Double handle hand riveter

A kind of riveting gun and handle-type technology, which is applied in the field of double-handle riveting guns, can solve the problems of lengthening, increased production cost, labor-intensive use, etc., and achieve the effects of reducing the overall volume, simple and reasonable structure, and avoiding conflicts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

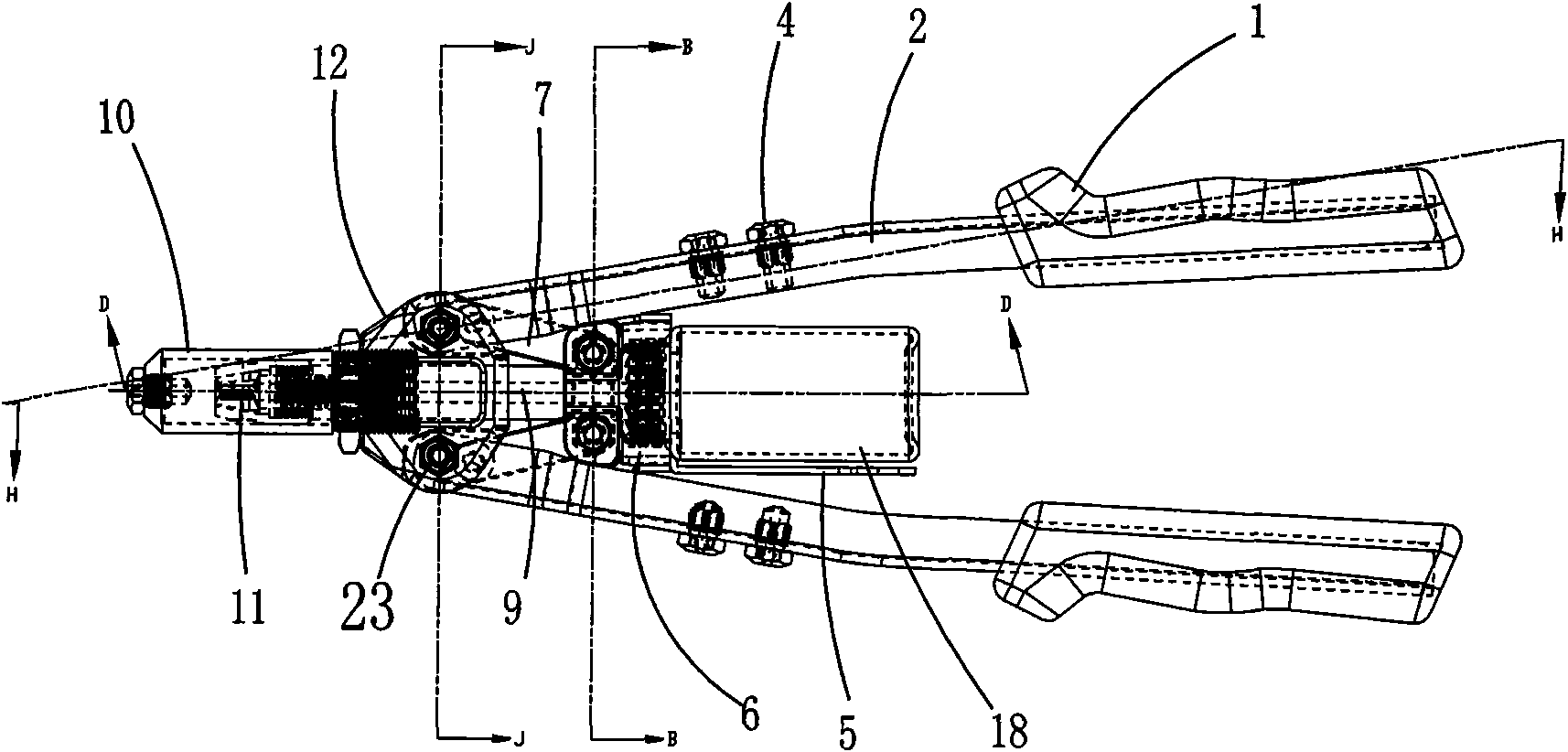

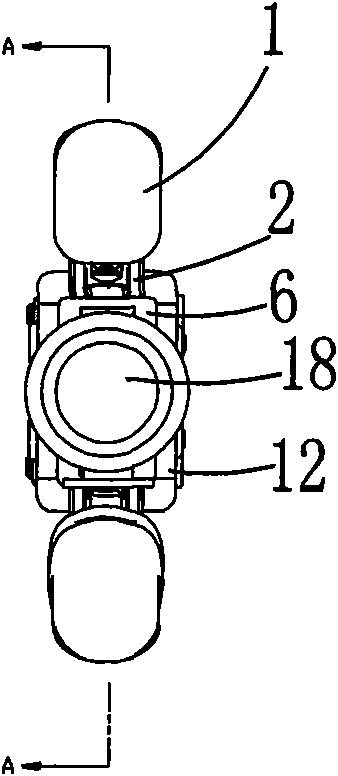

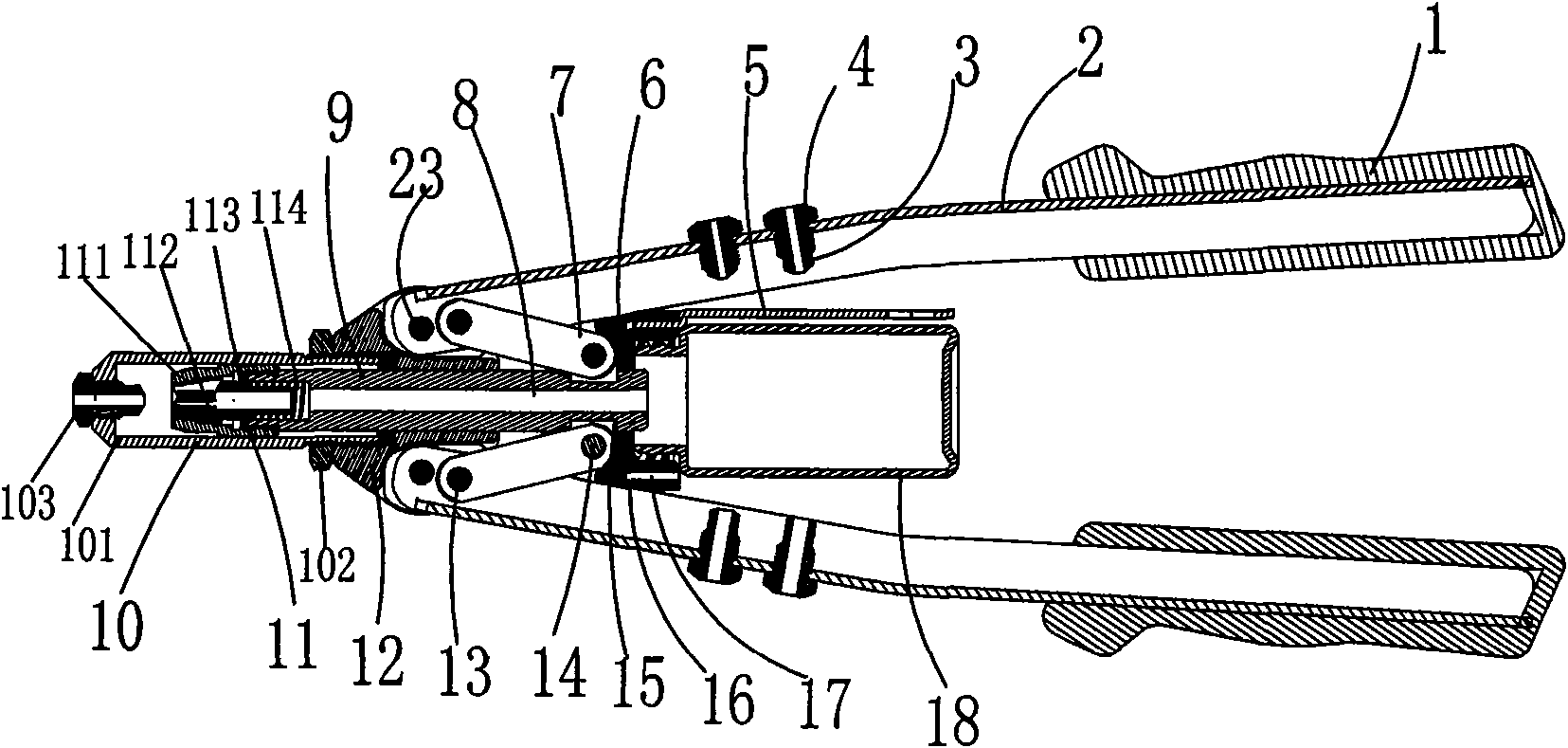

[0034] Such as Figure 1 to Figure 7As shown, a double-handled riveting gun includes a riveting gun base 12, an adjusting sleeve 101, an adjusting nut 102, and a guide nozzle 103 of the adjusting mechanism 10 arranged at the front end of the riveting gun base 12 are installed on the The catch seat 111, catch 112, ejector rod 113 and spring 114 of the blind rivet grip mechanism 11 in the adjustment mechanism 10, one end is respectively hinged with the two sides of the rivet gun seat 12 through the first screw shaft 23 The two handles 2 are movably inserted into the pull rod 9 in the center hole 20 of the rivet holder 12; it is characterized in that: the tail end of the pull rod 9 is provided with a fixing groove 21, and the fixing groove 21 The bottom surface is four planes, and every two adjacent planes are perpendicular to each other; in a pair of opposite surfaces of the fixing groove 21, two parallel to each other and compatible with the connecting rod 7 are embedded. Fixe...

Embodiment 2

[0041] Of course, the structure of the fixing groove 21 in the present invention can also adopt other structures besides the case of this embodiment. For example, the fixing groove 21 is an annular structure compatible with the fixing piece 15, which can also achieve the effects of easy manufacture, low cost, and firm and reliable use. The structure of embodiment 2 is basically the same as that of embodiment 1, the only difference between the two is that the fixing groove 21 provided at the tail end of the pull rod 9 is an annular groove (the figure of embodiment 2 is omitted). It is convenient to offer the annular groove processing, but it is very convenient and firm to be connected with the connecting rod 7 after the fixed piece 15 is installed.

Embodiment 3

[0043] Such as Figure 8 Shown, embodiment 3 product structure is close to embodiment 1,2.

[0044] Embodiment 3 is: a double-handled riveting gun, including a riveting gun base 12, an adjustment mechanism 10 arranged at the front end of the riveting gun base 12, one end of which is respectively connected to the riveting gun base through a first screw shaft 23 The two handles 2 hinged on both sides of 12 are movably inserted into the pull rod 9 in the central hole 20 of the rivet holder 12; it is characterized in that: the tail end of the pull rod 9 is provided with a fixing groove 21, The fixed slot 21 is embedded with a fixed piece 15 adapted thereto, and the left and right sides of the fixed piece 15 are connected to the handle 2 through the left and right connecting rods 7 respectively. 1. One end of the right connecting rod 7 is hinged to the fixed piece 15 through the second screw shaft 14, and the other end is hinged to the handle 2; the two sides of the riveting gun s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com