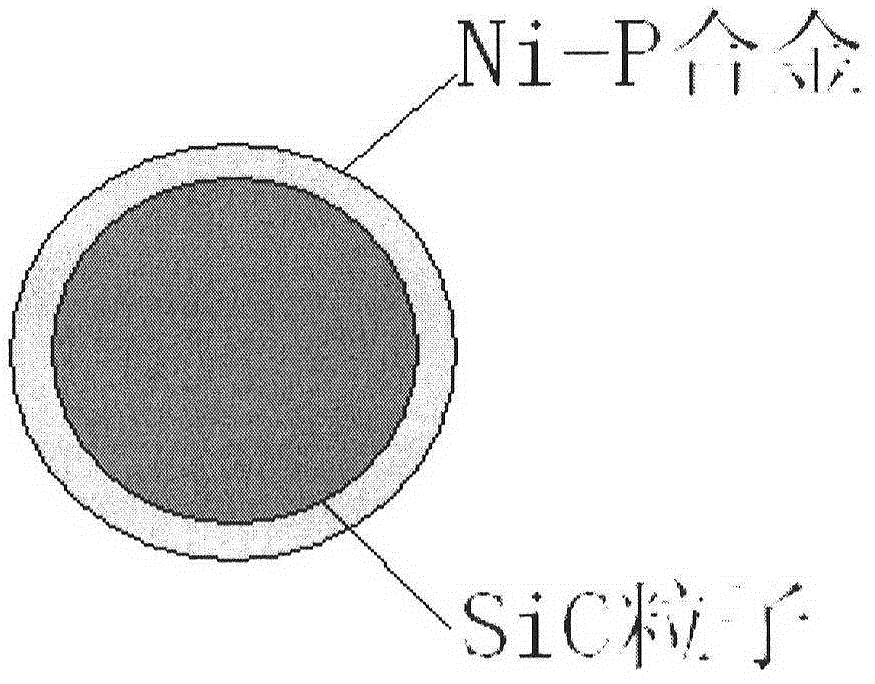

Method for chemically plating Ni-P alloy on surfaces of diamond particles

A technology of diamond particles and surface chemistry, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of complicated process, limited application, expensive drugs, etc., and achieve the effect of good effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

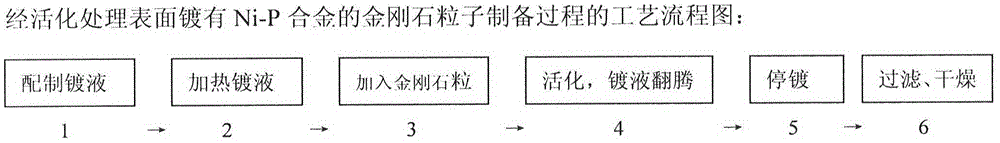

[0024] A method for chemically plating Ni-P alloy on the surface of diamond particles, comprising: (1) configuring plating solution: preparing the required plating solution for chemically plating Ni-P alloy in proportion, and the formula of said plating solution is: nickel sulfate 20g / L , sodium hypophosphite 10g / L, citric acid 10g / L, sodium acetate 5g / L, potassium iodate 0.01mg / L, sodium dodecylbenzenesulfonate 0.01mg / L; (2) Heating the bath: put The plating tank with the prepared plating solution is heated in a constant temperature water bath, and the plating temperature is 80°C; (3) Add diamond particles and stir: directly add the weighed diamond particles into the above plating solution, use the The glass rod coated with Ni-P alloy was induced to activate; (4) Plating until the plating solution was tumbling: the plating time was 3 hours, and the pH value of the plating solution was adjusted with 1:5 ammonia water, and the pH value was adjusted to 4.6 until There is a tumbl...

Embodiment 2

[0026] A method for chemically plating Ni-P alloy on the surface of diamond particles, comprising: (1) configuring plating solution: preparing the required plating solution for chemically plating Ni-P alloy in proportion, and the formula of said plating solution is: nickel sulfate 28g / L , sodium hypophosphite 20g / L, citric acid 20g / L, sodium acetate 15g / L, potassium iodate 0.02mg / L, sodium dodecylbenzenesulfonate 0.02mg / L; (2) Heating the bath: put The plating tank with the prepared plating solution is heated in a constant temperature water bath, and the plating temperature is 85°C; (3) Add diamond particles and stir: directly add the weighed diamond particles into the above plating solution, use the The glass rod coated with Ni-P alloy was induced to activate; (4) Plating until the plating solution was tumbling: the plating time was 4 hours, and the pH value of the plating solution was adjusted with 1:5 ammonia water, and the pH value was adjusted to 4.8 until There is a tumb...

Embodiment 3

[0028] A method for chemically plating Ni-P alloy on the surface of diamond particles, comprising: (1) configuring plating solution: preparing the required plating solution for chemically plating Ni-P alloy in proportion, and the formula of said plating solution is nickel sulfate 40g / L, Sodium hypophosphite 30g / L, citric acid 30g / L, sodium acetate 25g / L, potassium iodate 0.05mg / L, sodium dodecylbenzenesulfonate 0.05mg / L; The plating tank with the prepared plating solution is heated in a constant temperature water bath, and the plating temperature is 90°C; (3) Add diamond particles and stir: directly add the weighed diamond particles into the above plating solution, use the plated A glass rod with Ni-P alloy was used to induce activation; (4) Plating until the plating solution was tumbling: the plating time was 5 hours, and the pH value of the plating solution was adjusted with 1:5 ammonia water, and the pH value was adjusted to 5.0 until the plating solution There is a tumblin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com