Method for extracting grease from oil-tea camellia seed kernel and recovering saponin and saccharide active substances

An active substance and oil extraction technology, applied in the application field of biotechnology in grain, oil and food processing, to achieve the effect of mild action conditions, high yield of clear oil, and high recovery rate of saponins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

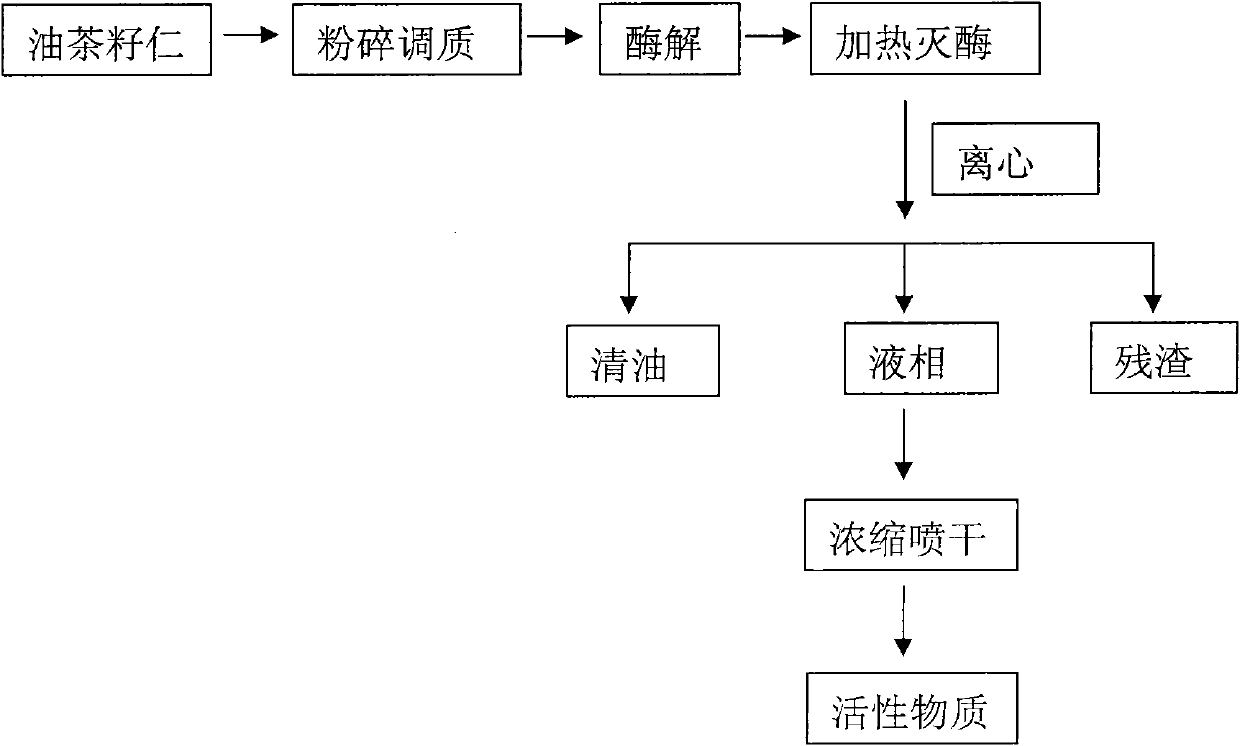

Method used

Image

Examples

Embodiment 1

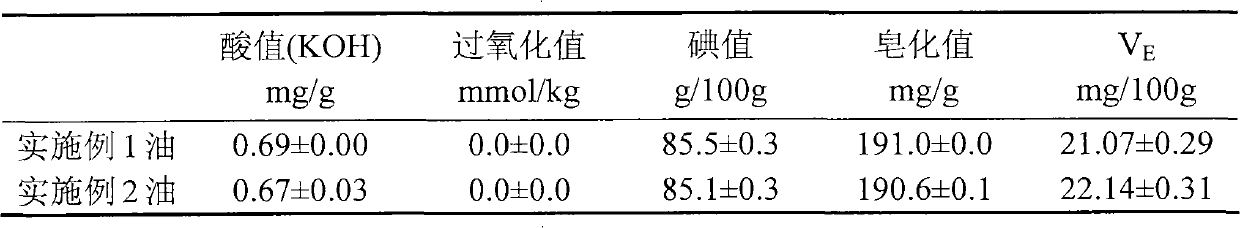

[0034]Take 1 kg of shelled Camellia oleifera seeds, grind them coarsely with a pulverizer, then finely pulverize them with a grinder, add 5L of water, stir evenly, adjust the pH of the system to 5.5, the temperature is 40°C, and add 0.5% pectinase by weight of Camellia oleifera seeds , after 4 hours of enzymolysis with slow stirring, the temperature of the system was raised to 80°C and kept for 10 minutes, and then centrifuged at 3500rpm for 10 minutes with a floor-standing centrifuge. The enzymolysis liquid was divided into three layers: clear oil, liquid phase and residue. Take out clear oil and weigh 403g, and the clear oil yield is 87.4%. After the liquid phase is concentrated by multi-effect concentration equipment, it is spray-dried to obtain active substances containing saponins and sugars, and the calculated yield of saponins is 67.8%. The quality indicators of each product are shown in Table 1-3.

[0035] Table 1 The physical and chemical properties of the Camellia o...

Embodiment 2

[0043] Take 500g of shelled Camellia oleifera seeds, pulverize them on a pulverizer, then pulverize them finely in a grinder, add 3L of water, stir well, adjust the pH of the system to 6.5, the temperature is 60°C, and add 1.5% pectinase by weight of Camellia oleifera seeds , after slow stirring for 3 hours of enzymolysis, the temperature of the system was raised to 85°C and kept for 8 minutes to inactivate the enzyme, and then centrifuged at 4000rpm for 15 minutes in a floor-standing centrifuge. The enzymolysis solution was divided into three layers: clear oil, liquid phase and residue; clear oil The yield is 89.4%. After the liquid phase is concentrated by multi-effect concentration equipment, it is spray-dried to obtain active substances containing saponins and sugars, and the calculated yield of saponins is 70.1%. The quality indicators of each product are shown in Table 1-3.

Embodiment 3

[0045] Take 1500g of shelled Camellia oleifera seeds, pulverize them on a pulverizer and then pulverize them finely with a grinder, add 6L of water, stir well, adjust the pH of the system to 8.0, the temperature is 50°C, and add 1% pectin by weight of Camellia oleifera seeds Enzyme, after slow stirring for 2 hours, the temperature of the system was raised to 90°C and kept for 5 minutes to inactivate the enzyme, and then centrifuged at 3000rpm for 15 minutes in a floor-standing centrifuge. The enzymolysis solution was divided into three layers: clear oil, liquid phase and residue; The clear oil yield is 89%. After the liquid phase is concentrated by multi-effect concentration equipment, it is spray-dried to obtain active substances containing saponins and sugars, and the calculated yield of saponins is 71.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com