Coal tar pretreatment purification method and system

A technology for coal tar and pretreatment, which is applied in the processing of tar, tar processing by distillation, and tar pitch/petroleum pitch/natural pitch by distillation, etc. Low yield, process and investment, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

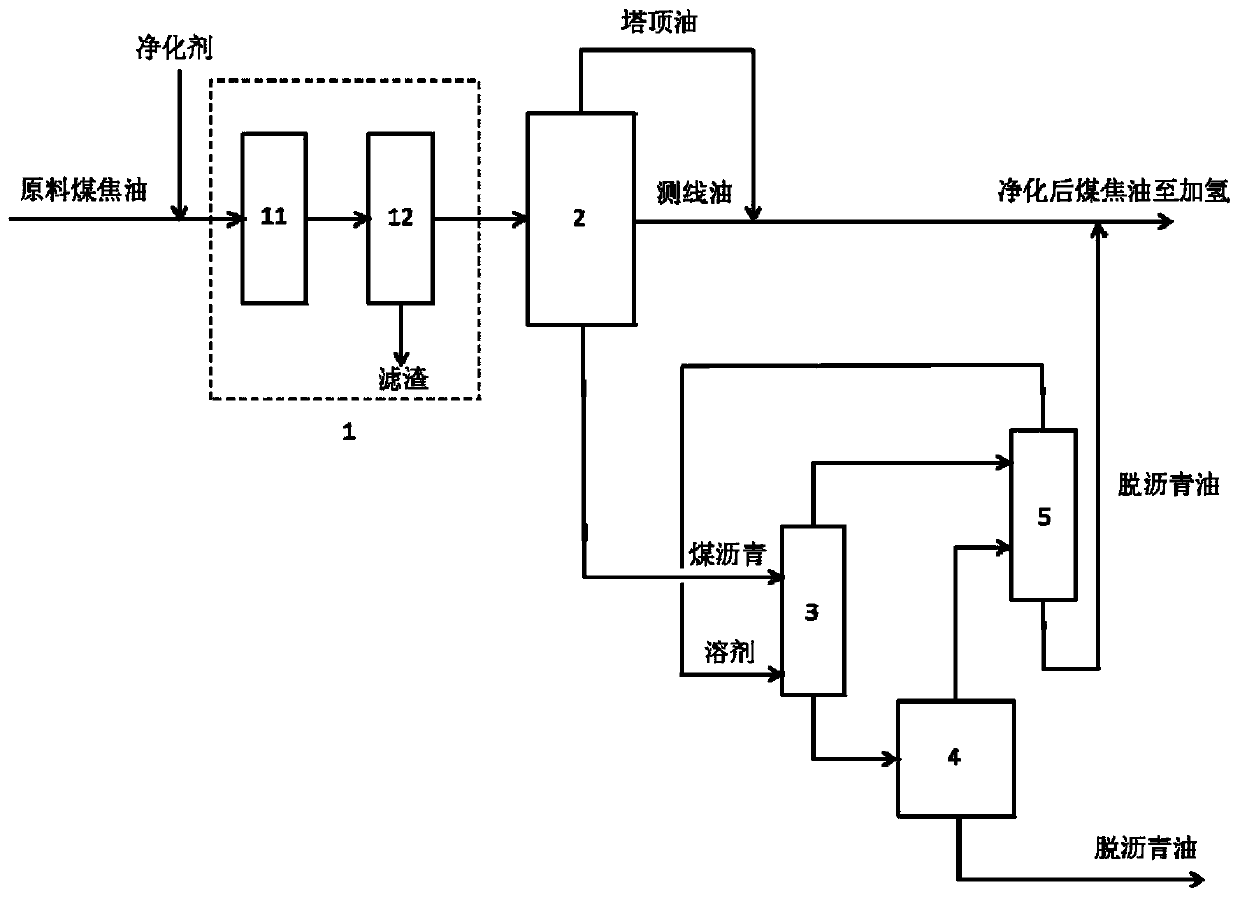

[0046] This embodiment provides a method for pretreatment and purification of coal tar, the process of which is as follows figure 1 As shown, the method includes the following steps:

[0047] (1) Add 0.2wt% scavenger ammonium sulfate of coal tar total amount to low-temperature coal tar, adopt 120 DEG C of flash to carry out flash evaporation dehydration to described low-temperature coal tar, to the described low-temperature coal after dehydration The tar is filtered to remove solid impurities, and the dehydrated and solidified coal tar is subjected to fractionation and cutting to obtain tower top oil, sideline oil and tower bottom coal tar pitch, and the tower bottom coal tar pitch accounts for 10 wt% of the total product of the fractionation and cutting;

[0048] (2) Solvent extraction is carried out to the coal tar pitch at the bottom of the tower obtained in step (1), the solvent is pentane, the volume ratio of the solvent and the coal tar pitch at the bottom of the tower i...

Embodiment 2

[0052] This embodiment provides a method for pretreatment and purification of coal tar, the process of which is as follows figure 1 As shown, the method includes the following steps:

[0053] (1) Add scavenger ammonium phosphate of 1.0wt% of the total amount of coal tar to the medium and low temperature coal tar, and use 180° C. flash evaporation to remove moisture from the coal tar, and dehydrate the medium and low temperature coal tar filtering to remove solid impurities, and fractionating and cutting the dehydrated and desolidified coal tar to obtain top oil, sideline oil and bottom coal tar pitch, and the bottom coal tar pitch accounts for 20 wt% of the total product of the fractionation and cutting;

[0054] (2) Carry out solvent extraction to the tower bottom coal tar pitch that step (1) obtains, solvent is cyclohexane, and the volume ratio of described solvent and described tower bottom coal tar pitch is 5:1, and temperature is 120 ℃, and pressure is 1.5 MpaG, the extr...

Embodiment 3

[0058] This embodiment provides a method for pretreatment and purification of coal tar, the process of which is as follows figure 1 As shown, the method includes the following steps:

[0059] (1) Add the scavenger ammonium polyphosphate of 0.5wt% of the total amount of coal tar pitch to the medium temperature coal tar, adopt 150 DEG C of flash evaporation to carry out flash evaporation to remove the moisture of the described coal tar, to the described medium temperature coal tar after dehydration filtering to remove solid impurities, and fractionating and cutting the dehydrated and desolidified coal tar to obtain top oil, sideline oil and bottom coal tar pitch, and the bottom coal tar pitch accounts for 15 wt% of the total product of the fractionation and cutting;

[0060] (2) solvent extraction is carried out to the coal tar pitch at the bottom of the tower that step (1) obtains, and solvent is toluene, and the volume ratio of described solvent and the coal tar pitch at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com