Silicone rubber composite material with gradient bubble structure, and preparation method of silicone rubber composite material

A technology of composite materials and silicone rubber, which is applied in the field of silicone rubber composite materials with gradient cell structure and preparation, can solve the problems of different and no research reports on silicone rubber materials, and achieve easy operation, good application prospects, and good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The first technical problem to be solved in the present invention is to provide a preparation method of a silicone rubber composite material with a gradient cell structure, the preparation method comprising the following steps:

[0038] 1) Preparation of silicone rubber composite material: using existing methods to make silicone rubber raw rubber, reinforcing filler, structural control agent and vulcanizing agent into a compound rubber;

[0039] 2) Preparing a silicon rubber composite body: hot pressing the mixed rubber obtained in step 1) to form a green body;

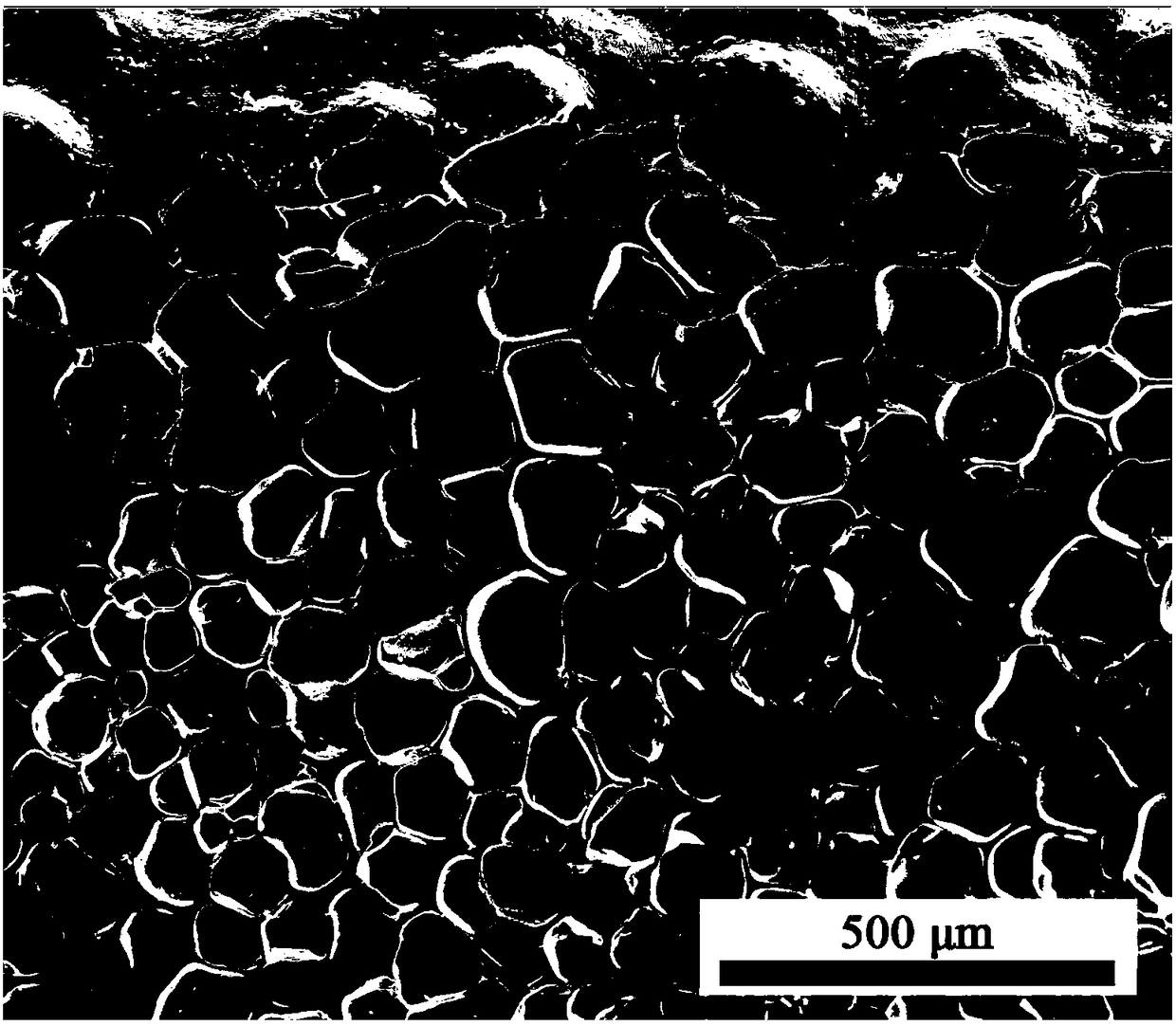

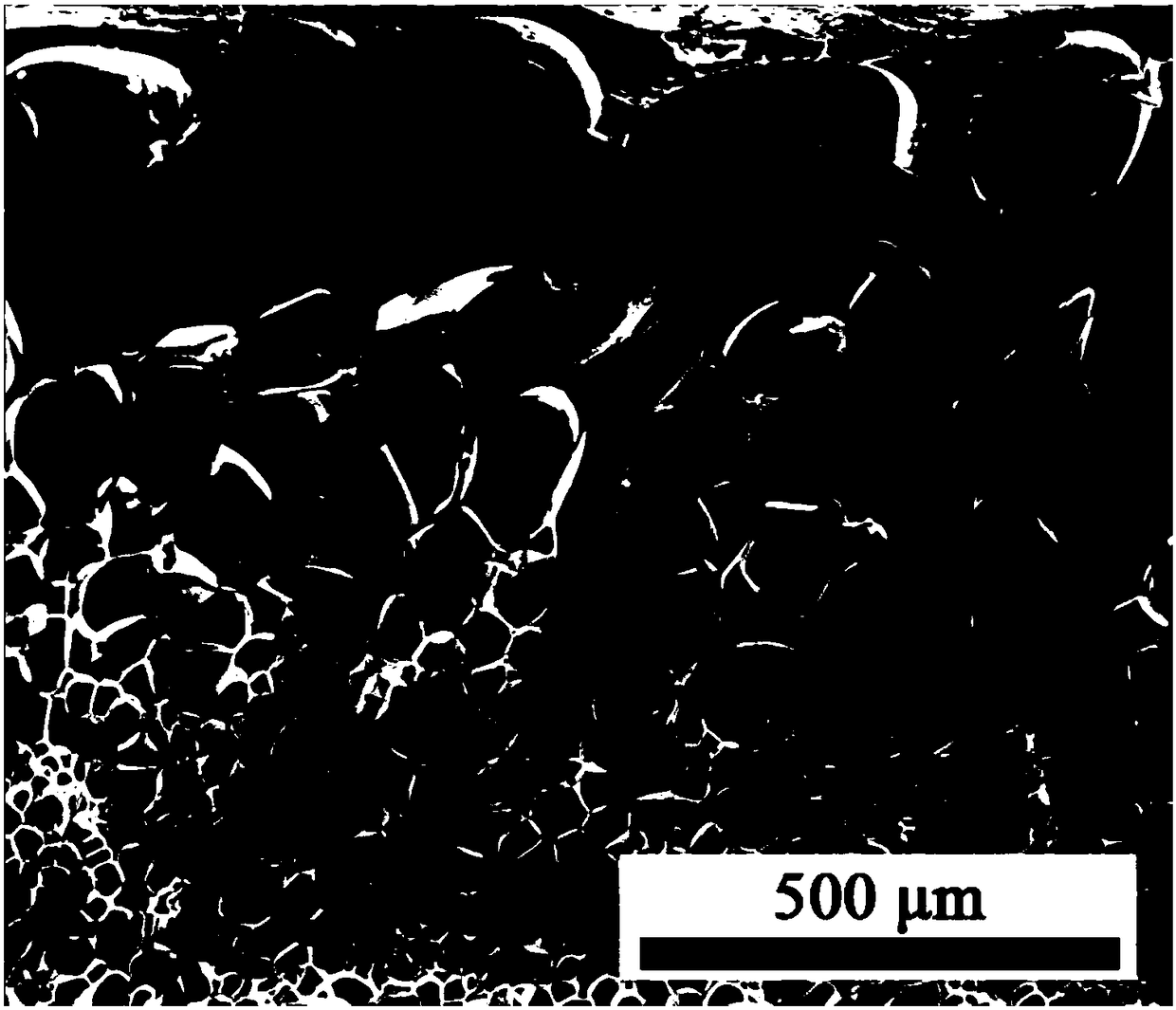

[0040] 3) Supercritical fluid foaming: Cover a part of the body obtained in step 2) with a stainless steel material, then place it in a high-pressure reactor, feed the gas for foaming, heat up, and pressurize until the gas turns into Supercritical fluid, when the supercritical fluid reaches a saturated state in the green body, the composite material green body is foamed by a rapid pressure relief method to obta...

Embodiment 1

[0048] A preparation method of a silicone rubber composite material with a gradient cell structure, comprising the following steps:

[0049] (1) Preparation of silicone rubber composite materials

[0050] Add 0.225g of graphene, 9g of white carbon black, 1.8g of hydroxy silicone oil, and 45g of methyl vinyl silicone rubber raw rubber into the internal mixer for mixing. After mixing, take out the mixture, and add 0.9g of it at room temperature after cooling Dicumyl peroxide, after mixing for 20min, obtains a silicone rubber composite material;

[0051] (2) Preparation of silicone rubber composite body

[0052] The composite material obtained in step (1) is placed on a flat hot plate at a temperature of 130° C. and a pressure of 10 MPa. After holding the pressure for 4 minutes under vacuum conditions, a sheet-shaped green body (cuboid) with a thickness of 2 mm is obtained;

[0053] (3) Supercritical fluid foaming

[0054] The green body is placed on a stainless steel plate, t...

Embodiment 2

[0059] A preparation method of a silicone rubber composite material with a gradient cell structure, comprising the following steps:

[0060] (1) Preparation of silicone rubber composite materials

[0061] Add 0.45g of graphene, 9g of white carbon black, 1.8g of hydroxy silicone oil, and 45g of methylvinyl silicone rubber raw rubber into the internal mixer for mixing. After the mixing is complete, take out the mixture, and add 0.9g of it at room temperature after cooling. Dicumyl peroxide, after mixing for 20min, obtains a silicone rubber composite material;

[0062] (2) Preparation of silicone rubber composite body

[0063] The composite material obtained in step (1) is placed on a flat hot plate at a temperature of 130° C. and a pressure of 10 MPa. After holding the pressure for 4 minutes under vacuum conditions, a sheet-shaped green body (cuboid) with a thickness of 2 mm is obtained;

[0064] (3) Supercritical fluid foaming

[0065] The green body is placed on a stainless...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com