Method for hydrogenating and liquefying coal with high content of inert components

A hydrogenation liquefaction, high content technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of low conversion rate, difficult liquefaction of Wucaiwan coal, low liquefaction yield, etc., and achieve the effect of increasing oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

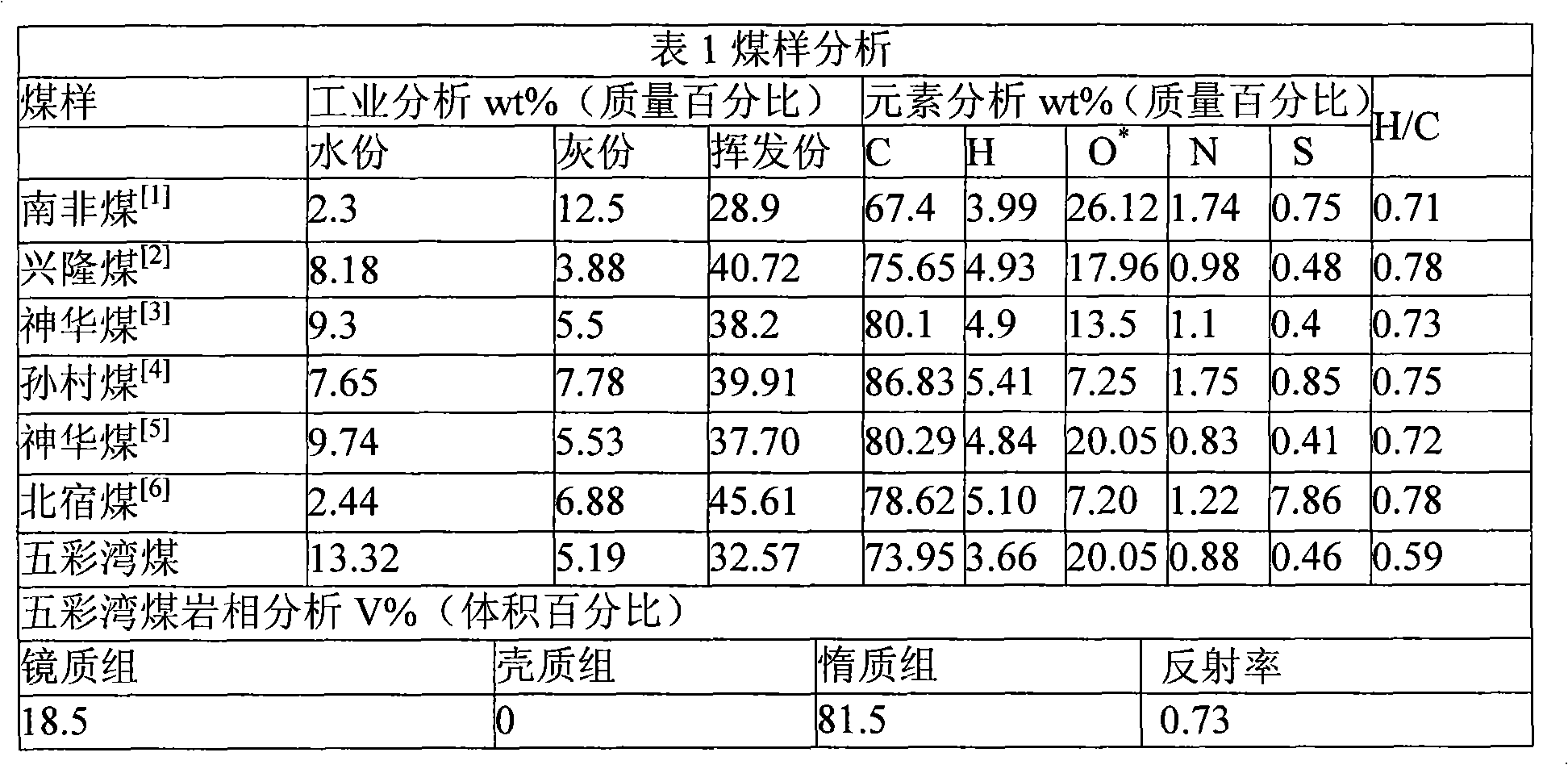

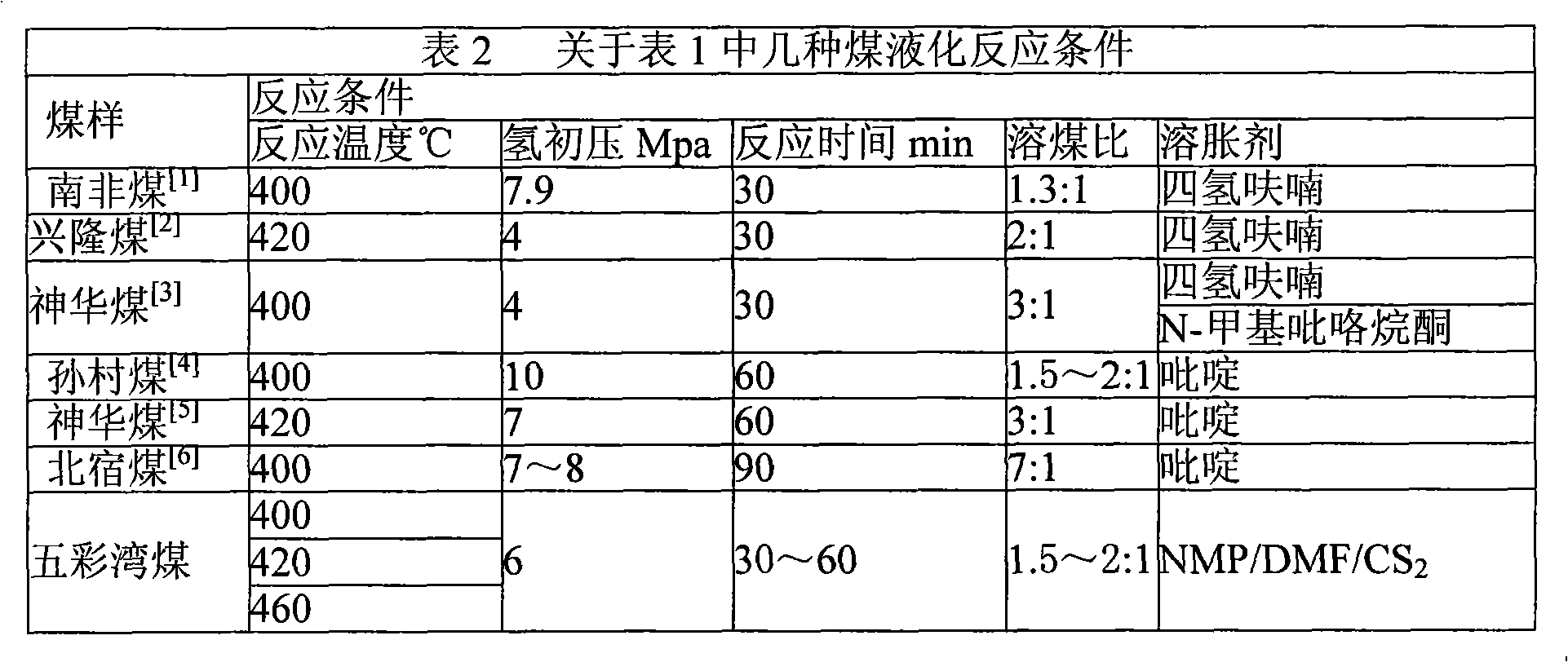

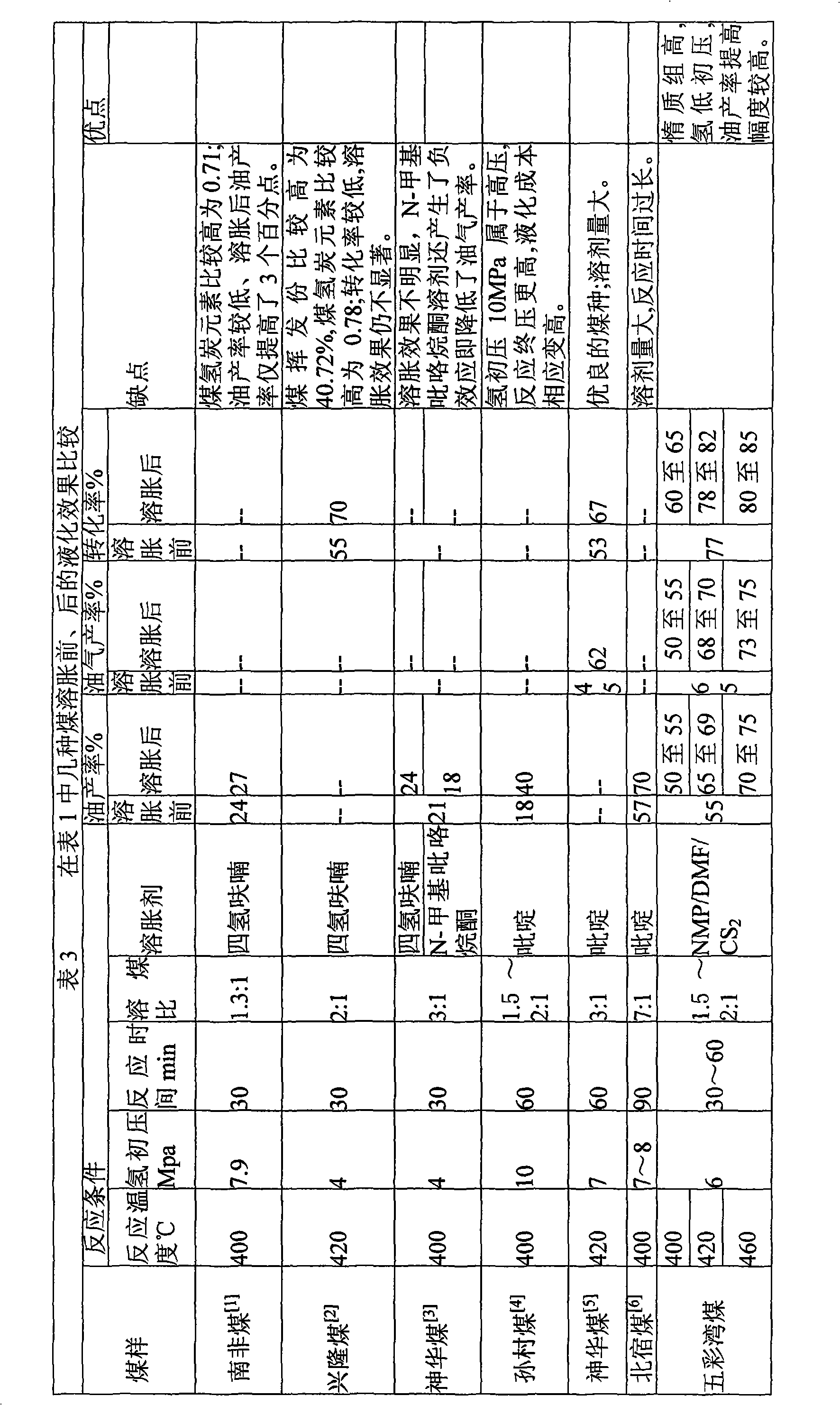

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The hydrogenation liquefaction method of this high-content inert component coal is carried out according to the following steps:

[0026] The first step of swelling treatment: N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF) and carbon disulfide (CS 2 ) mixed with Wucaiwan coal at a ratio of 2:1 while stirring, sealed and left to swell for 0.5 hours at room temperature, vacuum filtered and dried to obtain swelled coal; wherein, N-methylpyrrolidone (NMP) , N, N-dimethylformamide (DMF) and carbon disulfide (CS 2 ) to form a mixed solution with a volume ratio of 1:0:1, and the ratio unit of the above mixed solution to Wucaiwan coal is ml / g;

[0027] The second step of hydrogenation liquefaction reaction: the required amount of the above-mentioned swelling coal, catalyst ferric oxide, cocatalyst elemental sulfur and hydrogen-donating solvent tetrahydronaphthalene are mixed evenly and poured into the reactor, and the reactor is sealed and poured into the...

Embodiment 2

[0029] Embodiment 2: the hydrogenation liquefaction method of this high-content inert component coal is characterized in that it is carried out according to the following steps:

[0030] The first step of swelling treatment: N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF) and carbon disulfide (CS 2 ) mixed with Wucaiwan coal at a ratio of 10:1 while stirring, sealed and left to swell for 24 hours at room temperature, vacuum filtered and dried to obtain swollen coal; wherein, N-methylpyrrolidone (NMP) , N, N-dimethylformamide (DMF) and carbon disulfide (CS 2 ) to form a mixed solution with a volume ratio of 2:0 to 1:1, and the unit of the ratio of the above mixed solution to Wucaiwan coal is ml / g;

[0031] The second step of hydrogenation liquefaction reaction: the required amount of the above-mentioned swelling coal, catalyst ferric oxide, cocatalyst elemental sulfur and hydrogen-donating solvent tetrahydronaphthalene are mixed evenly and poured into the reactor, and t...

Embodiment 3

[0033] Embodiment 3: the hydroliquefaction method of this high-content inert component coal is carried out according to the following steps:

[0034] The first step of swelling treatment: N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF) and carbon disulfide (CS 2 ) mixed with Wucaiwan coal at a ratio of 2 to 10:1 while stirring, then sealed and left to swell for 0.5 to 24 hours at room temperature, vacuum filtered and dried to obtain swollen coal; wherein, N-formazol Nylpyrrolidone (NMP), N, N-dimethylformamide (DMF) and carbon disulfide (CS 2 ) to form a mixed solution with a volume ratio of 1 to 2:0 to 1:1, and the ratio of the above mixed solution to Wucaiwan coal is in ml / g;

[0035] The second step of hydrogenation liquefaction reaction: the required amount of the above-mentioned swelling coal, catalyst ferric oxide, cocatalyst elemental sulfur and hydrogen-donating solvent tetrahydronaphthalene are mixed evenly and poured into the reactor, and the reactor is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com