Casting box of roller for rod and wire and medium-wide strip steel rolling mill and using method thereof

A bar and wire rod and steel rolling mill technology is applied in the field of casting boxes for rod and wire rods and rolls used in medium-broadband steel rolling mills, and can solve the problems of low production efficiency and long roll blank molding time, so as to improve production efficiency, reduce pores and blisters, The effect of easy size guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

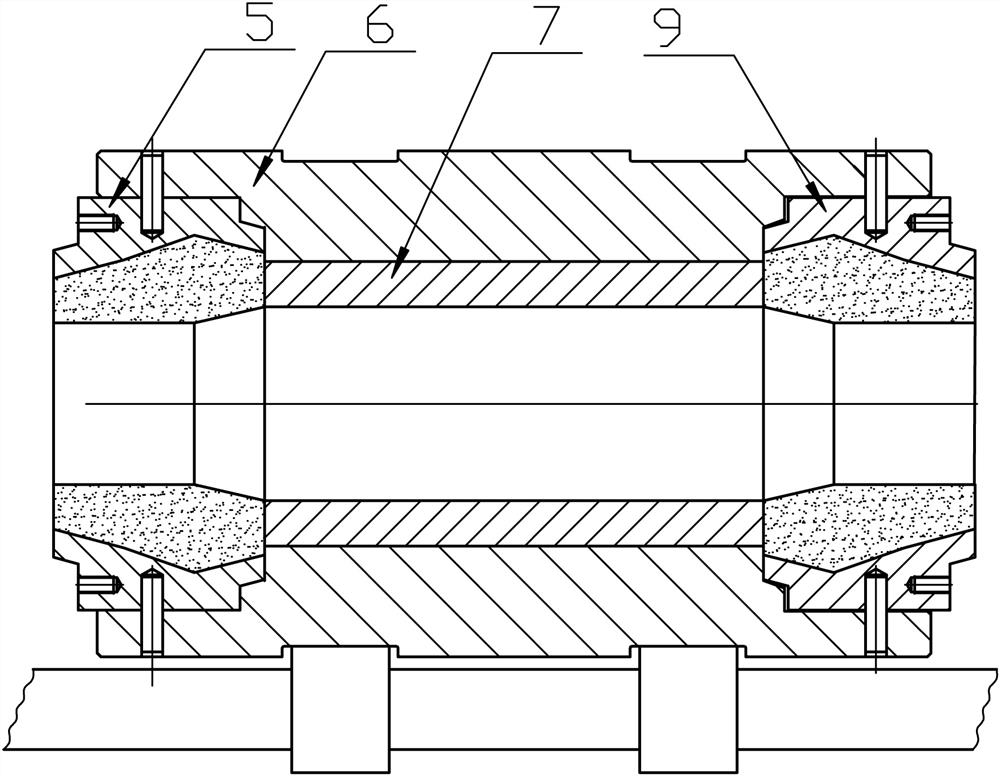

[0035] The roll includes a roll body 8 and a working layer 7 made of high-hardness wear-resistant material covering the outer circle of the middle part of the roll body 8, and the two ends of the roll body 8 are roll necks.

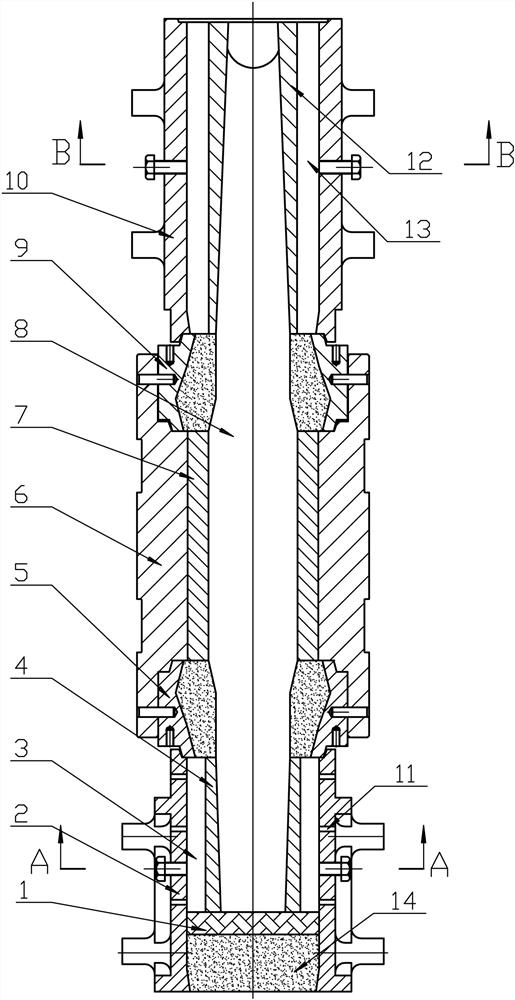

[0036] Such as Figures 1 to 5 As shown, a casting box for rods and wires and rolls for medium and wide strip mills includes an upper mold, an upper end cover 9, a cold form 6, a lower end cover 5 and a lower mold that are connected vertically from top to bottom.

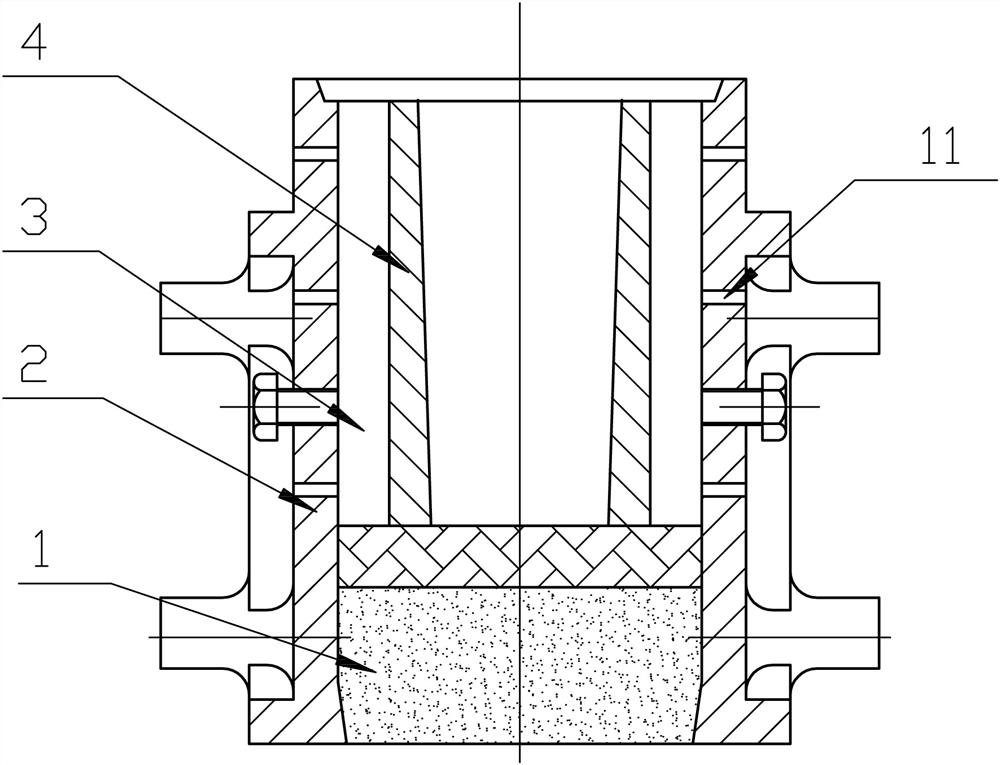

[0037] The lower mold is a double-layer structure, which includes a vertical cylindrical inner steel mold 4, a cylindrical bottom box 2 set outside the inner steel mold 4, and a bottom box 2 arranged between the inner steel mold 4 and the bottom box 2. Six pieces of rectangular support plate armor 3 in between. There is a gap between the inner steel formwork 4 and the bottom box 2, and the support plate 3 is vertically arranged in the gap and evenly distributed along the circumference of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com