High-thermal-conductivity carbon fiber/polyetheretherketone electromagnetic shielding composite material

A polyetheretherketone, electromagnetic shielding technology, applied in shielding materials, magnetic field/electric field shielding, electrical components, etc., can solve the problems of inability to build a heat conduction network, poor heat conduction performance, and difficulty in forming a heat conduction path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

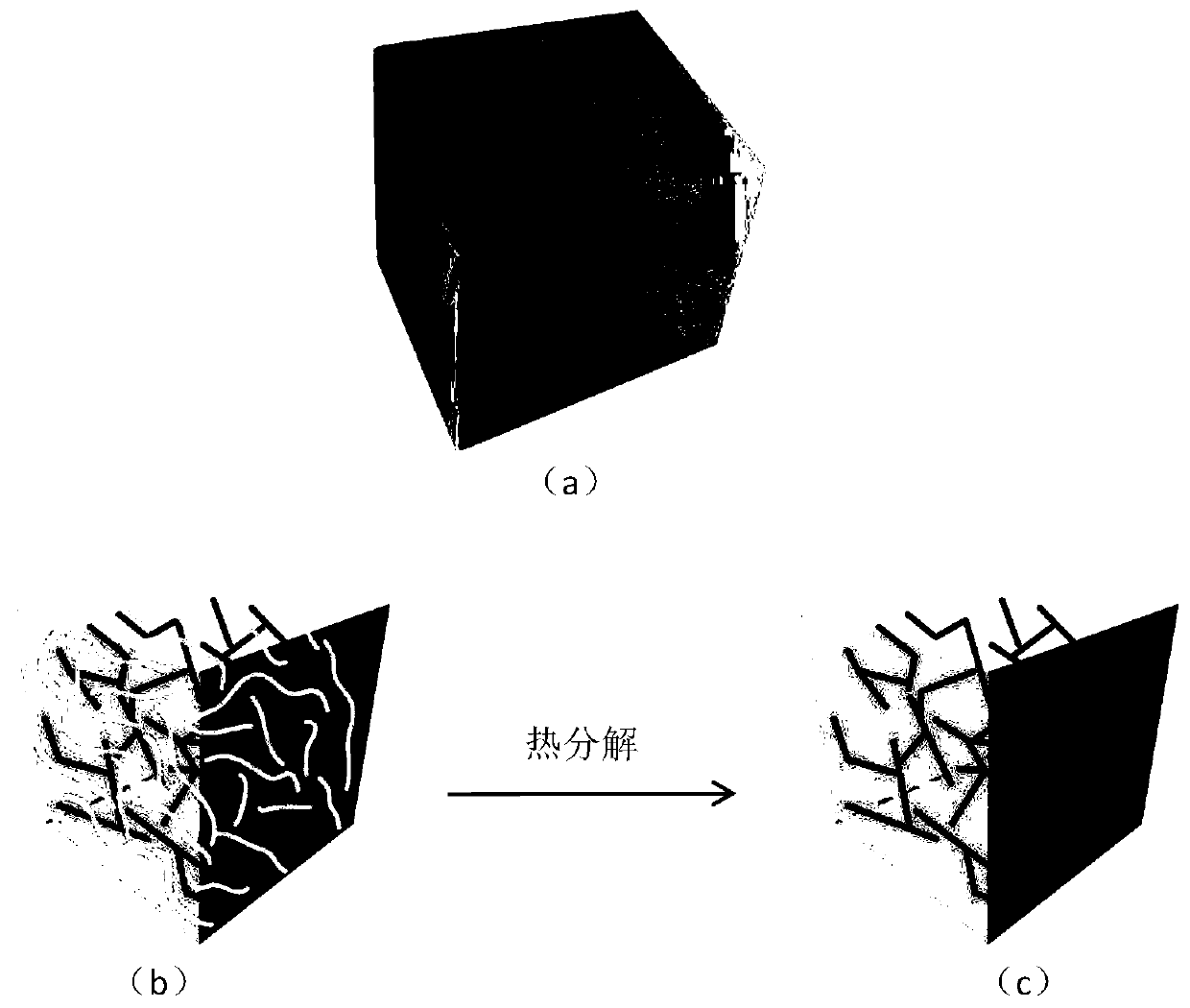

[0018] 1. Preparation of high thermal conductivity carbon fiber / polyether ether ketone electromagnetic shielding composite material

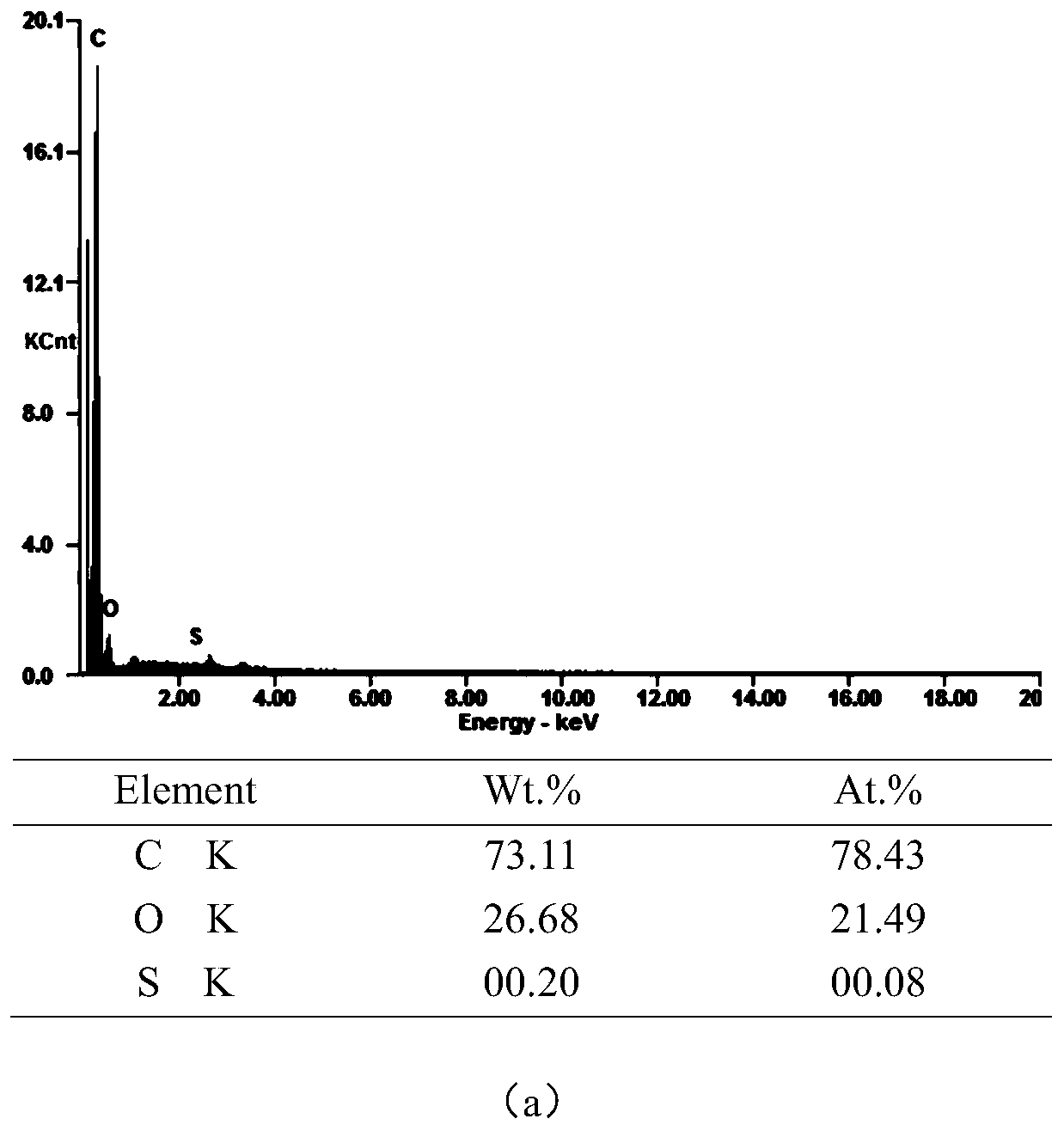

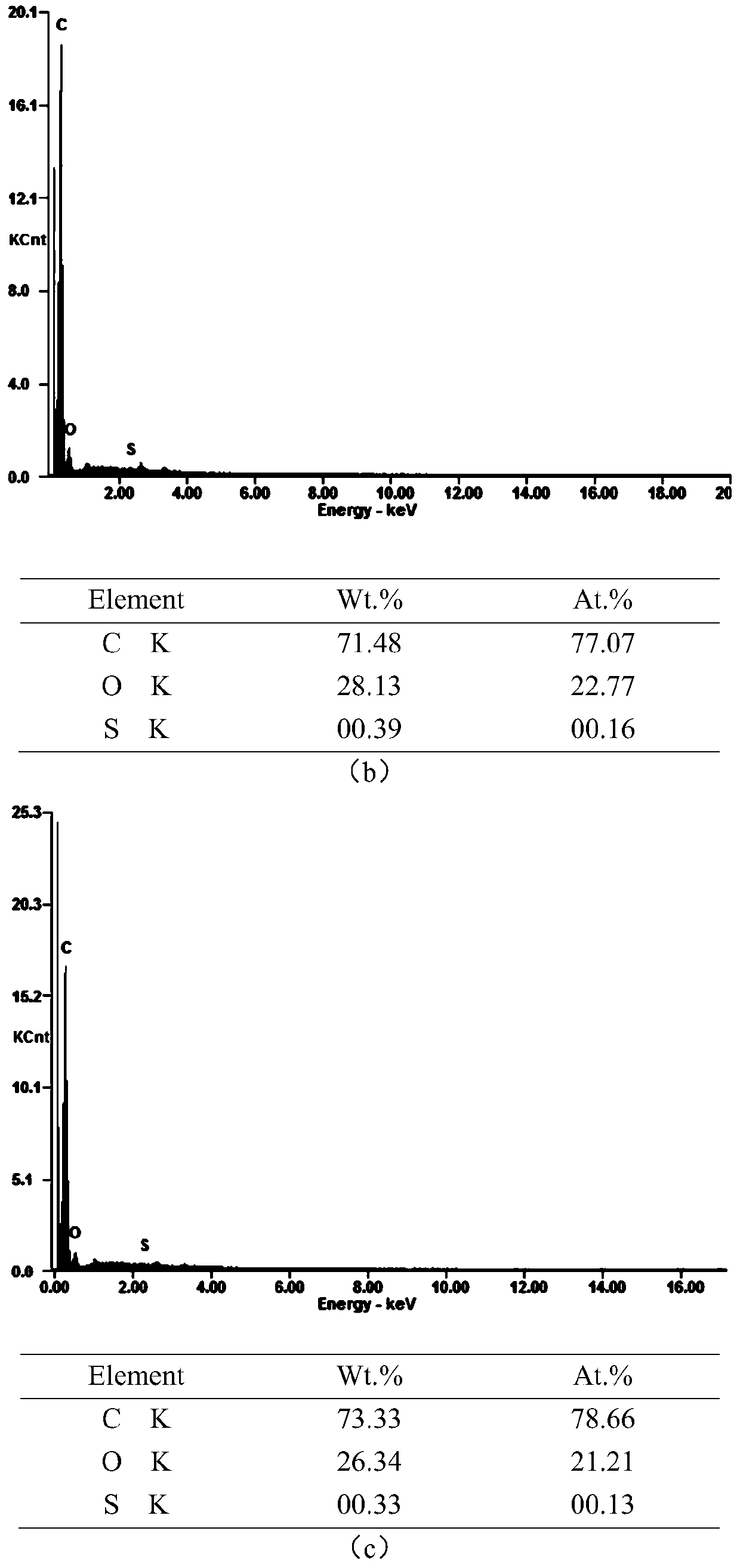

[0019] The composite material includes 30wt.% of sulfonated polyetheretherketone and its sodium salt bicomponent, 40wt.% of polyetheretherketone and 30wt.% of carbon fiber. The melt index of polyetheretherketone is 21g / 10min; the carbon fiber is pitch-based carbon fiber, the aspect ratio is (200-2000):1, and the length is 200-500μm. The specific operation is as follows:

[0020] Dissolve 4,4'-difluorobenzophenone into 98wt.% concentrated sulfuric acid, and the mass ratio of 4,4'-difluorobenzophenone to concentrated sulfuric acid is 1:10. The reaction system was kept stirring at 100° C. for 10 h. The reaction was cooled to room temperature, and the reaction solution was poured into a large amount of ice water to cool. Then NaCl was added to the reaction solution until precipitation occurred, the product was filtered, washed repeatedly with dei...

Embodiment 2

[0053] 1. Preparation of high thermal conductivity carbon fiber / polyether ether ketone electromagnetic shielding composite material

[0054] The composite material comprises 20wt.% of sulfonated polyetheretherketone and its sodium salt, 50wt.% of polyetheretherketone and 30wt.% of carbon fiber. The melt index of PEEK is 21g / 10min; the carbon fiber is pitch-based carbon fiber, the aspect ratio is (200-2000):1, and the length is 200-500μm. The specific preparation of sulfonated polyether ether ketone and its sodium salt is the same as in Example 1, the preparation of sulfonated polyether ether ketone with a sulfonation degree of 30%, and the neutralization ratio of sulfonated polyether ether ketone sulfonate is 48.89%. Two-component sulfonated polyether ether ketone and its sodium salt.

[0055] After uniformly mixing all the raw materials in proportion, the composite material is prepared by hot pressing. Under the condition of no pressure at 350°C, melt all the resin in the i...

Embodiment 3

[0061] 1. Preparation of high thermal conductivity carbon fiber / polyether ether ketone electromagnetic shielding composite material

[0062] The composite material comprises 10wt.% of sulfonated polyetheretherketone and its sodium salt, 60wt.% of polyetheretherketone and 30wt.% of carbon fiber. The melt index of PEEK is 21g / 10min; the carbon fiber is pitch-based carbon fiber, the aspect ratio is (200-2000):1, and the length is 200-500μm. The specific preparation of sulfonated polyether ether ketone and its sodium salt is the same as in Example 1, the preparation of sulfonated polyether ether ketone with a sulfonation degree of 30%, and the neutralization ratio of sulfonated polyether ether ketone sulfonate is 48.89%. Two-component sulfonated polyether ether ketone and its sodium salt.

[0063] After uniformly mixing all the raw materials in proportion, the composite material is prepared by hot pressing. Under the condition of no pressure at 350°C, melt all the resin in the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com