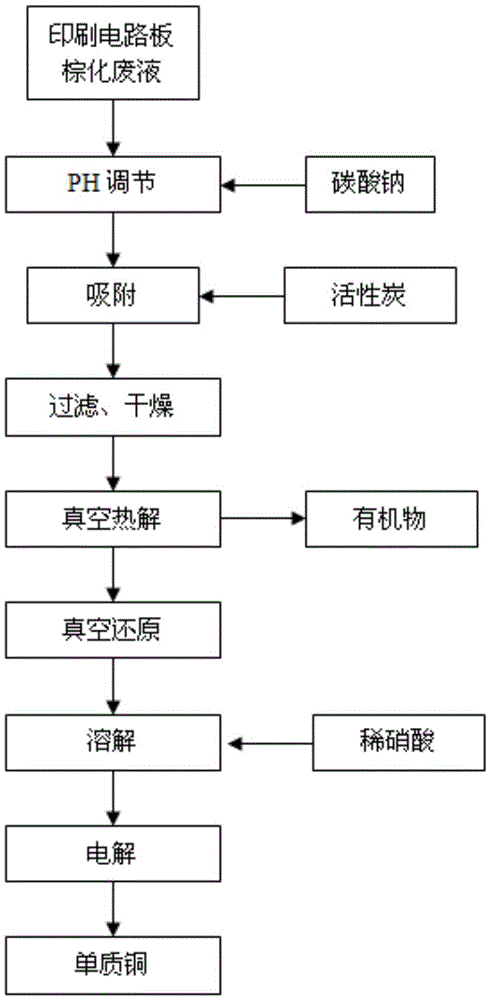

Method for recovering copper from brown oxidation wastewater of printed circuit board

A printed circuit and copper recovery technology, which is applied in the field of resource recovery, can solve the problems of high reagent consumption, poor economy, secondary pollution, etc., and achieve the effect of high added value, easy realization of process parameters and equipment, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Under normal temperature conditions, take 2L of waste browning solution, the copper content is 30g / L, and the theoretical copper content is 60g; add 200g sodium carbonate to the browning solution, and the pH value is 6.5; then add powdered activated carbon 0.6Kg, stir the solution for 30min, fully Reaction; filter and dry the waste browning liquid to obtain the filter residue; put the filter residue powder into the vacuum pyrolysis reactor, start the vacuum pump, adjust the pressure of the vacuum reactor to 30Pa, raise the temperature of the reactor to 550°C, and perform constant temperature pyrolysis After 10 minutes, the organic matter in the filter residue is fully pyrolyzed and volatilized, and collected by condensation in the condenser; the temperature of the vacuum reactor is lowered to 250°C, and heated at a constant temperature for 30 minutes to fully react carbon and copper oxide to obtain copper powder and carbon powder. The product is taken out, washed with cl...

Embodiment 2

[0031] Under normal temperature conditions, take 1L of waste browning solution, the copper content is 30g / L, and the theoretical copper content is 30g; add 150g sodium carbonate to the browning solution, and the pH value is 6.8; then add 0.5Kg of powdered activated carbon, stir the solution for 30min, fully Reaction; filter and dry the waste browning liquid to obtain the filter residue; put the filter residue powder into the vacuum pyrolysis reactor, start the vacuum pump, adjust the pressure of the vacuum reactor to 30Pa, raise the temperature of the reactor to 600°C, and perform constant temperature pyrolysis After 10 minutes, fully pyrolyze and volatilize the organic matter in the filter residue, and condense and collect it through the condenser; reduce the temperature of the vacuum reactor to 270°C, and heat at a constant temperature for 30 minutes to fully react the carbon and copper oxide, and obtain the product of copper powder and carbon powder The product is taken out,...

Embodiment 3

[0033]Under normal temperature conditions, take 1L of waste browning solution, the copper content is 30g / L, and the theoretical copper content is 30g; add 100g sodium carbonate to the browning solution, and the pH value is 6.5; then add 0.4Kg of powdered activated carbon, stir the solution for 30min, and fully Reaction; filter and dry the waste browning liquid to obtain the filter residue; put the filter residue powder into the vacuum pyrolysis reactor, start the vacuum pump, adjust the pressure of the vacuum reactor to 30Pa, raise the temperature of the reactor to 600°C, and perform constant temperature pyrolysis After 10 minutes, the organic matter in the filter residue is fully pyrolyzed and volatilized, and condensed and collected by the condenser; the temperature of the vacuum reactor is lowered to 260°C, and heated at a constant temperature for 30 minutes to fully react carbon and copper oxide to obtain copper powder and carbon powder. The product is taken out, washed wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com