Foundry technique method of lower support board of ball type support

A ball bearing and casting process technology, which is applied to manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of a large number of risers, prone to blisters, sand inclusion, and high production costs, and achieves a simple process method. The effect of easy operation, improving process preparation speed and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

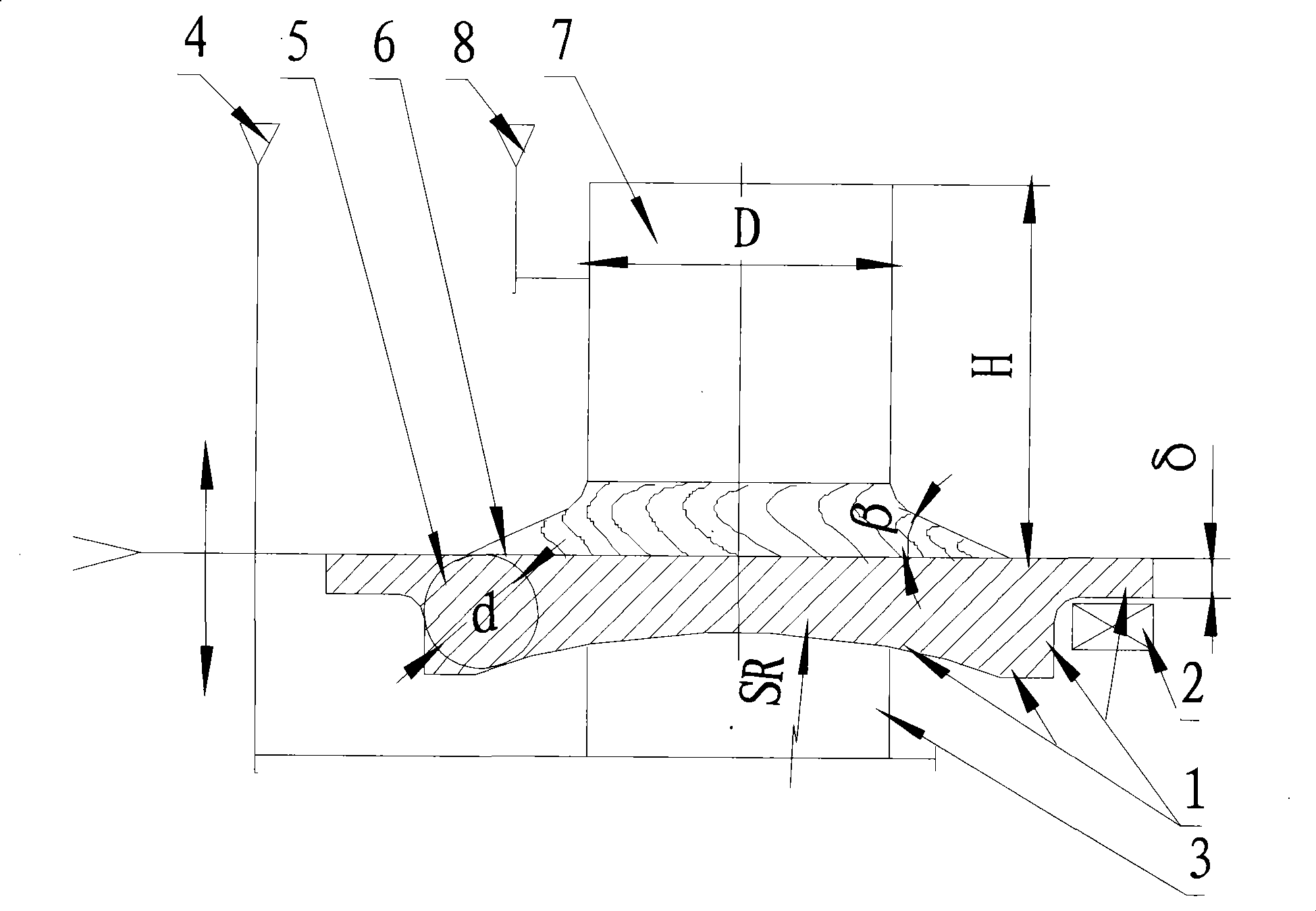

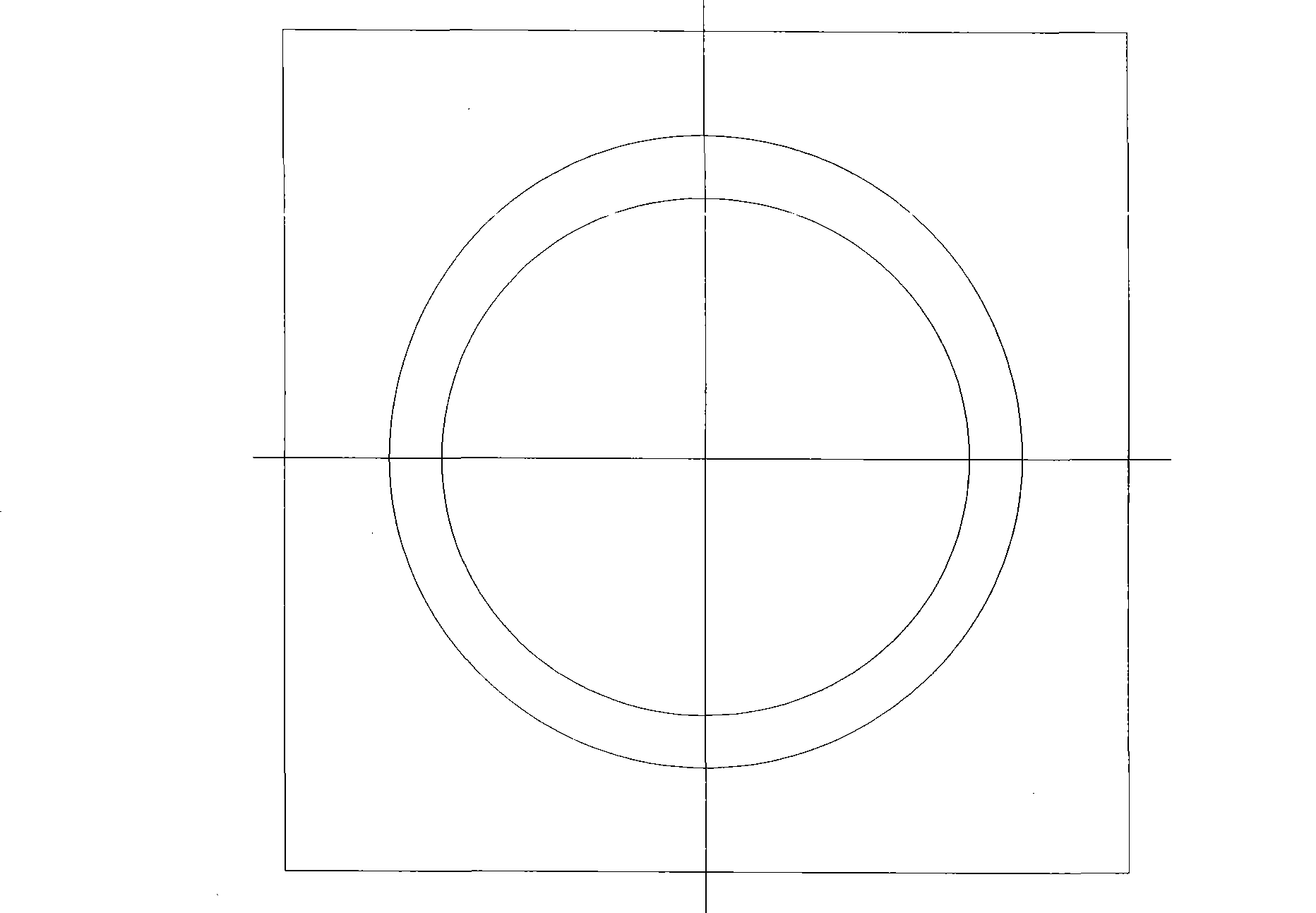

[0025] As shown in Figures 1 and 2: a casting process method for the lower bearing plate of a spherical bearing, which is based on the shape and structure of the lower bearing plate of the spherical bearing, a square plate-shaped piece, one side is a large plane, and the other side has an edge The four corners are in the shape of a flat plate, and the middle part is a circular boss with a concave spherical surface. The large plane faces upward and is poured horizontally. A cylindrical riser is set in the center of the large plane, and horizontal subsidies are set around the riser. In conjunction with the use of external chillers, To meet the feeding requirements of sequential solidification of castings. Molten steel pouring adopts two straight sprues to pour at the same time, and four inner runners are located at the edge of the riser and are introduced into the mold through the bottom trans tangent.

[0026] Its technological implementation process is as follows:

[0027] 1....

Embodiment approach 2

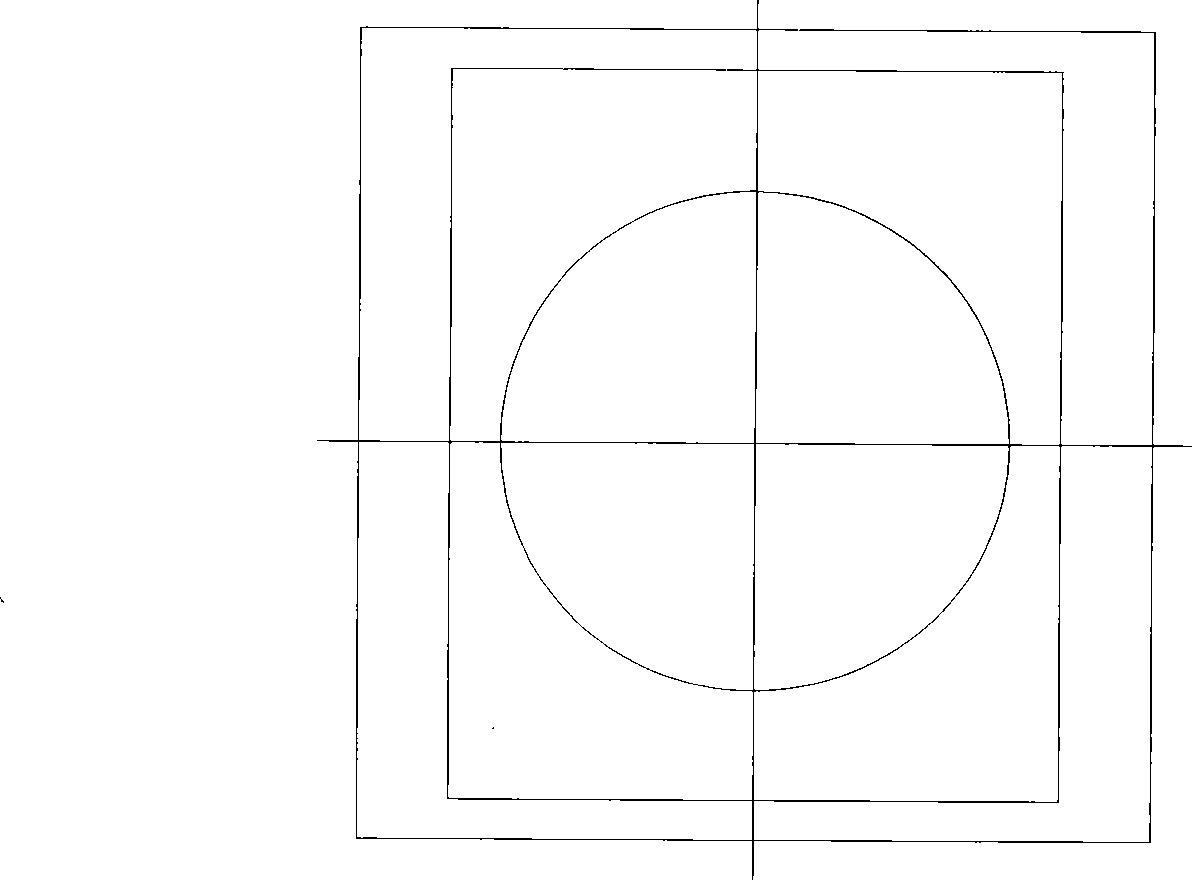

[0035] As shown in Figures 1, 3, and 4: the casting process of the lower bearing plate of this spherical bearing can also be used for steel castings whose lower bearing plate is a rectangular boss structure, and the lower bearing plate is large. The plane faces upward and pours horizontally; the bottom surface of the rectangular convex platform and the concave spherical surface in the middle of the mold on the other side are scraped off with a scraper 1, and the rest of the parts are pounded out as a real sample model. Other processes are the same as the above-mentioned circular boss casting casting process.

[0036] The casting process for the lower bearing plate of the spherical bearing can also be used for other steel castings with similar structural shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com