Double-cylinder type magneto-rheological damper with inner and outer coils

A magnetorheological shock absorber and double-barrel technology, which is applied in the field of vehicle vibration reduction, can solve the problems of high processing cost, strong shock absorber pressure, and high difficulty in processing and assembling, so as to reduce the processing and assembling cost, improve the sealing effect, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only for the present invention but not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions shown in the drawings.

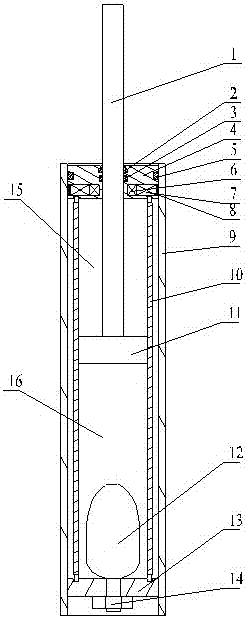

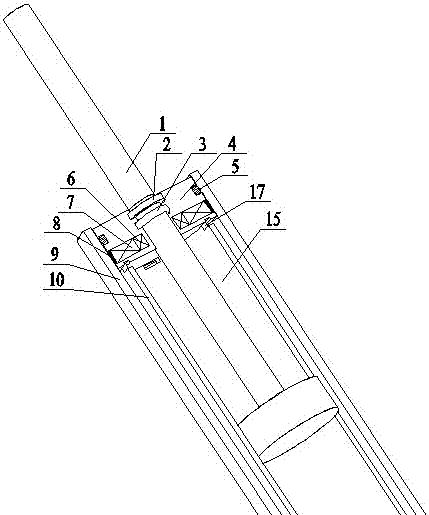

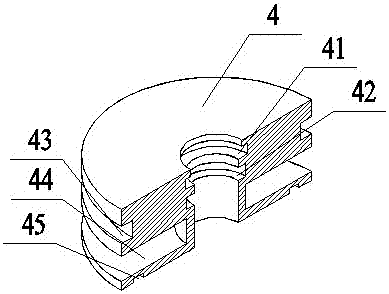

[0021] Such as figure 1 and 2 A dual-tube magneto-rheological shock absorber with inner and outer double coils shown mainly includes a piston rod 1, a piston 11, an inner cylinder 10, an outer cylinder 9, an end cover 4, a dust-proof ring 2, an inner O Type ring 3, outer O-ring 5, inner coil 6, outer coil 7, coil protection layer 8, compensation airbag 12, bottom positioning piece 13, nut 14, etc. The piston rod 1 is tightly connected with the piston 11. The piston 11 is located inside the inner cylinder 10 and is slidably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com