Impregnation or supercritical fluid pretreatment assisted metal plating textile preparation method

A supercritical fluid and auxiliary metal technology, applied in the field of textiles, can solve problems such as inability to meet demand, and achieve the effects of good UV resistance, good repeatability and high binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] c. Preparation of metal-plated textiles: Mix stabilizer, metal salt and reducing agent to obtain solution A; put the textiles dried in step b into solution A for microwave treatment, take them out, wash them with water, and dry them; The temperature of the microwave treatment is 30-80°C, and the treatment time is 5-10 minutes; the mass ratio of the stabilizer, metal salt and reducing agent is: 0.1-1:1:1-100;

[0031] Preferably, the microwave treatment in step c also includes turning over every 1 min.

[0032] In a specific embodiment, the cleaning in step a is: the textiles are ultrasonically cleaned in ethanol and acetone solutions for 10-30 minutes respectively.

[0033] The invention pre-treats the textile fabric with a coupling agent to enhance the binding force between the coating and the textile fabric.

[0034] In a specific embodiment, the textile is at least one of natural fiber fabrics or chemically synthesized textile fibers, or natural fiber yarns or chemi...

Embodiment 1

[0044] The bamboo pulp fiber fabric with a size of 5cm×5cm was ultrasonically cleaned with acetone and ethanol for 30 minutes respectively, and the fabric was taken out and dried naturally in a ventilated place; Dissolve 5ml of silane in 45ml of ethanol, add the solution to the dye kettle, put the cloth sample into the reaction kettle, take it out after supercritical static treatment at 10Mpa and 40℃ for 10min, and dry it in the air; add 0.08gAgNO 3 Dissolve in 40ml of deionized water respectively, add 6ml of 1% sodium citrate, and stir evenly; then put the silane-treated bamboo pulp fiber fabric into the above silver nitrate solution, heat it with microwave for 8min, turn over every 1min, wash with water, and Dry in an oven at 80°C.

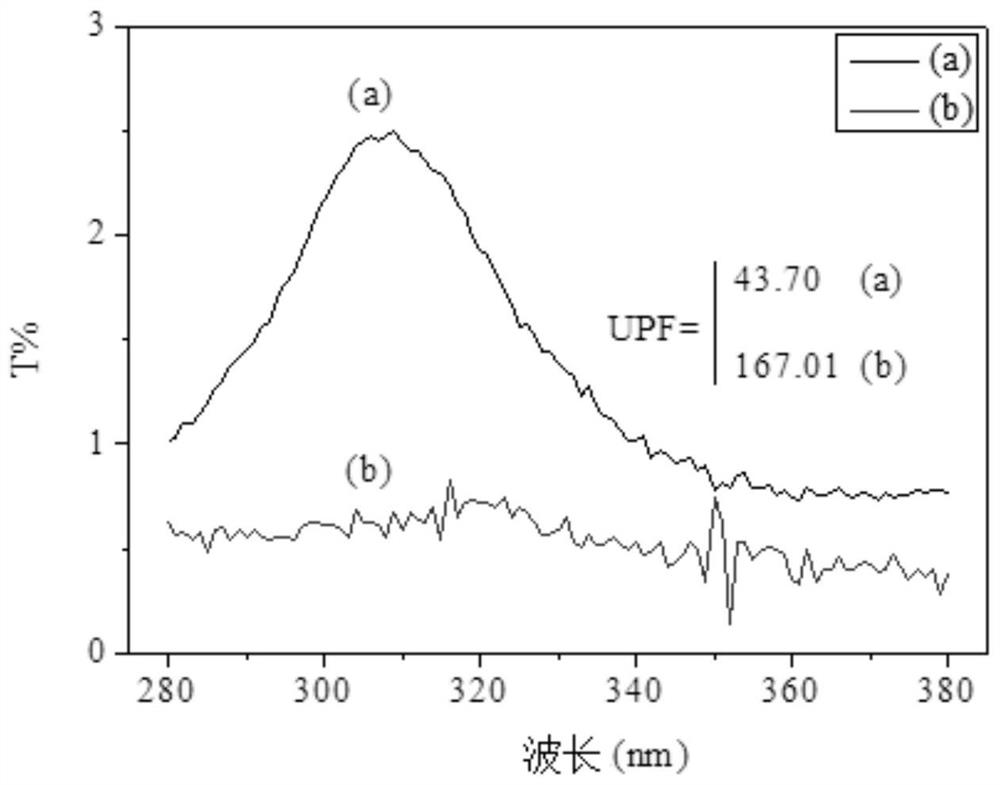

[0045] The microstructure and macroscopic performance of gained nano-silver plating bamboo pulp fiber fabric are as follows:

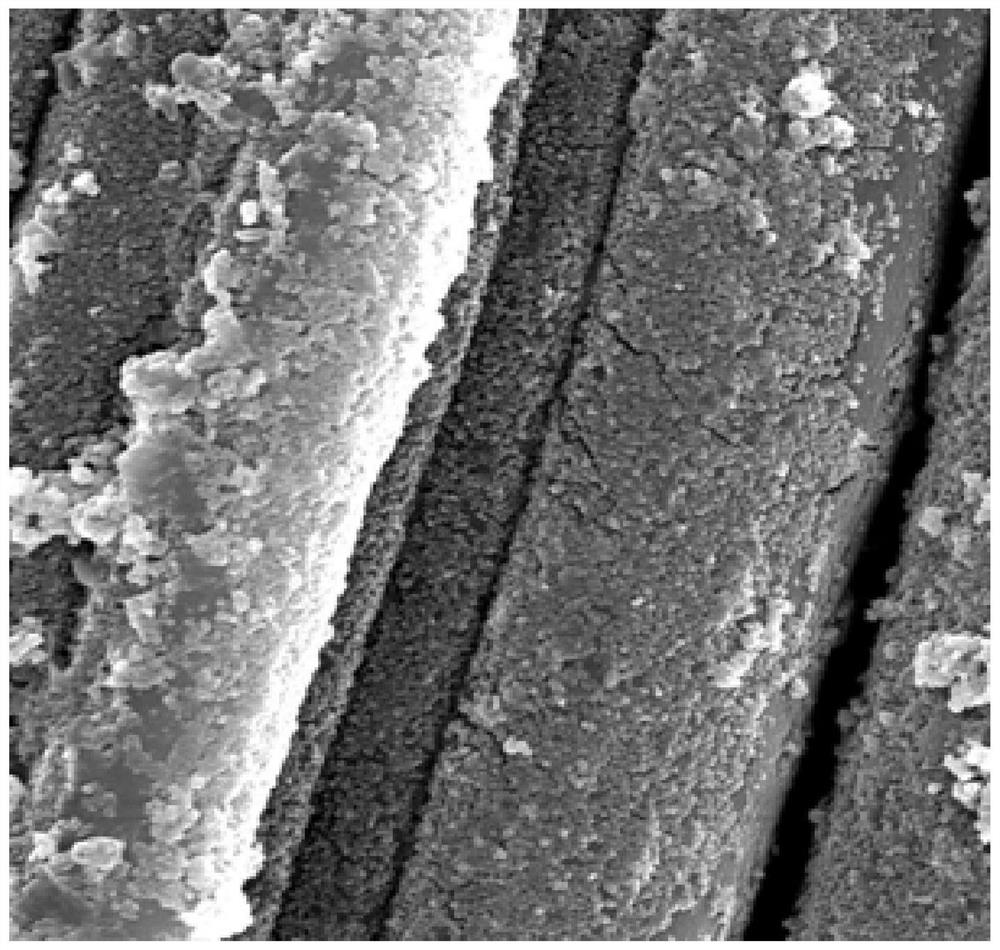

[0046] figure 1 It is a scanning electron microscope (SEM) photo of nanosilver. Depend on figure 1 It can be seen ...

Embodiment 2

[0050]Clean the bamboo pulp fiber fabric with a size of 5cm×5cm with acetone and ethanol for 30 minutes respectively, take out the fabric and let it dry naturally in a ventilated place; in the fume hood, take 10 bamboo pulp fiber fabrics cleaned with ethanol and acetone and lay them flat Well, dissolve 5ml of silane in 45ml of ethanol, add the solution to the dye kettle, put the cloth sample into the reaction kettle, take it out after supercritical static treatment at 10Mpa and 40℃ for 10 minutes, and dry it in the air; add 0.08gAgNO 3 Dissolve in 40ml of deionized water, add 2ml, 4ml, 6ml, 8ml, 10ml of 1% sodium citrate respectively, and stir evenly; then put the silane-treated bamboo pulp fiber fabric into the above silver nitrate solution, microwave heat treatment for 8min, Turn over every 1 min, wash with water, and dry in an oven at 80°C.

[0051] Sedimentation rate under different pretreatment and different sodium citrate content conditions:

[0052] The deposition rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com