Processing method for sintering and film-formation of self-cleaning glass with photocatalytic performance

The technology of glass sintering and processing method is applied in the processing field of self-cleaning glass sintering and film formation with photocatalytic properties, which can solve the problems of glass being difficult to clean and achieve the effect of preventing static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Titanium dioxide inorganic aqueous solution is made of titanium tetrachloride (16% titanium, 34% chlorine) and 35% ammonia water to generate titanium hydroxide, then add ammonium ions, and then stir the titanium hydroxide three times, precipitate, separate, and wash to improve Purity, then add hydrogen peroxide to generate titanium peroxide, heat the titanium peroxide to dissolve in water, and finally form an amorphous titanium peroxide modified anatase sol

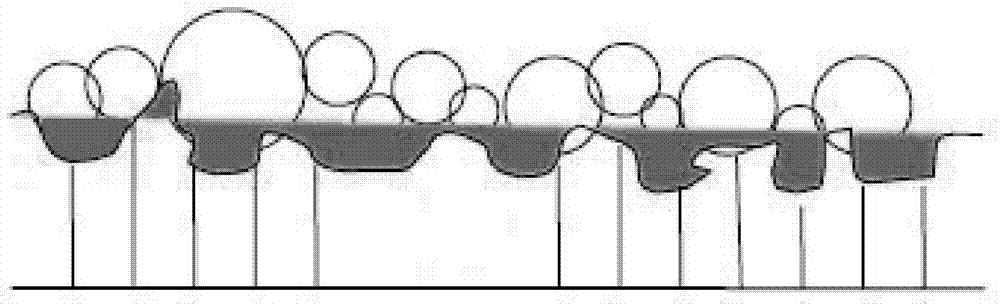

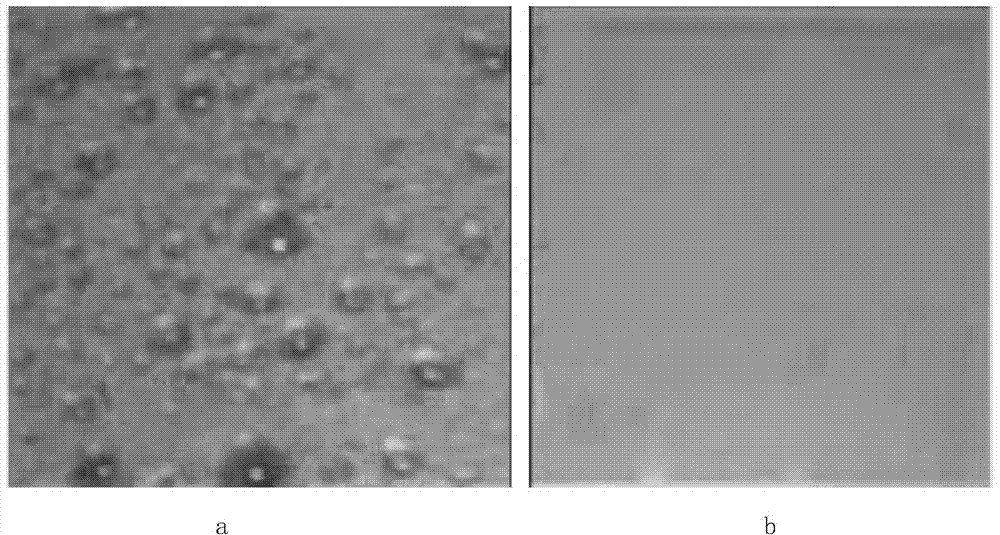

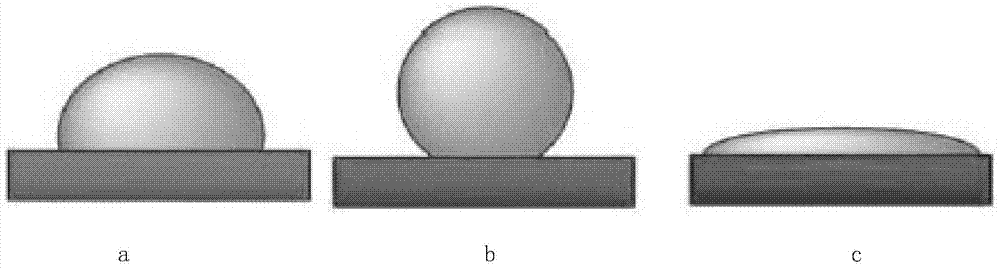

[0038] 2. In the dust-free workshop, first use the existing technology to degrease the glass and perform electrostatic dust removal treatment, and then perform the following operations at a speed of 1m / min: ①under the hot air preheater at a temperature of 50°C to 60°C Carry out preheating; ②Use a reciprocating automatic spray gun to spray nano-silica aqueous solution on the glass surface; ③Use an ultraviolet lamp dryer to dry at a temperature of 50°C to 60°C; ④Use a reciprocating automatic spray gun to dry at a t...

Embodiment 2

[0041] Embodiment 2 is basically the same as Embodiment 1, and can also be applied to fields such as aluminum plates and exterior walls, and can sinter composite titanium dioxide films at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com