Gas diffusion layer for proton exchange membrane fuel cells and preparation method thereof

A gas diffusion layer and proton exchange membrane technology, which is applied to fuel cell parts, fuel cells, electrical components, etc., can solve the problems of increased preparation complexity, high equipment requirements, and large footprint, and achieve good electronic conductivity , good conductivity and mass transfer performance, low electronic resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

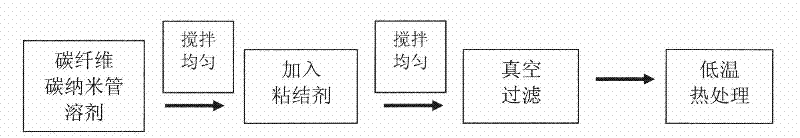

Method used

Image

Examples

Embodiment 1

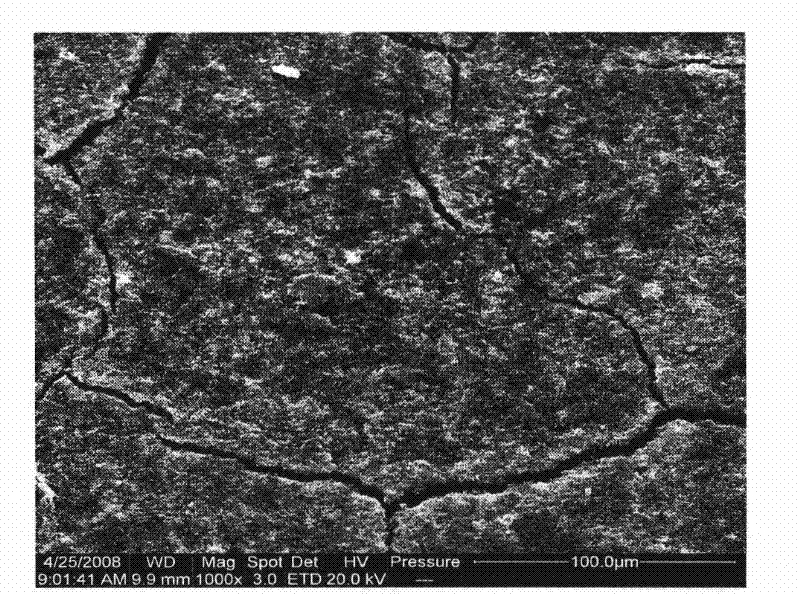

[0032] Embodiment 1: get 10mg polyacrylonitrile carbon fiber ( ) and 10mg carbon nanotubes ( ), add 20g of absolute ethanol, ultrasonically vibrate for 10min, then add 10.5mg10wt.% polytetrafluoroethylene emulsion to disperse evenly, place in a Buchner funnel (diameter is 70mm) vacuum filtration (vacuum degree is 0.01MPa, vacuumized The time is 10s), and the wet gas diffusion layer is prepared, and finally the wet gas diffusion base layer is placed in a high-temperature firing furnace, and fired at 340° C. for 30 minutes. The prepared gas diffusion layer is placed on both sides of the proton exchange membrane with the catalytic layer to form a membrane electrode. Place this component on both sides of the cathode and anode flow field plates to form a single cell. See Figures 3 and 4 for battery performance curves.

Embodiment 2

[0034] Embodiment 2: get 10mg polyacrylonitrile carbon fiber ( ), 10mg carbon nanofibers ( ) and 10mg carbon nanotubes ( ), add 60g of absolute ethanol, ultrasonically vibrate for 10min, then add 34mg10wt.% polytetrafluoroethylene emulsion to disperse evenly, place in a Buchner funnel for vacuum filtration (vacuum degree is 0.05MPa, and the time of vacuuming is 100s), and the preparation The wet gas diffusion layer is obtained, and finally the wet gas diffusion base layer is placed in a high-temperature firing furnace at 300° C. for 60 minutes.

Embodiment 3

[0035] Embodiment 3: get 10mg viscose-based carbon fiber ( ), 10mg carbon nanofibers ( ) and 100mg carbon nanotubes ( ), add 360g deionized water, then add 1200mg10wt.% fluorinated ethylene propylene emulsion to disperse evenly, place in a Buchner funnel for vacuum filtration (vacuum degree is 0.09MPa, and the time of vacuuming is 240s), and a wet gas diffusion layer, and finally put the wet gas diffusion substrate layer in a high-temperature firing furnace, and bake it at 400°C for 10 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com