Optical fiber fast terminating assembly

An optical fiber and fast technology, which is applied in the field of high-performance sealed optical fiber rapid termination components, can solve problems such as defects and failures, and achieve the effects of high reliability, pollution prevention, and reliability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

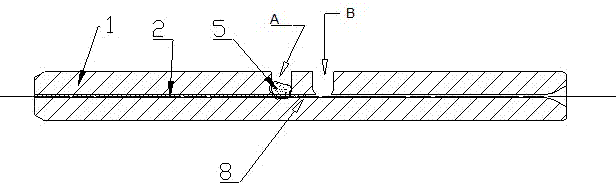

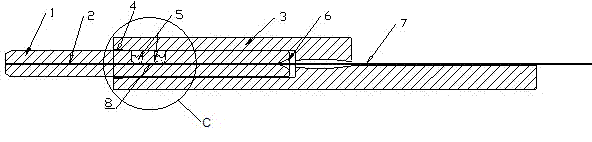

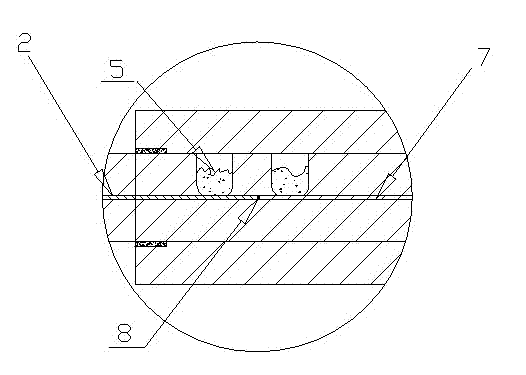

[0025] Such as figure 1 As shown, the present invention discloses a rapid optical fiber terminal assembly, which includes a body 1 and an inner hole located in the body 1, wherein two grooves A and B are opened on the body 1 until the inner hole is exposed, and the inner hole is pre-embedded. The optical fiber 2 and the access optical fiber 7 are respectively connected to the two ends of the ferrule body. The fiber butt joint end face 8 of the pre-embedded optical fiber 2 and the access optical fiber 7 is located at the inner hole in the middle of the two grooves A and B. The two grooves A, B are used to fill matching gel 5.

[0026] The body 1 can be made into a green body by extrusion or injection molding, and then polished and ground by a precision grinder. It can also be modified by using a grinder cutter or corrosion process. The diameter of the inner hole is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com