Novel blowout-prevention and anchoring integrated tool

An anchoring and new technology, applied in the fields of production fluids, drilling equipment, measurement, etc., can solve the problems of tool failure, increase operation time, weak circlip structure, etc., and achieve short tool length, prevent insufficient meshing force, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

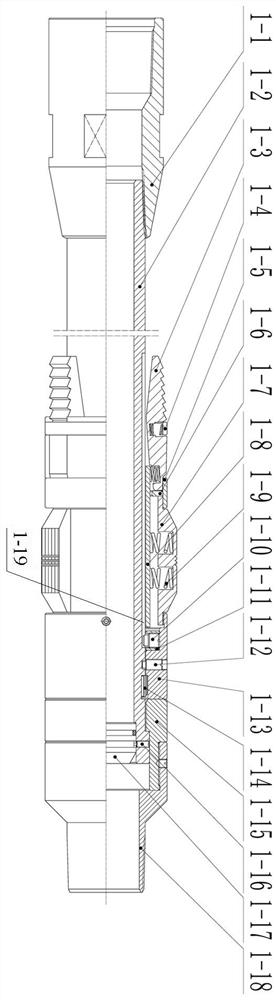

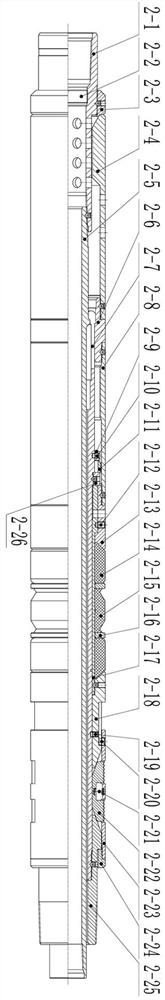

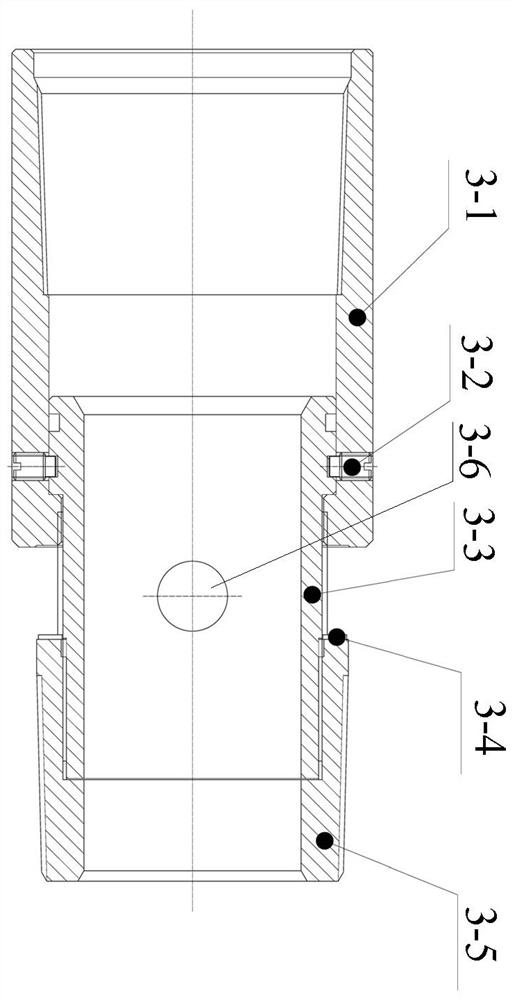

[0040] The specific structure of this example is: a new integrated tool for blowout prevention and anchoring includes an anti-rotation part, a throwaway part, a pressure relief channel part, an anchor part, a gravity valve part, a through rod 6, a screen 7, and the anchor The fixed part includes support slip 4;

[0041] The anti-rotation part includes an anti-rotation anchor 1, which includes an upper joint 1-1, a center pipe 1-2, slips 1-3, a fixed ring 1-4, a spacer ring 1-5, and a retaining ring 1. -6, friction block 1-7, friction body 1-8, spring 1-9, guide pin 1-10, guide ring 1-11, release pin 1-12, guide sleeve 1-13, circlip Ⅰ1-14, Connecting sleeve 1-15, blowout prevention pin 1-16, blowout prevention live plug 1-17 and lower joint 1-18;

[0042] The upper end of the upper joint 1-1 is threaded to the lower end of the screw pump, the lower end of the upper joint 1-1 is threaded to the central pipe 1-2, and the outer wall of the lower part of the upper joint 1-1 is a tapere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com