Composite foam film and preparation method thereof

A composite foam and polymer technology, applied in electrical components, magnetic field/electric field shielding, etc., can solve the problems of poor conductivity, poor conductivity and dispersion of carbon black, and large amount of raw materials added, and achieve excellent conductivity and electromagnetic shielding performance. , The electrical conductivity and electromagnetic shielding performance are stable, and the effect of improving the electrical conductivity and electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

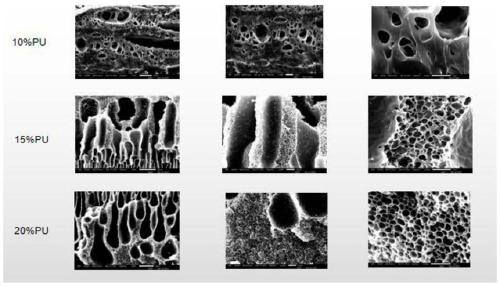

[0042] The preparation of polyurethane (PU) foam film specifically comprises the following steps:

[0043] Dissolve PU in DMF and stir magnetically at 600r / min for 12 hours to prepare a solution with a PU mass concentration of 1% by weight; then take the resulting solution and solidify it with a polytetrafluoroethylene template to form a film in water for 6 hours. Wet samples were obtained after changing the water for the first time, and polyurethane foam membranes were obtained at -40°C with a pressure of 30Pa in a freeze dryer for 48 hours.

[0044] The difference between Embodiment 2-5 and Embodiment 1 lies in that the concentration of PU is different, and other steps are the same as Embodiment 1, and will not be repeated here.

[0045] The performance parameter data of Examples 1-5 are shown in Table 1.

[0046] Table 1

[0047] Example PU concentration (wt%) Solubility Film forming Average thickness mm Mass (mg / cm2) Example 1 1 soluble Unab...

Embodiment 6

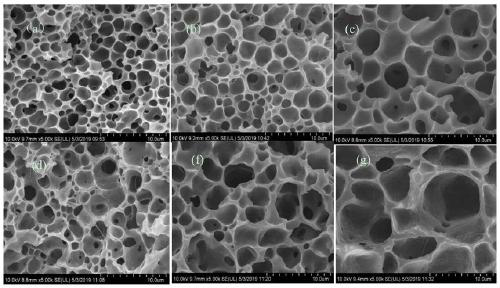

[0051] The preparation method of silver nanowire / polyurethane composite foam film specifically comprises the following steps:

[0052] S1. Preparation of polyurethane solution: dissolve PU in DMF and stir magnetically at 600 r / min for 12 hours to prepare a solution with a mass concentration of PU of 15 wt %;

[0053] S2, preparation of silver nanowires;

[0054] S3, the preparation of silver nanowire / polyurethane composite foam film: get the silver nanowire solution that the concentration of silver nanowire is 0.1wt%, disperse in DMF and add the solution that PU mass concentration is 15wt% to dissolve and stir to obtain uniform colloid after 8 hours, Then pour the mixed solution into the polytetrafluoroethylene template and place it in deionized water for 6 hours, and change the water repeatedly 3 times in the morning, middle and evening to remove the solute DMF, and finally dry it in a freeze dryer to obtain a silver nanowire / polyurethane composite. foam film.

Embodiment 11

[0069] The preparation method of silver nanowire / polyacrylonitrile composite foam film specifically comprises the following steps:

[0070] S1. Preparation of polyacrylonitrile solution: dissolve polyacrylonitrile in tetrahydrofuran (THF) and stir magnetically at 500 r / min for 14 hours to prepare a solution with a mass concentration of polyacrylonitrile of 15 wt %;

[0071] S2, preparation of silver nanowires;

[0072] S3, preparation of silver nanowire / polyacrylonitrile composite foam film: take the silver nanowire aqueous solution whose concentration of silver nanowire is 0.86wt% and disperse in THF and add the solution that the mass concentration of polyacrylonitrile is 15wt% to dissolve and stir for 8 hours Obtain a homogeneous colloid, then pour the mixed solution into a polytetrafluoroethylene template and place it in deionized water for 6 hours, change the water repeatedly in the morning, middle, and evening to remove the solute THF, and finally dry it in a freeze dryer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com