Level sight lens and method and tool for assembling same

An assembly tool and sight glass technology, which is applied in the field of sight glass, can solve problems such as low pressure bearing capacity, perishable threads, and reduced service life of the sight glass, so as to achieve excellent sealing performance and avoid complex processing techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

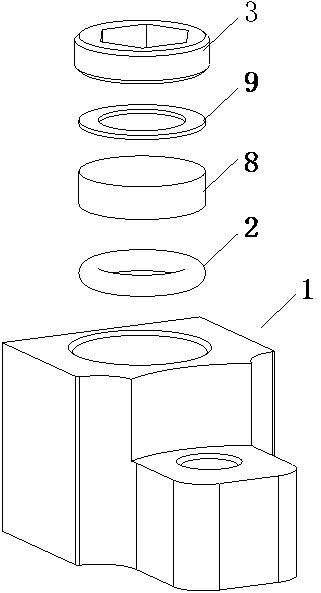

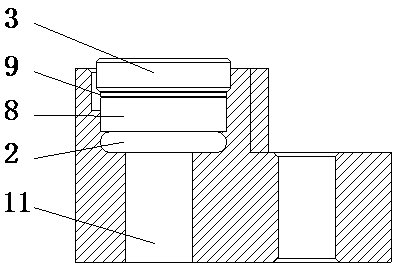

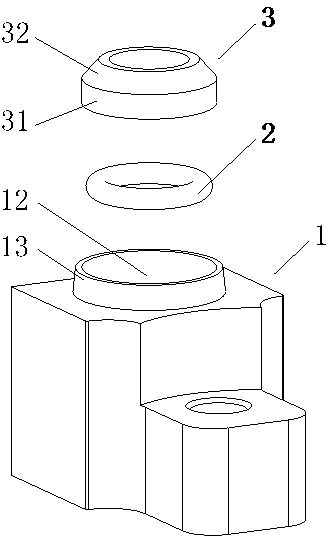

[0036] Sight glass, if attached image 3 , 4 , 5, including a mirror body 1, an O-ring 2 and a see-through mirror, the see-through mirror includes an inner lens and an outer lens seat 3, the mirror is provided with a sight hole 11, and the sight hole An installation cavity 12 for installing an O-shaped sealing ring and a perspective mirror is provided around the upper part, and the lens seat 3 includes a lower cylindrical part 31 and an upper truncated cone part 32; the upper surface of the mirror body is at the upper edge of the installation cavity A ring-shaped pressing piece 13 is provided, and the said ring-shaped pressing piece 13 can be bent inward to fit the inclined surface of the truncated conical portion 32 of the lens holder.

[0037] The upper edge of the cylindrical portion of the lens seat is slightly higher than the upper surface of the lens body.

[0038] An assembly method for the above-mentioned sight glass, comprising the following steps:

[0039] Step A:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com