Anti-segregation ore-blending system of high-pressure roller mill

A high-pressure roller mill and anti-segregation technology, which is applied in the field of mine beneficiation, can solve problems such as segregation, meet the requirements of material supply, meet the continuity and stability, and improve the effect of equipment processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

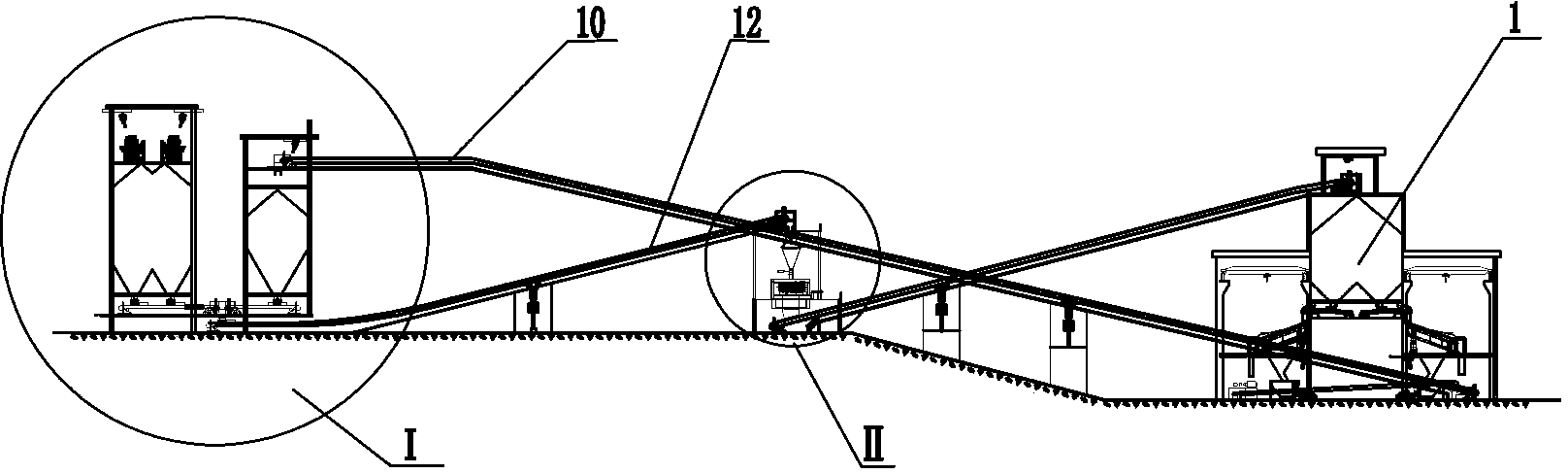

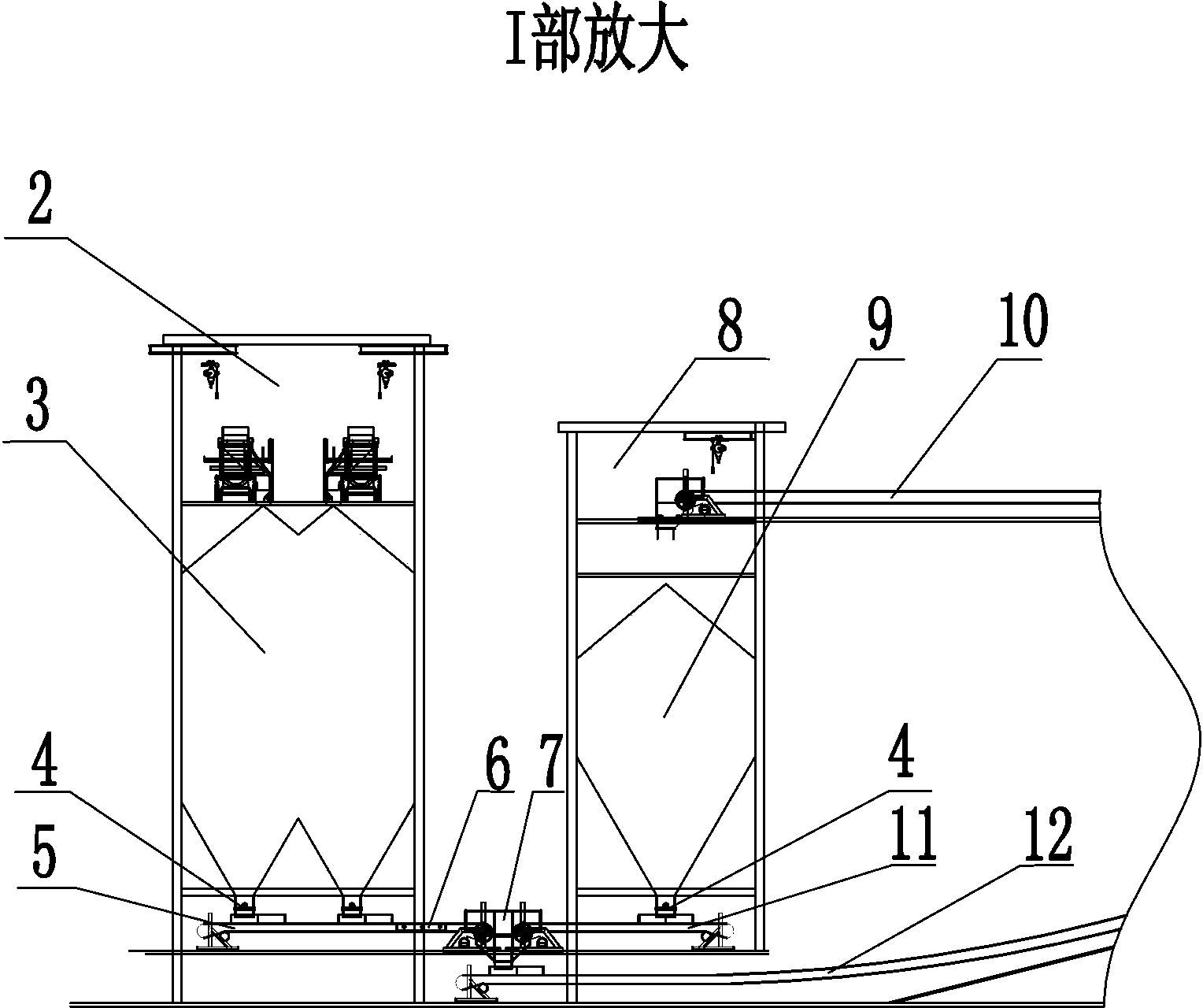

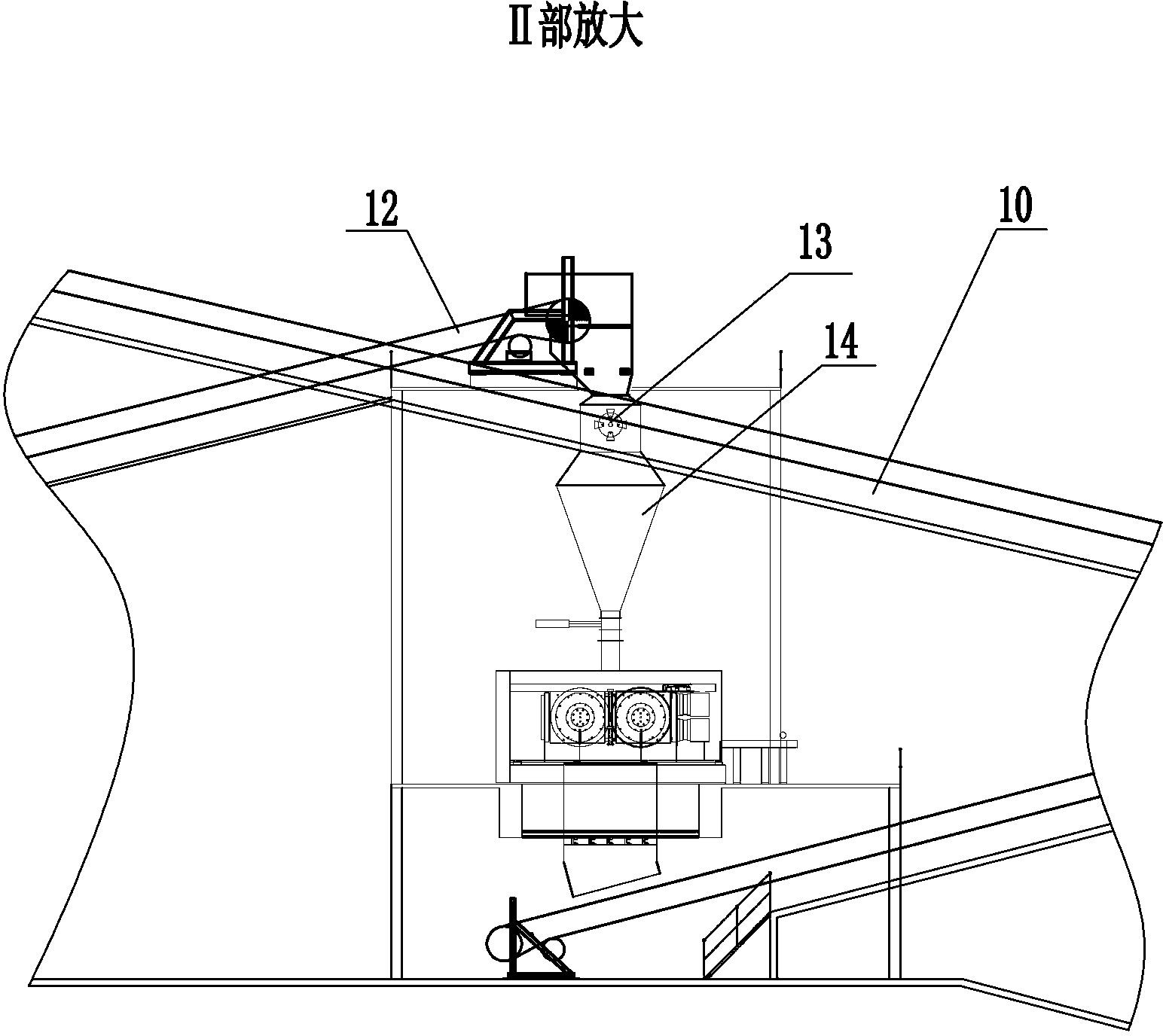

[0017] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 , 2 As shown in and 3, the high-pressure roller mill anti-segregation ore blending system of the present invention is characterized in that it includes a material distribution and batching system, an aggregate conveyor belt conveyor 12, a stirring system and a central control system, and the described material distribution and batching system includes side by side The arranged raw material bin 2 and the return bin 8 on the screen are respectively arranged on the raw material bin chute 3 in the raw material bin 2 and the return bin 8 on the screen and the return bin chute 9 on the screen, and are arranged in the raw material bin chute. 3 and the pneumatic valve 4 at the outlet of the return bin chute 9 on the sieve, the unloading belt machine I5 arranged below the outlet of the raw material bin chute 3, the unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com