Cutter abrasion monitoring method based on co-integration modeling

A tool wear and tool technology, used in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of unstable threshold value, error-prone tool wear, and difficulty in pre-determining the threshold value. The method is simple and avoids complexity. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

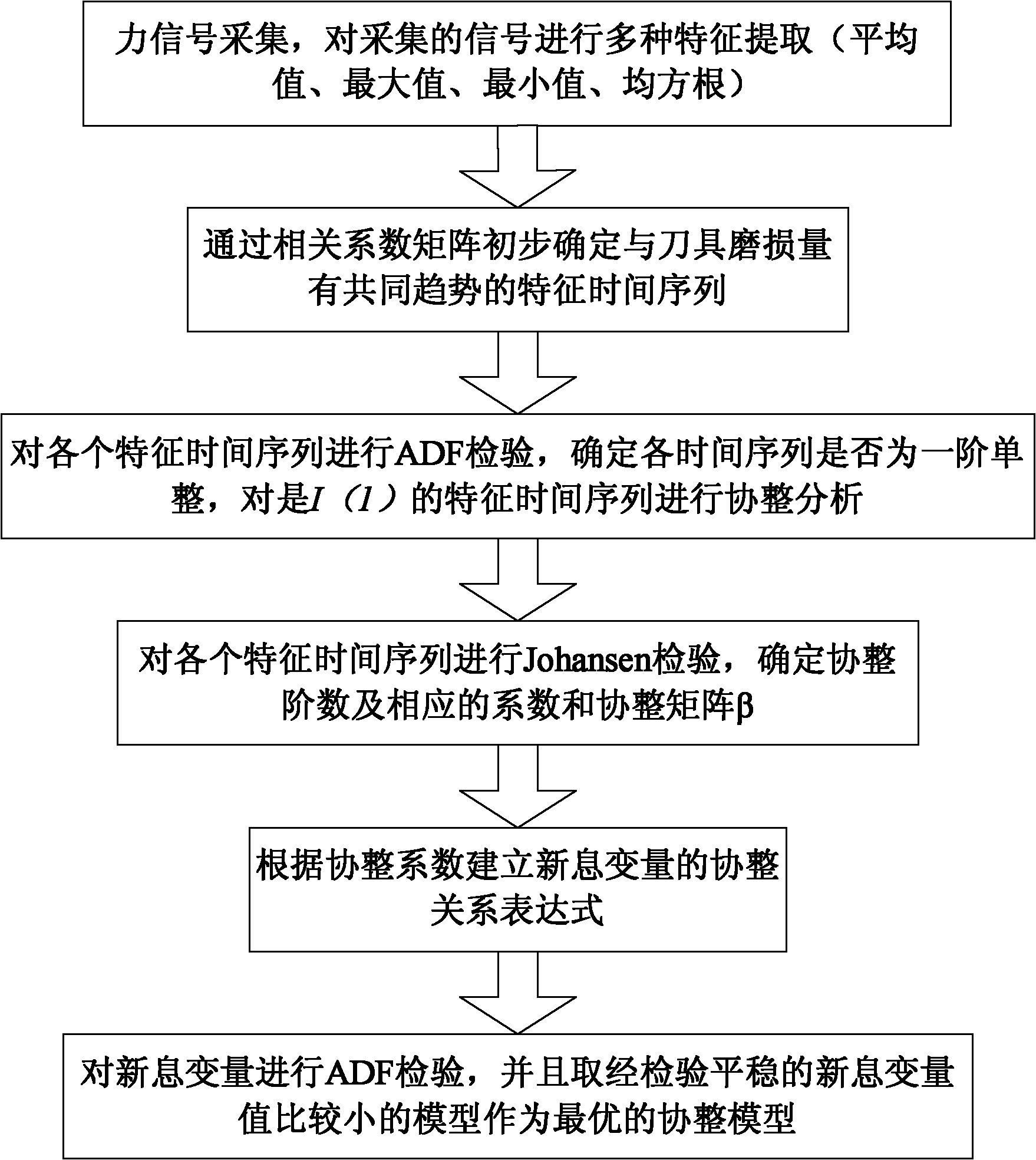

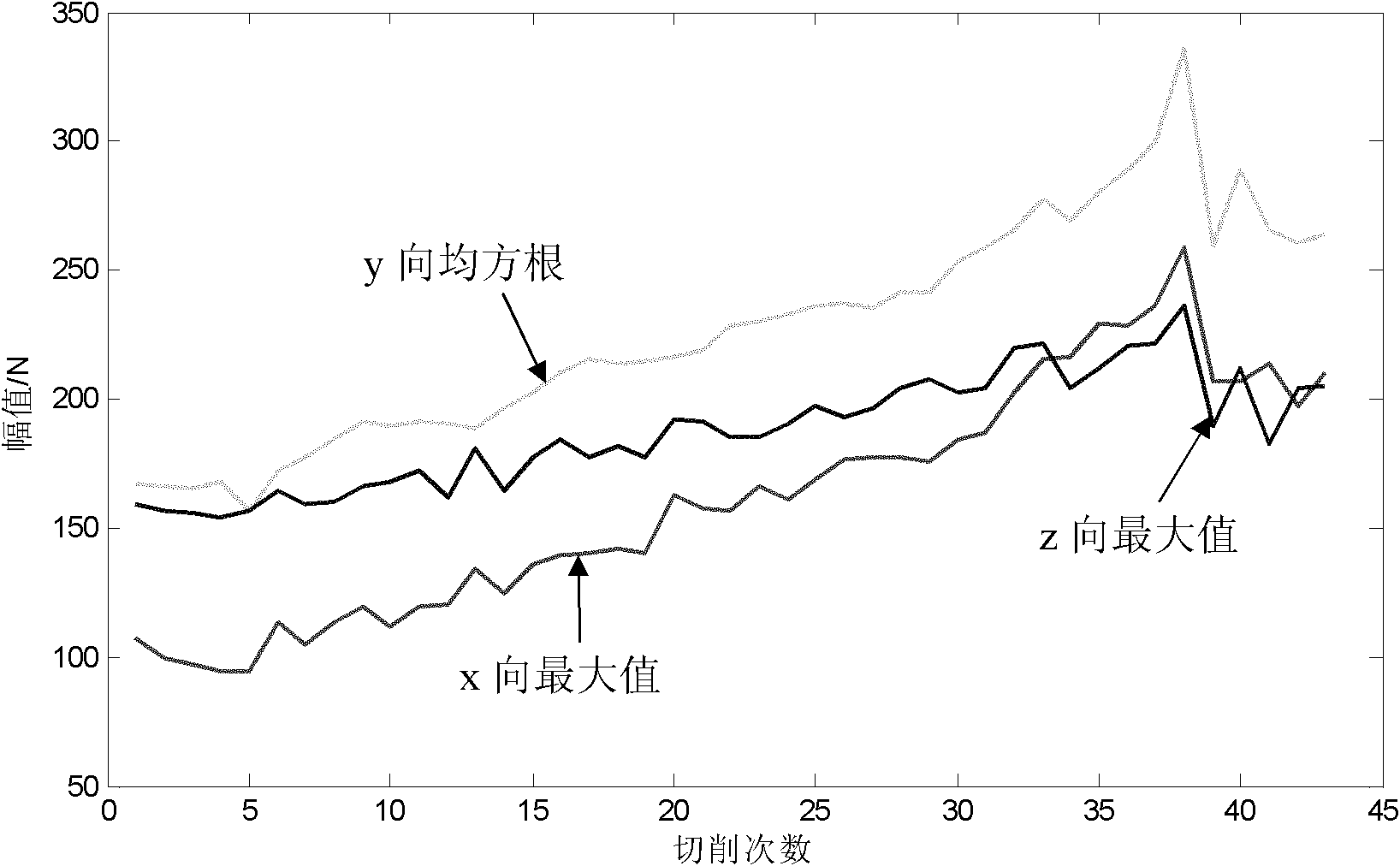

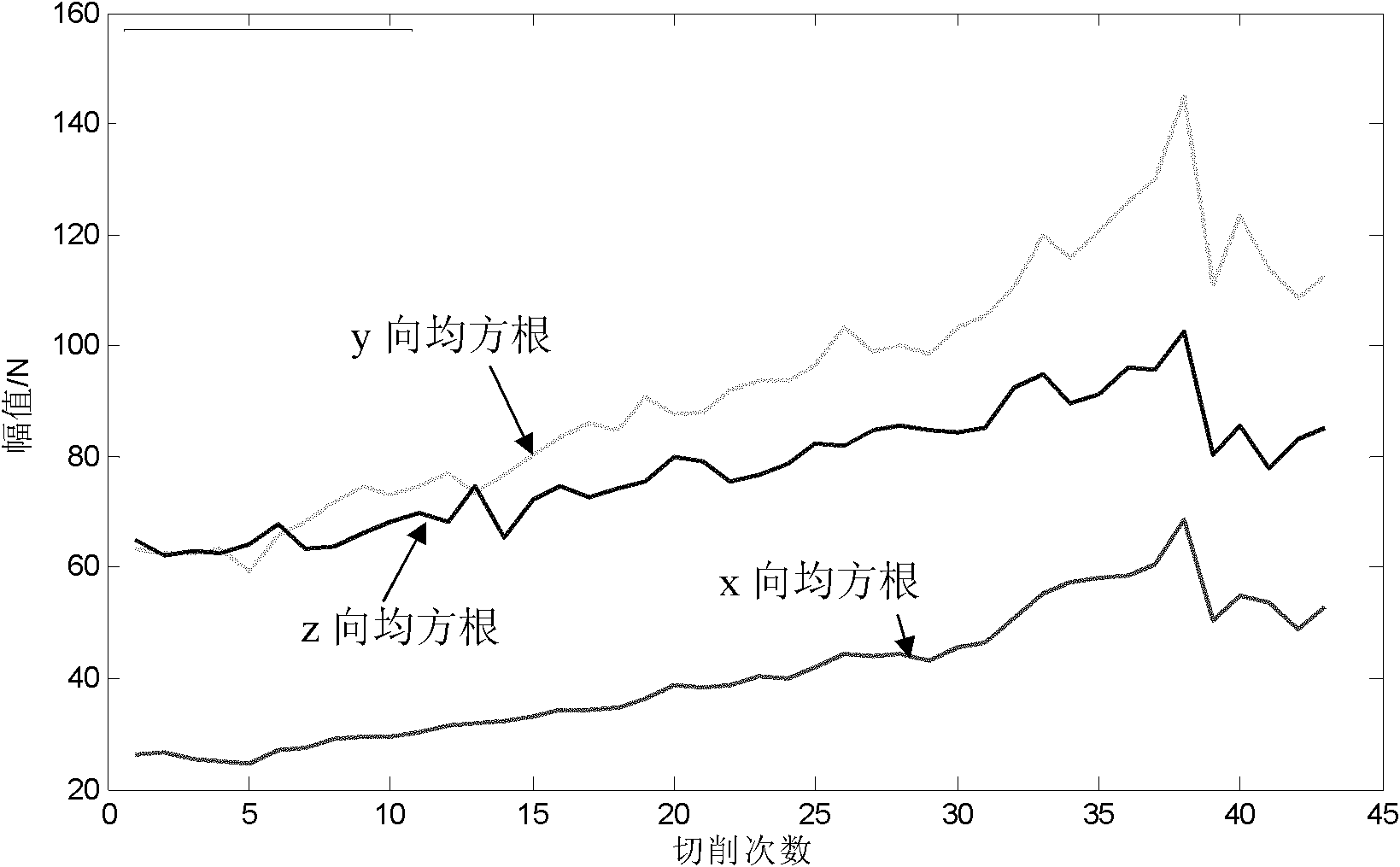

[0032] The tool wear monitoring method based on co-integration modeling in the present invention collects tool cutting signals and extracts the characteristics of the signals to discover the inherent relatively stable law between the tool wear state and the extracted features, so as to achieve the extraction by analyzing the signals feature can accurately predict the method of tool wear; in the present invention, the co-integration theory in economics is applied to tool wear monitoring, and the tool wear co-integration model of tool wear and signal characteristic time series is established according to co-integration theory, The established co-integration model is tested and analyzed to determine the optimal model, and the tool wear amount is accurately predicted by establishing the model relationship between the tool wear amount and the signal characteristic time series.

[0033] The present invention will be further described in detail below in combination with specific embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com