Vertical hinged door special for lifting opening

A technology for swing doors and hoisting openings, applied in door/window fittings, wing fan suspension devices, buildings, etc., can solve problems such as troublesome and dangerous, falling door panels, etc., to prevent chain loss, increase the number of meshing teeth, and improve operating life. and reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

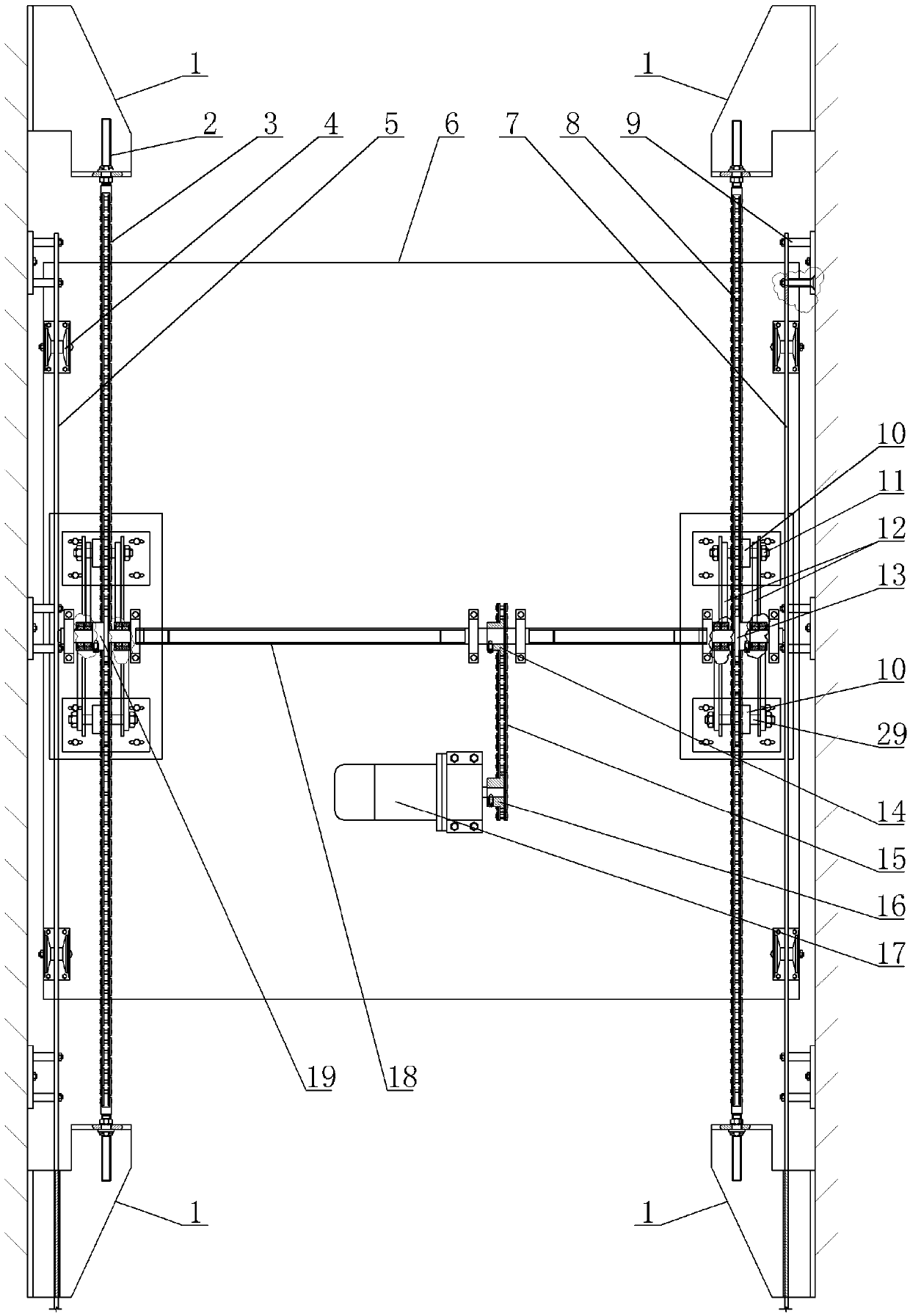

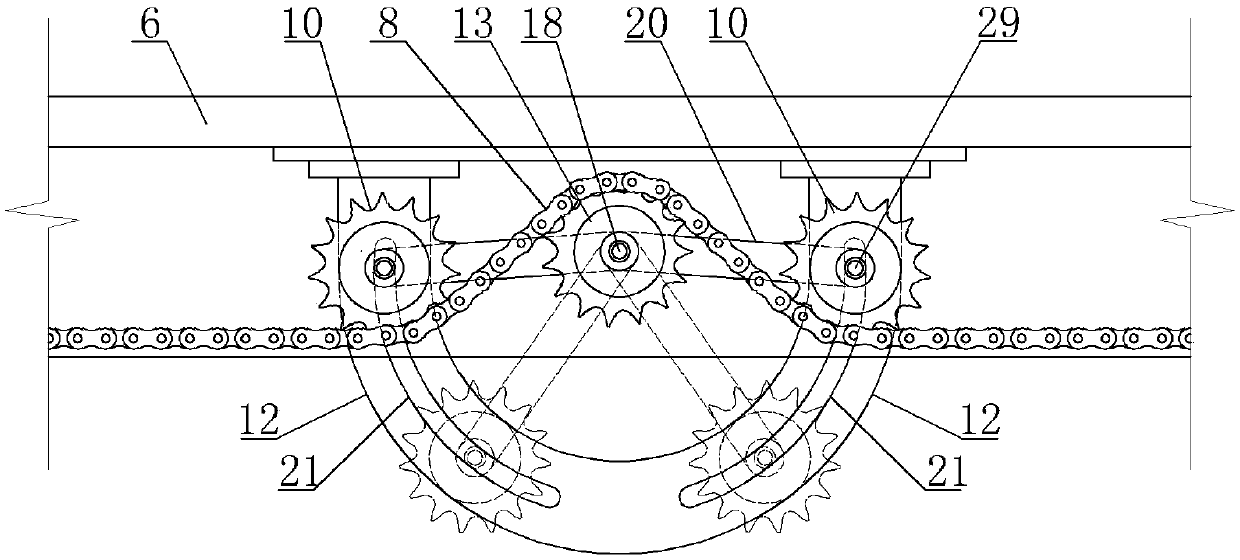

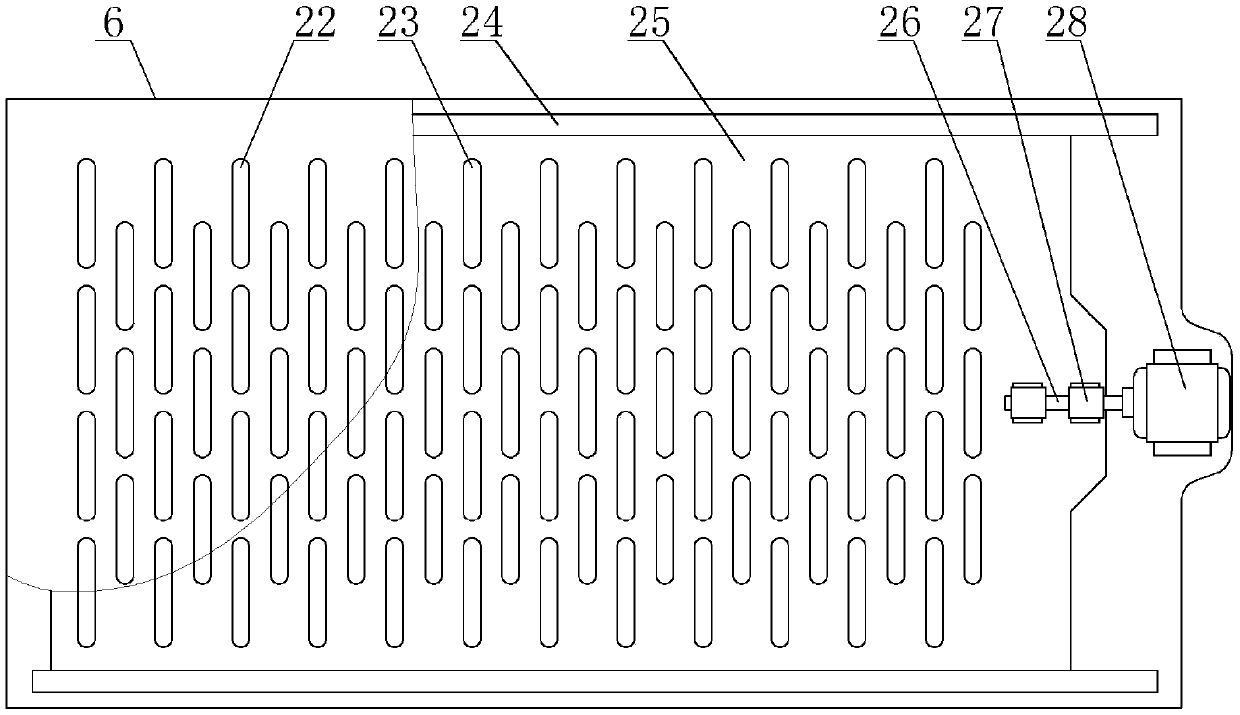

[0013] The special casement door for the hoisting port includes a door panel 6 and a translation device; the door panel is equipped with a translation motor 17 and a translation shaft 18. A guide sprocket 14 is fixed on the top, and a drive sprocket 16 is fixed on the motor shaft of the translation motor. The drive sprocket is dynamically connected with the guide sprocket through a guide chain 15, and the left end of the translation shaft is fixed with a left rail chain. Wheel 19, the right end are fixedly equipped with right guide rail sprocket wheel 13; Arc-shaped elongated holes 21 are provided on the elongated holes, and two anti-off axles 29 are housed in the elongated holes. One end of the two anti-off axles is respectively equipped with nuts 11 that are threaded, and the other end of the two anti-off axles is respectively equipped with rotating Connected anti-off sprocket 10, one of the two anti-off sprockets is placed in front of the corresponding guide rail sprocket, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com