Lead-acid storage battery and manufacturing method thereof

A technology of lead-acid battery and lead wire, which is applied in the direction of lead-acid battery, lead-acid battery electrode, lead-acid battery construction, etc. It can solve the problems of low weight specific energy of lead-acid battery, complex pole group structure and manufacturing process, etc., and achieve simplification The overall structure and production process, good high current characteristics, and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

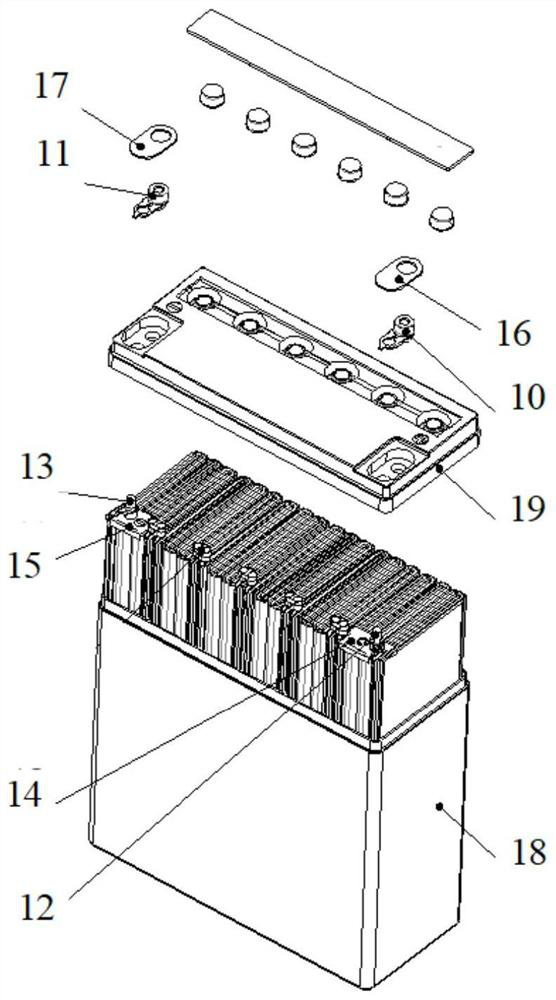

[0094] The lead-acid battery of the present embodiment includes a plurality of pole groups, and the specific structure is as follows:

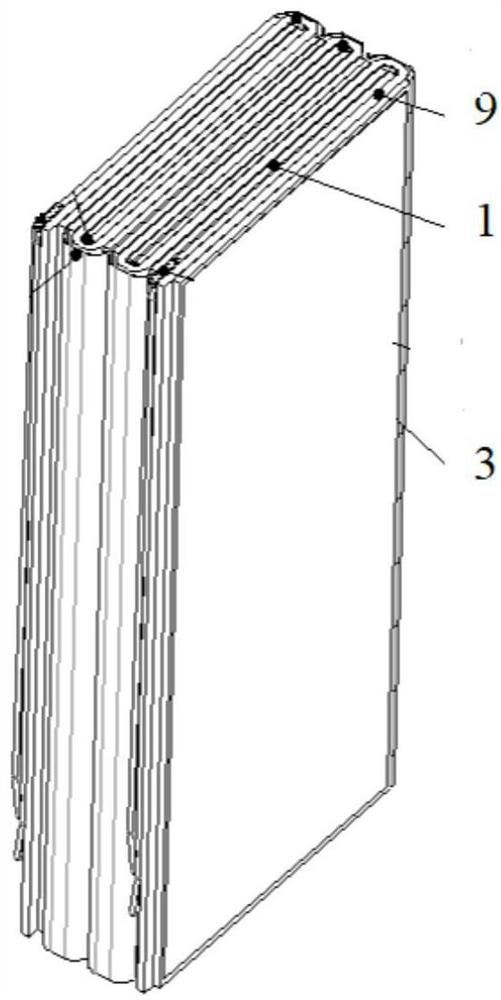

[0095]The pole group includes a six-piece negative grid group, a separator and a six-piece positive grid group stacked together, and then folded front and back in a certain order until the entire pole group is folded out.

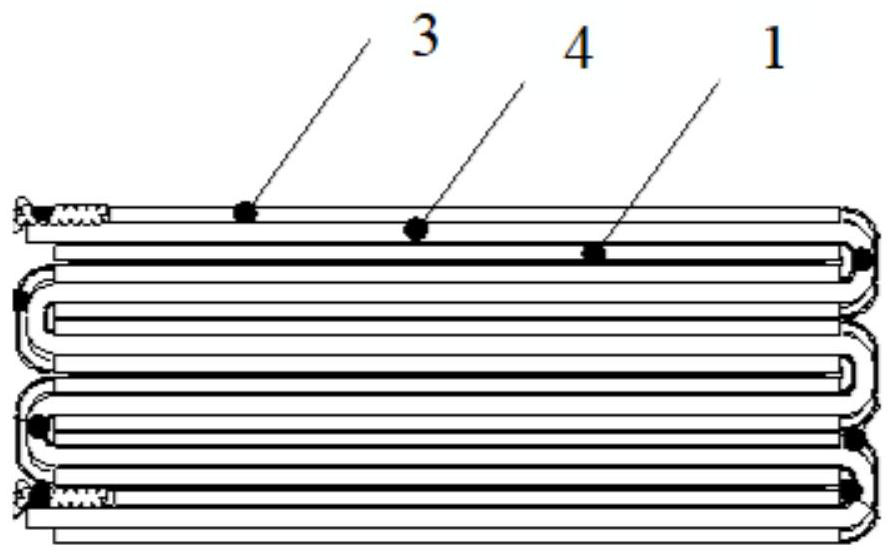

[0096] The positive electrode grid group of six consecutive pieces is folded forward and backward five times. Starting from the first piece, two adjacent pairs of positive electrode insulating frames are bent together, forming a positive small bend, and the opposite A positive large bend is formed between two adjacent pairs of positive insulating frames pasted together, wrapping a pair of negative insulating frames and corresponding separators, and so on, finally forming three pairs of positive insulating frames pasted together, and A layer of silica-coated paper is added in the middle of each pair of positive electrode ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com