A kind of high-temperature water-based high-covering white ink and preparation method thereof

A white ink, water-based technology, used in inks, household appliances, applications, etc., can solve problems such as poor ability to adapt to environmental temperature changes, no stable performance, etc., to improve gloss, reduce waste, and reduce trachoma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

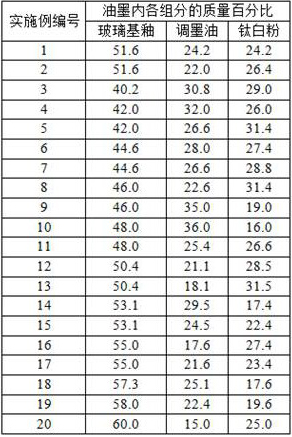

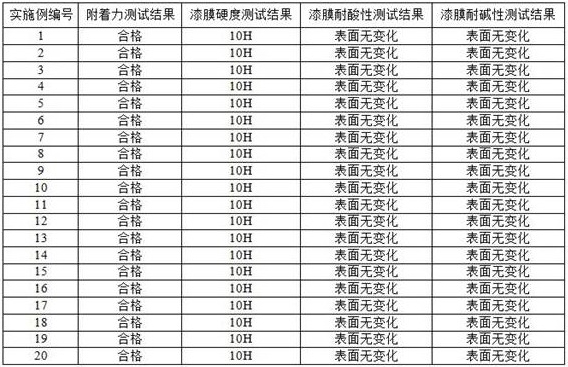

Examples

Embodiment 1

[0069] S01, preparation of glass-based glaze:

[0070] The components and mass percentages in the glass-based glaze are:

[0071] Sodium borate 23.4%, silicon oxide 31.1%, zinc oxide 10.9%, potassium carbonate 5.5%, soda ash 7.8%, lithium carbonate 6.9%, silica lime 6.0%, titanium dioxide 1.5%, tin oxide 2.3%, potassium feldspar 4.6%;

[0072] The raw materials in the above-mentioned glass-based glaze are mixed evenly and then melted at 1000°C. After melting, water quenching, water milling, pressure filtration, drying and sieving are carried out in sequence to obtain the glass-based glaze. The above water milling time is 20 hours, the ratio of beads to water is 3:1:1, and the size ratio of beads is large: medium: small = 1:1:3. Use a 500-mesh vibrating sieve to filter the water for grinding, then press filter to remove water and dry , and sieved with 500 meshes after drying to obtain glass-based glaze;

[0073] S02, preparation of varnish:

[0074] Each component and mass p...

Embodiment 2

[0081] S01, preparation of glass-based glaze:

[0082] The components and mass percentages in the glass-based glaze are:

[0083] Sodium borate 23.4%, silicon oxide 30.0%, zinc oxide 10.9%, potassium carbonate 1.0%, soda ash 15.0%, lithium carbonate 5.3%, silica lime 6.0%, titanium dioxide 1.5%, tin oxide 2.3%, potassium feldspar 4.6%;

[0084] The raw materials in the above-mentioned glass-based glaze are mixed evenly and then melted at 1000°C. After melting, water quenching, water milling, pressure filtration, drying and sieving are carried out in sequence to obtain the glass-based glaze. The above water milling time is 20 hours, the ratio of beads to water is 3:1:1, and the size ratio of beads is large: medium: small = 1:1:3. Use a 500-mesh vibrating sieve to filter the water for grinding, then press filter to remove water and dry , and sieved with 500 meshes after drying to obtain glass-based glaze;

[0085] S02, preparation of varnish:

[0086] Each component and mass ...

Embodiment 3

[0093] S01, preparation of glass-based glaze:

[0094] The components and mass percentages in the glass-based glaze are:

[0095] Sodium borate 15.2%, silicon oxide 40.0%, zinc oxide 20.0%, potassium carbonate 1.0%, soda ash 8.5%, lithium carbonate 7.8%, silica lime 2.0%, titanium dioxide 2.0%, tin oxide 3.0%, potassium feldspar 0.5%;

[0096] The raw materials in the above-mentioned glass-based glaze are mixed evenly and then melted at 1000°C. After melting, water quenching, water milling, pressure filtration, drying and sieving are carried out in sequence to obtain the glass-based glaze. The above water milling time is 20 hours, the ratio of beads to water is 3:1:1, and the size ratio of beads is large: medium: small = 1:1:3. Use a 500-mesh vibrating sieve to filter the water for grinding, then press filter to remove water and dry , and sieved with 500 meshes after drying to obtain glass-based glaze;

[0097] S02, preparation of varnish:

[0098] Each component and mass p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com