Self-adaptive double-sealing-steel-ball clamping underwater pipeline connector

A double-seal and self-adaptive technology, applied in the direction of adjustable connections, pipes/pipe joints/fittings, pipe components, etc., can solve the problems that hinder the efficient and reliable connection, failure, and high relative position requirements of the pipeline, so as to prevent seawater from corroding the interior The effect of simple structure and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

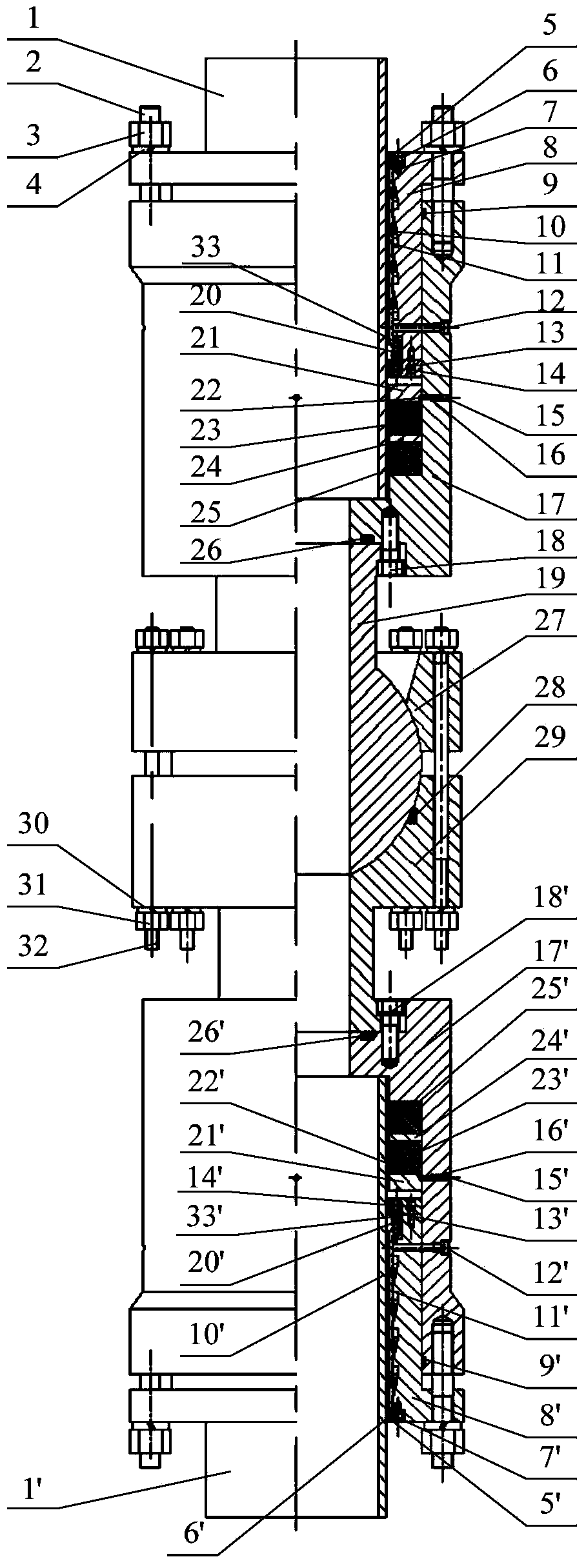

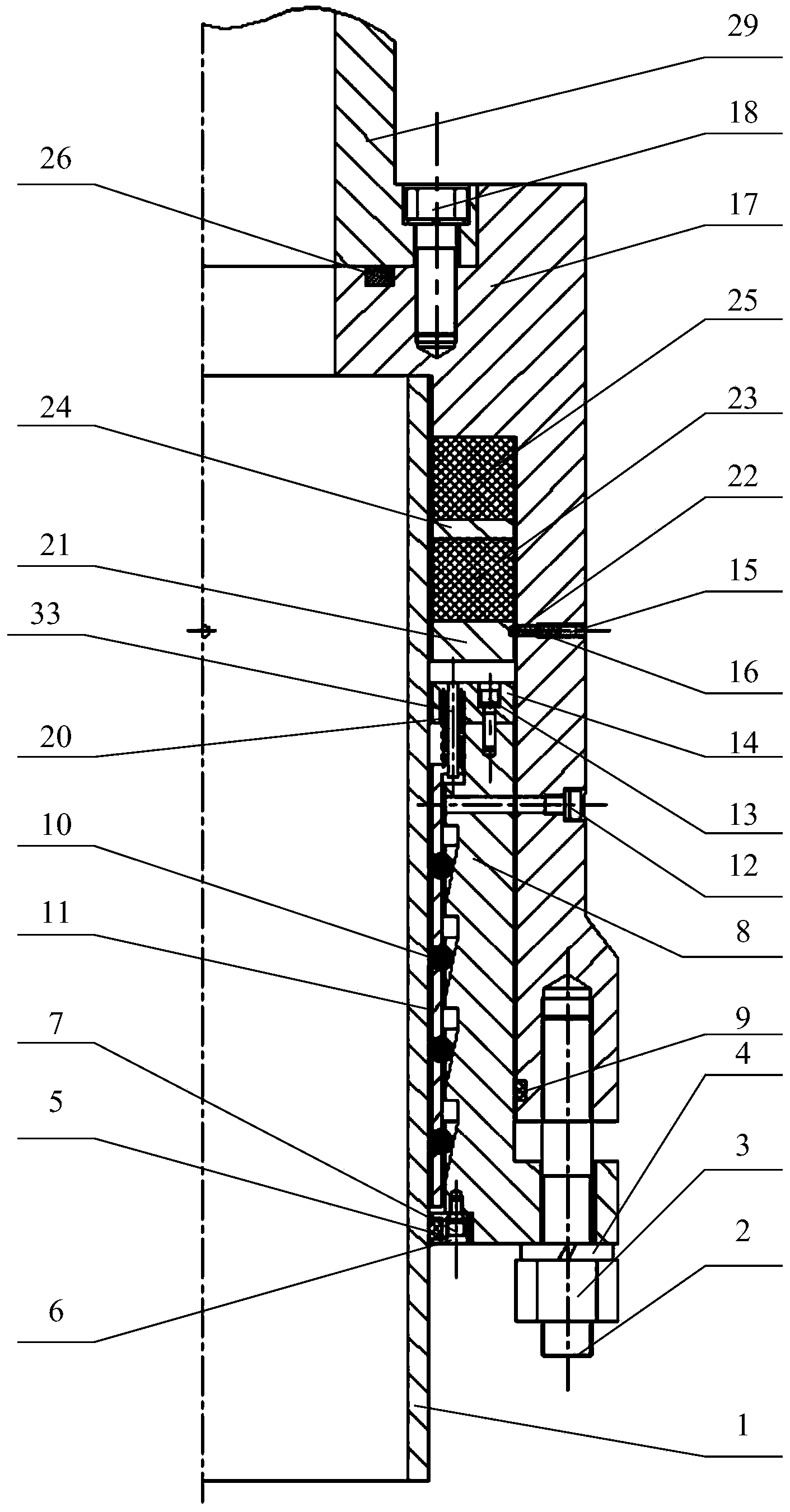

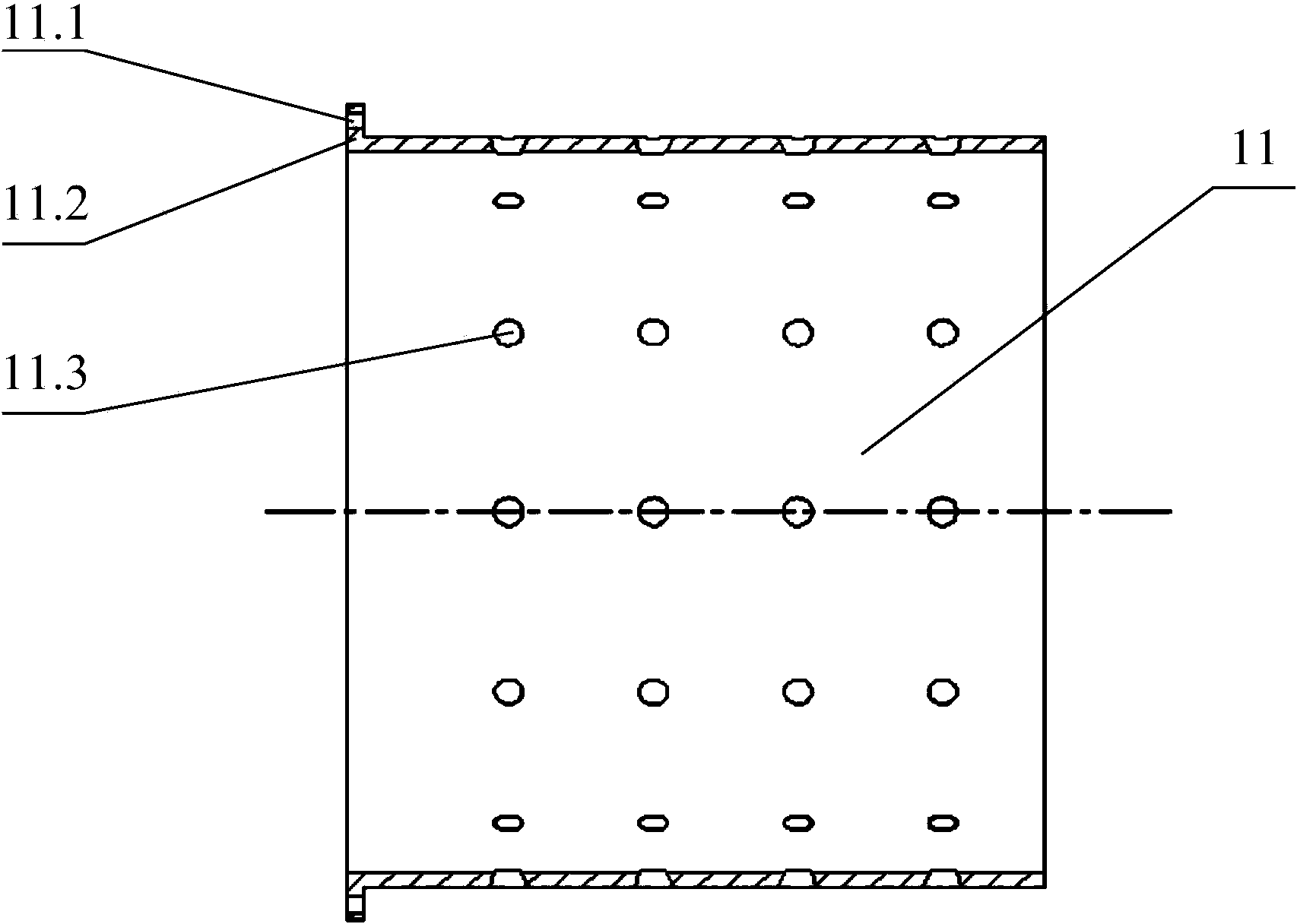

[0018] combine Figure 1~6 , the self-adaptive double-seal steel ball clamping underwater pipe connector of the present invention consists of 20 stud bolts 2, 20 nuts 3, 20 spring washers 4, 2 rubber sealing rings 5, 5', 2 end caps 6, 6', 20 end cover screws 7, 7', 2 clamping propellers 8, 8', 2 rubber sealing rings 9, 9', 96 steel balls 10, 10', 2 ball cages 11, 11' , 4 drain outlet screws 12, 12', 2 cage retaining rings 14, 14', 20 retaining ring screws 13, 13', 20 springs 20, 20', 20 guide pins 33, 33', 2 1 sealing ring retaining ring 21, 21', 2 pipe rubber sealing rings 23, 23', 2 sealing ring retaining rings 24, 24', 2 pipe rubber sealing rings 25, 25', 8 positioning balls 22, 22 ', 8 positioning screws 15, 15', 8 positioning springs 16, 16', 2 cylinder blocks 17, 17', 2 rubber sealing rings 26, 26', 20 screws 18, 18', spherical base 19 , flange ring 27, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com