Embedded type low-flow-resistance plunger pump cylinder structure

A low flow resistance, plunger pump technology, applied in variable capacity pump parts, parts of pumping devices for elastic fluids, pumps, etc. , the effect of reducing resistance

Pending Publication Date: 2019-04-16

金职液压动力(金华)有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, the cylinder hole is deep, and the processing of complex shapes at the bottom of the cylinder hole is limited by machine tools, machining tools and cost factors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

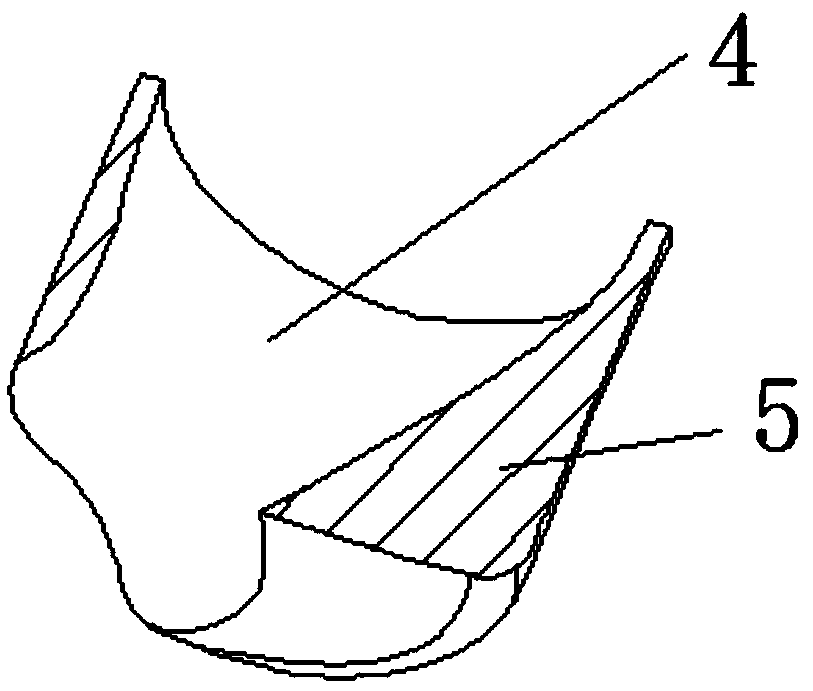

[0036] refer to Figure 5 As shown, the difference from the first embodiment is that the embedded rectifying block 5 is formed by stacking sheet-like plates 9 , and the stacking method can be vertical or horizontal.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

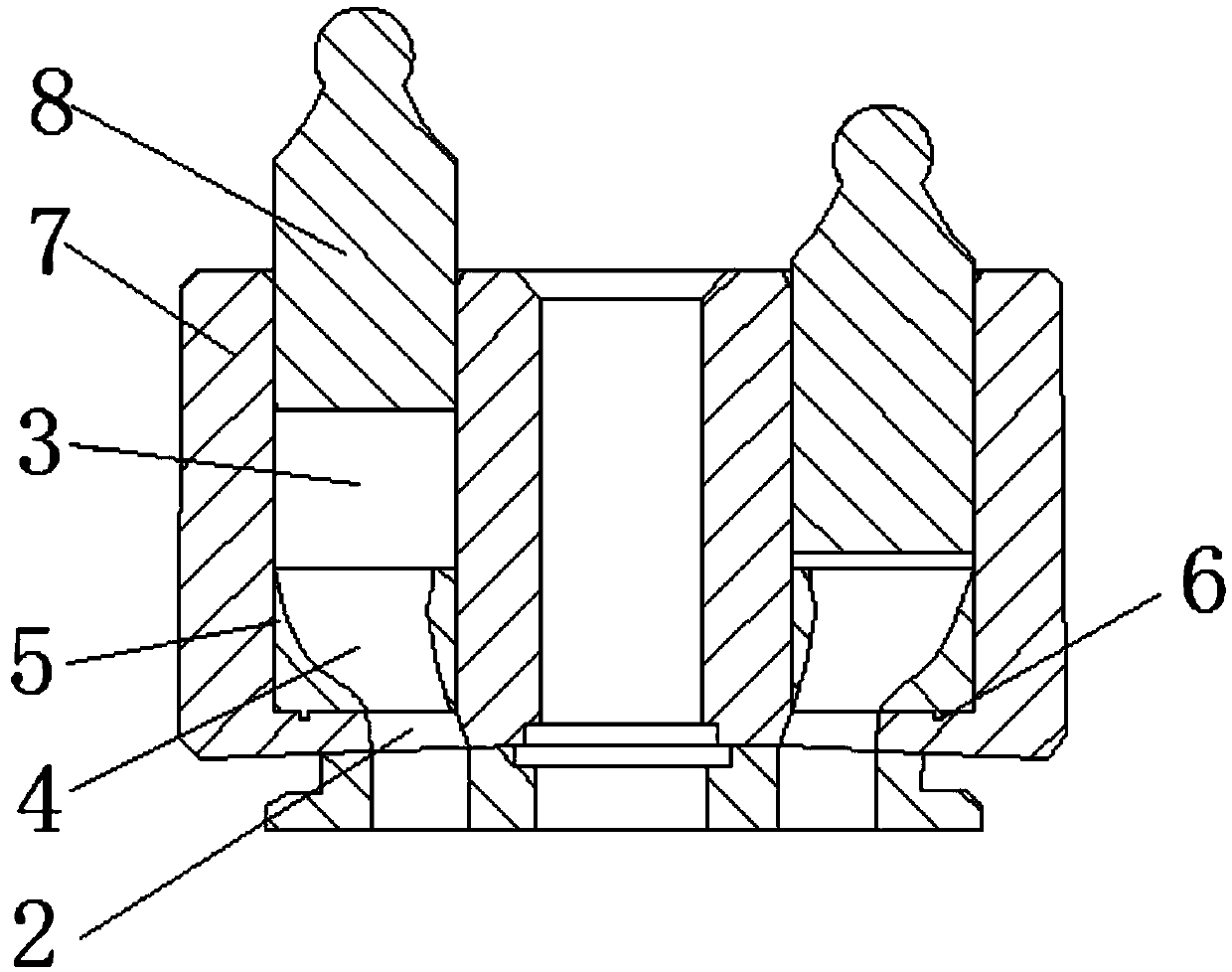

The invention discloses an embedded type low-flow-resistance plunger pump cylinder structure which can reduce resistance of hydraulic medium fluid, improves self-sucking performance, facilitates increasing rotation speed and improves flow. The embedded type low-flow-resistance plunger pump cylinder structure comprises a cylinder body which can reduce processing processes and reduces production cost, wherein a plunger pump hole and a waist-shaped hole are distributed in the cylinder body; the plunger pump hole mutually communicates with the waist-shaped hole; the bottom end in the plunger pumphole is embedded with an embedded type rectifying block; a runner which communicates with the waist-shaped hole for enabling the hydraulic medium flow to be smoother is distributed in the embedded type rectifying block; and the runner is a smooth curved surface or a surface set which consists of a plurality of discrete planes or curved surfaces.

Description

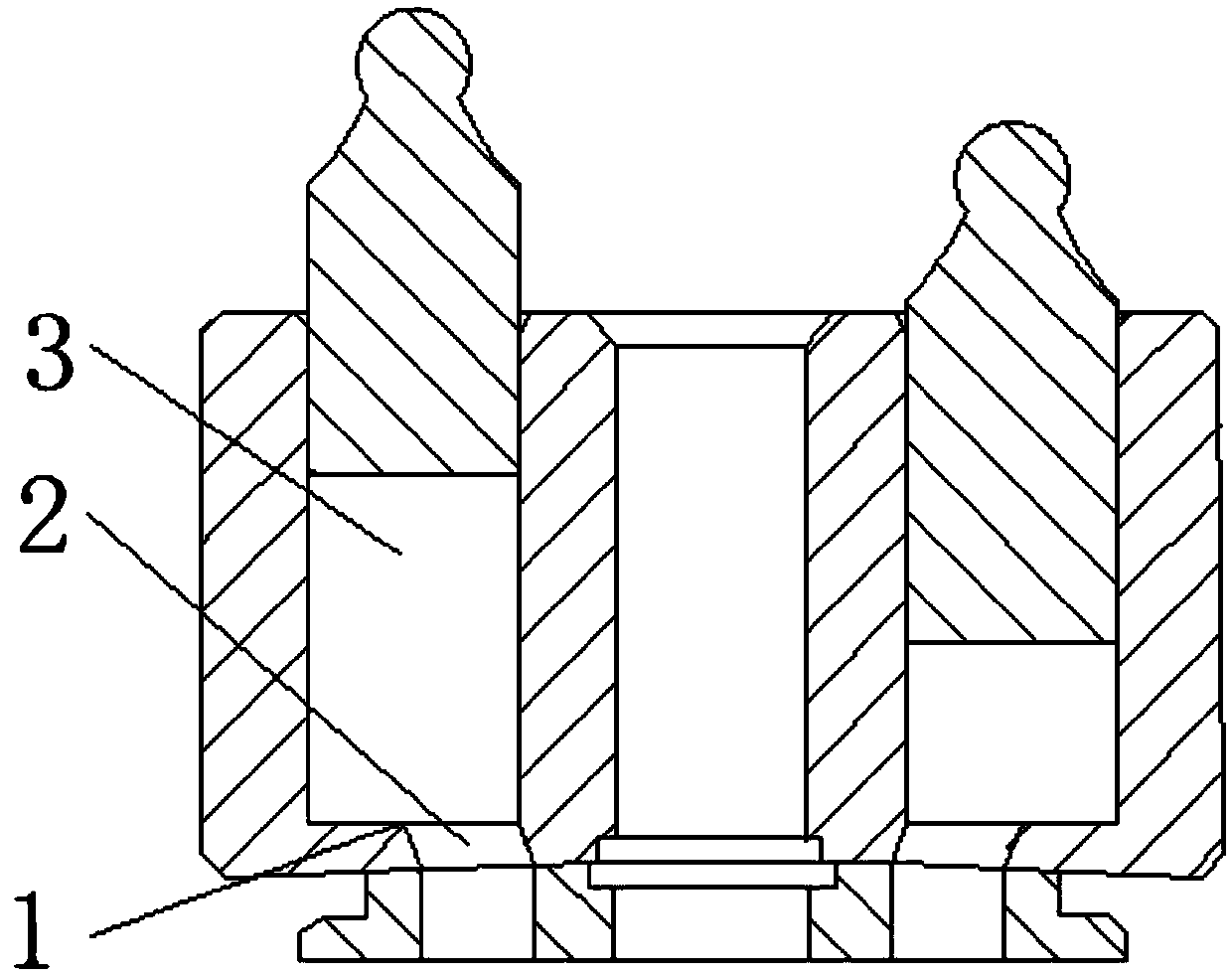

technical field [0001] The invention relates to an embedded low-flow-resistance plunger pump cylinder body structure. Background technique [0002] When the axial piston pump is working, the cylinder rotates, and the plunger in the cylinder hole reciprocates along the axis, such as figure 1 As shown, the suction and discharge of the hydraulic medium are completed after the waist hole 2 communicates with the plunger hole 3 in the cylinder. The bottom of the plunger hole 3 is circular or tapered by the machining tool, and the waist hole 2 is connected to the bottom shape to form a machined edge 1, which hinders the flow of the hydraulic medium when sucking / discharging the hydraulic medium. Flow, the self-priming performance of the plunger pump is affected, which is not conducive to increasing the speed and increasing the flow. At the same time, the cylinder bore is relatively deep, and the processing of complex shapes at the bottom of the cylinder bore is limited by machine ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04B53/16F04B1/22

CPCF04B1/2035

Inventor 朱日明章跃洪盛继生施卫明

Owner 金职液压动力(金华)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com