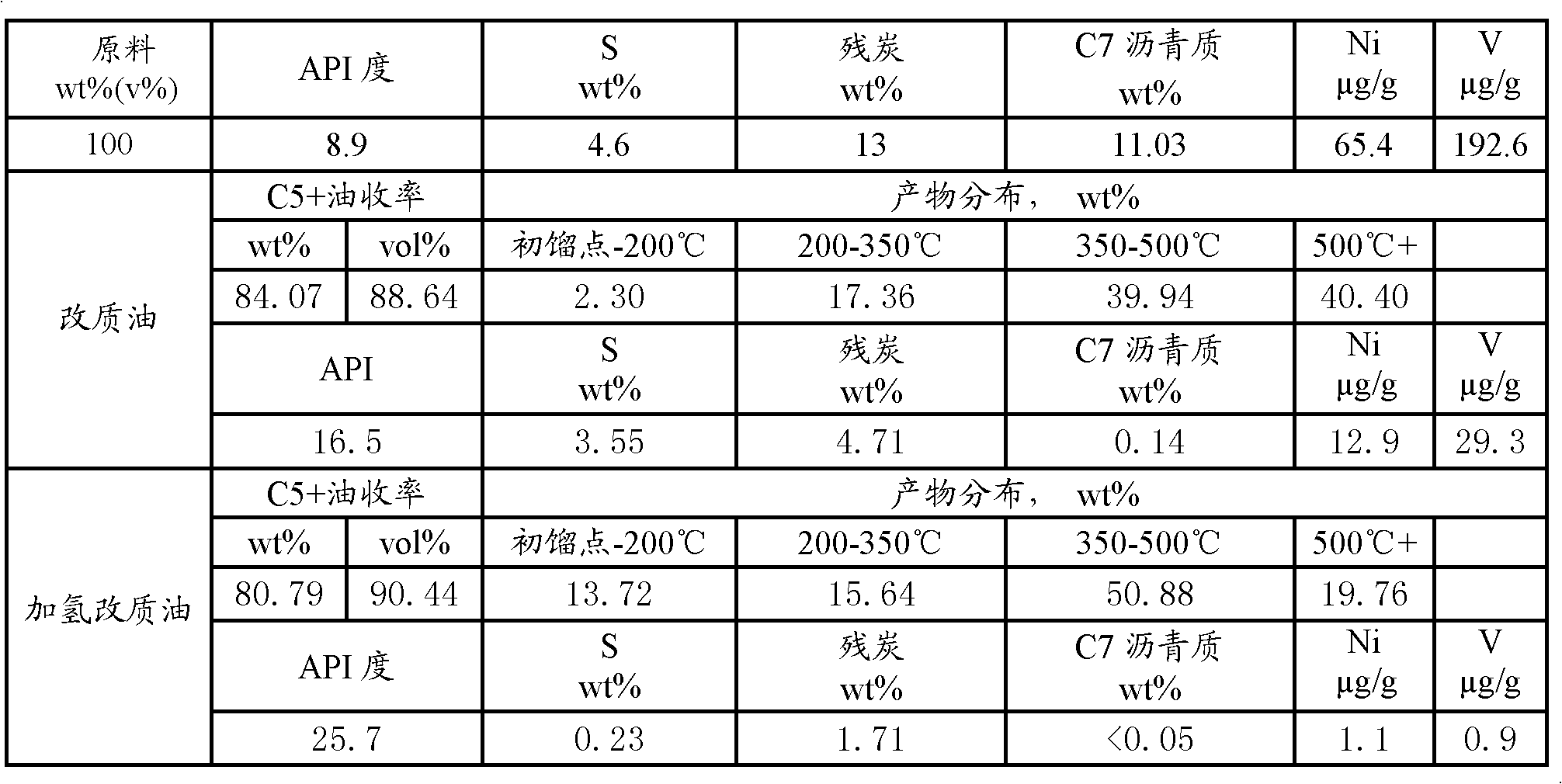

[0056] Canadian Athabasca oil sand asphalt has an API of 8.9, a sulfur content of 4.60% by weight, a Concord carbon residue CCR of 13.0%, a C7 asphaltene content of 11.03% by weight, and Ni and V contents of 69μg / g and 190μg / g, respectively.

[0057] By adopting atmospheric distillation, a 200-350°C diesel fraction of 12.04% by weight is obtained, and the yield of atmospheric column bottoms (residual oil) is 87.96% by weight.

[0058] The bottom product of the atmospheric column is solvent deasphalted with a mixed solvent of nC4-nC5, and the composition of the extraction solvent is nC4:nC5=50:50 (wt / wt). The specific operation of the solvent deasphalting process is the same as in Example 1, but the total solvent mass ratio is 3.95:1, the main solvent: secondary solvent: dispersing solvent = 0.759: 0.203: 0.038, the extraction tower bottom temperature is 140°C, and the tower top temperature is 160°C. The extraction pressure is 5.0MPa.

[0059] The deasphalted oil discharged from the ...

Embodiment 3

[0065] Canadian Athabasca oil sand asphalt has an API of 8.9, a sulfur content of 4.6wt%, a Concord carbon residue CCR of 13.0%, a C7 asphaltene content of 11.4wt%, and Ni and V contents of 65.4μg / g and 192.6μg / g, respectively.

[0066] Using atmospheric and vacuum distillation, the 200-350℃ diesel fraction was 12.04wt% and the 350-500℃ straight-run wax oil yield was 32.75wt%, and the vacuum column bottoms (boiling point higher than 500℃ residue) yield was 55.21 wt%.

[0067] The residual oil at the bottom of the vacuum column was deasphalted by using n-pentane (nC5) as the extraction solvent, and the specific operation was the same as in Example 1. The total solvent mass ratio is 3.7:1, of which the main solvent: auxiliary solvent: dispersing solvent=0.811:0.135:0.054, the extraction tower bottom temperature is 160°C, the tower top temperature is 170°C, and the extraction pressure is 5.5MPa.

[0068] The deasphalted oil discharged from extraction tower 4 is under supercritical cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com