Patents

Literature

72results about How to "Avoid complex processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

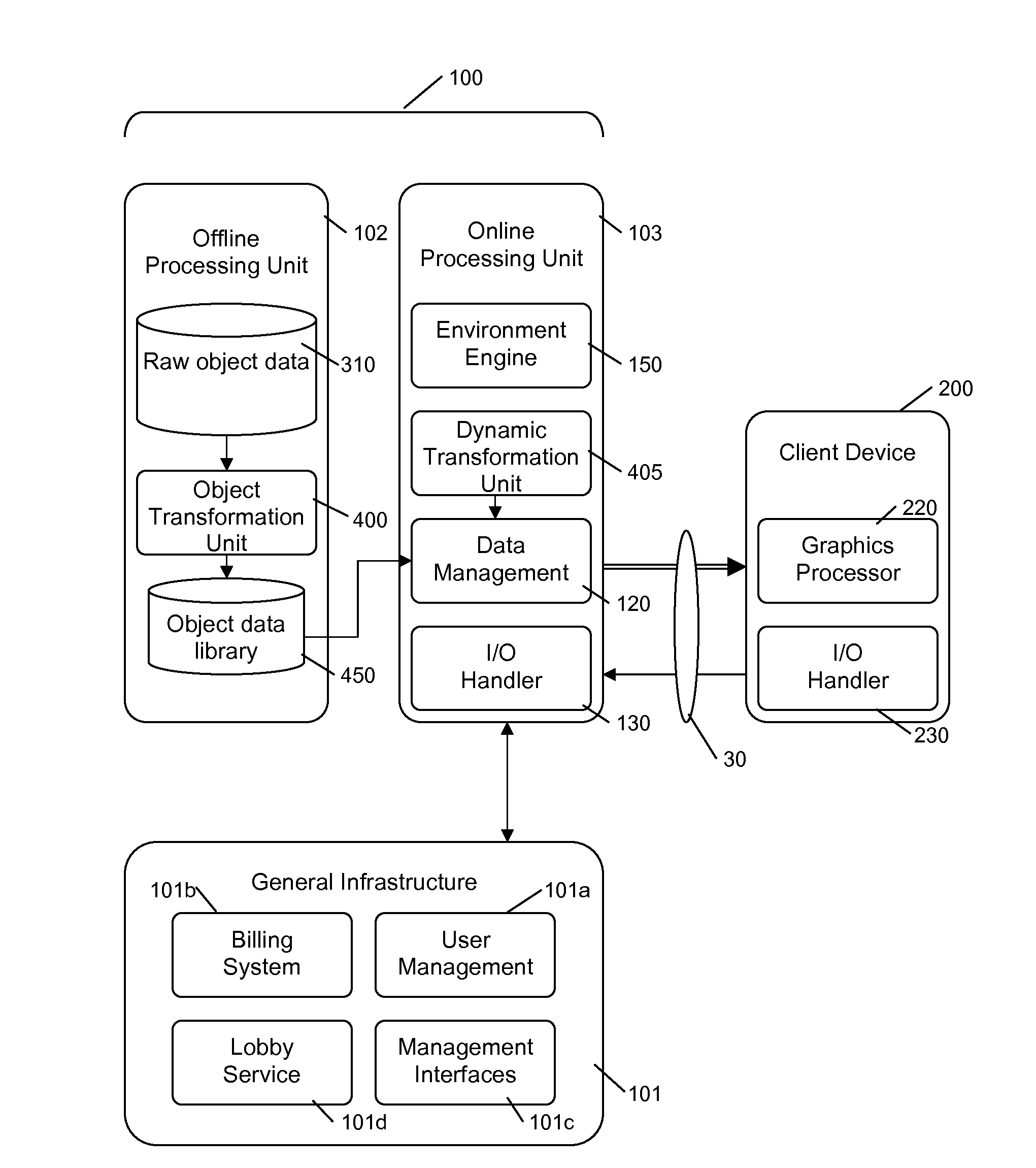

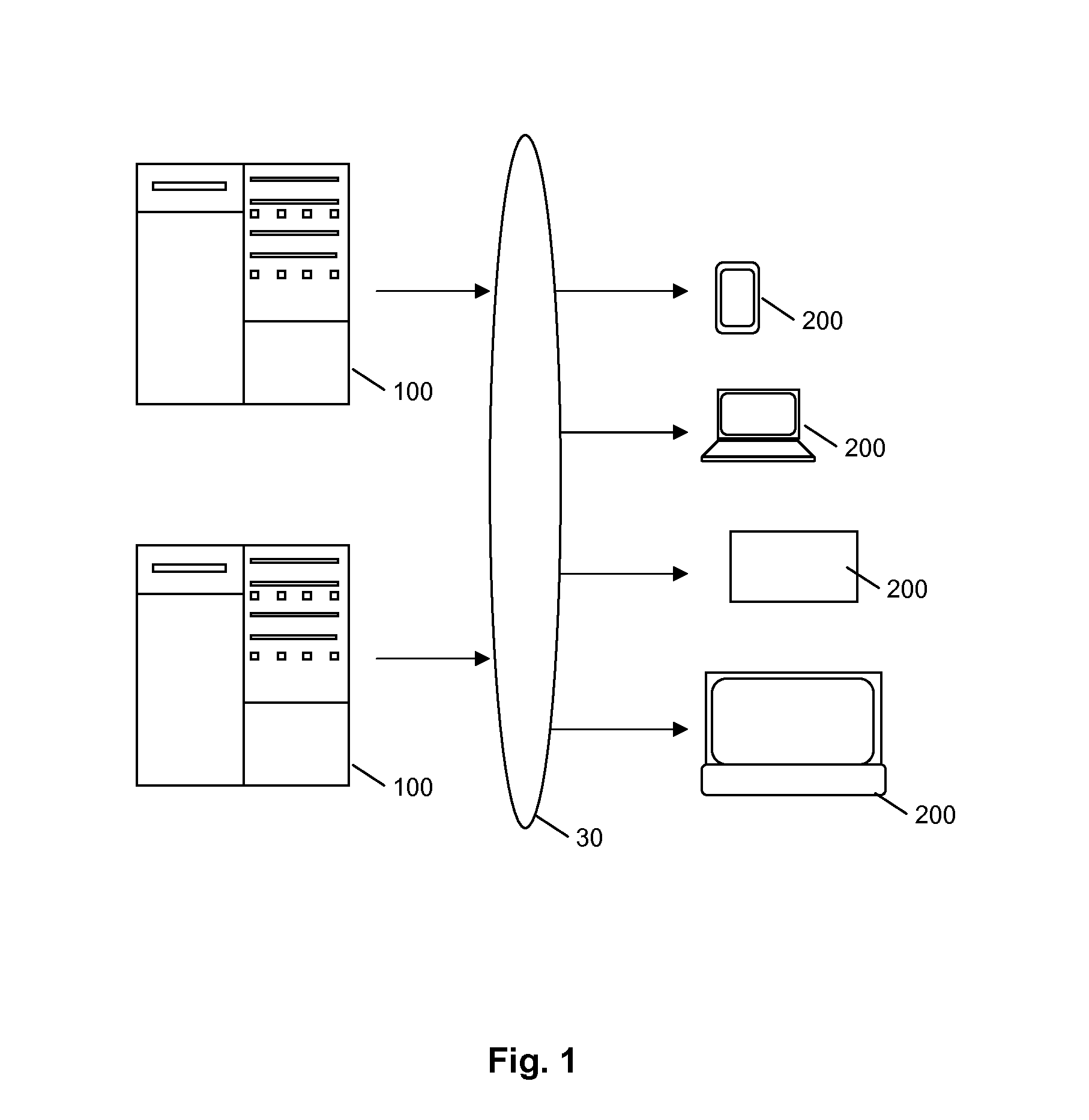

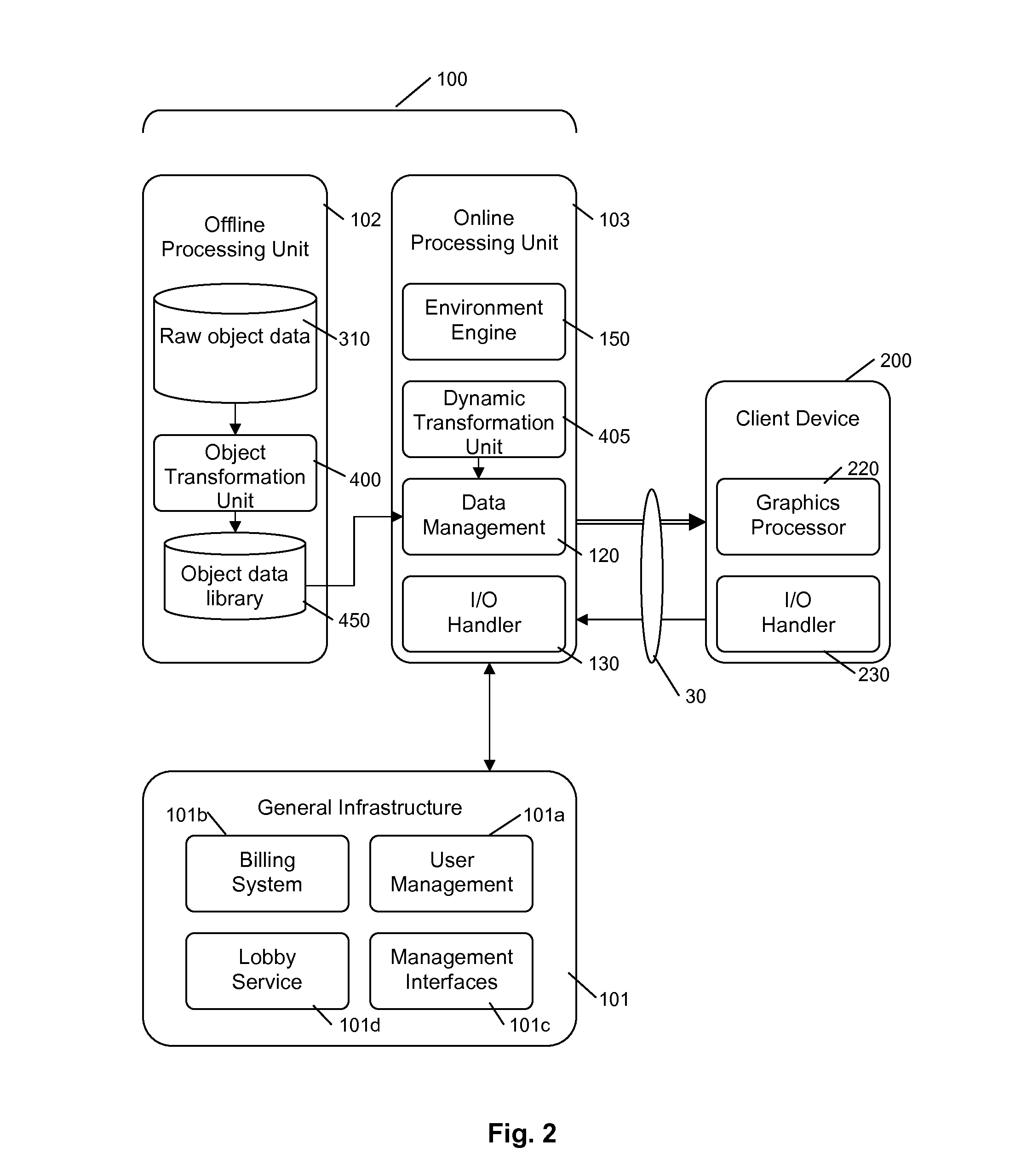

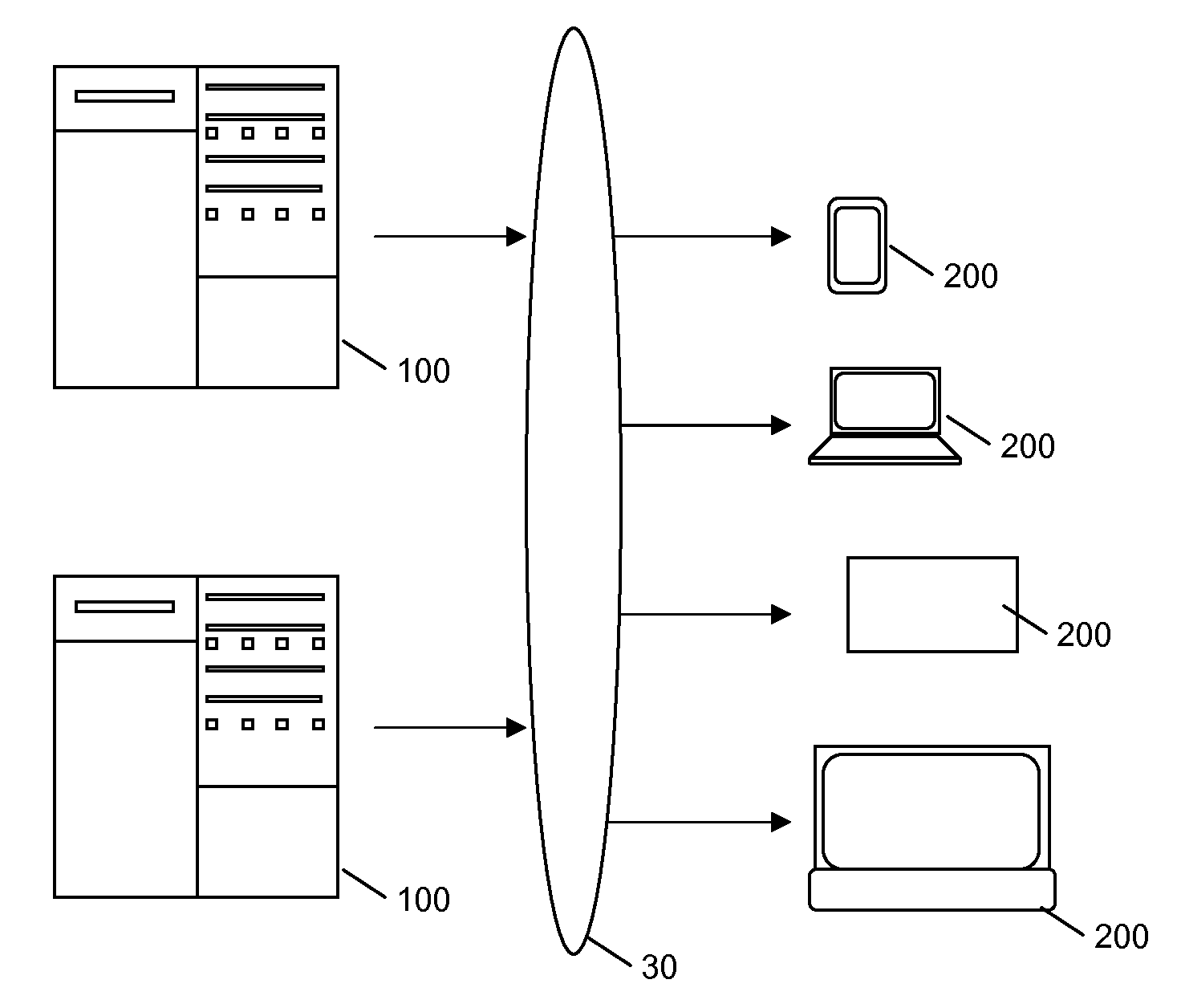

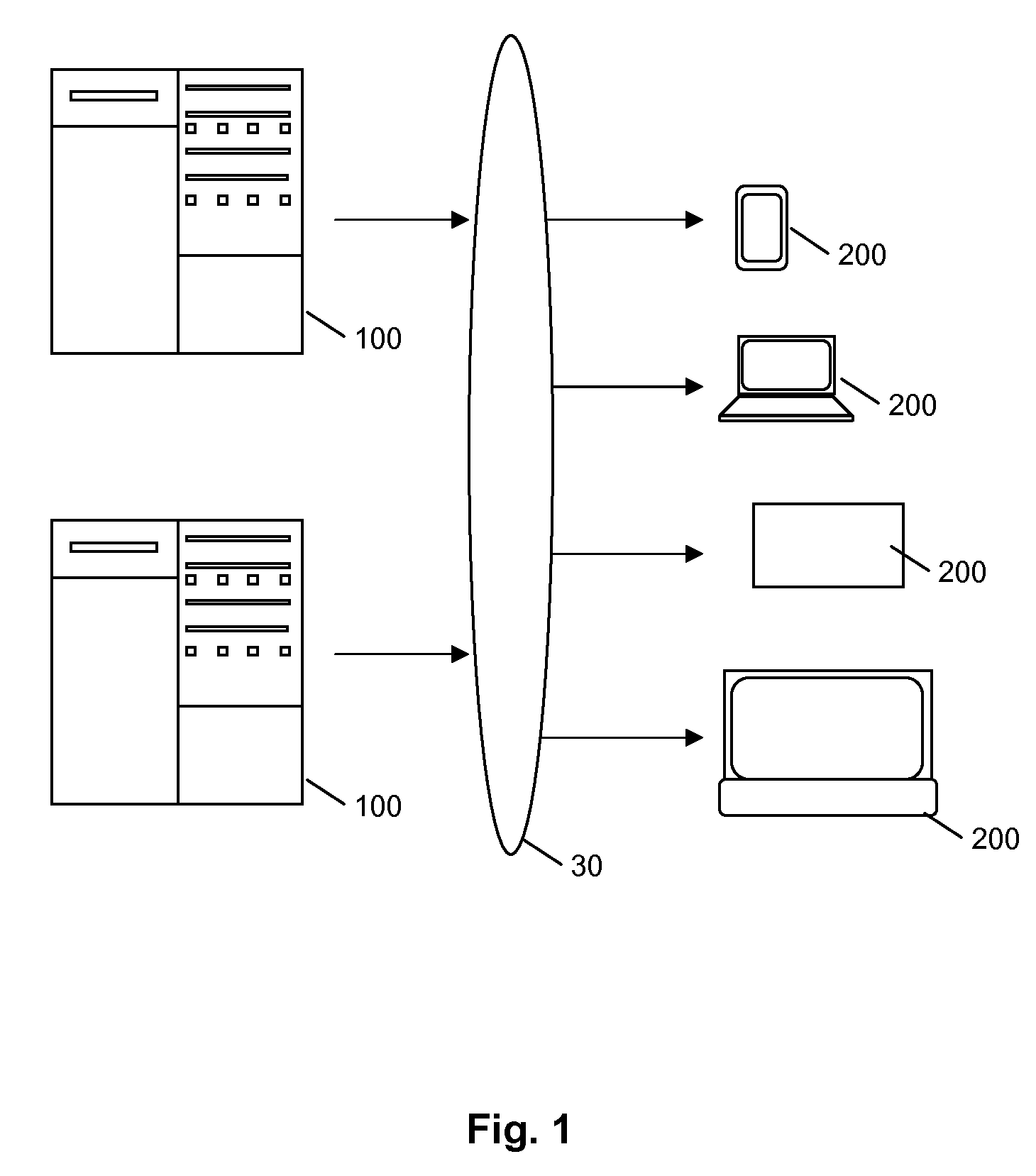

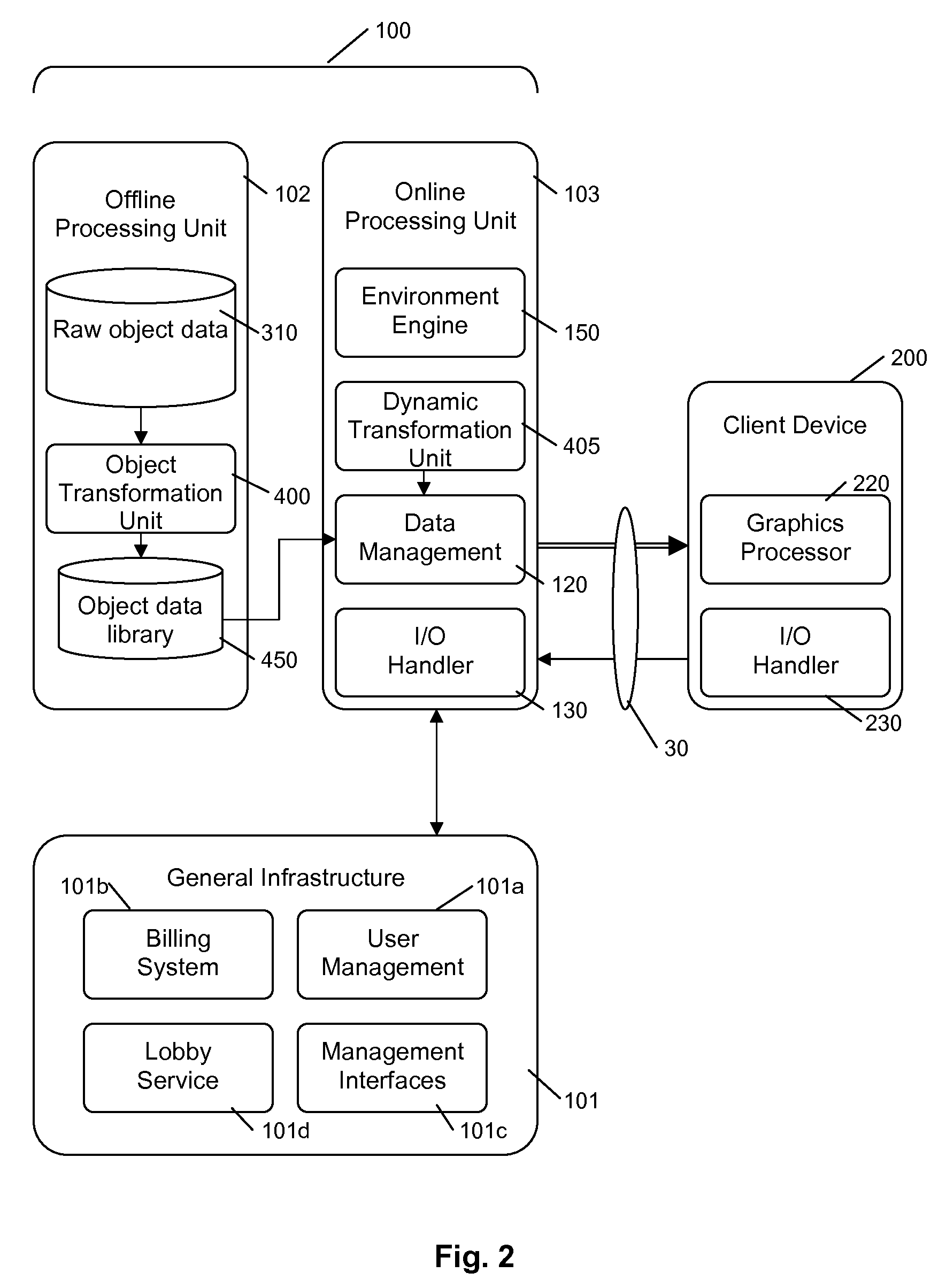

Multimedia content delivery system

ActiveUS20130024545A1High degree of controlHigh degree of flexibilityDetails involving 3D image dataImage codingGraphicsManagement unit

A multimedia content delivery system includes a server apparatus (100) for delivering graphical information across a network (30) to a client device (200). An environment engine (150) controls a virtual environment responsive to user commands. An object transformation unit (400, 405) transforms original object data (310) relating to a plurality of objects into compressed object data (350). A data management unit (120) transmits the compressed object data to the client device (200). The compressed object data (350) is decompressed and rendered by the client device (200) to output images to represent the virtual environment on a visual display device. Server-side and client side I / O handler units (130, 230) provide the user commands from the client device (200). The compressed object data (360) may comprise coefficients of a solution to a partial differential equation. Methods and apparatus are described relating to polygon-based object geometry (510) and pixel-based image files (600) which are transformed and regenerated using coefficients (540, 606) of a solution to a partial differential equation.

Owner:ANTI MATTER GAMES LTD

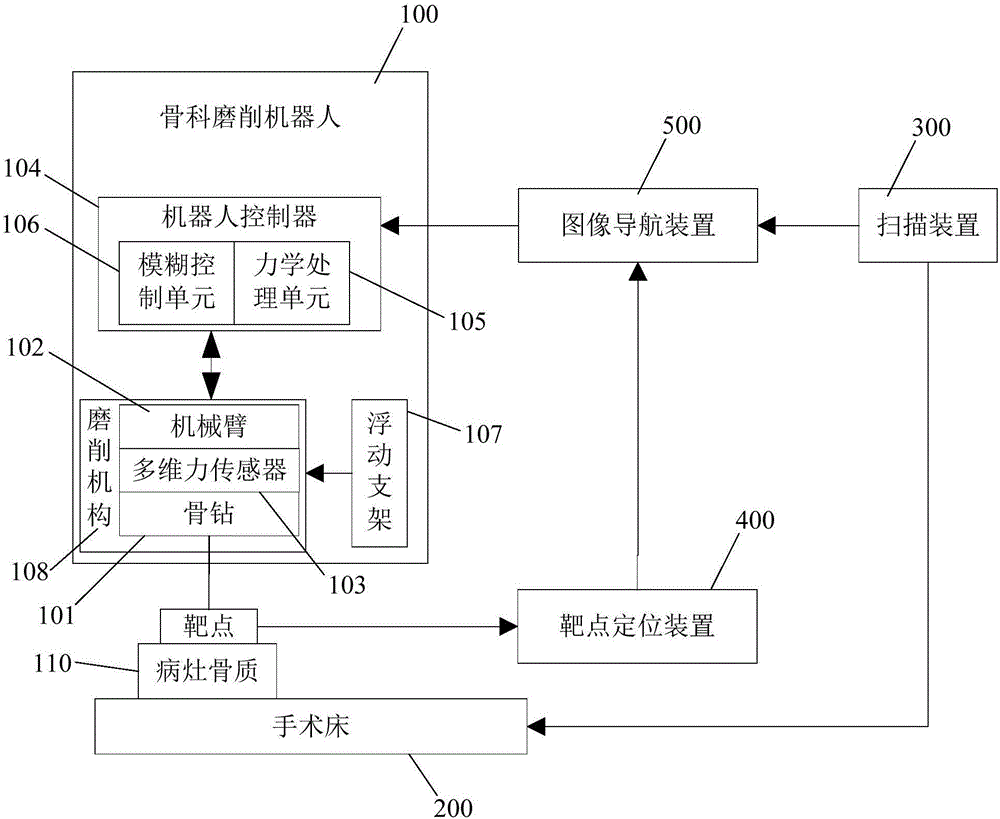

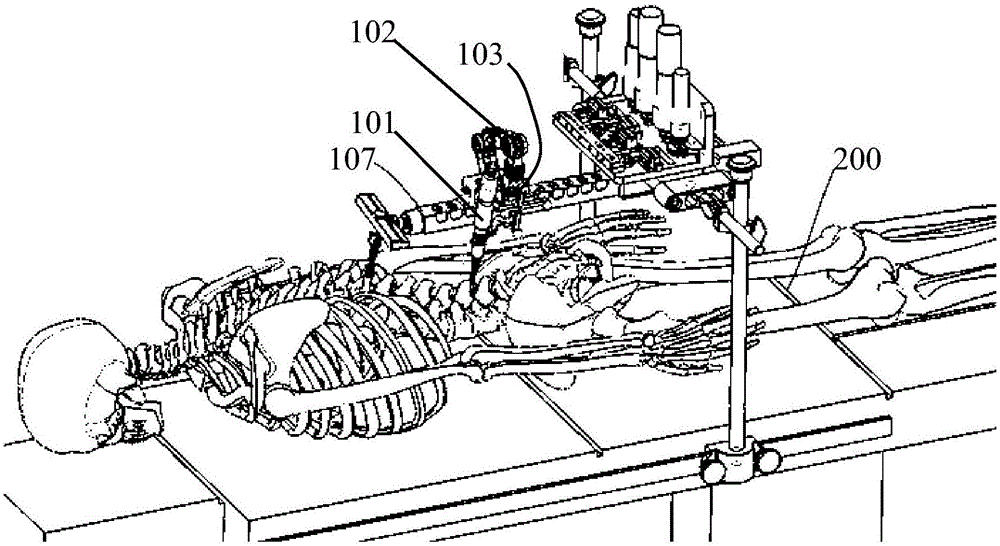

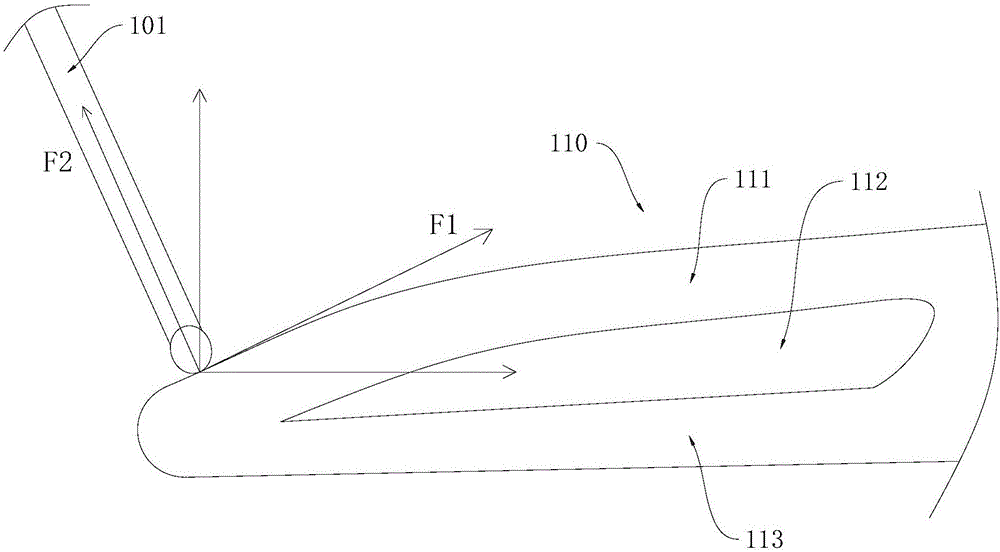

Bone grinding robot, and vertebral plate surgical robot control system and method

InactiveCN106725711AImprove processing speedHigh control precisionSurgical navigation systemsSurgical robotsSurgical robotControl system

The invention discloses a bone grinding robot which comprises a bone drill for grinding a focal bone, a mechanical arm for driving the bone drill to move, a multi-dimensional force sensor for collecting acting force generated by the bone drill during grinding of the focal bone, and a robot controller, wherein the bone drill, the mechanical arm and the multi-dimensional force sensor are electrically connected to the robot controller respectively; the robot controller is used for decomposing the acting force collected by the multi-dimensional sensor into tangential force along the tangent plane of the focal bone and axial force along the axis of the bone drill, controlling the moving posture of the mechanical arm so as to keep the tangential force at a preset value, and obtaining a grinding depth position of the bone drill for the focal bone according to a force value of the axial force. According to the bone grinding robot, the calculation processing process can be simplified, and the grinding depth can be judged, so that the surgical precision is improved, and the surgical accuracy and safety are improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

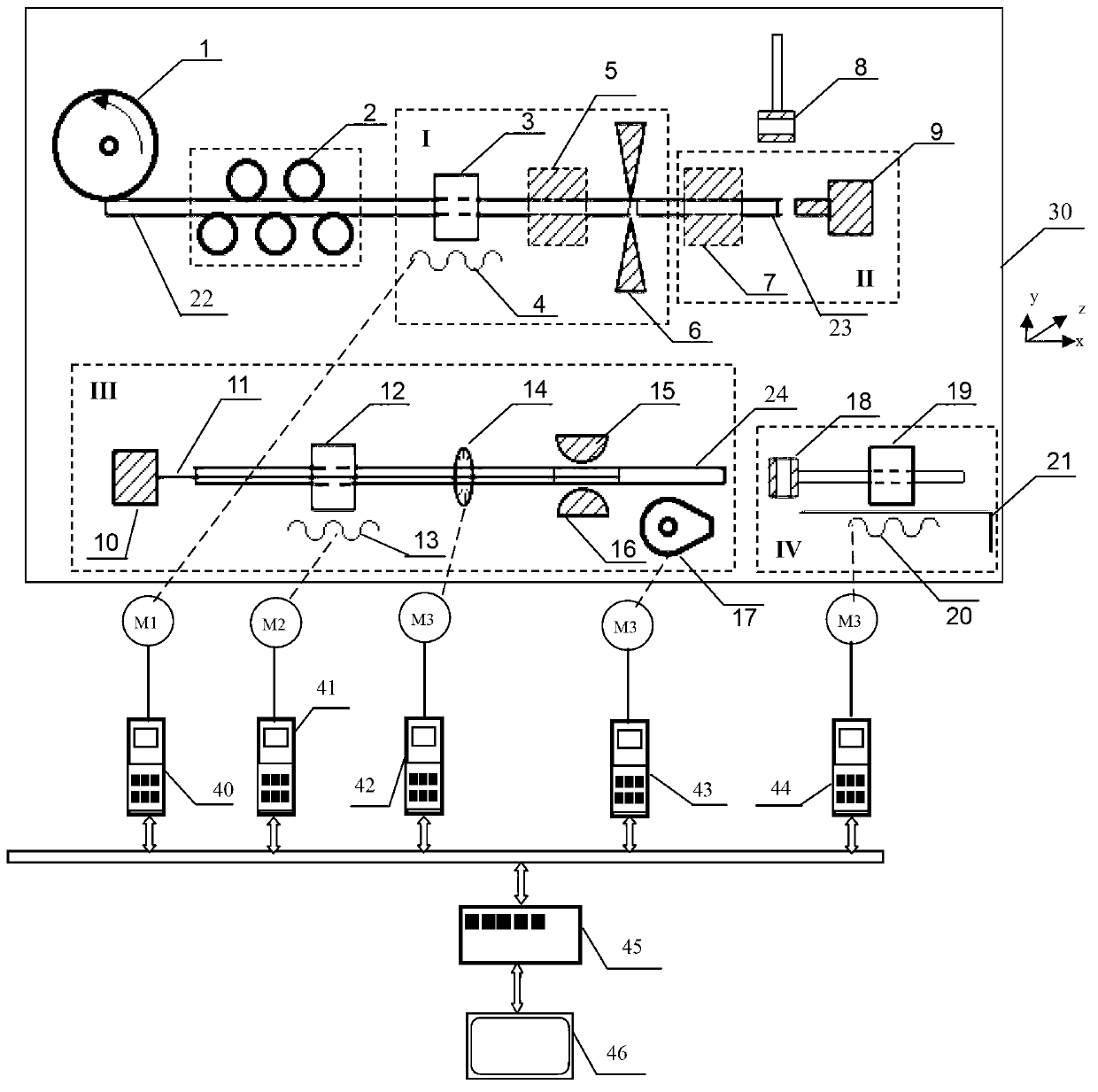

Method for optimization of pipe integrated numerical control machining process

InactiveCN103341521AImprove production efficiencyImprove processing qualityMetal-working feeding devicesStripping-off devicesNumerical controlMotor drive

The invention provides a method for optimization of a pipe integrated numerical control machining process. The method comprises the following steps of rough shape cutting, pipe end molding, bend pipe molding, and split charging and discharging. A controller transmits control signals to servo drivers ((40)-(44)). The servo drivers drive motors (M1-M5) on processing devices and the motors drive the corresponding processing devices to work so that high-precision processing is finished. The method can automatically realize integrated numerical control machining or any combined machining such as pipe rough shape cutting and feeding, chipless rough shape cutting, spinning pipe end molding, bend pipe and manipulator automatic-feeding, three-dimensional bend pipe and manipulator automatic-discharging according to drawing information only by manual introduction of a pipe to a material picking opening of a machine tool, can avoid complex processing adopting multiple machine tools and multiple processing steps, can realize continuous automatic production, can improve production benefits and processing quality of pipe production, and can be used for bending molding processing of pipes used in the industries of air conditioners, water heaters, refrigerators or automobiles.

Owner:WUHAN UNIV OF TECH

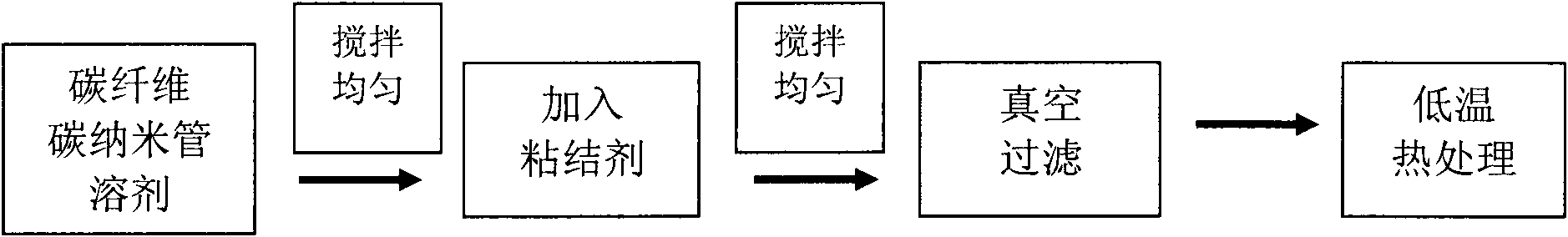

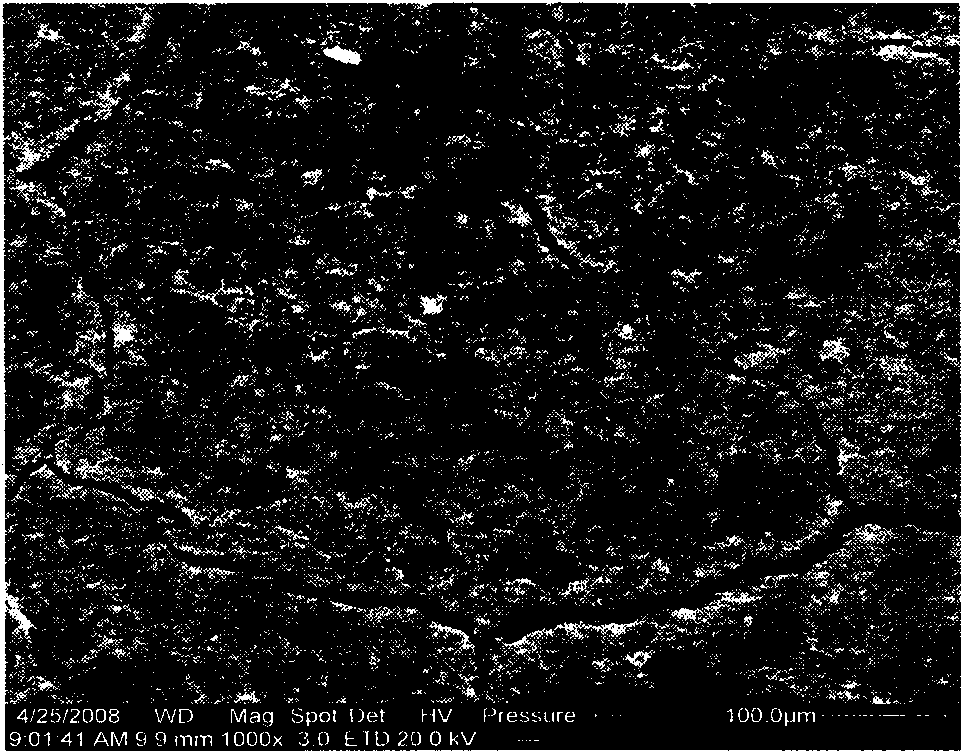

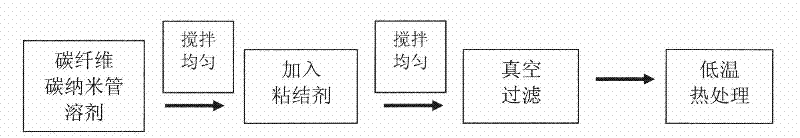

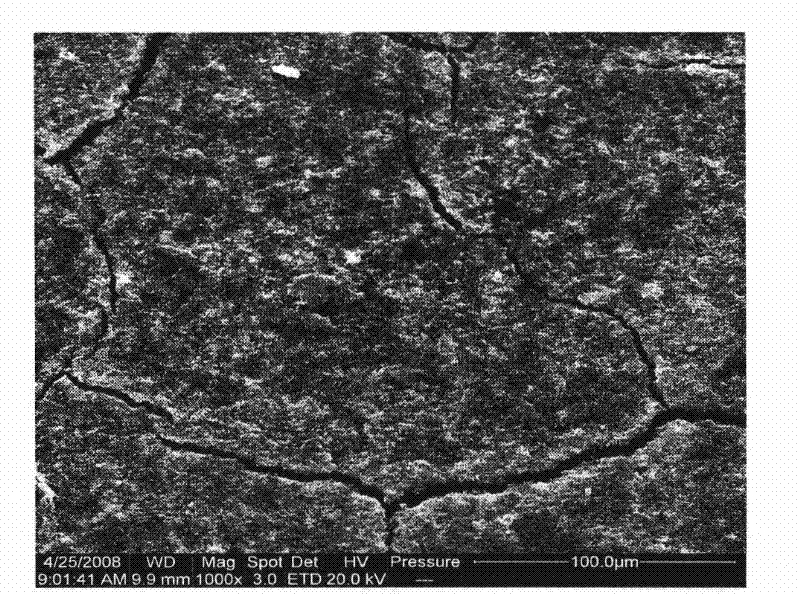

Gas diffusion layer for proton exchange membrane fuel cells and preparation method thereof

ActiveCN101771155ALow electrical resistanceImprove electronic conductivityCell electrodesFinal product manufactureFiberCarbon fibers

The invention relates to a gas diffusion layer for proton exchange membrane fuel cells; the gas diffusion layer is composed of a carbon nano tube, a carbon fiber and a binder and can be directly used as the gas diffusion layer for the proton exchange membrane fuel cells; the preparation process is as follows: a certain amount of the carbon fiber and the carbon nano tube are weighted according to the proportion and are dispersed uniformly in the solvent; and then a certain amount of the binder is added in the mixture and is mixed uniformly to form slurry; and then the slurry is poured into a filter to carry out vacuumizing filtration, so as to obtain a wet type gas diffusion layer; finally, the prepared wet type gas diffusion layer is placed in a calcining furnace for carrying out heat treatment. The gas diffusion layer in the invention has good electrical conductivity and mass transfer property, can be directly used as the gas diffusion layer for the proton exchange membrane fuel cells, so as to avoid complex treatment process when commodity carbon paper is used; the gas diffusion layer prepared by the method has the advantages of low raw material price, easily-obtaining raw material, simple technology process and controllable thickness / shape, thereby being suitable for mass production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

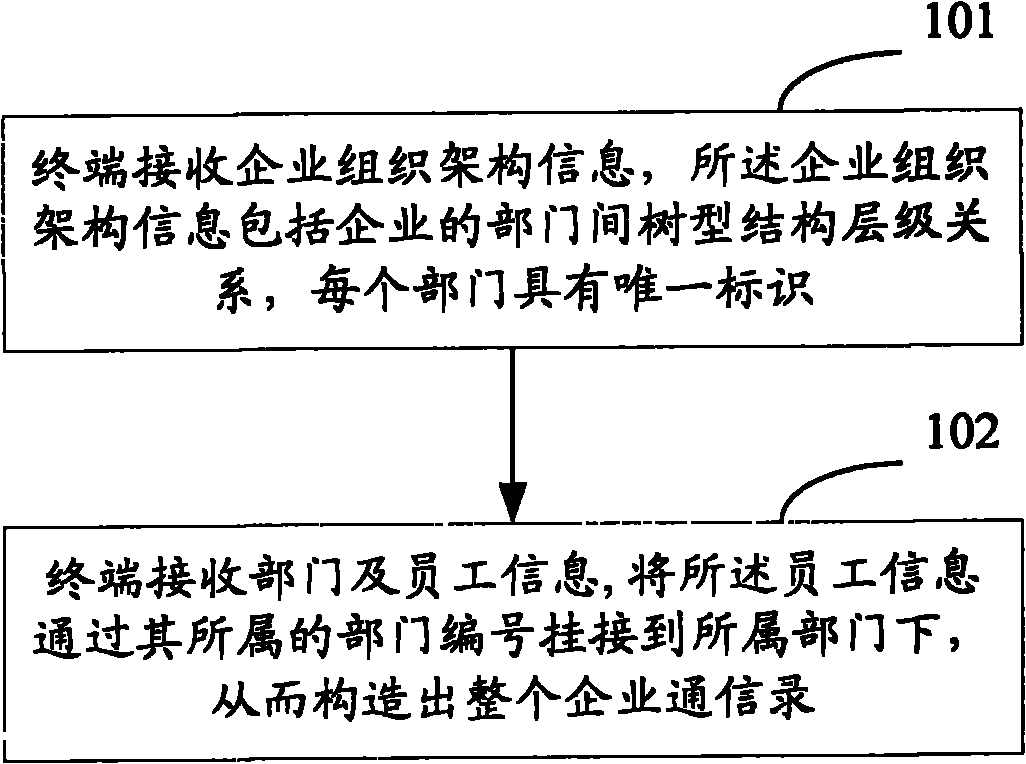

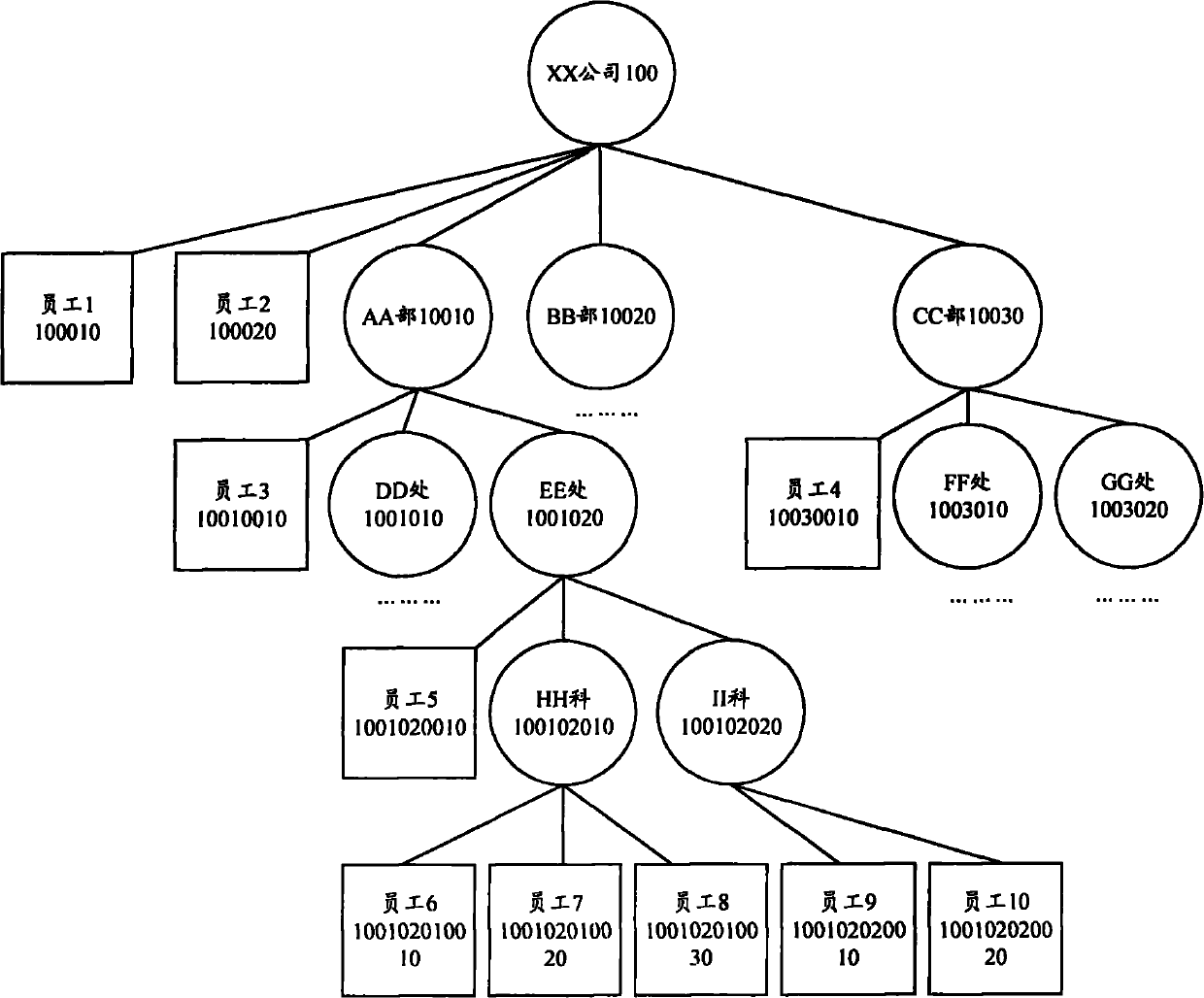

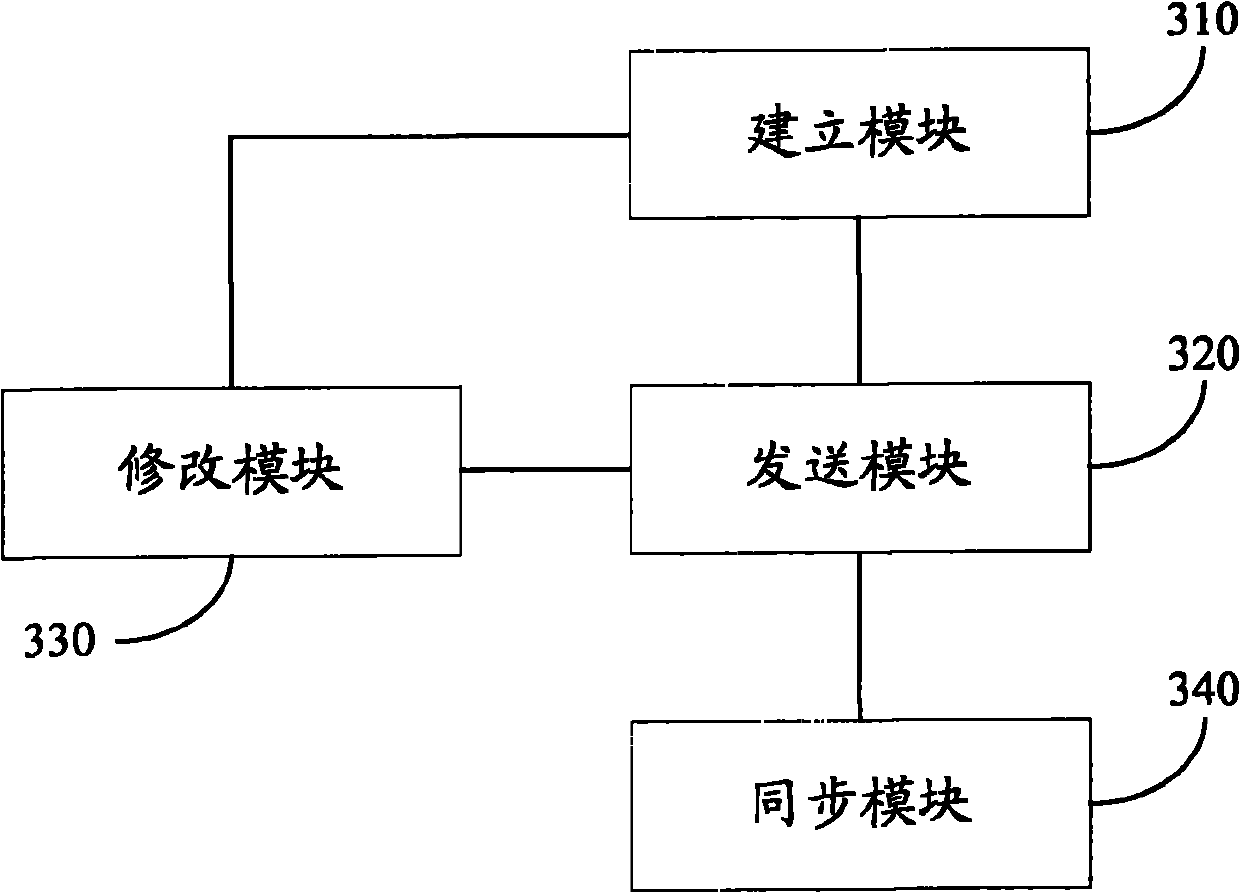

Method, system and device for sharing enterprise address book

The embodiment of invention discloses a method for sharing an address book, comprising the following steps that: a terminal receives enterprise organizational structure information transmitted by a server, wherein the enterprise organizational structure information comprises the hierarchical relationship of a tree structure among departments of the enterprise and each department is provided a unique identification; the terminal receives information of the departments and staff of the server, wherein the department information is correlated to each department in the enterprise organizational structure through serial number of the departments; and the information of the staff is hung and connected to the subsidiary department through serial numbers of the departments, thereby the whole enterprise address book is constructed. In the invention, a method for conveniently searching and dialing numbers of the staff in the enterprise can be provided, which avoids the trouble for searching the enterprise address book by logging on the internet.

Owner:CHINA MOBILE COMM GRP CO LTD

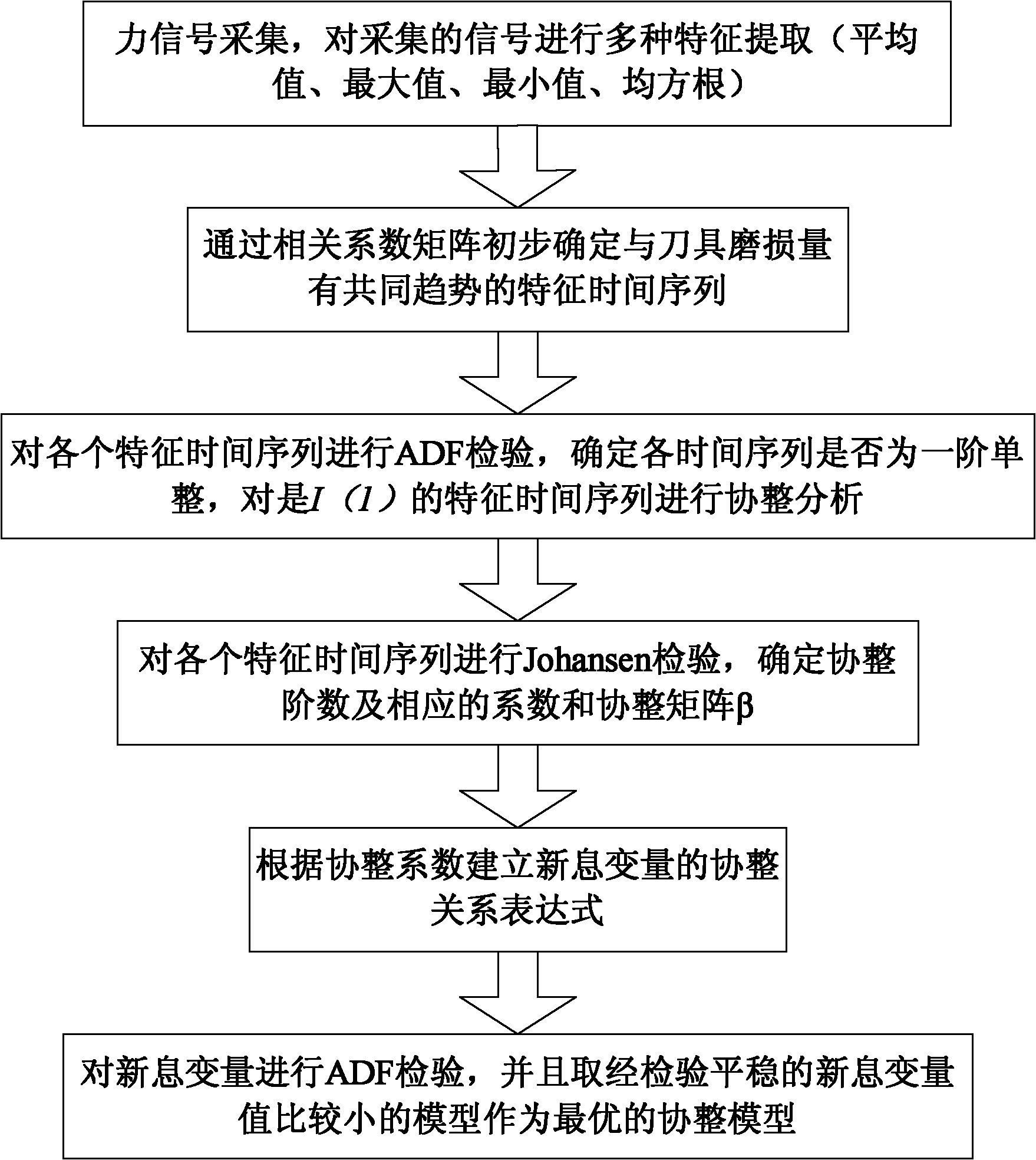

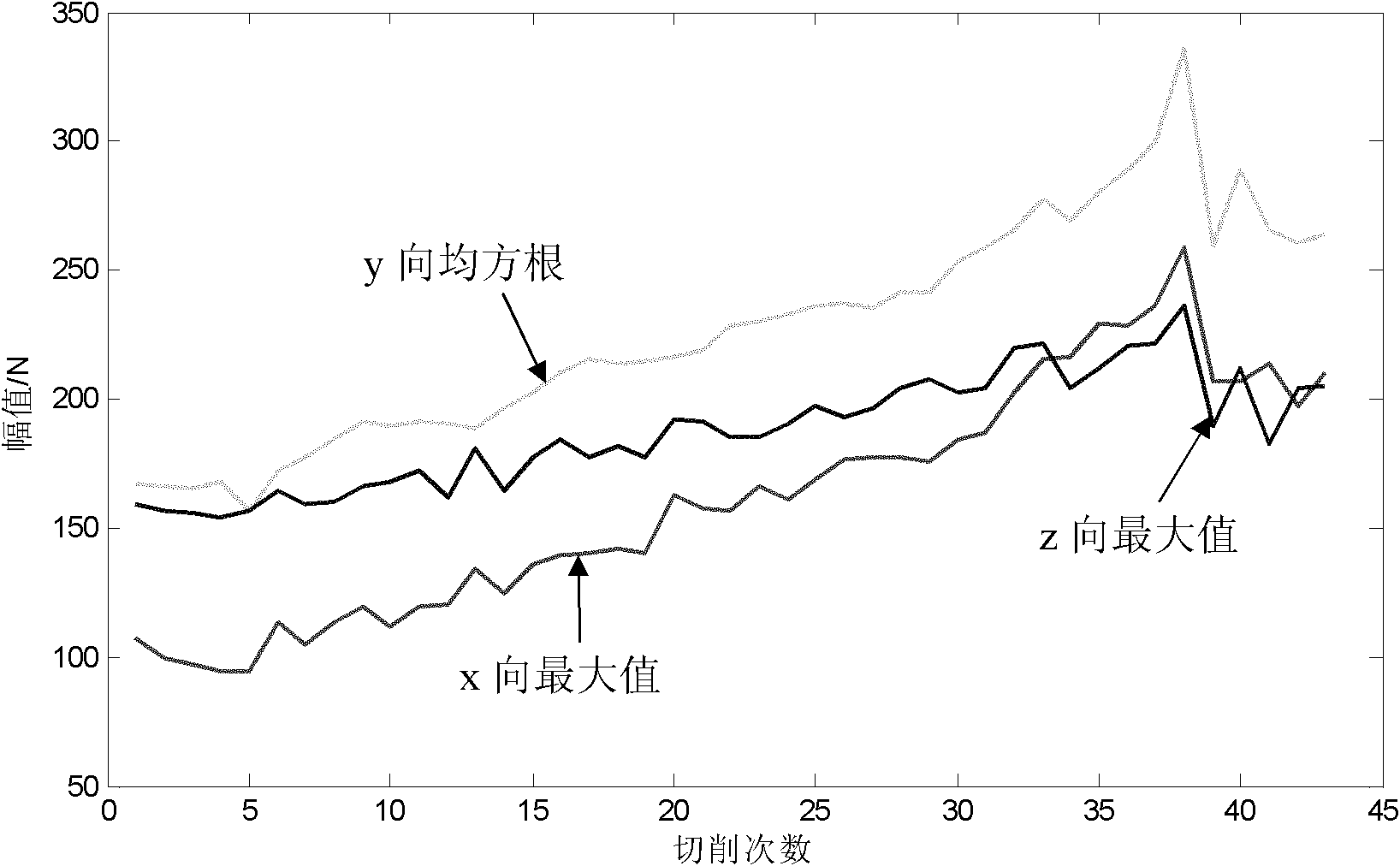

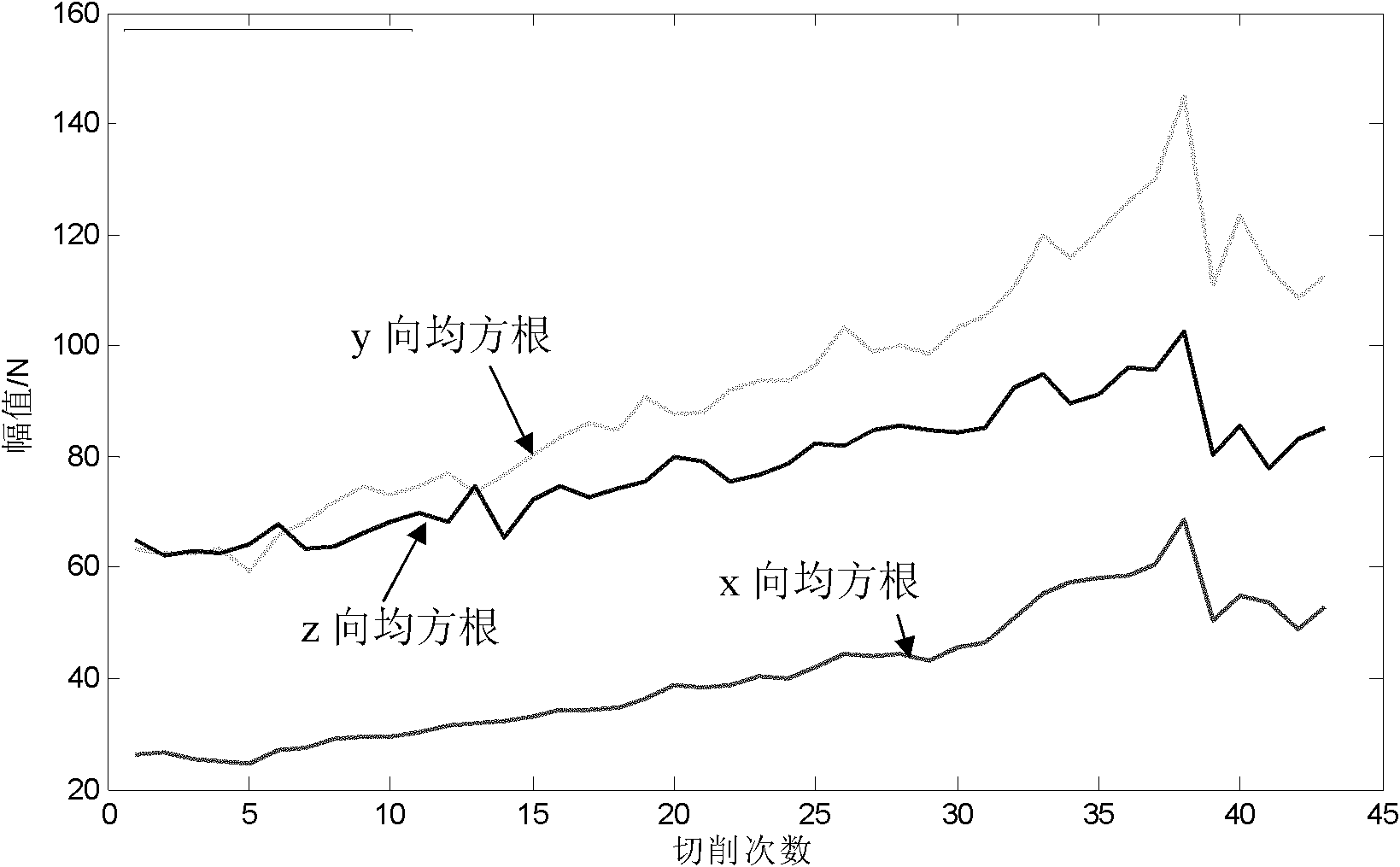

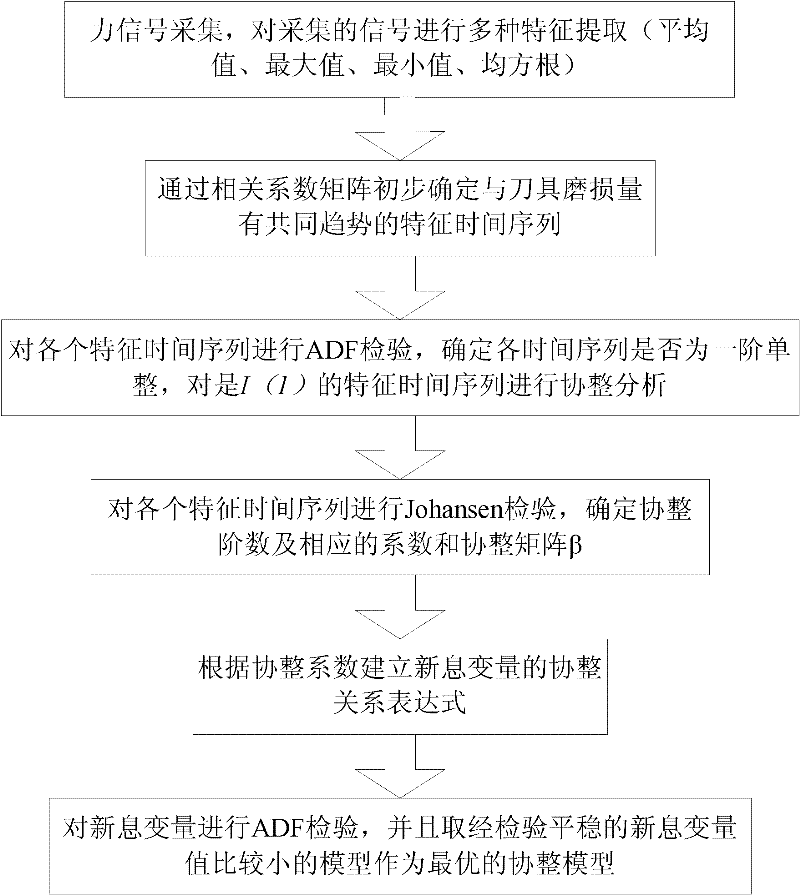

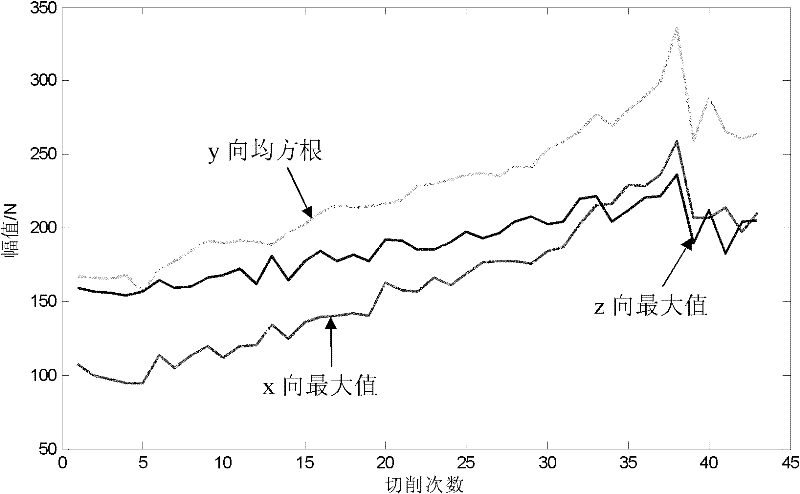

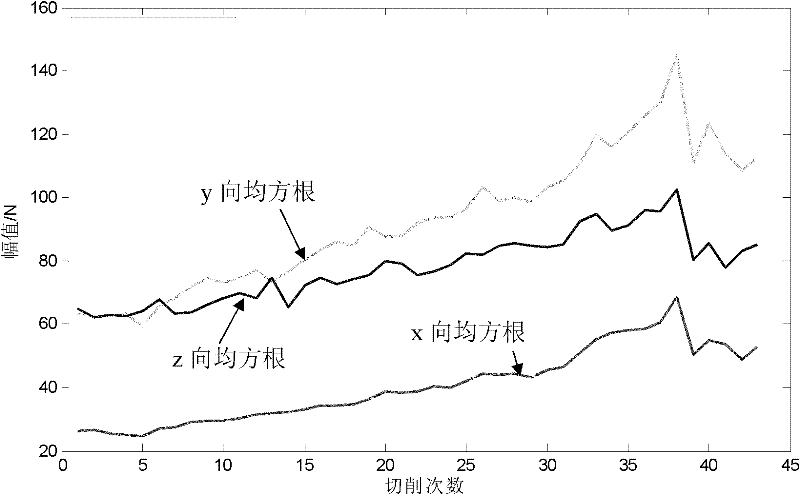

Cutter abrasion monitoring method based on co-integration modeling

ActiveCN102152172AAccurate predictionAvoid complex processingMeasurement/indication equipmentsEngineeringCutting force

The invention relates to a cutter abrasion monitoring method based on co-integration modeling. The cutter abrasion monitoring method comprises the steps of: extracting a plurality of characteristics of a cutting force signal by means of a cutter cutting experiment; primarily selecting characteristic time sequences with the same trend with a cutter in abrasion loss by using a coorelation coefficient matrix; carrying out an ADF (Augmented Dickey-Fuller) test on each selected characteristic time sequence to judge whether the selected characteristic time sequences are I (1); carrying out co-integration analysis under the condition of guaranteeing that all the selected characteristic time sequences are I (1); solving characteristic values and a co-integration matrix beta; then carrying out Johansen test so as to determine a co-integration order r and related co-integration coefficients; establishing a co-integration relational expression of innovation variables according to the co-integration coefficients; determining an optimal co-integration model by comparing calculated values of the expression; carrying out ADF test on the determined innovation variables; and if the innovation variables are stable, judging that the established co-integration model is correct, and further predicting the abrasion loss of the cutter by using the model. By means of the cutter abrasion monitoring method, the abrasion state of the cutter can be monitored accurately so as to reduce the dimensional deviation of a processed workpiece, caused by the cutter abrasion.

Owner:TIANJIN UNIV

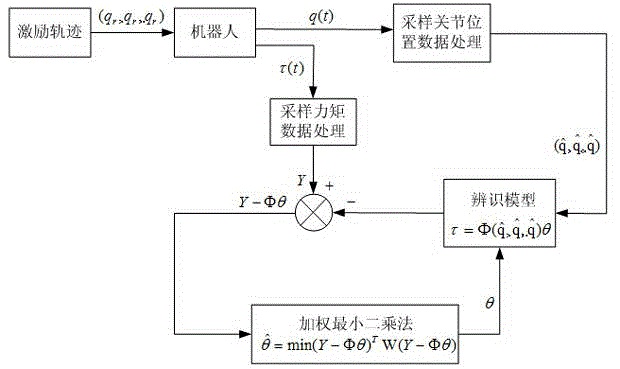

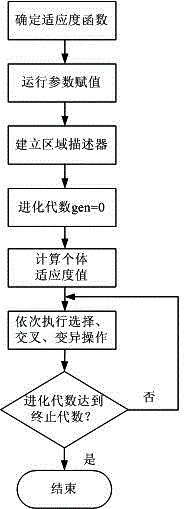

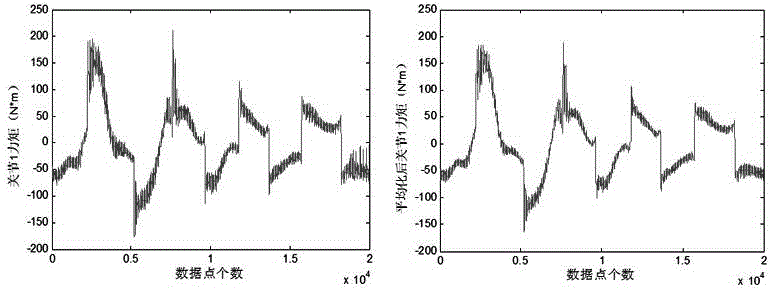

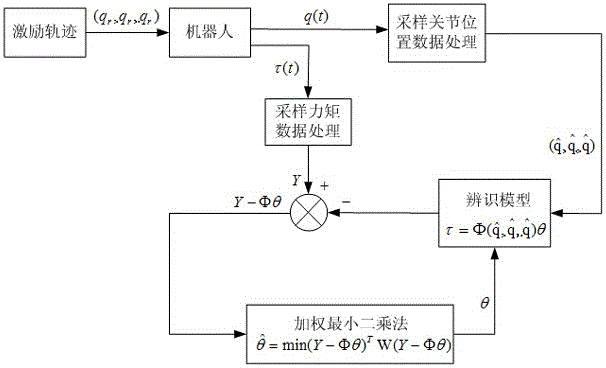

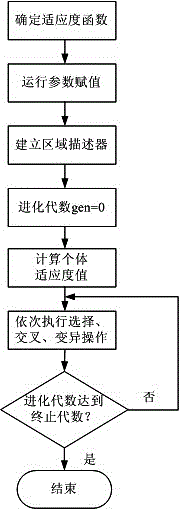

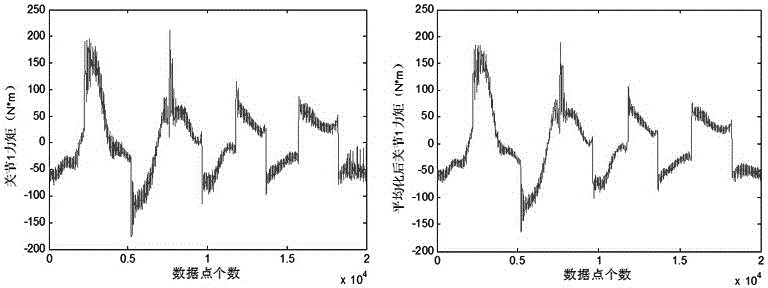

Method for improving robot parameter identification accuracy

ActiveCN104614991ARemove noise signalImprove optimization efficiencyAdaptive controlSignal-to-noise ratio (imaging)Genetic algorithm

The invention discloses a method for improving robot parameter identification accuracy and belongs to the field of industrial robot control. The method comprises optimizing stimulation trajectories through a genetic algorithm; stimulate a robot to perform cyclical movement according to the optimized stimulation trajectories; sampling actual joint positions and actual torque data during moving and processing the data to obtain torque values, joint positions, joint speeds and joint accelerated speeds which are high in signal to noise ratio; establishing a dynamic linear model, and identifying all parameters related to joint dynamics through a weighted least square method. By the aid of the method, the actual trajectory Fourier series form is fit through an inverse method, and accordingly, speeds and accelerated speeds which cannot be obtained directly in experiments can be obtained conveniently, noise signals in sampling position signals and torque signals can be eliminated through an equalization method, the signal to noise ratio is improved and the robot parameter identification accuracy is improved.

Owner:NANJING ESTUN ROBOTICS CO LTD

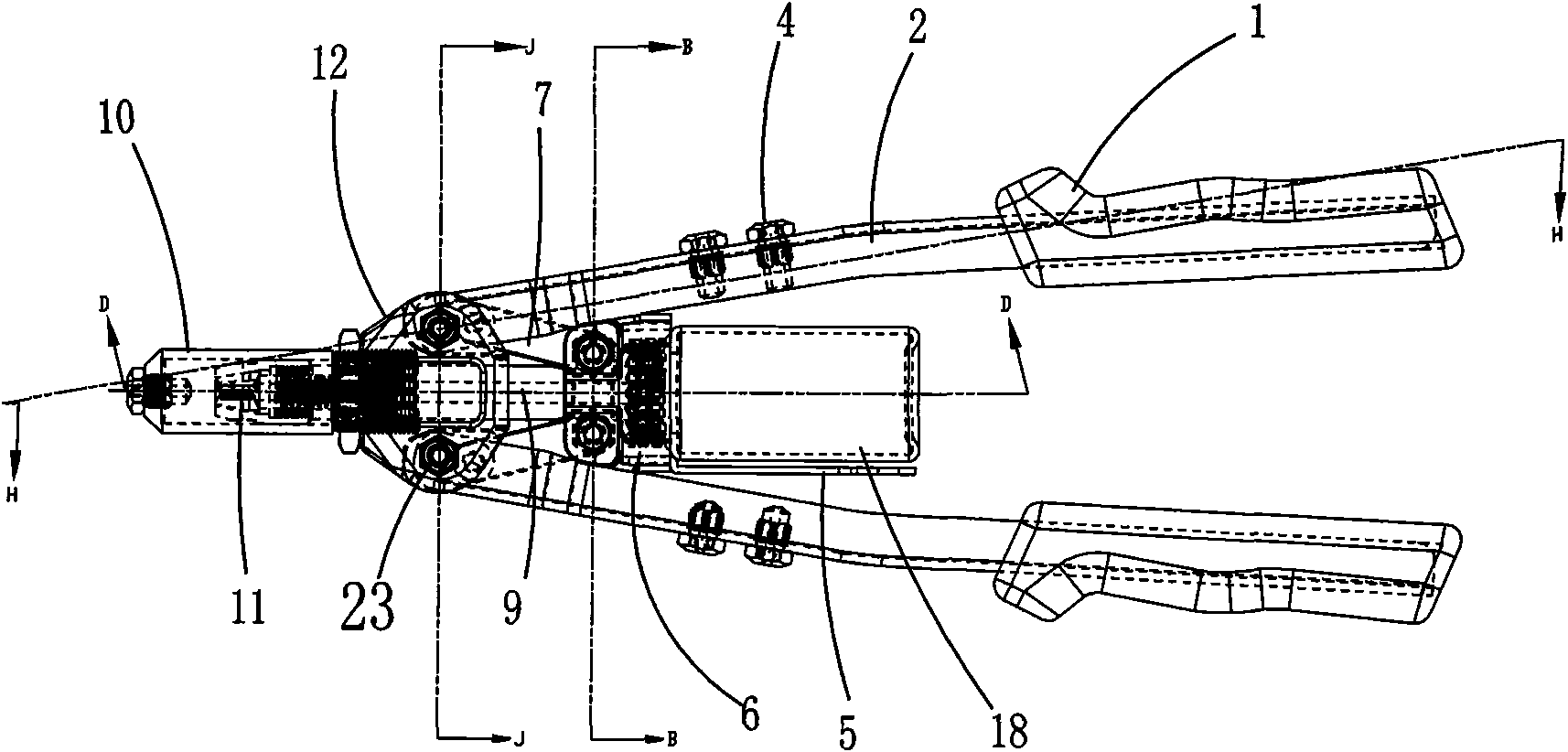

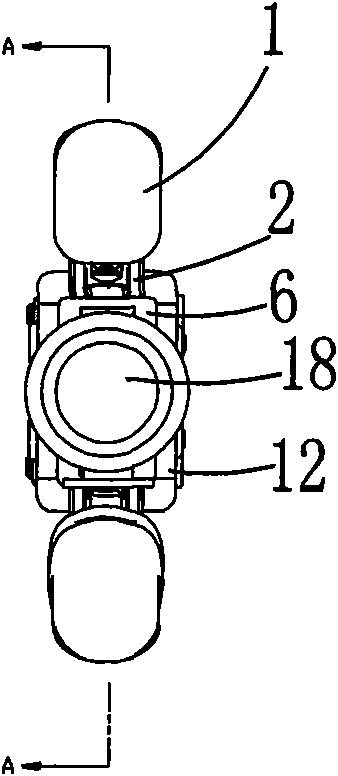

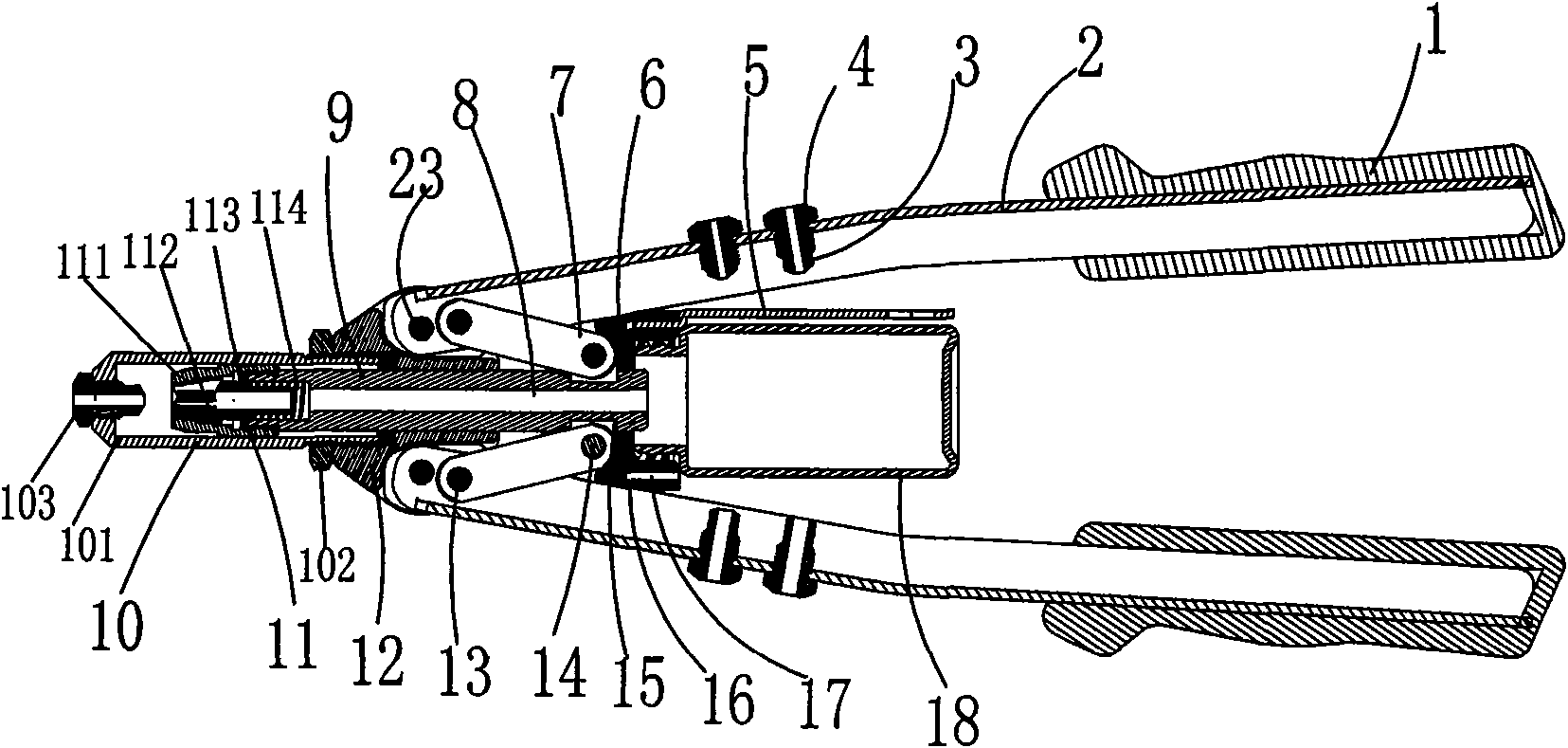

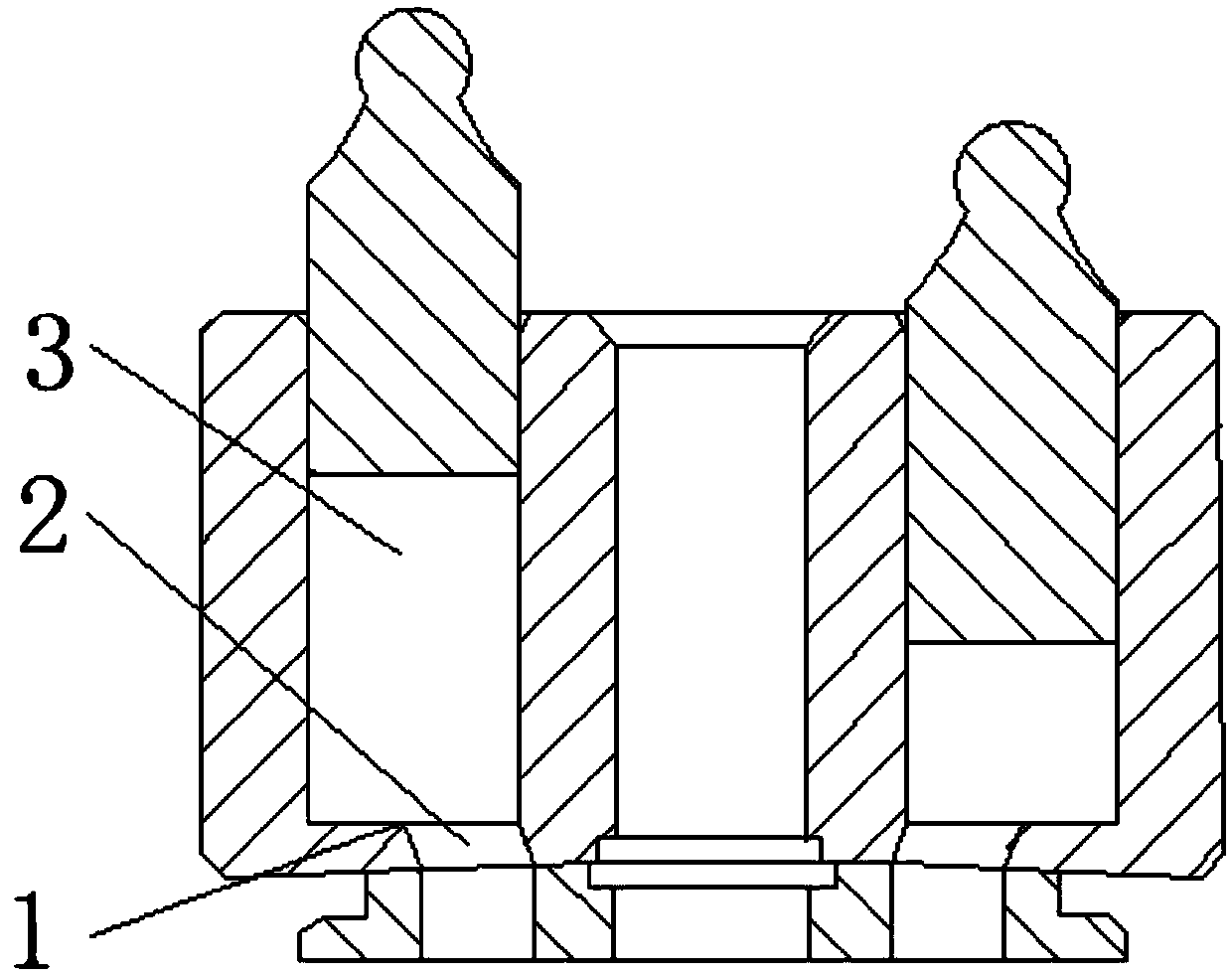

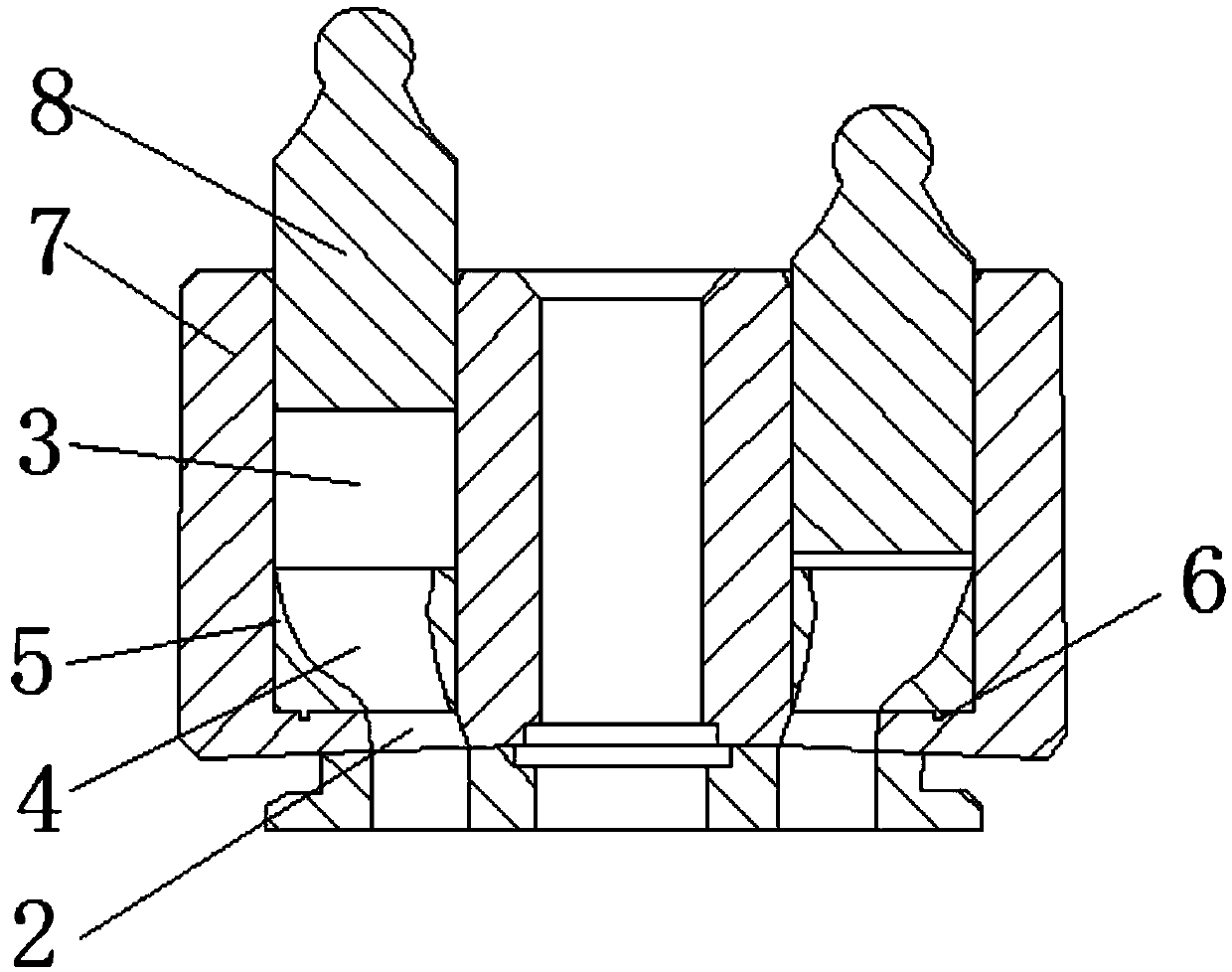

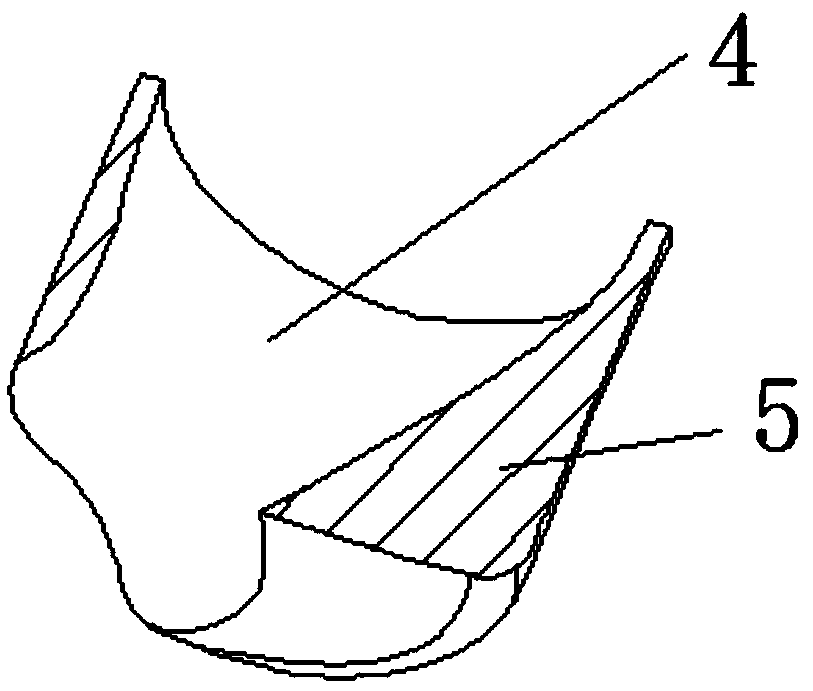

Double handle hand riveter

The invention discloses a double handle hand riveter comprising a riveter base, a regulating mechanism, a riveter holding mechanism, one end of which is hinged with two handles on both sides of the riveter base and a tie bar in a central hole of the riveter base, characterized in that rear end of the tie bar is provided with a fixed groove embedded with a fixed piece, both sides of which are respectively connected with the handles via a connecting rod; one end of the collecting rod is connected with the fixed piece via a second screw shaft and the other end is hinged with the handle. Handle matching grooves are arranged on both sides of the base. The handles are respectively hinged with the riveter base via a first screw shaft in the handle matching groove. The connecting rod is hinged with the handle via a pin rod. The hand riveter can be handle screw by replacing riveter holding mechanism with a screw holding mechanism. Manufacturing process of the fixed groove, the tie bar and the fixed piece on the tie bar is simple and reduces cost. Due to rational connection among the collecting rod, the handle and the riveter base, volume of the invention is reduced.

Owner:袁建明

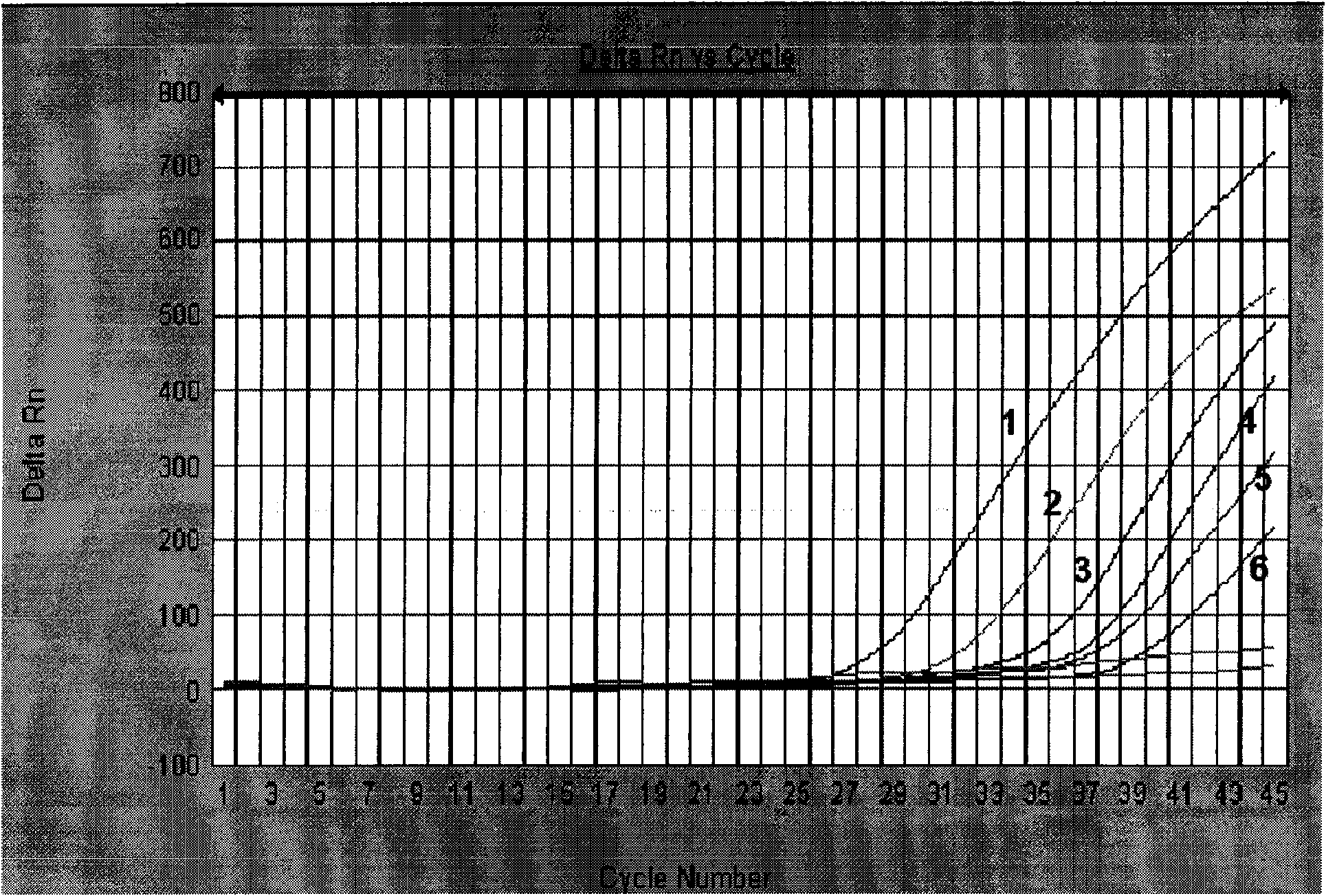

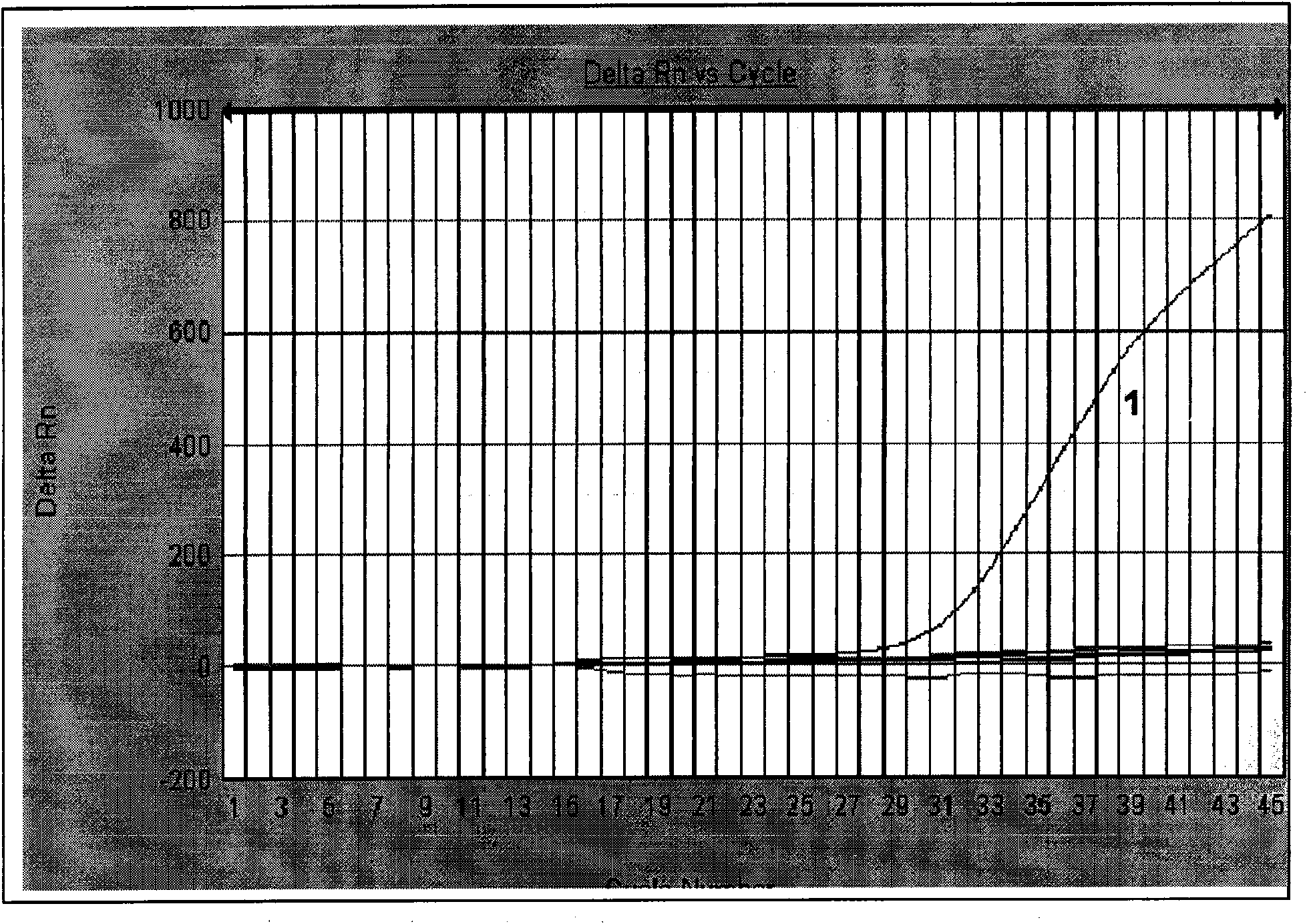

Method for detecting allergen filbert component in foods by fluorescent PCR technology

InactiveCN101643787AAvoid complex processingReduce distractionsMicrobiological testing/measurementFluorescence/phosphorescenceBiologyArachis hypogaea

The invention discloses a method for detecting an allergen filbert component in foods by a fluorescent PCR technology, belonging to allergen detecting technologies, in particular a method for detecting an allergen filbert component in foods by an exonuclease probe fluorescent PCR technology (TaqMan). Aiming at an allergen almond component rCor a 1.0401 DNA sequence a primer and a TaqMan probe aredesigned, the fluorescent PCR detecting method is established. The method includes the designed primer and the probe of the filbert component specificity, and the fluorescent PCR reaction condition matched with the primer and the probe. The method has no cross reaction with peanuts, buckwheat, chestnuts, pine nuts, macadamia nuts, walnuts, and the like and has favorable specificity; and the detecting sensitivity can reach 5mg / kg. The method can be used for detecting the allergen in the foods and preventing anaphylactic reaction caused by the foods and has practical meanings.

Owner:ANIMAL & PLANT & FOOD INSPECTION CENT OF TIANJIN ENTRY EXIT INSPECTION & QUARANTINE BUREAU

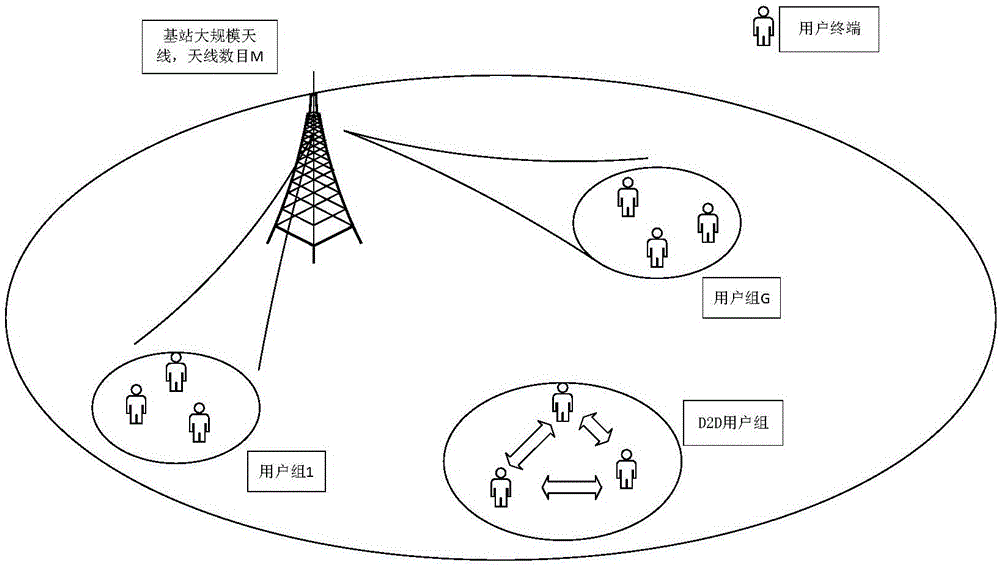

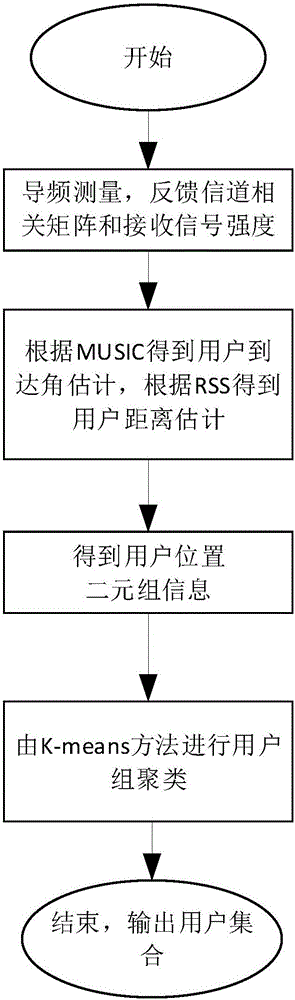

Channel correlation-based user group partition method under D2D

ActiveCN105848097AInterference coordinationSuitable for proximity needsSpatial transmit diversityWireless commuication servicesMultiple signal classificationTwo step

The invention discloses a channel correlation-based user group partition method under D2D. The method comprises the following steps: (1) enabling users to measure a pilot frequency transmitted by a base station, and feeding back channel correlation matrixes and receiving signal intensities by means of an uplink; (2) obtaining the estimated positions of all the users according to an MUSIC (multiple-signal-classification) method and an RSS (receive-signal-strength) method, and adopting a binary group to indicate user positions; (3) carrying out clustering processing on the user by using a K-means method. The user group partition method provided by the invention can complete the partition of a two-step pre-coded user group of a cellular network and the discovery of a D2D cluster at the same time by utilizing cellular channel correlation matrix information, thus avoiding a complicated operation of directly utilizing channel correlation information to process medium and high-dimension matrix subspace division and projection; the method has the characteristics of being simple and efficient.

Owner:HUAZHONG UNIV OF SCI & TECH

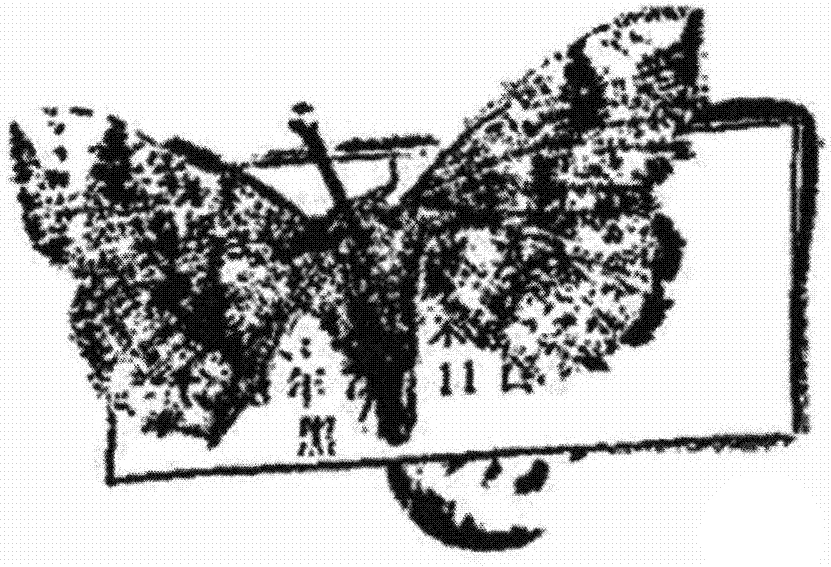

CNN-based automatic identification method of lepidopteron types

InactiveCN107292314AScale invariantRepresentativeCharacter and pattern recognitionFault toleranceMinimum bounding box

The invention relates to a CNN-based automatic identification method of lepidopteron types. During preprocessing, background removing is carried out on a collected insect specimen image; a minimum bounding box of a foreground image is calculated; and an effective foreground area is obtained by cutting out. Feature extraction is carried out by using an Imagenet pre-training depth learning neural network model. And classification and identification are carried out based on two kinds of conditions; when samples are sufficient, parameters of a DCNN classification layer are trained based on a fine tuning network structure, thereby realizing end-to-end classification and identification; and when a sample data set is small and insufficient samples are provided for training DCNN parameters, an X<2> kernel SVM classifier for a small sample set is used for realizing classification and identification. The automatic identification method has advantages of simple operation, high identification precision, high fault tolerance, good time performance and the capability of improving lepidopteron type identification obviously.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

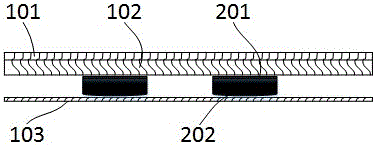

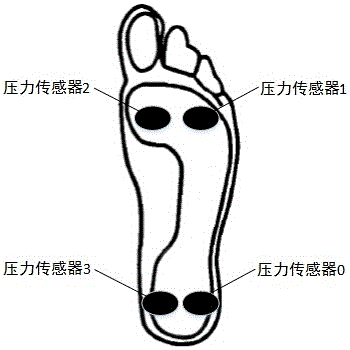

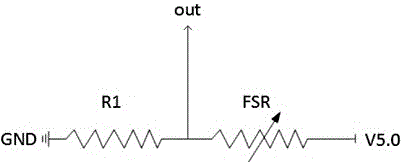

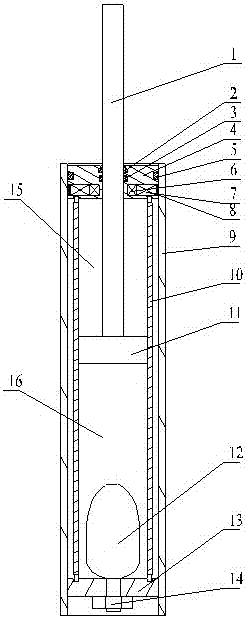

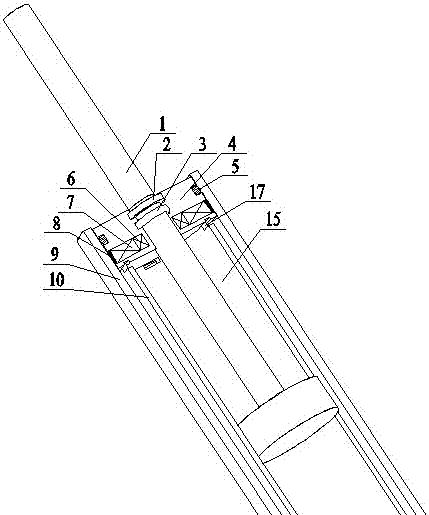

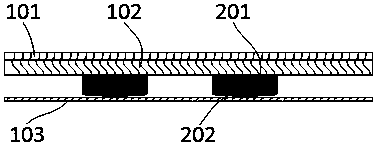

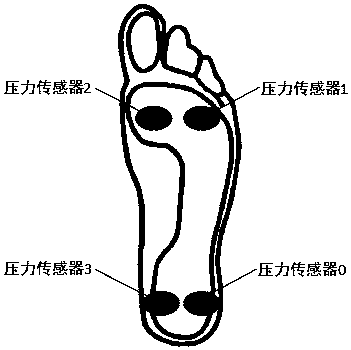

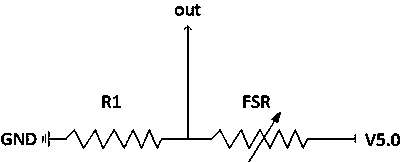

Plantar pressure measuring device and method for exoskeleton control

ActiveCN105662419AReduce usageAvoid complex processingProgramme-controlled manipulatorDiagnostic signal processingAnkle boneEngineering

The invention discloses a plantar pressure measuring device and method for exoskeleton control. The device comprises a measuring device pressure shoe; four pressure sensors (202) are arranged inside the measuring device pressure shoe respectively at positions corresponding to metatarsal bones and ankle bones and generate micro weak electrical signals; a central processing unit acquires and processes the micro weak electrical signals; exoskeleton plantar pressure is measured by adopting a method of different weights aiming at different pressure sensor data in different modes. The plantar pressure measuring device and method disclosed by the invention have the benefits that the exoskeleton plantar pressure at a main forced part is acquired by utilizing the four thin film pressure sensors at a sole, so that the use of a large amount of sensors is avoided, the structure is simple, and the cost is low; the different modes when a wearer wear exoskeletons to stand and walk are divided, different processing is performed aiming at the data in the different modes, an algorithm is simple, the complicated processing of the data when a large amount of sensors are used is avoided, and the processing speed of the data is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Double-cylinder type magneto-rheological damper with inner and outer coils

ActiveCN107314077ASimple structureLow processing and assembly costsSpringsNon-rotating vibration suppressionEngineeringMagneto rheological damper

The invention discloses a double-cylinder type magneto-rheological damper with inner and outer coils. The double-cylinder type magneto-rheological damper comprises a piston rod, a piston, an inner cylinder barrel, an outer cylinder barrel, an end cover, a dustproof ring, the inner coil, the outer coil, a coil protective layer, a compensation air bag, a bottom locating piece and a nut, wherein the piston rod is tightly connected with the piston; the piston is positioned in the inner cylinder barrel; the inner cylinder barrel is fixed with the bottom locating piece through the end cover; the bottom locating piece is tightly connected with the outer cylinder barrel; a through hole is formed in the middle of the bottom locating piece and used for compensating for an air bag valve port so as to enable the air bag valve port to extend out of the damper; the compensation air bag is mounted at the bottom of the inner cylinder barrel; the end cover is tightly connected with the outer cylinder barrel; the inner coil and the outer coil are wound on the end cover; the dustproof ring is mounted at the top of the inner hole of the end cover; and an end part groove is formed in the part below the end cover. The double-cylinder type magneto-rheological damper with inner and outer coils has the benefits as follows: the structure is simple, the processing and manufacturing are convenient, the cost is low, the damping force of the damper is adjusted, the inner coil has a sealing function, and the sealing performance is good.

Owner:YANCHENG BUGAO AUTO PARTS MFG CO LTD

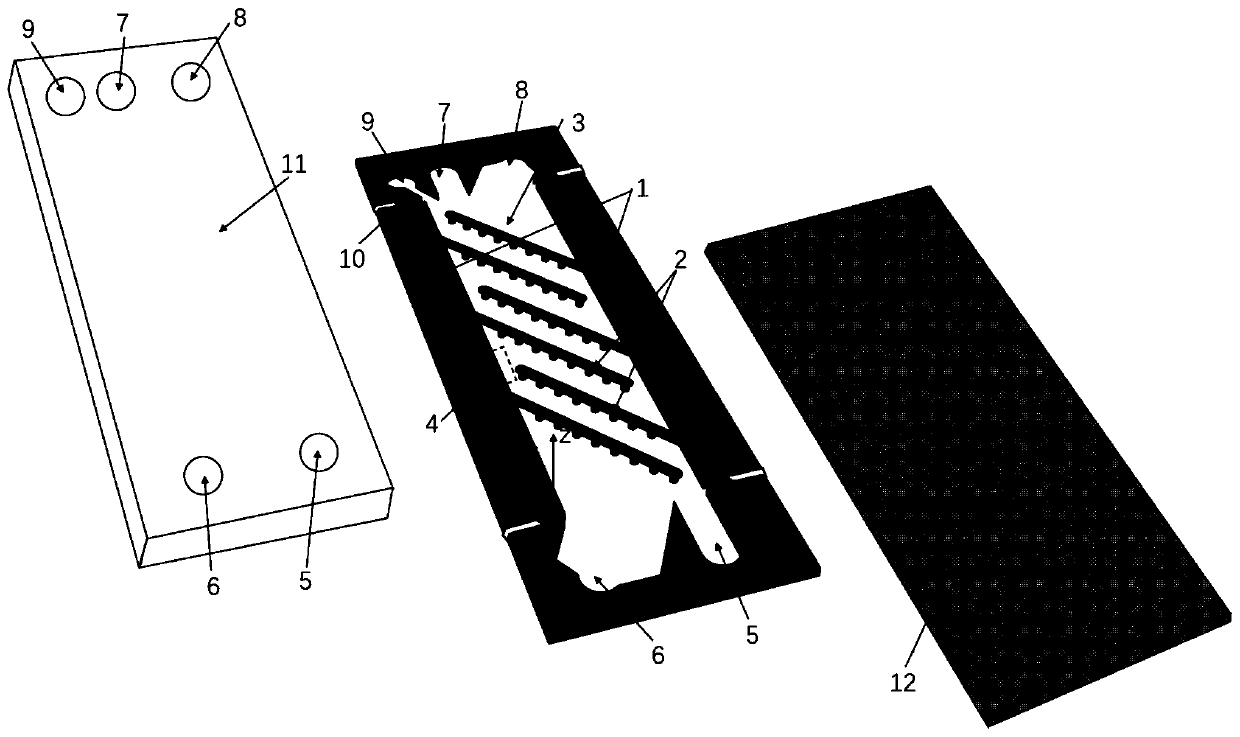

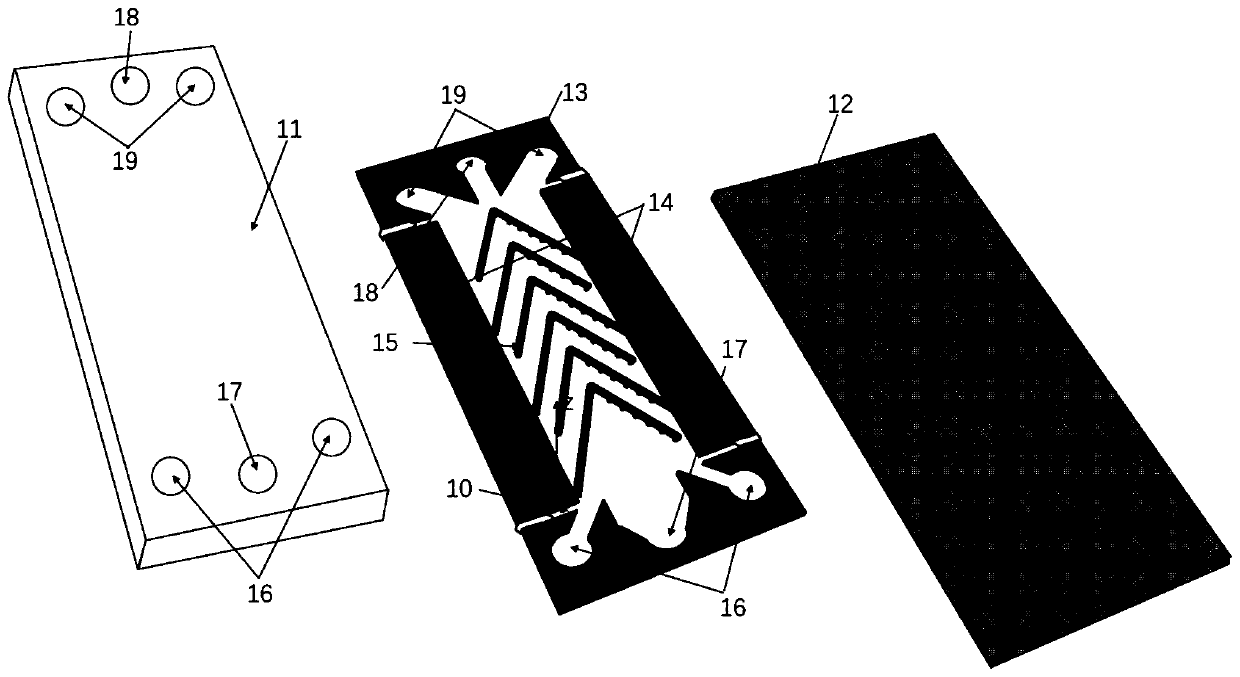

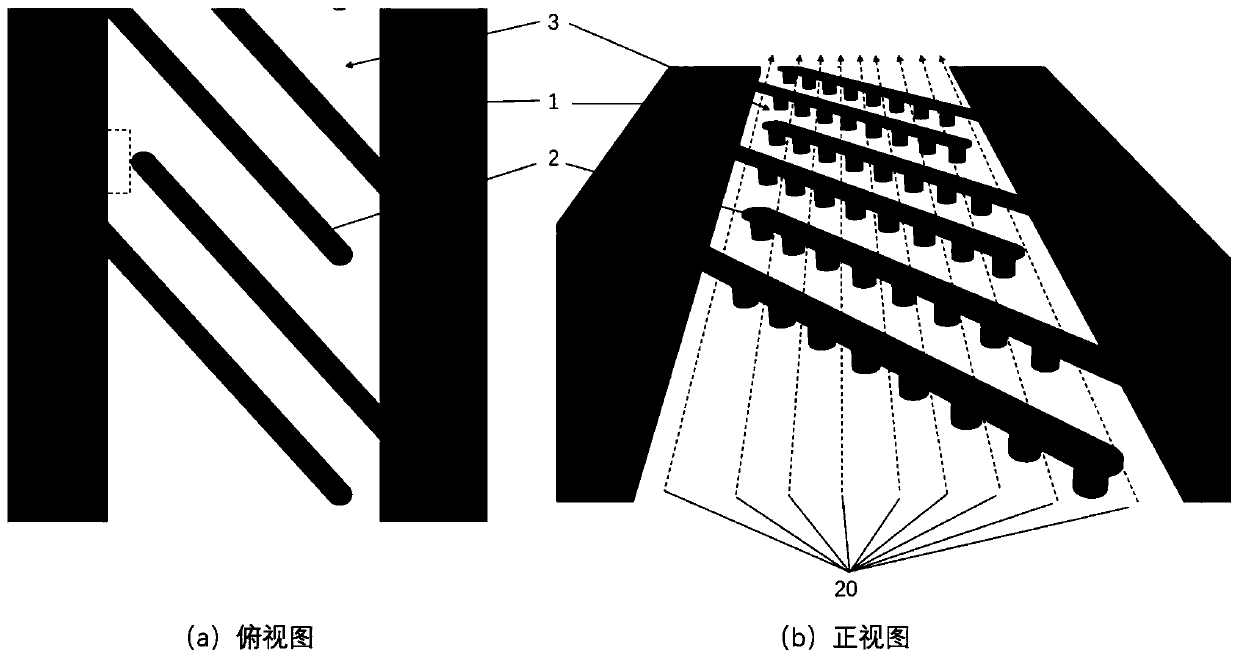

Slide rail type dielectrophoresis electrode structure for high-throughput continuous flow cell separation

ActiveCN110628568AImprove work efficiencyEnables three-dimensional control and separationBioreactor/fermenter combinationsBiological substance pretreatmentsMicro fluidicMicrofluidic chip

The invention discloses a slide rail type dielectrophoresis electrode structure for high-throughput continuous flow cell separation and belongs to the technical field of micro-fluidic chips. The structure comprises an interdigital electrode array formed by slide rail type electrodes which form an inclination angle alpha with a main runner and cross the main runner, a pair of main electrode which alternately extend to be interdigital and located on two sides of the main runner, parallel sub-runners formed by dividing the main runner by non-uniform side wall structures of the interdigital electrodes, an insulating groove and an inlet / outlet of a sample. The slide rail electrodes with non-uniform side wall structures are placed in the main runner at a certain inclination angle, so that cellsslide along two side walls of a slide layer under the action of dielectrophoresis force and drag force of fluid and enter a migration outlet, and continuous separation of cells is realized. Besides, by changing one-way slide rail type electrodes into two-way V-shaped slide rail type electrodes, the throughput is further improved while continuous cell separation is realized.

Owner:BEIJING UNIV OF CHEM TECH

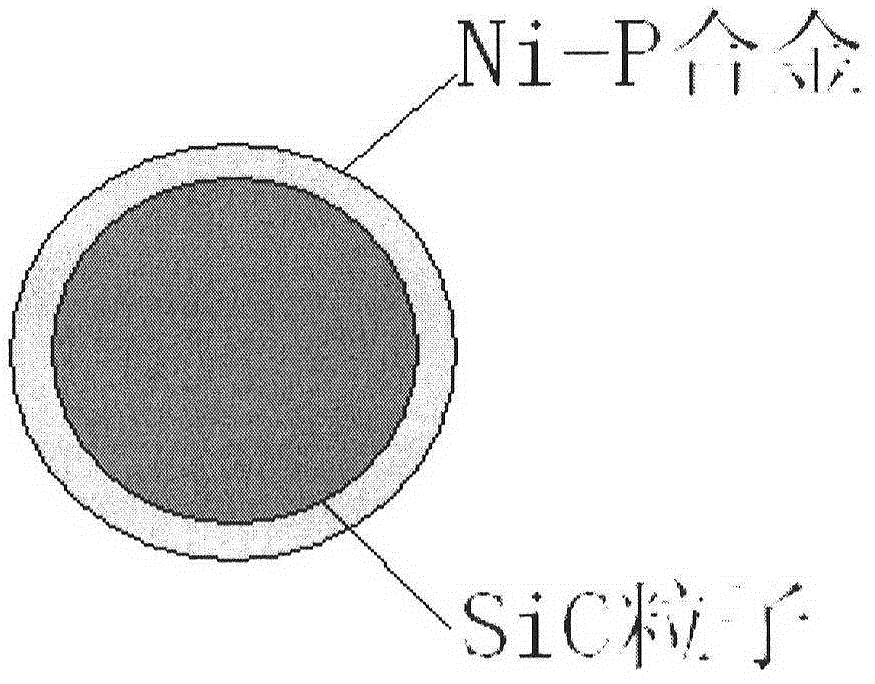

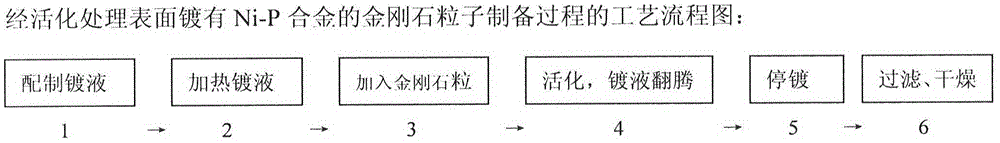

Method for chemically plating Ni-P alloy on surfaces of diamond particles

InactiveCN104694912AGood effectAvoid complex processingLiquid/solution decomposition chemical coatingWater bathsMetal matrix composite

The invention discloses a method for chemically plating a Ni-P alloy on surfaces of diamond particles. The method for chemically plating the Ni-P alloy on the surfaces of the diamond particles comprises the following steps: directly adding weighed diamond particles into a chemically plating Ni-P alloy solution; using a glass rod which is plated with the alloy for inducing and activating a chemically plating solution in a constant temperature water bath; or adding iron pieces which are plated with the alloy for the induction and the activation until occurring a boiling phenomenon; finishing the plating; obtaining the diamond particles plated with the Ni-P alloy element layer by means of precipitating, filtering, drying, and the like. The particles can be used as particle reinforcements for preparing metal-base composite materials. Meanwhile, the particles are a basic raw material for preparing engineering materials and functional materials.

Owner:QINGDAO UNIV OF SCI & TECH

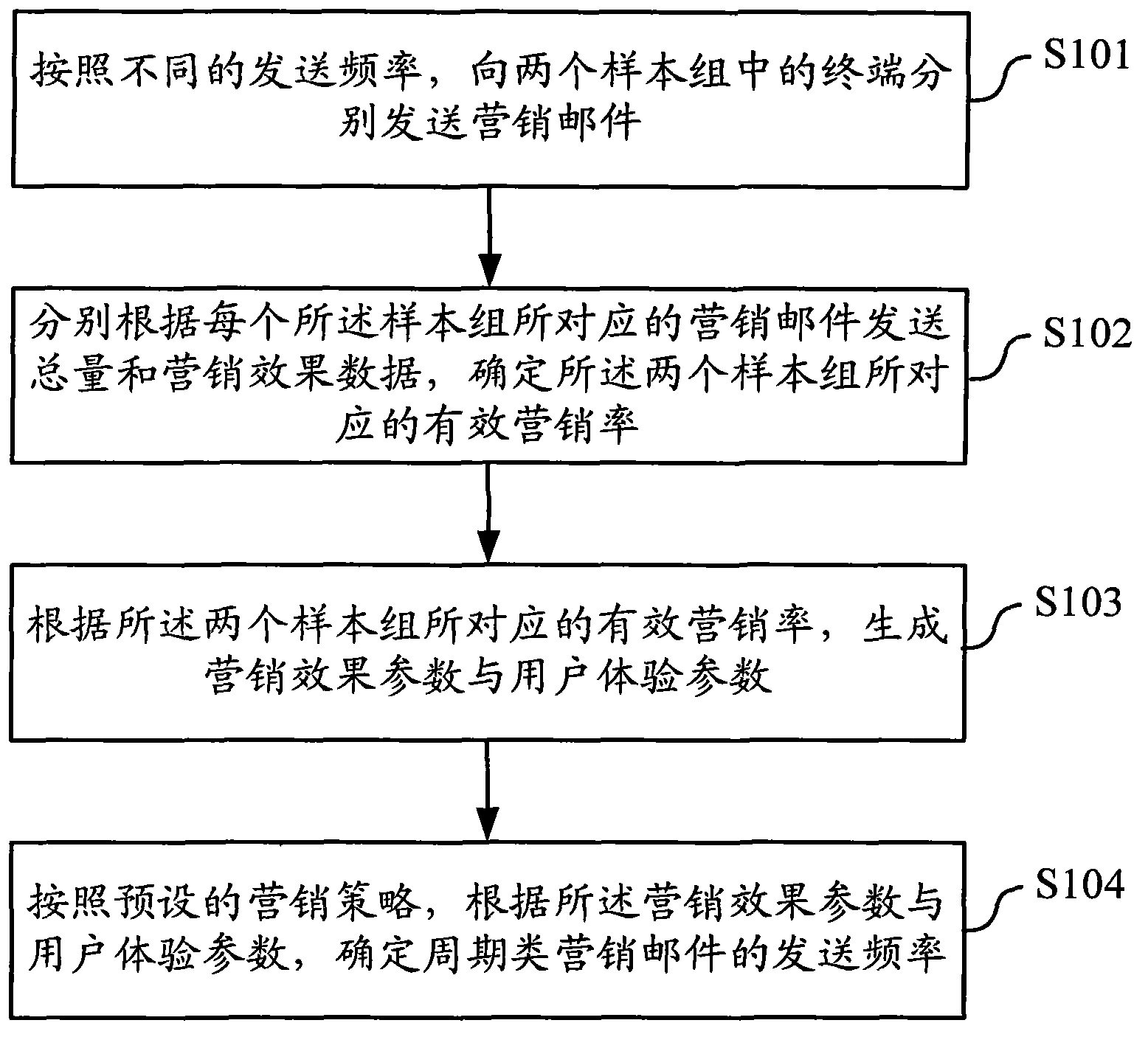

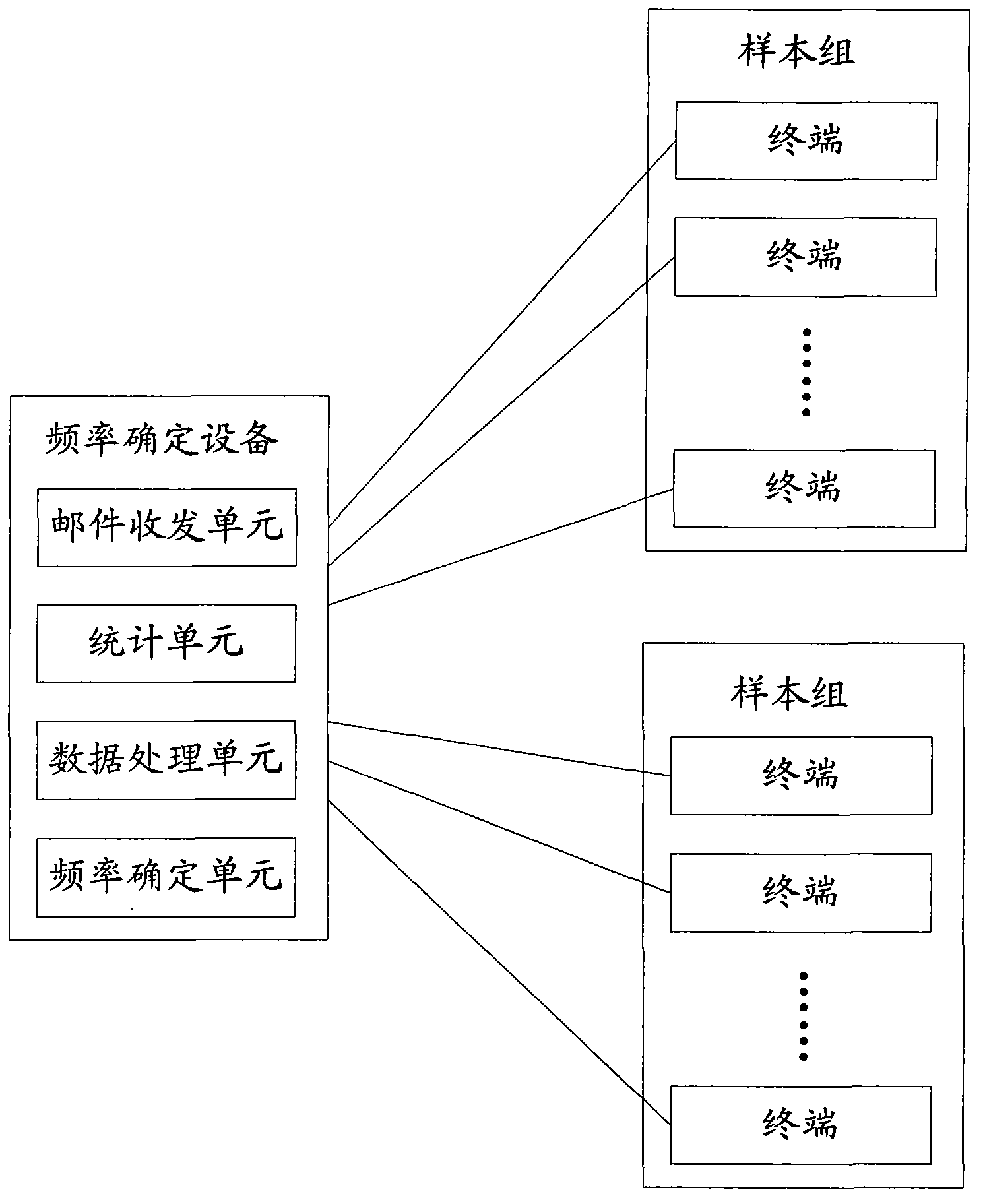

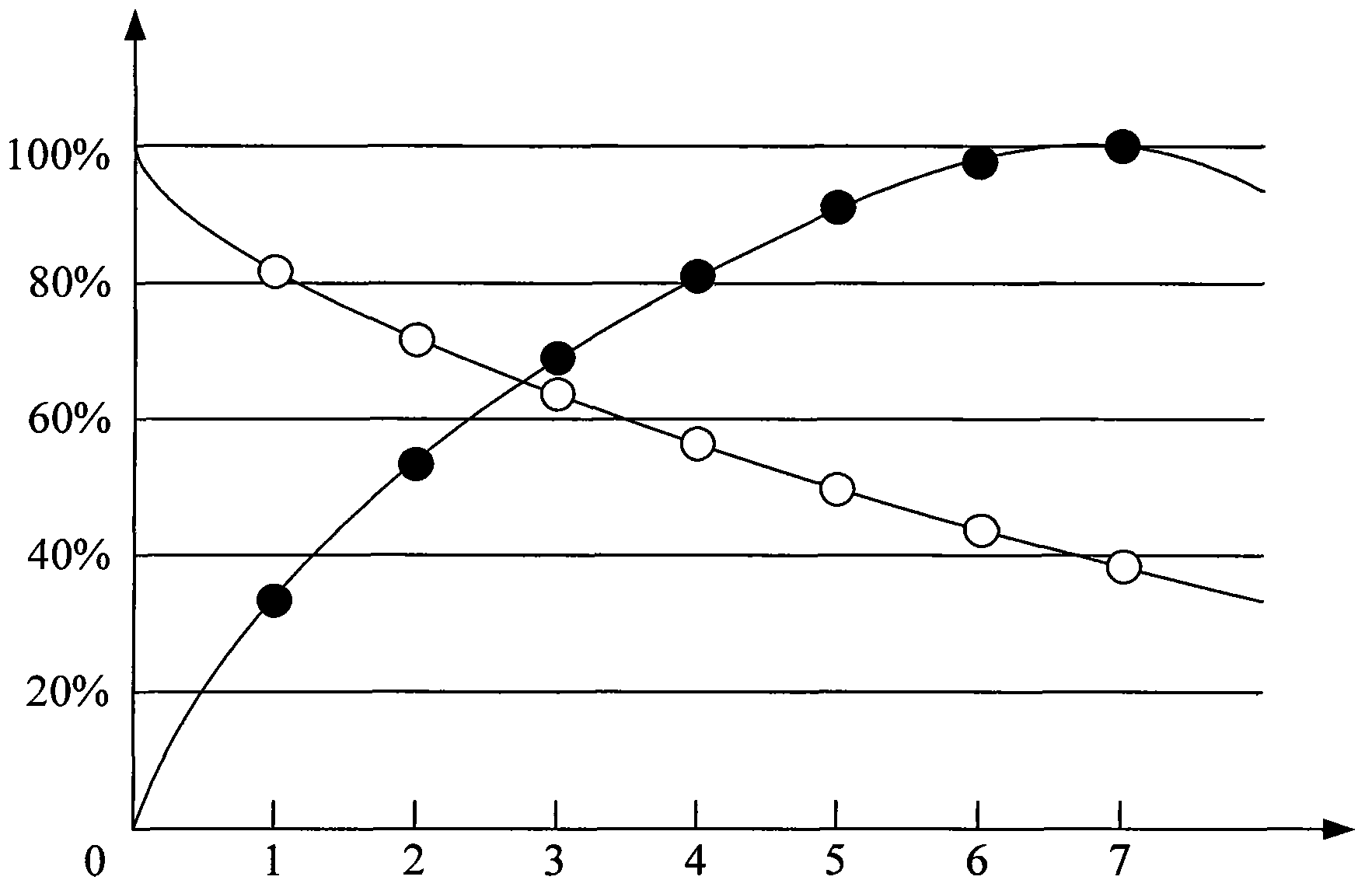

Method and device for determining sending frequency of periodic marketing mails

The invention discloses a method and device for determining the sending frequency of periodic marketing mails. According to the technical scheme, the marketing mails are sent to terminals of two sample sets according to different sending frequencies respectively, a marketing effect parameter and a user experience parameter are determined according to corresponding statistical information, the sending frequency of the periodic marketing mails is determined according to the corresponding parameters and a preset marketing strategy, and then sending effect rule information of the marketing mails can be obtained according to quantitative sending data statistics. The specific handling process is easy, the finally determined sending frequency considers the marketing effect and user experience, the sending frequency of the marketing mails is calculated accurately, and mass data statistics or a complex handling process caused by non-directional sample data collection can be avoided.

Owner:ALIBABA GRP HLDG LTD

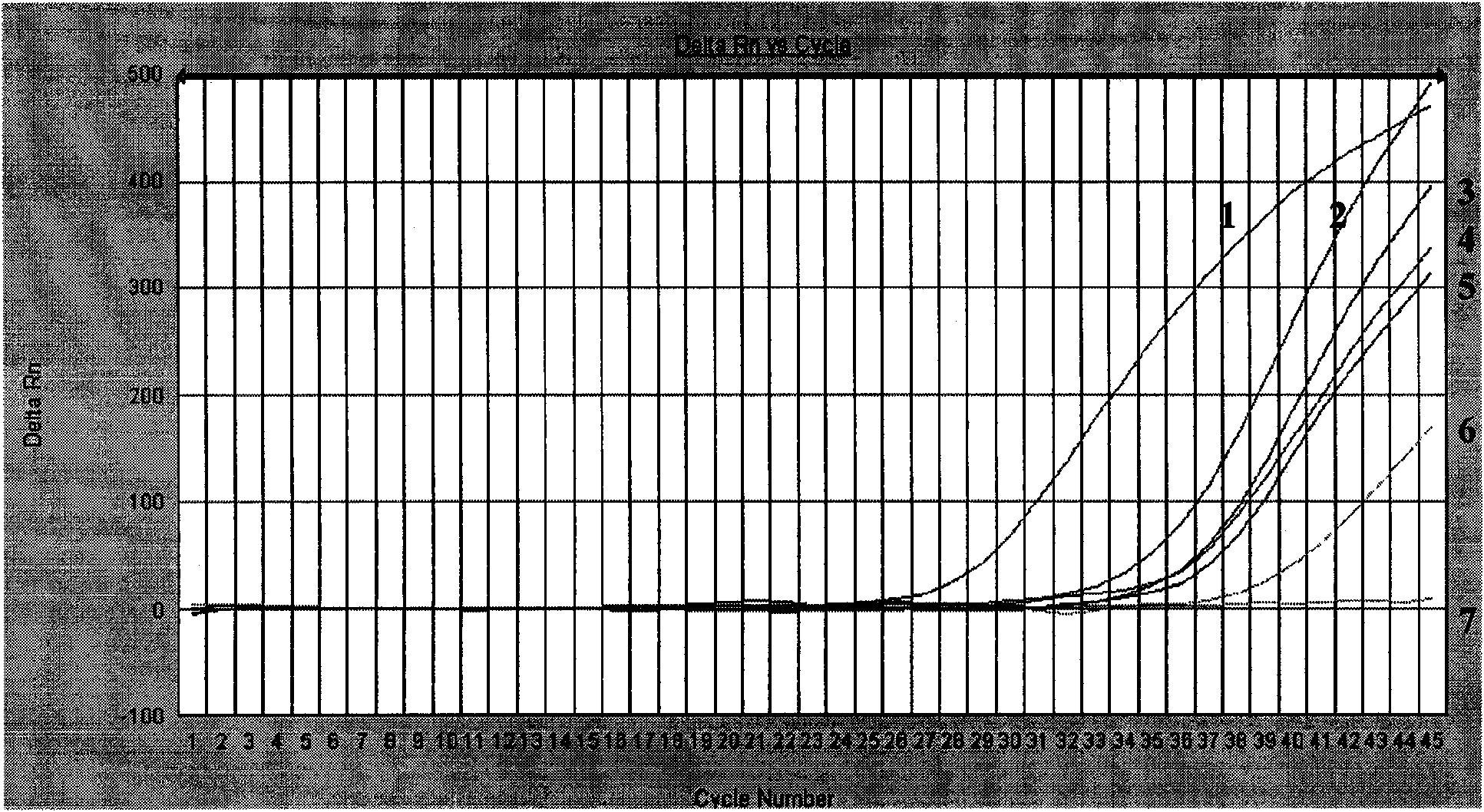

Dual PCR (Polymerase Chain Reaction) detection method for soybean and peanut components in walnut milk beverage

InactiveCN103540673AAvoid complex processingShorten the timeMicrobiological testing/measurementSeeds sesameSoya bean

The invention discloses a method for simultaneously detecting soybean and peanut components doped in walnut milk by using a dual PCR (Polymerase Chain Reaction) technology. According to the method, a specific primer is designed aiming at the soybean and peanut components so as to establish a dual PCR detection method for main doped components, namely the soybean and peanut components, in the walnut milk. The dual PCR detection method comprises the specific primer aiming at the soybean and peanut components and a PCR reaction condition matched with the specific primer; the primer designed by the method has no crossed reactions with other common leguminous plants and non-leguminous plants including peanuts, filberts, walnuts, pine nuts, pistachio nuts, carya illinoensis koch, cashew nuts, almonds, sesames, apples and the like, and has the good specificity; the method disclosed by the invention can be used for simultaneously detecting the soybean and peanut components which are mainly doped in the walnut milk; the result is obtained rapidly, accurate and reliable; the method has an actual application value for detecting that soybean and peanut proteins in the market are used for replacing walnut proteins. Meanwhile, the method has an important reference value for rapid and specific detection when other low-price plant proteins are used for replacing the walnut proteins and relative milk products.

Owner:KUNMING UNIV OF SCI & TECH

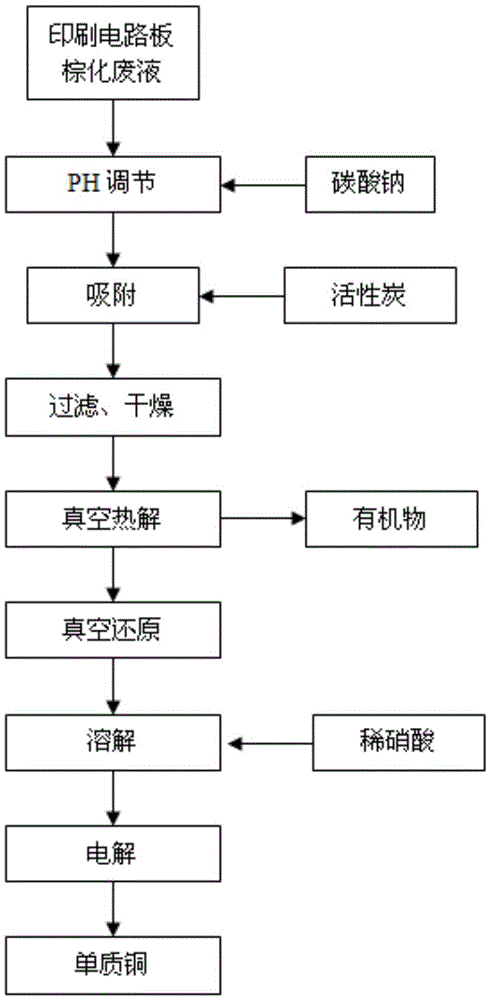

Method for recovering copper from brown oxidation wastewater of printed circuit board

ActiveCN105567980AAvoid complex processingIncrease added valuePhotography auxillary processesProcess efficiency improvementActivated carbonElectrolysis

The invention relates to a method for recovering copper from brown oxidation wastewater of a printed circuit board, belonging to the technical field of resource recovery. The method comprises the steps of firstly, adding sodium carbonate into brown oxidation wastewater to regulate the PH value; then, adding powdered activated carbon to adsorb, filter and drying, and carrying out vacuum pyrolysis and vacuum reduction in a vacuum reactor; and next, dissolving and electrolyzing to obtain cathode copper, wherein the recovery rate of copper can be up to more than 98% so that the purification treatment of the brown oxidation wastewater is realized. According to the method, the treatment process is simple, process parameters and equipment are easily realized, the additional value is high, and the economic and environmental benefits are favorable.

Owner:广西振钢再生资源有限公司

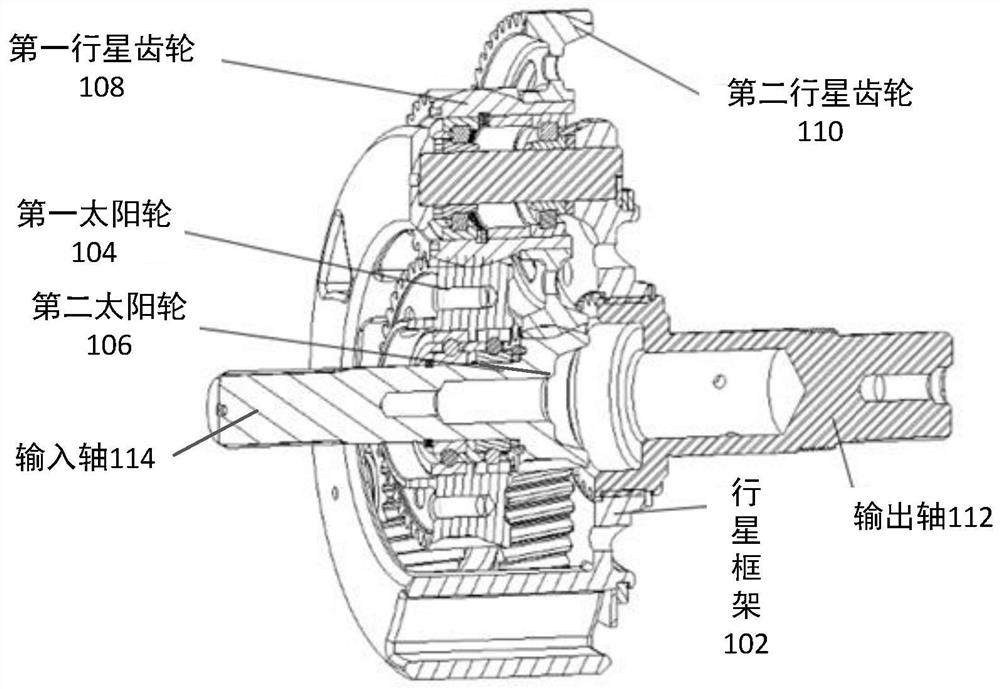

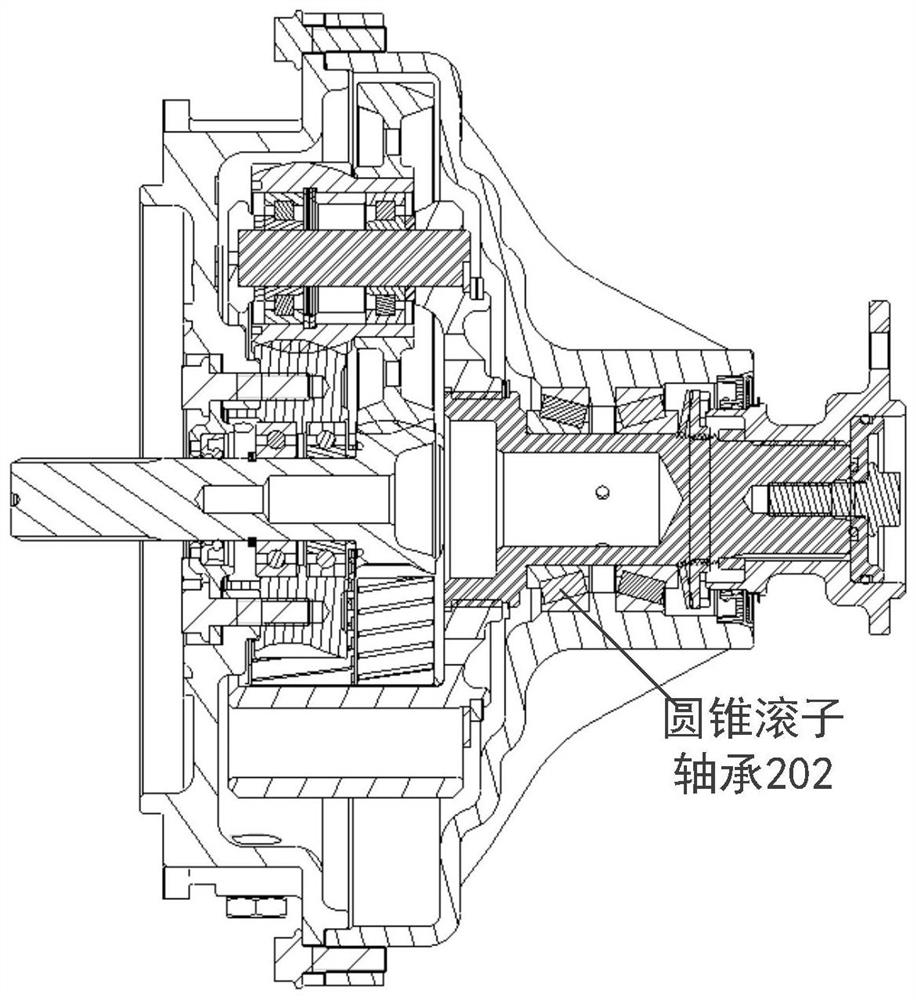

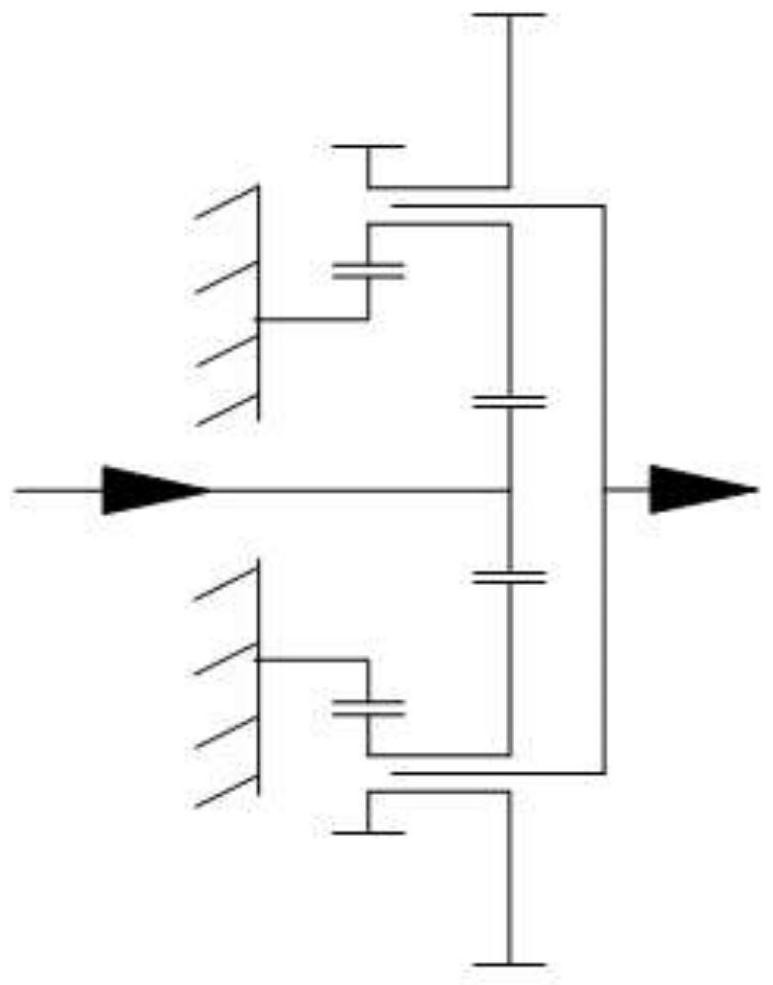

External meshing duplex planet row speed reducer and driving device

PendingCN111734790AReduce processing stepsExpected deceleration effectToothed gearingsGearing detailsReduction driveGear wheel

The invention discloses an external meshing duplex planet row speed reducer and a driving device. The speed reducer comprises a shell, a planet frame, a first sun gear, a second sun gear, duplex planet gears, an input shaft and an output shaft, wherein the first sun gear and the second sun gear are coaxially arranged in the center of the planet frame in tandem front and back, the second sun gear is rigidly connected with the input shaft, and the first sun gear is rigidly connected with the shell; the duplex planet gears comprise a first planet gear and a second planet gear, and the first planet gear and the second planet gear are coaxially arranged on a planet gear shaft in the middle of the planet frame in a sleeving mode and a tandem mode front and back; the axis of the duplex planet gears is parallel to the main axis of the speed reducer, the first planet gear is externally meshed with the first sun gear, and the second planet gear is externally meshed with the second sun gear; andthe output shaft is in spline connection with the planet frame.

Owner:南京清研易为新能源动力有限责任公司

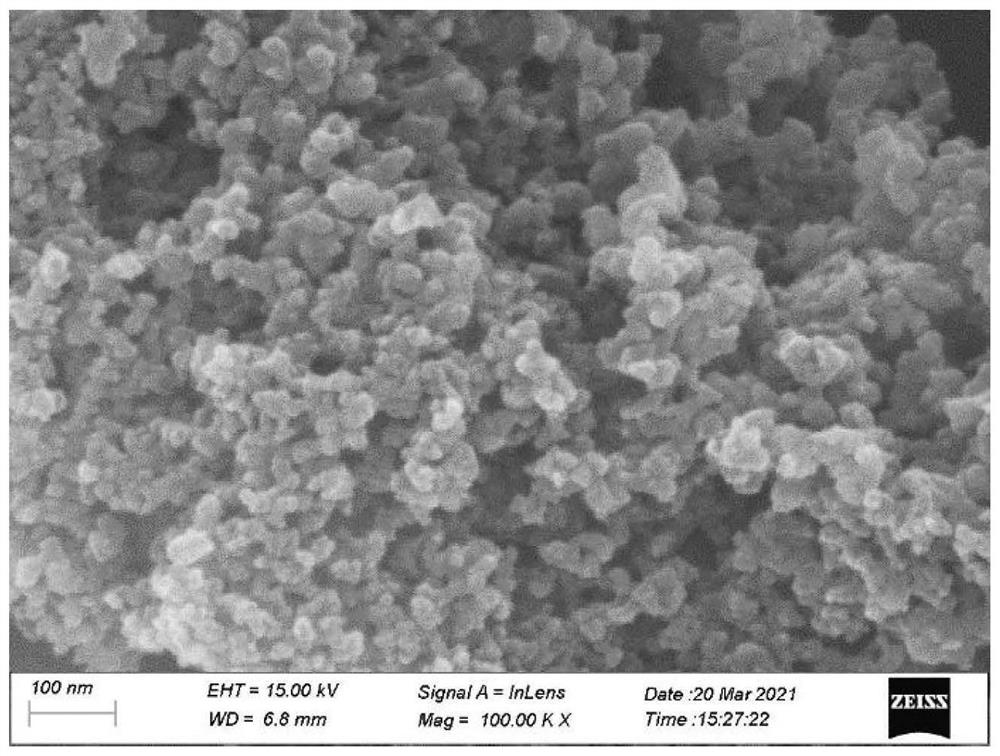

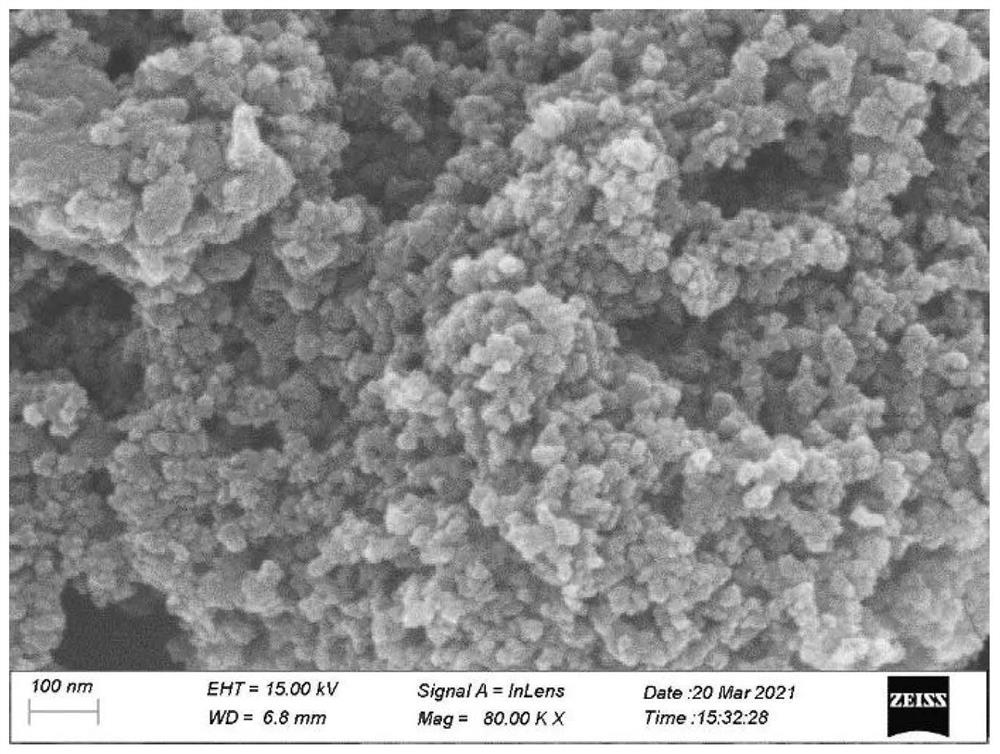

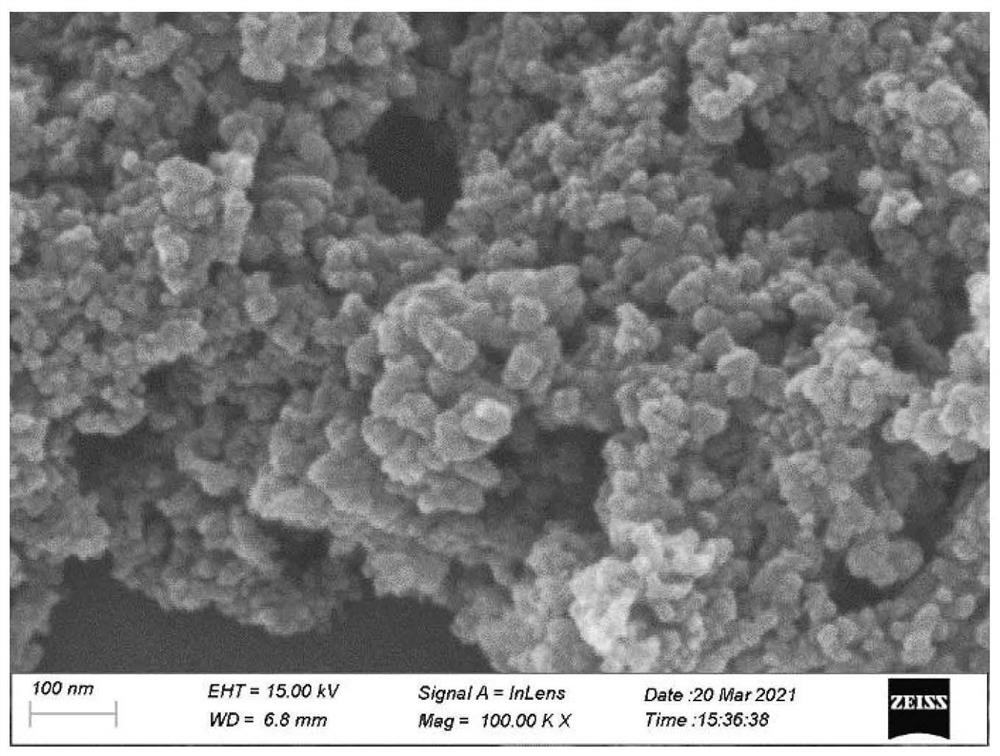

Solvent circulation preparation method and application of metal atomic-scale dispersed nitrogen-carbon material

ActiveCN113373474AAvoid complex processingLow priceCell electrodesElectrolytic organic productionArgon atmospherePhysical chemistry

The invention belongs to the field of preparation of novel materials, and particularly relates to a solvent circulation preparation method and application of a metal atomic-scale dispersed nitrogen-carbon material. The preparation method comprises the following steps: A, dissolving metal powder or metal salt in formamide to prepare a solution, conducting reacting at 80-240 DEG C for 2-24 hours, and performing solid-liquid separation to obtain a first solid product and a formamide solution L1; B, carrying out primary solvent circulation operation, namely dissolving metal powder or metal salt in the formamide solution L1, conducting reacting at 80-240 DEG C for 2-24 hours, and carrying out solid-liquid separation to obtain a second solid product and a formamide solution L2; and C, calcining the first solid product and / or the second solid product in an argon atmosphere, and controlling a temperature at 400-1200 DEG C to obtain the metal nitrogen-carbon material. According to the method, the formamide solvent in the reaction is recycled for the first time, the metal nitrogen-carbon material prepared from the recycled solvent has the same structure as the metal nitrogen-carbon material prepared from fresh formamide, and the catalytic performance of the metal nitrogen-carbon material is equal to the catalytic performance of the metal nitrogen-carbon material prepared from fresh formamide.

Owner:BEIJING UNIV OF CHEM TECH

Cutter abrasion monitoring method based on co-integration modeling

ActiveCN102152172BAccurate predictionAvoid complex processingMeasurement/indication equipmentsEngineeringCutting force

The invention relates to a cutter abrasion monitoring method based on co-integration modeling. The cutter abrasion monitoring method comprises the steps of: extracting a plurality of characteristics of a cutting force signal by means of a cutter cutting experiment; primarily selecting characteristic time sequences with the same trend with a cutter in abrasion loss by using a coorelation coefficient matrix; carrying out an ADF (Augmented Dickey-Fuller) test on each selected characteristic time sequence to judge whether the selected characteristic time sequences are I (1); carrying out co-integration analysis under the condition of guaranteeing that all the selected characteristic time sequences are I (1); solving characteristic values and a co-integration matrix beta; then carrying out Johansen test so as to determine a co-integration order r and related co-integration coefficients; establishing a co-integration relational expression of innovation variables according to the co-integration coefficients; determining an optimal co-integration model by comparing calculated values of the expression; carrying out ADF test on the determined innovation variables; and if the innovation variables are stable, judging that the established co-integration model is correct, and further predicting the abrasion loss of the cutter by using the model. By means of the cutter abrasion monitoring method, the abrasion state of the cutter can be monitored accurately so as to reduce the dimensional deviation of a processed workpiece, caused by the cutter abrasion.

Owner:TIANJIN UNIV

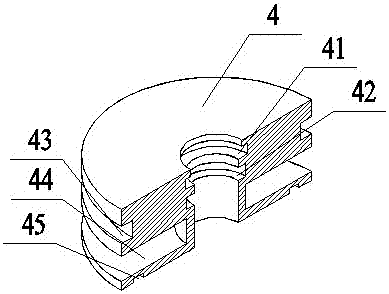

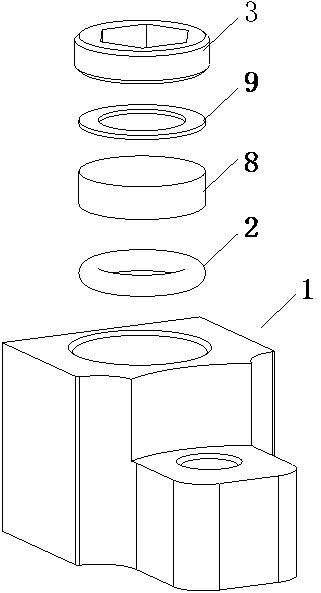

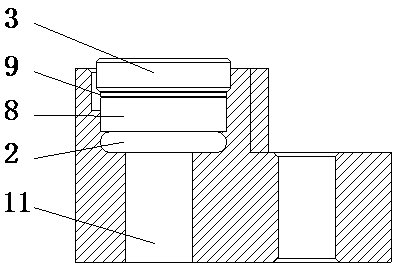

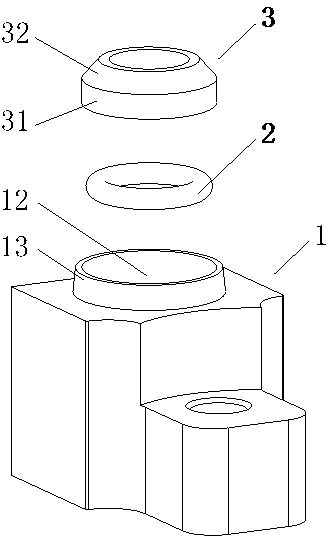

Level sight lens and method and tool for assembling same

The invention discloses a level sight lens and a method and tool for assembling the level sight lens. The level sight lens comprises a lens body, an O-shaped sealing ring and a prospective lens. The prospective lens comprises a lens sheet and a lens sheet base, a level sight hole is formed in the lens body, and a mounting cavity used for mounting the O-shaped sealing ring and the prospective lens is arranged on the periphery of the upper portion of the level sight hole; an annular pressing sheet is arranged on the upper edge of the mounting cavity and arranged on the upper surface of the lens body, and the annular pressing sheet can be bent inwards to be attached to the inclined face of the circular cone table portion of the lens sheet base. The method for assembling the level sight lens comprises the step A of placing the sealing ring and the prospective lens in the mounting cavity of the lens body in sequence, and the step B of providing the assembling tool and bending the annular pressing sheet on the lens body inwards to be attached to the inclined face of the circular cone table portion of the lens base. The assembling tool comprises a press block, a cavity is arranged on the bottom portion of the press block, and the inner side wall of the cavity is an inclined face with an inclined center. According to the level sight lens and the method and tool for assembling the level sight lens, the lens sheet base is pressed by the annual pressing sheet, the defects that in the prior art, due to threaded connection, processing is complex, efficiency is low, the bearing capacity is low, and corrosion easily occurs are avoided.

Owner:ZHEJIANG CHUANGLI AUTOMOTIVE AIR CONDITIONER

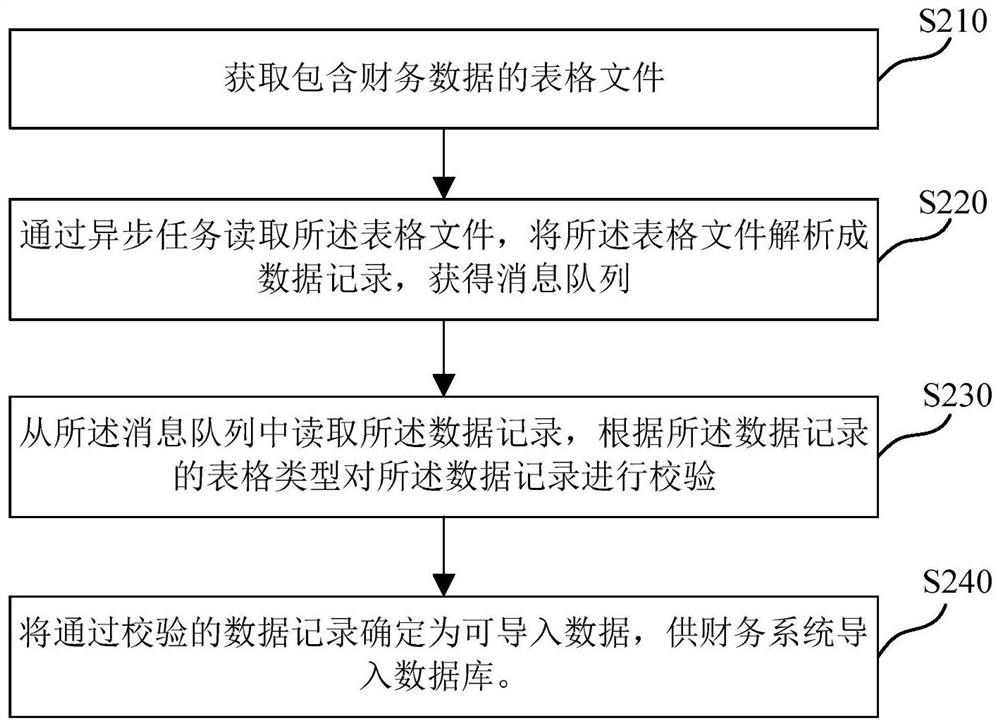

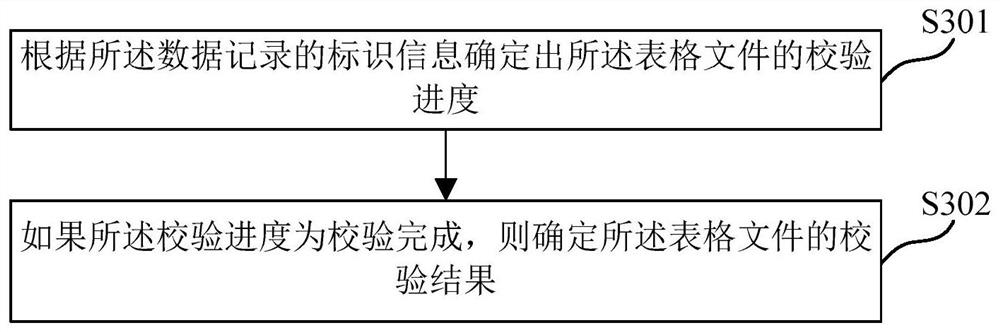

Data processing method and device, computer readable medium and electronic equipment

PendingCN112445866ARelieve pressureEasy to useFinanceRelational databasesTable (database)Message queue

The embodiment of the invention provides a data processing method, a data processing device, a computer readable medium and electronic equipment, and relates to the technical field of data processing.The data processing method comprises the steps of obtaining a table file containing financial data; reading the table file through an asynchronous task, and analyzing the table file into a data record to obtain a message queue; reading the data record from the message queue, and verifying the data record according to the file type of the data record; and determining the data record passing the verification as importable data for a financial system to import into a database. According to the technical scheme of the embodiment of the invention, the table file of the financial data is analyzed into the data record, so that the financial data is uniformly processed, manual account checking is converted into automatic checking, and the operation complexity is reduced.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

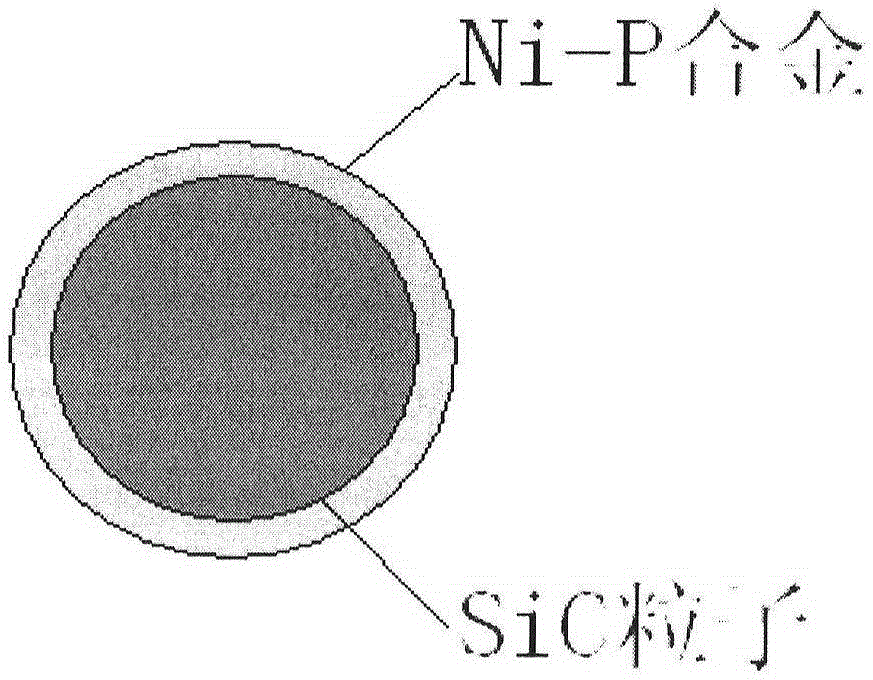

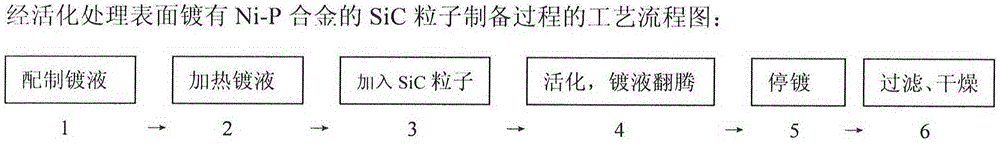

Method for chemically plating Ni-P alloy on SiC particle surface

InactiveCN104694911AGood effectAvoid complex processingLiquid/solution decomposition chemical coatingWater bathsChemical plating

The invention discloses a method for chemically plating Ni-P alloy on SiC particle surface. The method for chemically plating the Ni-P alloy on the SiC particle surface includes that directly adding weighted SiC particles to chemical plating Ni-P alloy solution, using a glass rod plated with the alloy to induce and activate the chemical plating solution in thermostatic water bath, or adding a metal plate plated with the alloy to induce and activate till appearing a writhing phenomenon, ending plating, and obtaining the SiC particles plated with Ni-P alloy element layers through precipitating, filtering, drying and the like. The particles can be used as particle reinforcement to prepare metal-base composite material, and meanwhile, the particles are basic raw material for preparing engineering material and function material.

Owner:QINGDAO UNIV OF SCI & TECH

Multimedia content delivery system

ActiveUS9189868B2High degree of controlHigh degree of flexibilityDetails involving 3D image dataImage codingGraphicsManagement unit

Owner:ANTI MATTER GAMES LTD

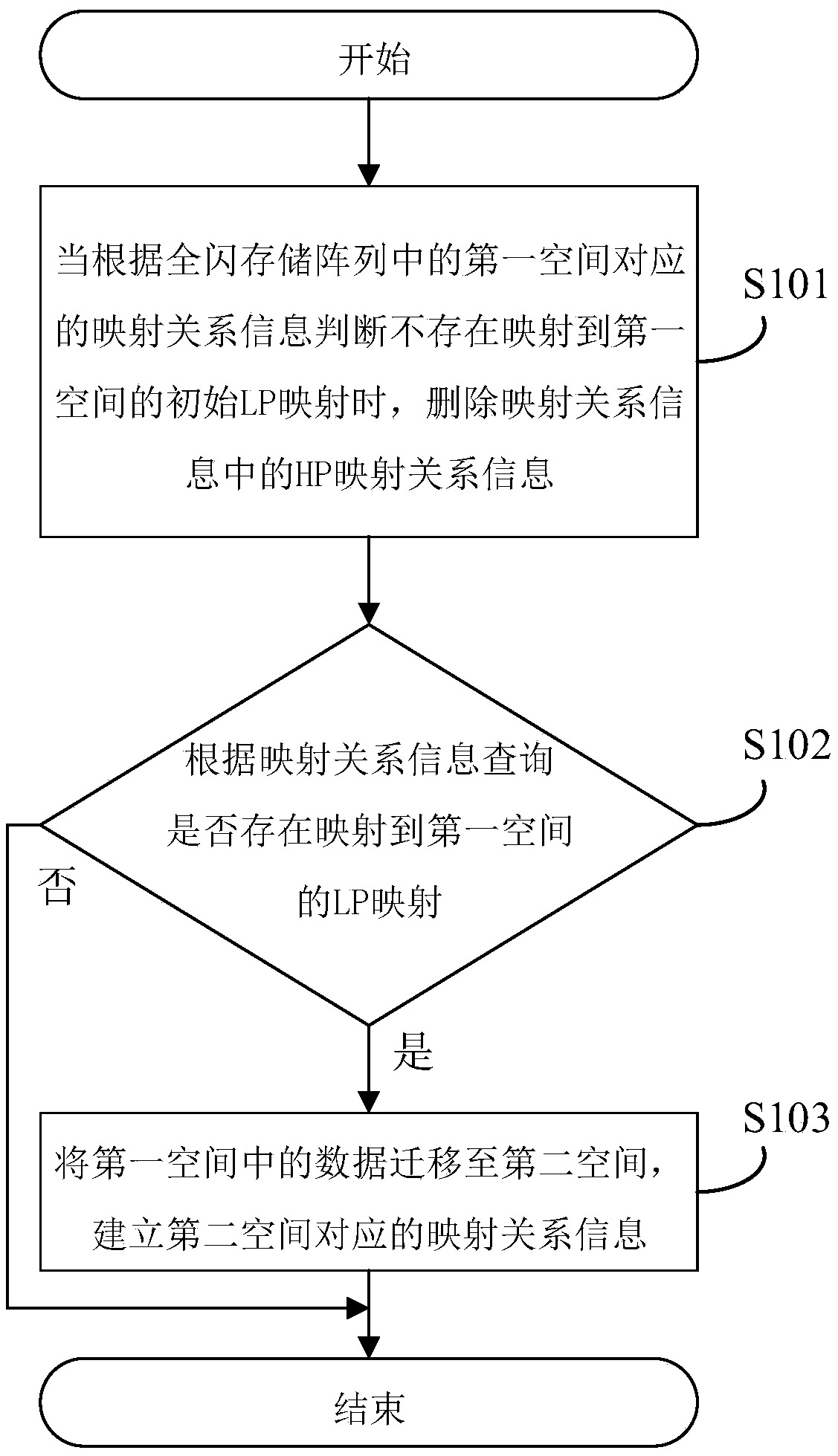

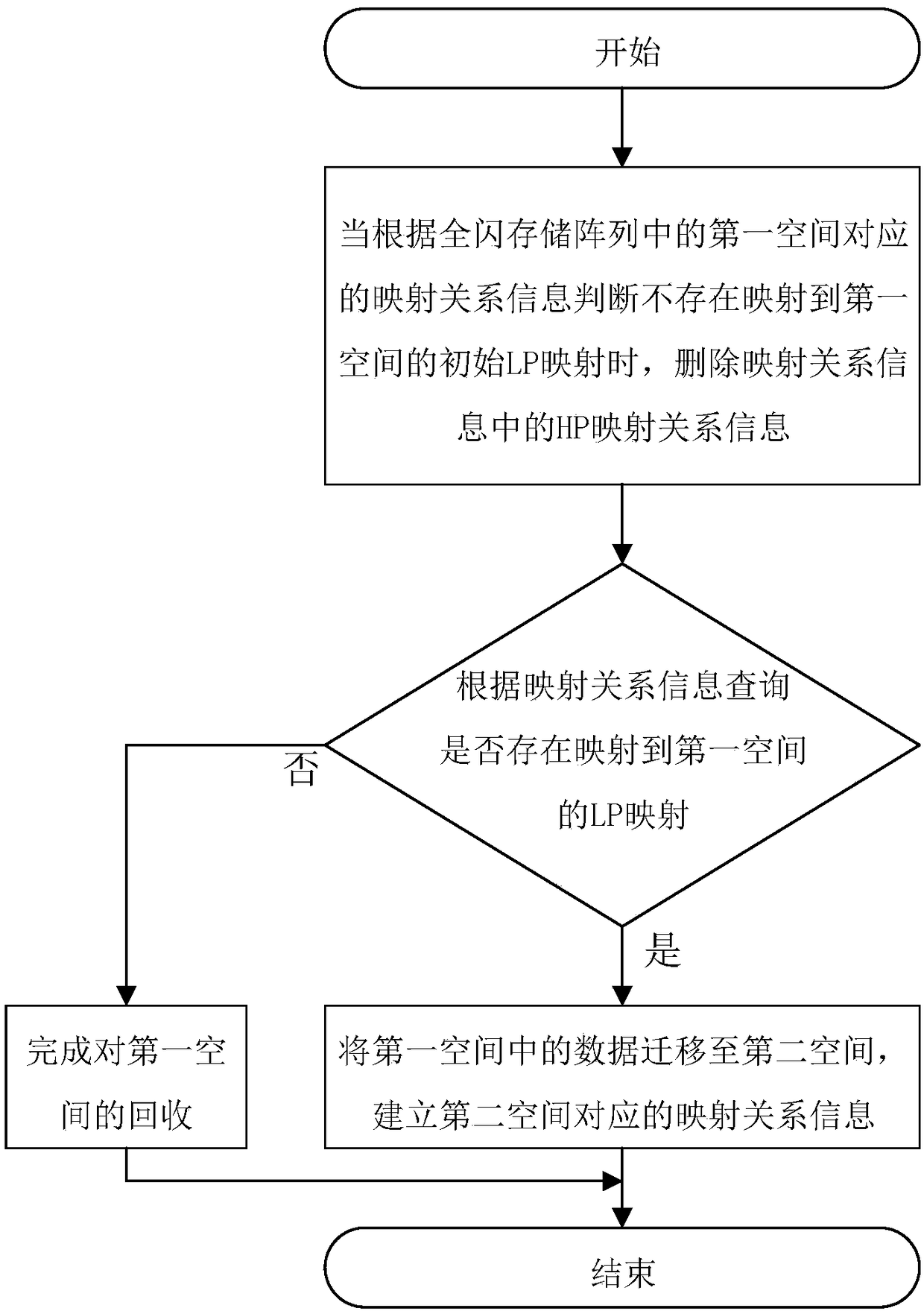

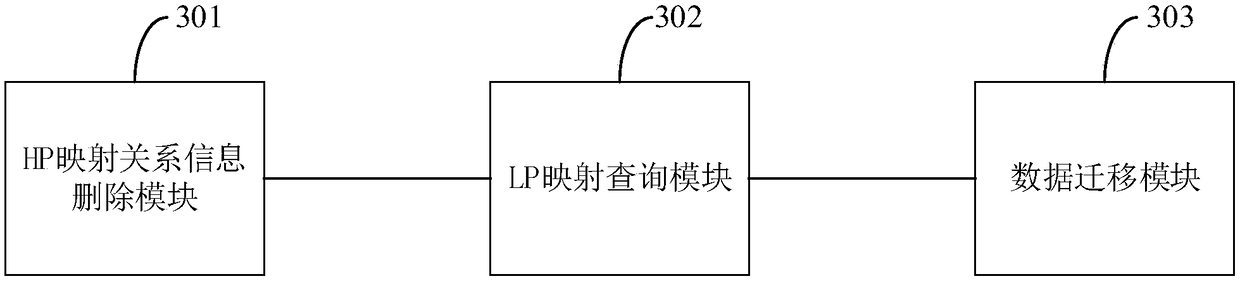

A garbage collection method and system in an all-flash memory array

The present application provides a garbage collection method in an all-flash memory array. The garbage collection method includes: deleting HP mapping relationship information in mapping relationshipinformation when it is determined that there is no initial LP mapping to the first space according to mapping relationship information corresponding to the first space in the all-flash memory array; Querying whether there is an LP mapping to the first space according to the mapping relation information; if so, the data in the first space is migrated to the second space, and mapping relationship information corresponding to the second space is established. The existence of LP mapping to the first space is queried, which shows that the host IO writes the same data when deleting the HP mapping relationship information and does not need to wait until the deletion of the HP mapping relationship information is completed. It is possible to avoid having the master IO wait without affecting the response of the service. The present application also provides a garbage collection system in an all-flash memory array, the all-flash memory array and a computer-readable storage medium, all of which have the above beneficial effects.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

The Method of Improving the Accuracy of Robot Parameter Identification

ActiveCN104614991BRemove noise signalImprove optimization efficiencyAdaptive controlAlgorithmGenetics algorithms

The invention discloses a method for improving robot parameter identification accuracy and belongs to the field of industrial robot control. The method comprises optimizing stimulation trajectories through a genetic algorithm; stimulate a robot to perform cyclical movement according to the optimized stimulation trajectories; sampling actual joint positions and actual torque data during moving and processing the data to obtain torque values, joint positions, joint speeds and joint accelerated speeds which are high in signal to noise ratio; establishing a dynamic linear model, and identifying all parameters related to joint dynamics through a weighted least square method. By the aid of the method, the actual trajectory Fourier series form is fit through an inverse method, and accordingly, speeds and accelerated speeds which cannot be obtained directly in experiments can be obtained conveniently, noise signals in sampling position signals and torque signals can be eliminated through an equalization method, the signal to noise ratio is improved and the robot parameter identification accuracy is improved.

Owner:NANJING ESTUN ROBOTICS CO LTD

Gas diffusion layer for proton exchange membrane fuel cells and preparation method thereof

ActiveCN101771155BLow electrical resistanceImprove electronic conductivityCell electrodesFinal product manufactureProtonHigh activity

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Embedded type low-flow-resistance plunger pump cylinder structure

PendingCN109630404AAvoid complex processingReduce processing costsPositive displacement pump componentsPositive-displacement liquid enginesCylinder blockEmbedded system

The invention discloses an embedded type low-flow-resistance plunger pump cylinder structure which can reduce resistance of hydraulic medium fluid, improves self-sucking performance, facilitates increasing rotation speed and improves flow. The embedded type low-flow-resistance plunger pump cylinder structure comprises a cylinder body which can reduce processing processes and reduces production cost, wherein a plunger pump hole and a waist-shaped hole are distributed in the cylinder body; the plunger pump hole mutually communicates with the waist-shaped hole; the bottom end in the plunger pumphole is embedded with an embedded type rectifying block; a runner which communicates with the waist-shaped hole for enabling the hydraulic medium flow to be smoother is distributed in the embedded type rectifying block; and the runner is a smooth curved surface or a surface set which consists of a plurality of discrete planes or curved surfaces.

Owner:金职液压动力(金华)有限公司

A plantar pressure measuring device and method for exoskeleton control

ActiveCN105662419BReduce usageAvoid complex processingProgramme-controlled manipulatorDiagnostic signal processingAnkle boneTarsus Bone

The invention discloses a plantar pressure measuring device and method for exoskeleton control. The device includes a measuring device pressure shoe, and the inside of the measuring device pressure shoe is respectively provided with four pieces of pressure sensors ( 202), the pressure sensor (202) generates a weak electrical signal, and the central processing unit collects and processes the weak voltage signal; corresponding to different modes of different pressure sensor data, different weights are used to measure the exoskeleton foot Bottom pressure. The present invention uses four thin-film pressure sensors on the soles of the feet to collect the pressure of the main stress-bearing parts of the soles of the exoskeleton, avoids the use of a large number of sensors, has a simple structure, and is low in cost; different modes for the wearer to stand and walk when wearing the exoskeleton Divide and process data differently in different modes. The algorithm is simple, which avoids complex data processing when using a large number of sensors, and improves the data processing speed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com