Positive electrode for lithium ion secondary cell, and lithium ion secondary cell

A secondary battery and lithium-ion technology, which is applied in the field of current collectors for lithium-ion secondary batteries and positive electrodes for lithium-ion secondary batteries, can solve problems such as unclear relationship between electrodes, and achieve good high-current characteristics and high durability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

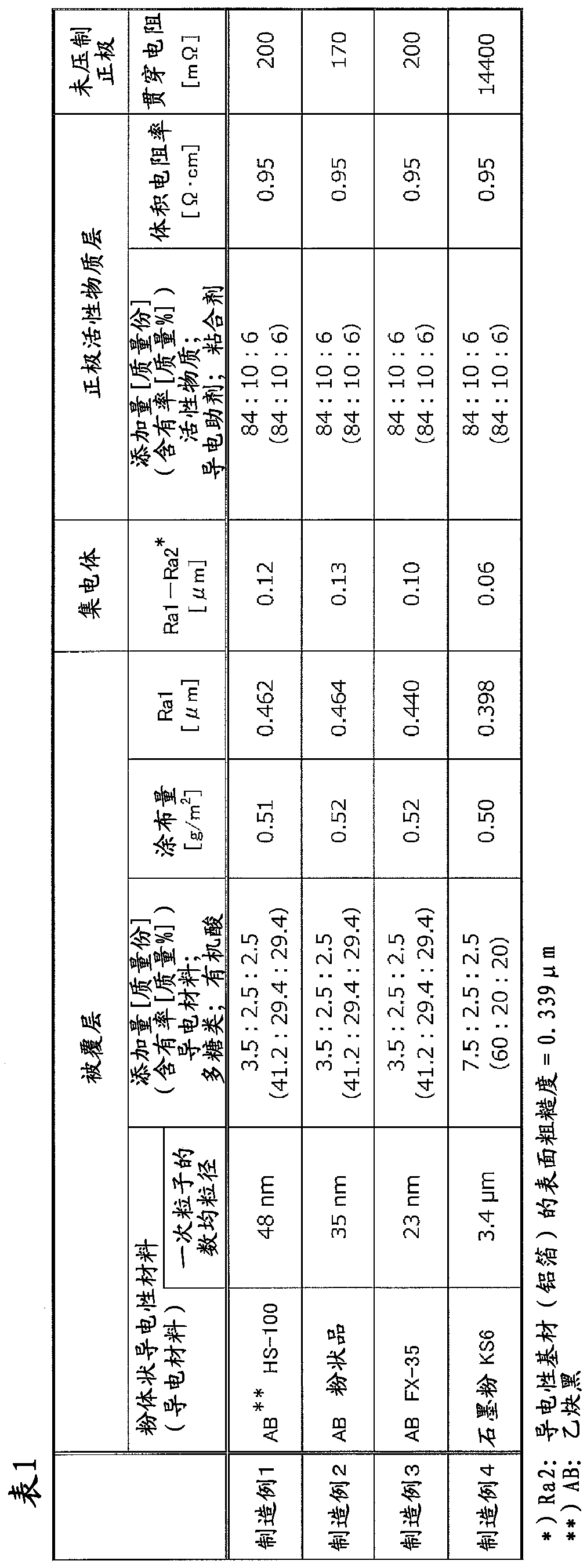

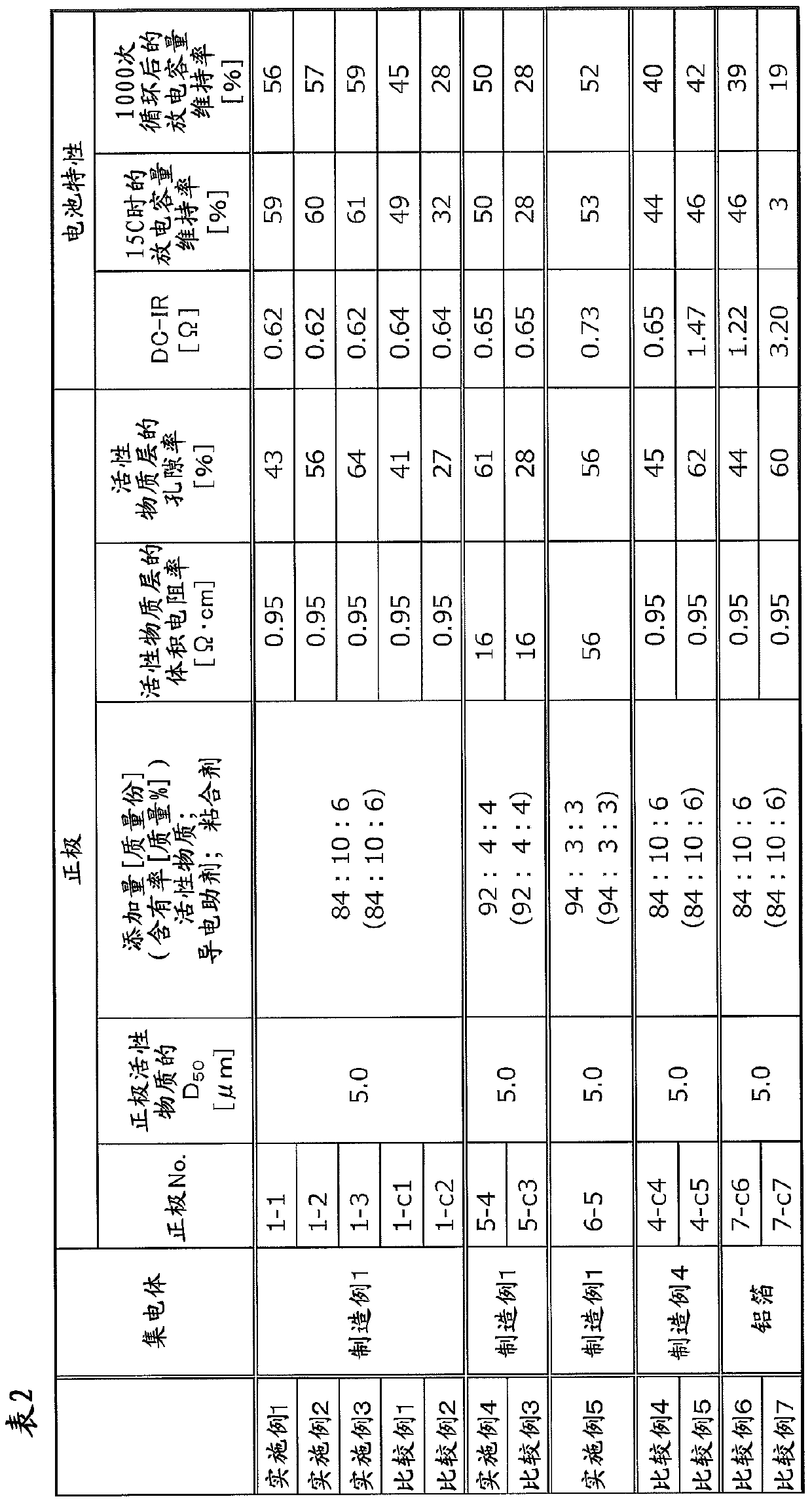

[0121] Hereinafter, examples of the present invention are shown, and the present invention will be described more specifically. In addition, these examples are simply illustrations for explanation, and the present invention is not limited by them at all.

[0122] [Manufacture and evaluation of current collectors for positive electrodes and positive electrodes]

manufacture example 1

[0124]

[0125] The number-average particle size of acetylene black HS-100 (manufactured by DENKA Co., Ltd., DENKA BLACK (registered trademark), pressed product, and primary particle (hereinafter sometimes simply referred to as primary particle size) as a powdery conductive material: 48 nm ) 3.5 parts by mass, glycerolated chitosan (manufactured by Dainichi Seika Co., Ltd., deacetylation degree: 86mol%, weight average molecular weight: 8.6×10 4 ) 2.5 parts by mass, 2.5 parts by mass of anhydrous pyromellitic acid as an organic acid, and 160 parts by mass of N-methyl-2-pyrrolidone (special grade reagent) were mixed.

[0126] The above material was processed at 300 rpm for 10 minutes using a dissolving and stirring type disperser (produced by Hideo Seiki Co., Ltd., DISPERMAT CV3), and then processed at 20,000 rpm for 30 seconds using a homogenizer (manufactured by Iada Trading Co., Ltd., PRO200) , and a coating liquid in which acetylene black was sufficiently dispersed was obt...

manufacture example 2

[0139] A positive electrode was produced in the same manner as in Production Example 1 except that the acetylene black HS-100 in Production Example 1 was changed to acetylene black powder (manufactured by DENKA Co., Ltd., DENKABLACK (registered trademark), powdery product, primary particle size: 35 nm). The current collector was used to evaluate the coating amount of the coating layer and the difference (Ra1-Ra2) of the surface roughness. An unpressed positive electrode 2 was produced, and the volume resistivity of the positive electrode active material layer and the penetration resistance of the positive electrode were evaluated. Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com