Non-refillable valve for steel welded cylinder

A non-repetitive, valve technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of destroying the valve structure, difficult to ensure that the factory valve does not leak, etc., to achieve the effect of ensuring no leakage and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

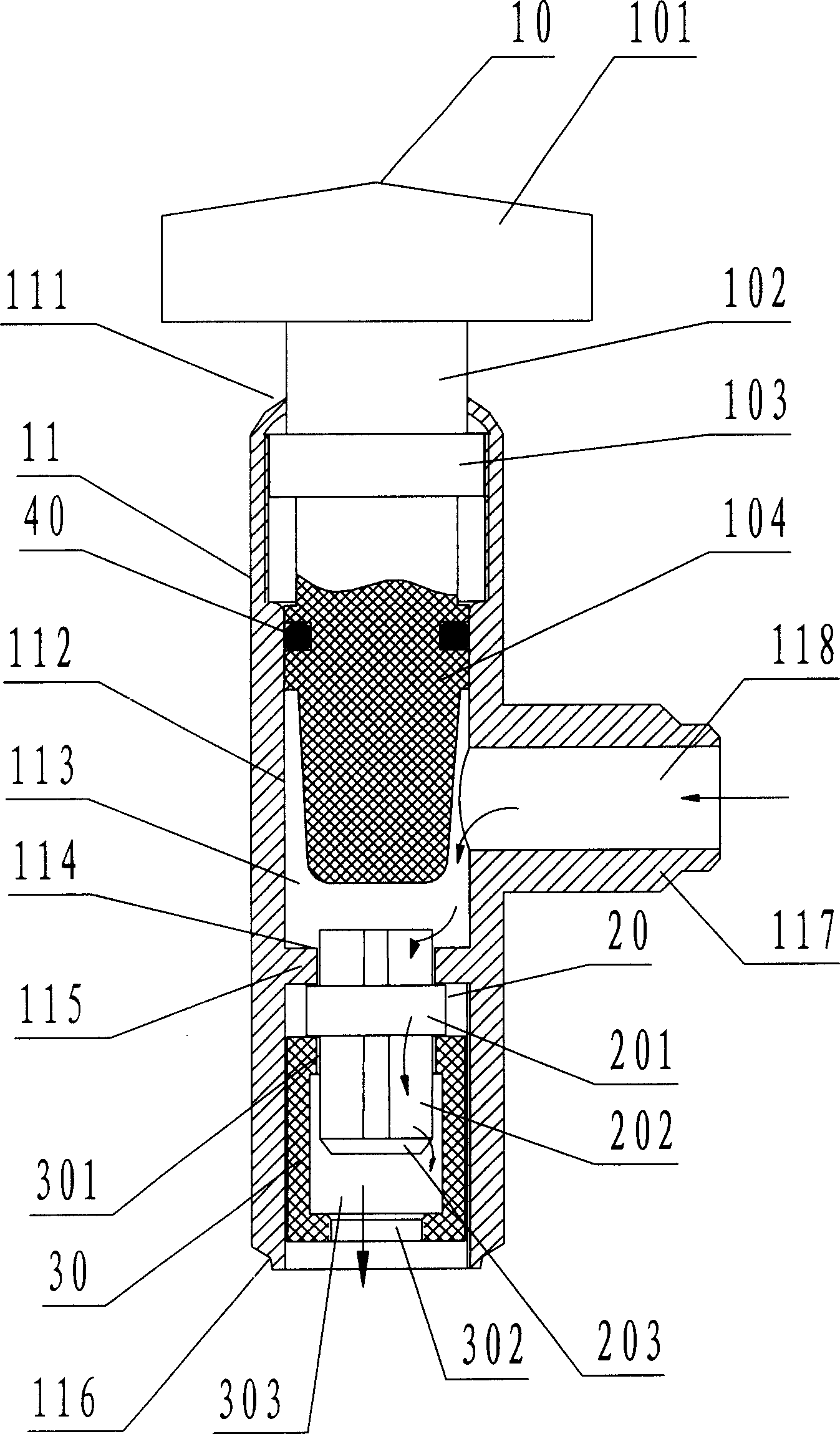

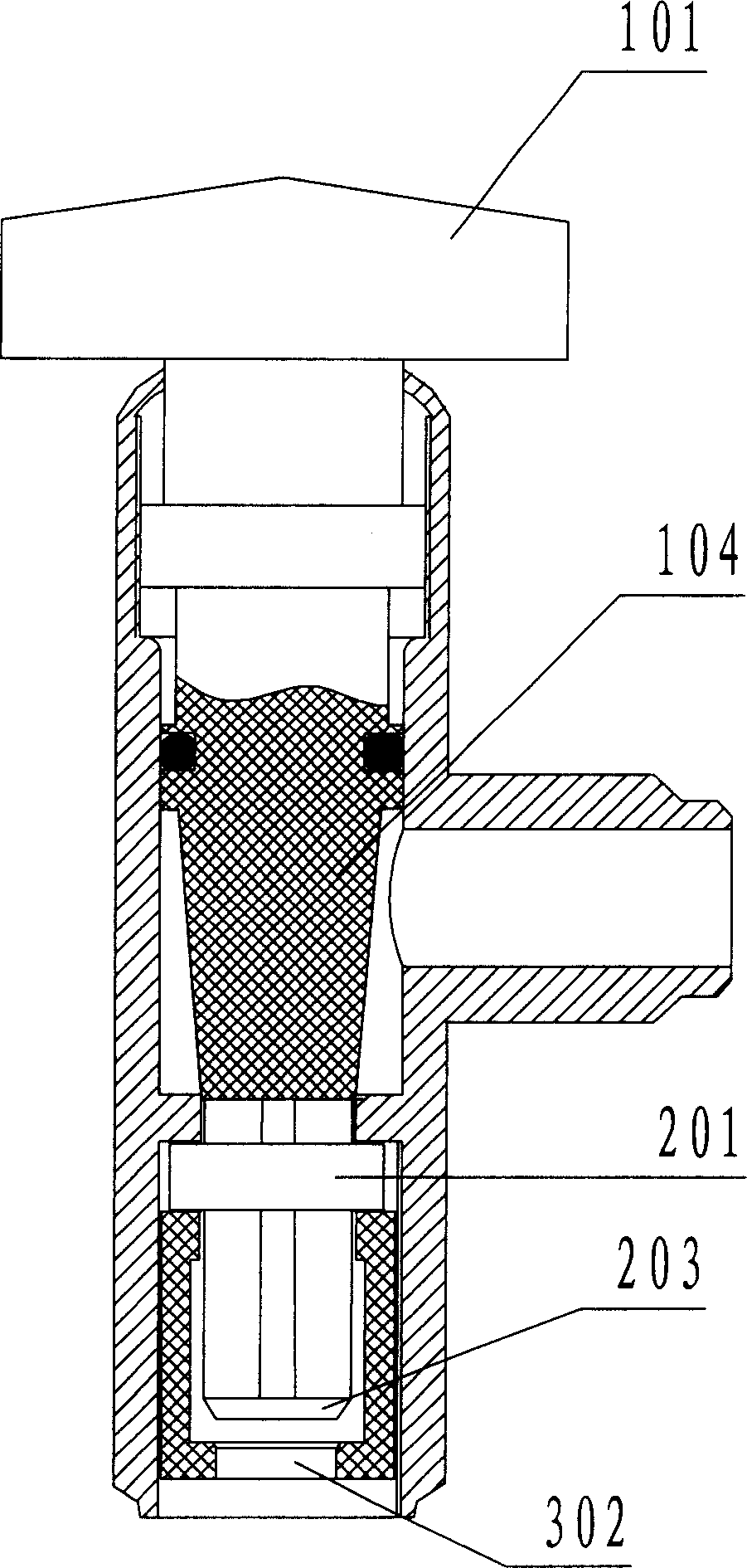

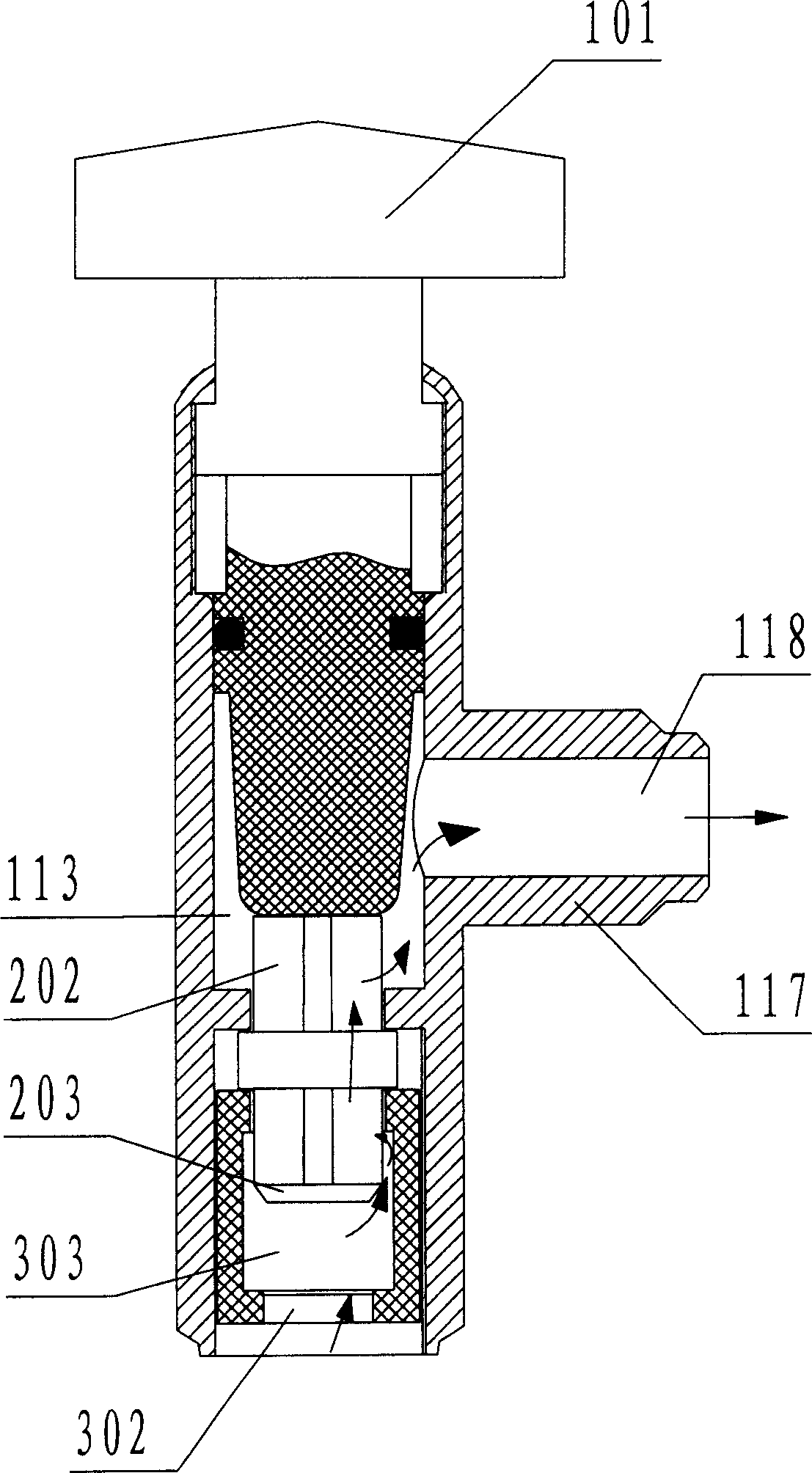

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment, Figure 1-8 The serial numbers in represent respectively: valve body 11, necking wall 111, valve inner wall 112, valve body cavity 113, sealing hole 114, valve body partition 115, connecting step 116, valve nozzle 117, air inlet 118; valve stem assembly 10. Valve handle 101, valve stem 102, threaded connector 103, upper valve core 104; lower valve core 20, positioning ring 201, lower valve core rod 202, sealing head 203, flow channel 204; supporting sleeve 30, cylinder cavity A through hole 301 on the partition, a through hole 302 under the partition of the cylinder cavity, a support sleeve cavity 303 ; a sealing ring 40 .

[0017] See attached figure 1 . The structure of the non-refillable valve for steel cylinders in this embodiment includes a valve body 11, a valve mouth 117 and components inside the valve. The valve body 11 and the valve mouth 117 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com